Transmission device of reciprocating bale plucker pressing roller

A technology of a reciprocating cotton picker and a transmission device is applied in the field of textile equipment manufacturing, which can solve the problems of inconvenient use, high manufacturing cost, time-consuming and labor-intensive, etc., and achieve the effects of improved fine grasping, low manufacturing cost, and convenient use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings:

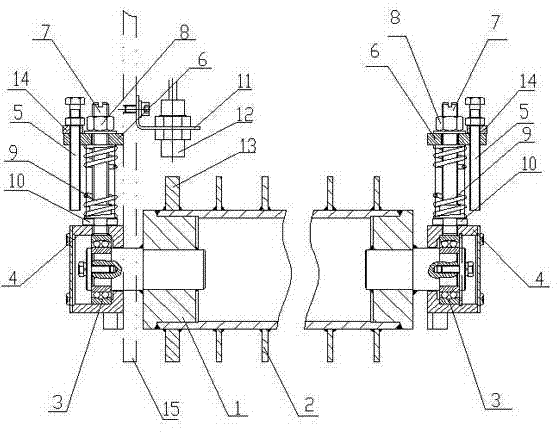

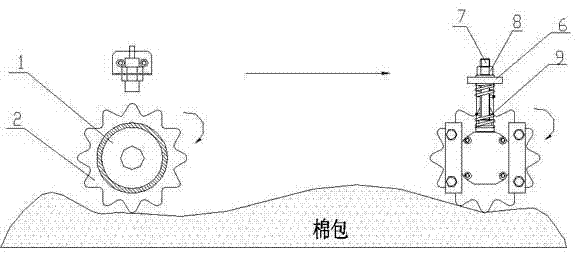

[0018] See attached figure 1 , figure 2 , The embodiment of the mechanical cotton pressing roller device of a reciprocating cotton grab machine of the present invention includes: a cotton pressing roller cylinder 1, a star-shaped tooth plate 2, a bearing 3 and a bearing seat 4 at both ends of the cotton pressing roller, and two cotton pressing rollers. On the side wall panel 15, the star-shaped toothed sheet 2 is fixed on the cotton pressing roller body 1 to form a cotton pressing roller, and the bearings 3 at both ends of the cotton pressing roller are all rolling bearings. A baffle 6 is fixed on the outer surfaces of the two wall panels 15 respectively. The baffle 6 has a light hole, and the baffle 6 is located directly above the bearing seat 4 at one end of the corresponding cotton pressing roller. A threaded hole is opened on each of the two bearing seats ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com