Widening reinforcing structure tightly adjacent to existing ballastless track roadbed

A subgrade and track technology, applied in the directions of roads, tracks, ballast layers, etc., can solve problems such as stress and deformation, and achieve the effects of strong integrity, high construction safety, and solving problems of ground bearing capacity and settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

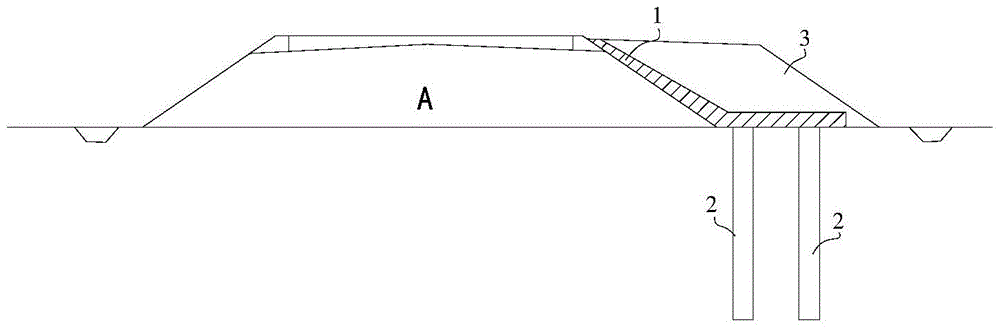

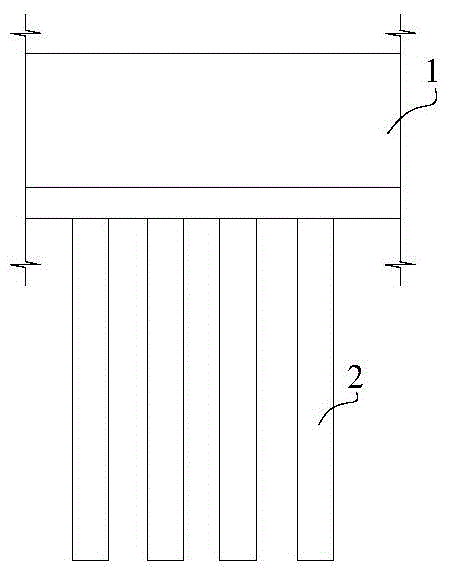

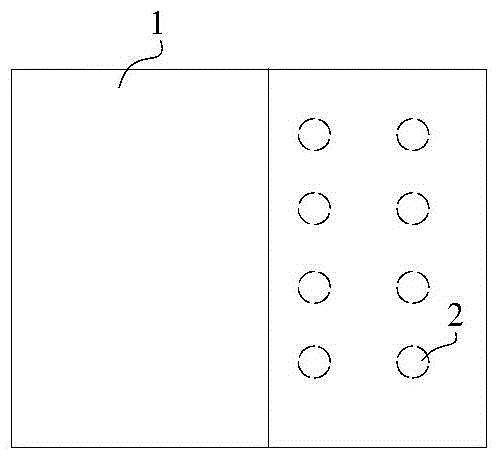

[0013] refer to figure 1 , figure 2 and image 3 , the side width reinforcement structure adjacent to the existing ballastless track subgrade of the present invention includes the existing ballastless track subgrade A and the newly built side filling subgrade B located on one lateral side thereof. The newly-built subgrade B includes a reinforced concrete pallet retaining wall 1, a reinforced concrete pile foundation 2 and a foam lightweight soil filler layer 3. The reinforced concrete pallet retaining wall 1 is located on the lateral side of the existing ballastless track subgrade A and extends along the track direction. The reinforced concrete pile foundations 2 are arranged in rows at intervals along the line direction in the foundation of the newly built subgrade B, and their upper ends are rigidly connected with the reinforced concrete tray reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com