Z-direction enhanced underwater sound absorption sandwich composite material and preparation method for same

A composite material and reinforcing material technology, which is applied in the field of Z-direction reinforced underwater sound-absorbing sandwich composite material and its preparation, can solve the problem that the structural bearing performance and sound-absorbing performance cannot be fully taken into account, and achieves improved bending stiffness and flat pressure. Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

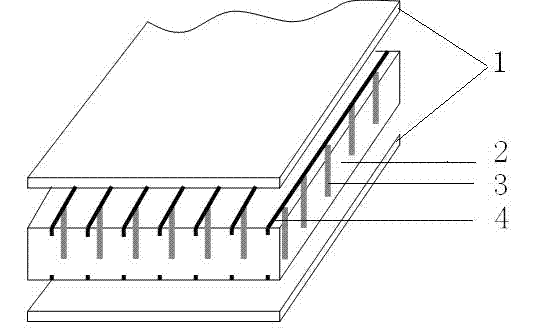

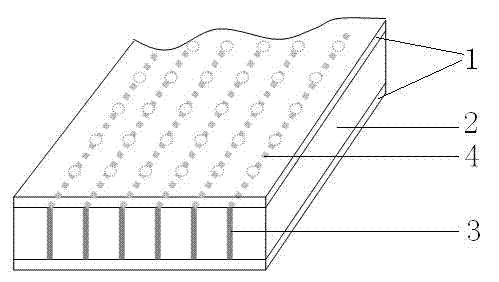

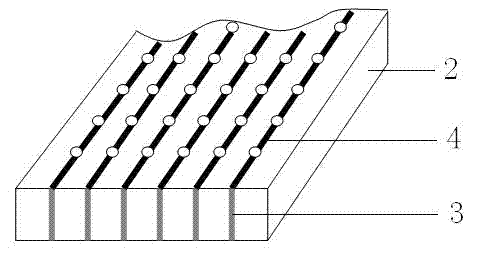

Embodiment 1

[0030] The Z-direction reinforced underwater sound-absorbing sandwich composite material in this embodiment is composed of glass fiber reinforced composite material upper and lower panels, sound-absorbing core layer and glass fiber reinforced composite material columns arranged between the upper and lower panels. The formula of the upper panel and the lower panel is: 3.0kg of matrix resin SWANCOR901-200, 0.06kg of curing agent MEKP, 0.009kg of accelerator cobalt naphthenate, S2 twill fabric as reinforcing fiber, fiber weight content of 60-62%, size It is 500mmх500mmх5mm; the sound-absorbing core layer formula is: epoxy resin matrix is 6kg (of which E51 is 2.4kg, 6350 is 3.6kg), filler is 2.4kg (of which glass flakes are 1.2kg, vermiculite powder is 0.6kg, semi-reinforcing carbon black 0.3kg, white carbon black 0.3kg), epoxy curing agent 5784 is 2.4kg, coupling agent KH550 is 0.06kg, the core layer size is 500mmх500mmх40mm, the upper and lower surfaces of the core material...

Embodiment 2

[0041] The difference between this embodiment and the first embodiment is that the sound-absorbing core layer is made of polyurethane elastomer material, and other compositions, structural forms, and preparation methods are the same as those of the first embodiment.

[0042] The improvement range of the structural performance and the underwater sound absorption performance in this embodiment is consistent with that of the first embodiment.

Embodiment 3

[0044] The difference between this embodiment and the first or second embodiment is that the sound-absorbing core layer is made of synthetic rubber, and the molding process of the rubber sound-absorbing material is a molding process. Other composition, structural form, preparation method are identical with embodiment one or two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com