Novel road crack filling machine

A seam filling machine and seam filling technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of wasting time and manpower, low efficiency of seam filling, uneven effect, etc., to reduce labor intensity, reduce manual work, improve The effect of filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

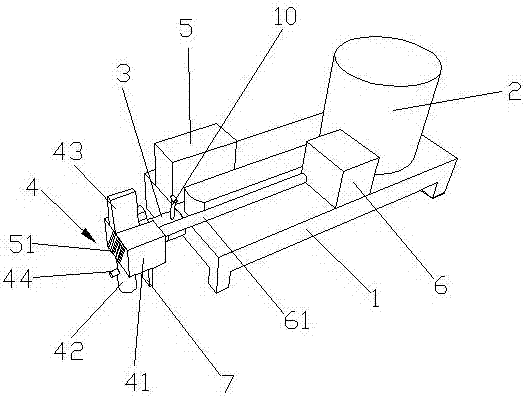

[0024] like Figure 1-4 As shown, a novel road seam filling machine of the present invention comprises a car body 1, an asphalt tank 2 is arranged at one end of the car body 1, and a seam filling pipe 3 is also arranged on the car body 1, and one end of the seam filling pipe 3 is connected with the asphalt The bottom of the tank 2 is connected, the other end of the seam filling pipe 3 is arranged on the other end of the car body 1, and the other end of the seam filling pipe 3 is also provided with a seam filling port 4, which includes a seam filling port seat 41. The seam filling seat 41 is movably arranged on the other end of the joint filling pipe 3, and the first joint filling nozzle 42 and the second joint filling nozzle 43 are oppositely arranged on the joint filling seat 41, and the first joint filling nozzle 42 is a hollow truncated cone structure, the second filling nozzle 43 is a hollow trapezoidal structure with one end open, the first filling nozzle 42 is also provi...

Embodiment 2

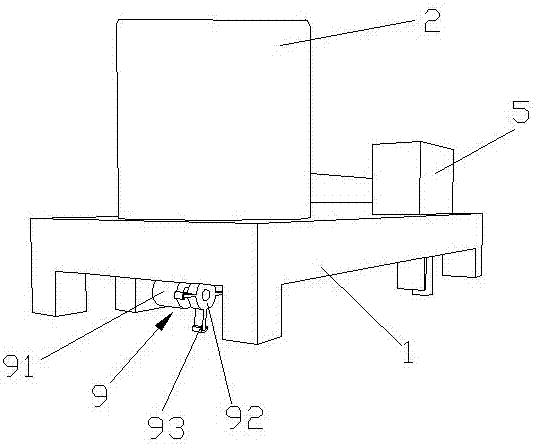

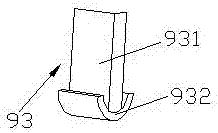

[0026] One end of the car body 1 is provided with an asphalt tank 2, and the car body 1 is also provided with a joint filling pipe 3. One end of the joint filling pipe 3 is connected to the bottom of the asphalt tank 2, and the other end of the joint filling pipe 3 is arranged on the bottom of the car body 1. On the other end, the other end of the seam filling pipe 3 is also movable to be provided with a seam filling mouth 4, the seam filling mouth 4 includes a seam filling mouth seat 41, and the seam filling mouth seat 41 is movably arranged on the other end of the seam filling pipe 3, and the seam filling mouth seat 41 There are first joint filling nozzle 42 and second joint filling nozzle 43 opposite to each other. The first joint filling nozzle 42 is a hollow truncated circular structure, and the second joint filling nozzle 43 is a hollow trapezoidal structure with one end open. Also be provided with on-off valve 44 on the seam filling nozzle 42, also be provided with heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com