Pearlite sand filling device and method

A filling device and filling method technology, which are applied to container filling methods, container discharge methods, ship construction details, etc., can solve problems such as difficulty in attaining vacuum degree, and achieve the effects of low cost, improved work efficiency, and fast filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

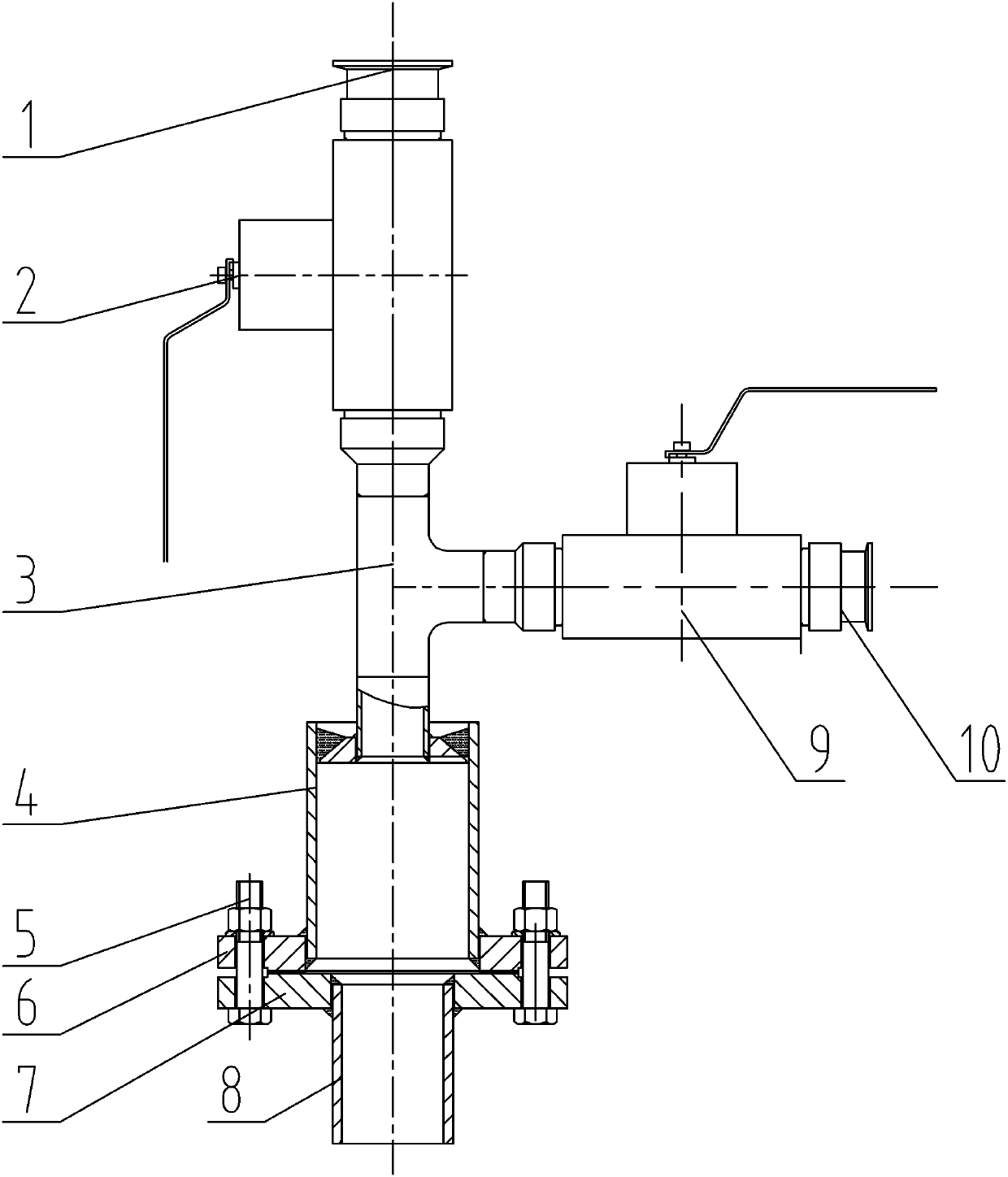

[0045] A method for filling a pearlite filling device, which comprises the following steps:

[0046] Step 1: Calculate the volume that needs to be filled with pearlite according to the size of the cryogenic container;

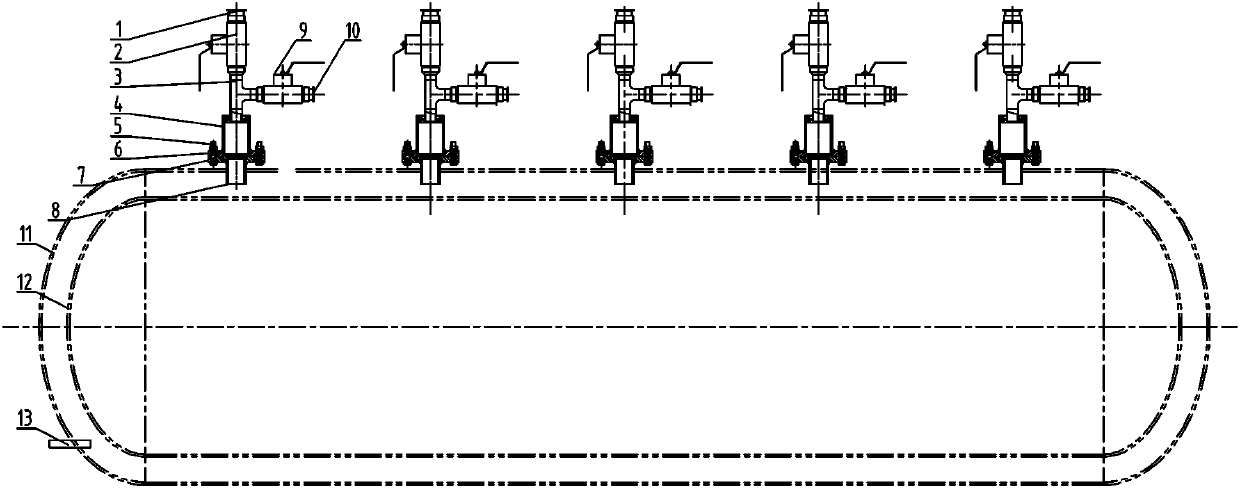

[0047] Step 2: Determine the number of pearlite filling devices according to the calculated volume that needs to be filled with pearlite;

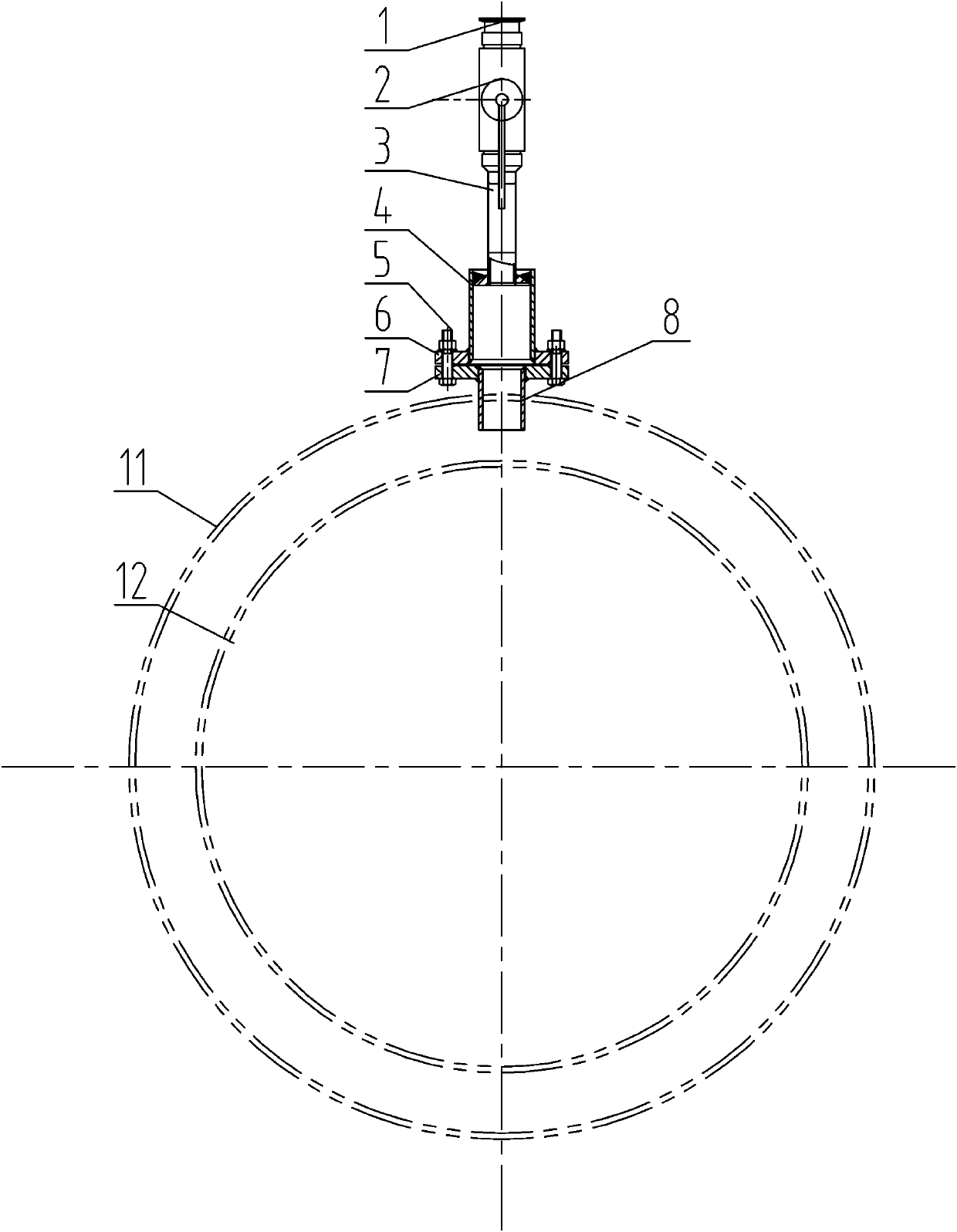

[0048]Step 3: Determine the position of the pearlite filling device on the cylinder according to the structure of the cryogenic container;

[0049] Step 4: Install the pearlite filling device at the corresponding position of the cryogenic container outer tank 11 of the cryogenic container according to the determined installation position;

[0050] Step 5: Connect the first pipe joint 10 of the pearlite filling device with the air heating device for supplying hot air, and connect the second pipe joint 1 with the pearlite storage tank;

[0051] Step 6: Connect the vacuum tube 13 to the vacuum pump, and vacuumize the interla...

Embodiment 3

[0059] In this embodiment, the low-temperature container that needs to be filled in practice is taken as an example to further illustrate the filling method of the present invention.

[0060] A method for filling with a pearlite filling device, comprising the following steps:

[0061] Step 1: Calculate the volume that needs to be filled with pearlite according to the size of the cryogenic container;

[0062] Interlayer volume calculation (based on 20m 3 Cryogenic liquid storage tank as an example)

[0063] The internal volume of the disc-shaped head of the shell: V01=1.7427m 3

[0064] Shell cylinder volume: V02= π / 4·Do 2 •Lo=π / 4×2.5 2 ×6.935=34.05m 3

[0065] Shell geometric volume: Vo= 2 V01+ V02=37.53m 3

[0066] Interlayer volume: Vj=Vo-Vi=37.53-(π / 4×(2.016) 2 ×5.985+2×1.1257+(278.4+348.9) / 7930)=16.1 m 3

[0067] In the formula: Do----inner diameter of shell cylinder; Do=2.5m;

[0068] Lo-----The length of the shell cylinder; Lo=6.935m;

[0069] Step 2: Deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com