Bioactive composite material for bones as well as preparation method and application of composite material

A technology of composite materials and modified materials, which is applied in the field of composite materials for bone and its preparation, can solve the problems of mismatching mechanical properties, low bioactivity of osteoconduction and osteoinduction, immune rejection, etc., and achieve effective bone defect repair, high Compressive strength and compressive modulus, effect of promoting osteogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

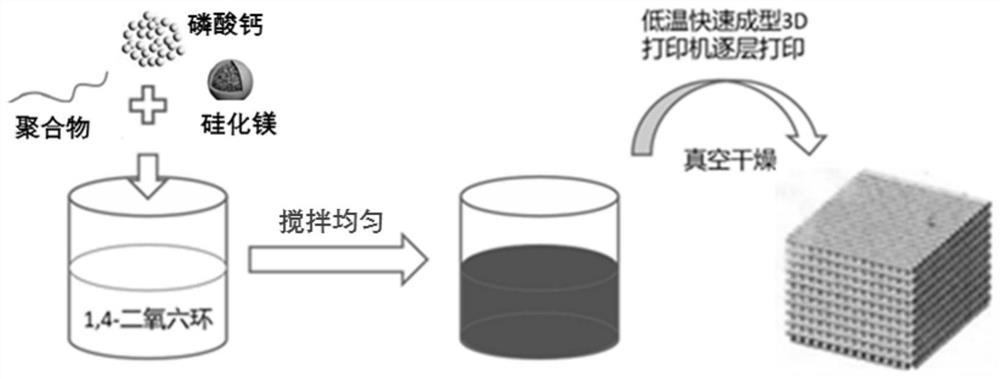

[0072] Example 1 Porous scaffolds were prepared using low-temperature deposition rapid prototyping 3D printing technology.

[0073]Using the established and optimized computer model of the structure and composition, the controllable preparation is carried out through the control of the manufacturing process parameters of the low-temperature deposition rapid prototyping 3D printing technology, so as to meet the special needs of various osteogenic material structures.

[0074] Forming raw material preparation: Dissolve the biodegradable polymer PLGA in the organic solvent 1,4-dioxane, stir to make it fully dissolved, and then pour the mixed solution into a low-temperature rapid deposition system for 3D printing to prepare magnesium silicide composite porous stand.

[0075] Molding and preparation of porous scaffolds: According to the selected ingredients, the preparation raw materials are mixed and placed in the material tank of the low-temperature deposition rapid prototyping s...

Embodiment 2

[0077] Example 2: PLGA / χMS magnesium silicide composite porous scaffold: the mass fraction of magnesium silicide is 10%.

[0078] The composite porous scaffold was prepared by the same preparation method as in Example 1. The difference from the preparation method in Example 1 is that in the preparation process of the molding raw materials, after dissolving the biodegradable polymer PLGA in the organic solvent 1,4-dioxane and stirring to fully dissolve it, magnesium silicide is added The particles are evenly dispersed in it, and then the mixed solution is poured into a low-temperature rapid deposition system for 3D printing to prepare a composite porous scaffold of magnesium silicide. The added amount of magnesium silicide particles is 10% of the mass of the composite porous support.

Embodiment 3

[0079] Example 3: PLGA / χMS magnesium silicide composite porous scaffold: the mass fraction of magnesium silicide is 20%.

[0080] The composite porous scaffold was prepared by the same preparation method as in Example 1. The difference from the preparation method in Example 1 is that in the preparation process of the molding raw materials, after dissolving the biodegradable polymer PLGA in the organic solvent 1,4-dioxane and stirring to fully dissolve it, magnesium silicide is added The particles are evenly dispersed in it, and then the mixed solution is poured into a low-temperature rapid deposition system for 3D printing to prepare a composite porous scaffold of magnesium silicide. The added amount of magnesium silicide particles is 20% of the mass of the composite porous support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com