Waste grease premixed reinforced asphalt mixture and preparation method thereof

A technology of asphalt mixture and premix, which is applied in the direction of climate change adaptation, etc., can solve the problems of high energy consumption, a large amount of harmful greenhouse gas emissions, etc., and achieve easy operation, good road performance and environmental protection benefits, and excellent use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of waste and old grease ready-mixed reinforced asphalt mixture of the present invention specifically comprises the following steps:

[0025] First, add 1.5% to 2.5% of the waste oil into the SK70# base asphalt, and stir it evenly at 125-145°C for 30 minutes to develop the waste oil soft asphalt. Viscosity-temperature curves determine that the heating temperature of waste oil soft asphalt is 130-140°C. Before preparing waste oil soft asphalt, heat SK70# base asphalt and waste oil to 135-140°C respectively;

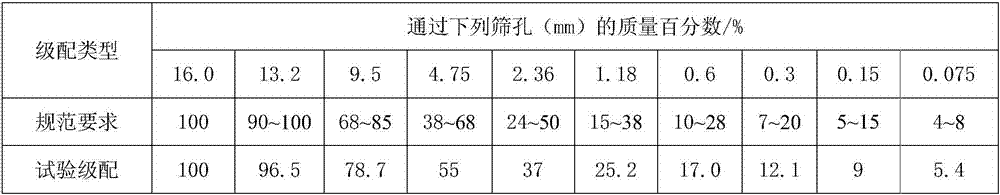

[0026] Secondly, use waste oil soft asphalt to pre-mix the aggregate to improve the construction workability of the asphalt mixture, and prepare the ready-mix material. The mass ratio of waste oil soft asphalt to aggregate (that is, the asphalt ratio) is 4.8%. Before pre-mixing, first heat the aggregate to 155-165°C in an oven, and heat the waste oil soft asphalt to 135-140°C, then stir the heated aggregate in an asphalt mixer for 90s, and fina...

Embodiment 1

[0031] In this example, the preparation method of waste oil ready-mixed reinforced asphalt mixture is as follows:

[0032] First, add 2.0% waste oil into SK70# matrix asphalt, and stir it evenly at 125-145°C for 30 minutes to prepare waste oil soft asphalt, and use the viscosity-temperature curve to determine the waste oil The heating temperature of soft asphalt is 135°C. Before producing waste oil soft asphalt, first heat SK70# base asphalt and waste oil to 135-140°C;

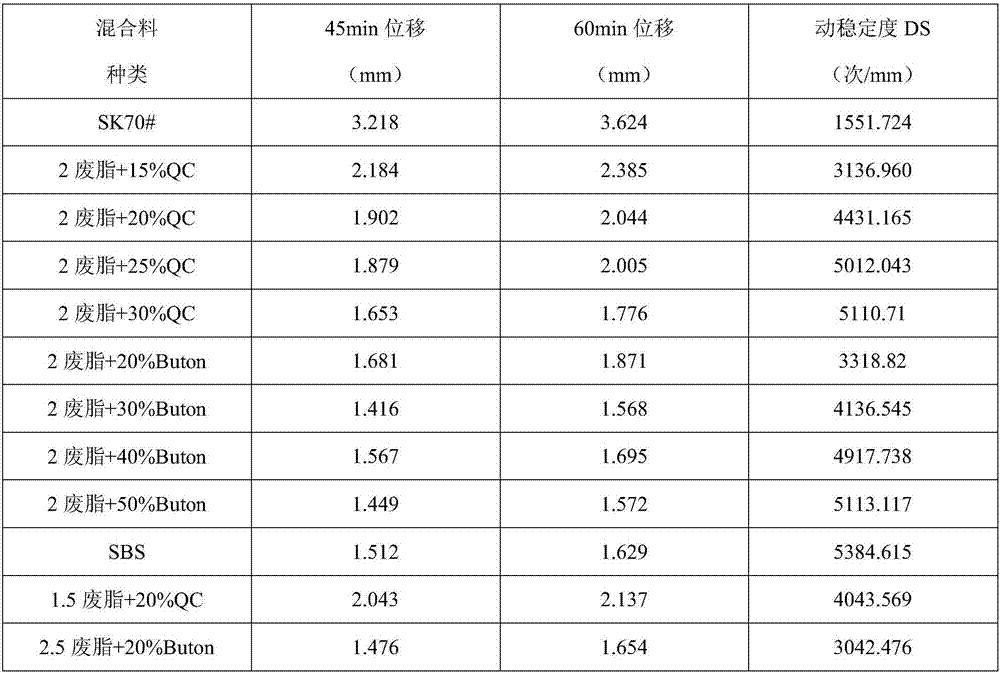

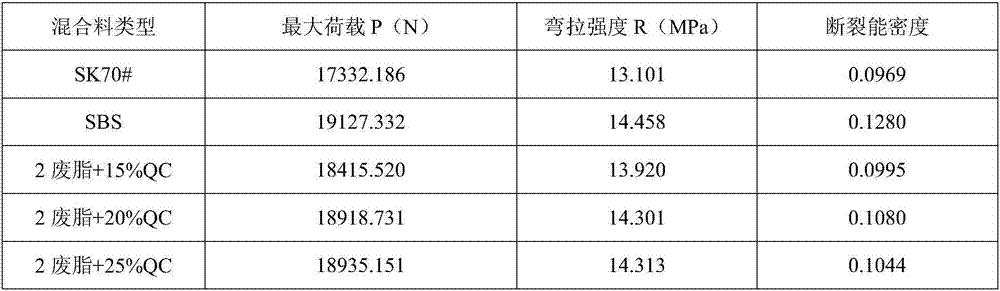

[0033] Secondly, waste oil soft asphalt is used to pre-mix the aggregate to improve the construction workability of the asphalt mixture, and the ready-mix material is prepared. The mass ratio of waste oil soft asphalt to aggregate is 4.8%. Before pre-mixing, First heat the aggregate to 155-165°C in an oven, heat the waste oil soft asphalt to 130-140°C, then stir the heated aggregate in an asphalt mixer for 90s, and finally add a predetermined amount of waste oil soft asphalt Stir the high-quality asphalt for ...

Embodiment 2

[0037] In this example, the preparation method of waste oil ready-mixed reinforced asphalt mixture is as follows:

[0038] First, add 2.0% waste oil into SK70# matrix asphalt, and stir it evenly at 125-145°C for 30 minutes to prepare waste oil soft asphalt, and use the viscosity-temperature curve to determine the waste oil The heating temperature of soft asphalt is 135°C. Before producing waste oil soft asphalt, first heat SK70# base asphalt and waste oil to 130-140°C;

[0039]Secondly, waste oil soft asphalt is used to pre-mix the aggregate to improve the construction workability of the asphalt mixture, and the ready-mix material is prepared. The mass ratio of waste oil soft asphalt to aggregate is 4.8%. Before pre-mixing, First heat the aggregate to 155-165°C in an oven, heat the waste oil soft asphalt to 135-140°C, then stir the heated aggregate in an asphalt mixer for 90s, and finally add a predetermined amount of waste oil soft asphalt Stir the high-quality asphalt for 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com