Large-span eccentric lean-against type steel box tied arch bridge surface towing erection construction system

A tied arch bridge and reclining type technology, which is applied in the field of floating tow frame construction system of large-span eccentric reclining steel box tied arch bridges, can solve the problems of short sailing time, less technical data and high safety risk, and achieves investment in investment. The effect of low cost, reasonable structure design and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

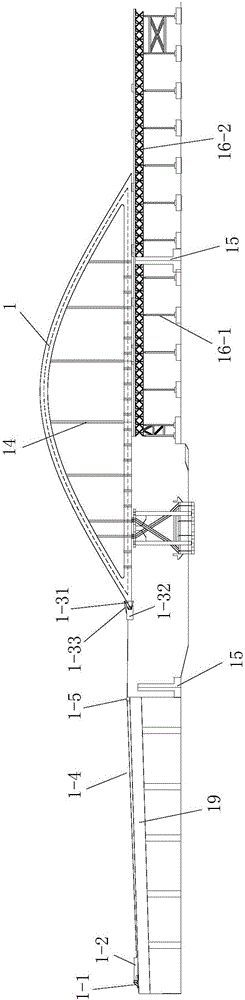

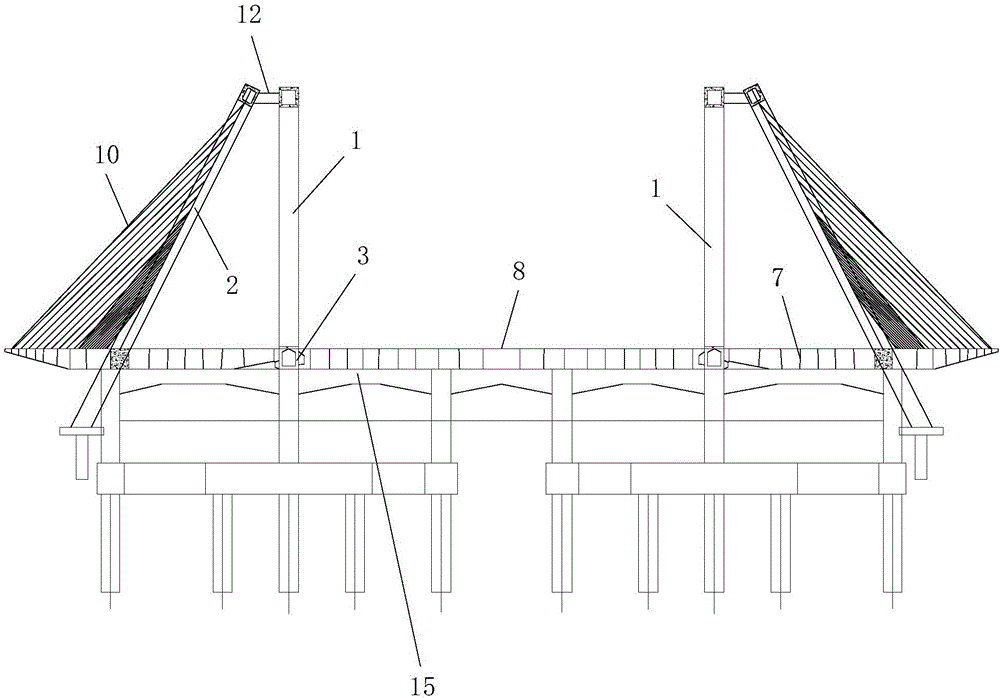

[0074] Such as figure 1 As shown, the present invention includes a sliding system for supporting and longitudinally sliding the bridge superstructure of the constructed arch bridge, a mobile support device supporting the front side of the bridge superstructure and dragging the bridge superstructure along the longitudinal bridge A traction system that translates forward, the mobile support device is located directly in front of the sliding system;

[0075] The sliding system includes a temporary support structure supporting the bridge superstructure, a glideway arranged on the temporary support structure and an upper sliding device located above the glideway, the temporary support structure and the The above-mentioned glideslopes are all arranged along the direction of the longitudinal bridge;

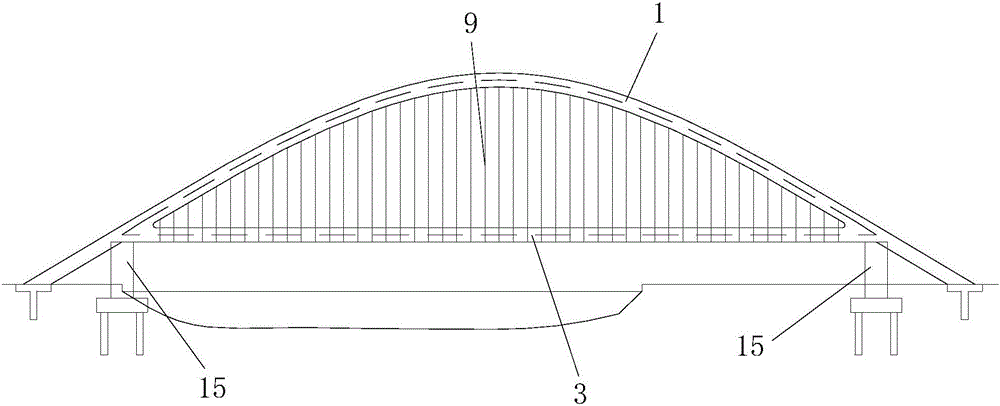

[0076] Such as Picture 1-1 , Figure 1-2 and Figure 1-3 As shown, the arch bridge under construction is a tied arch bridge erected on the river, and the tied arch bridge is a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com