Non-Newtonian Fluid Lining Support Structure and Construction Method

A non-Newtonian fluid and support structure technology, which is applied in wellbore lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems of uneven stress and poor support capacity of the second lining steel arch frame, and achieve easy heating and bonding , avoid waste, reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

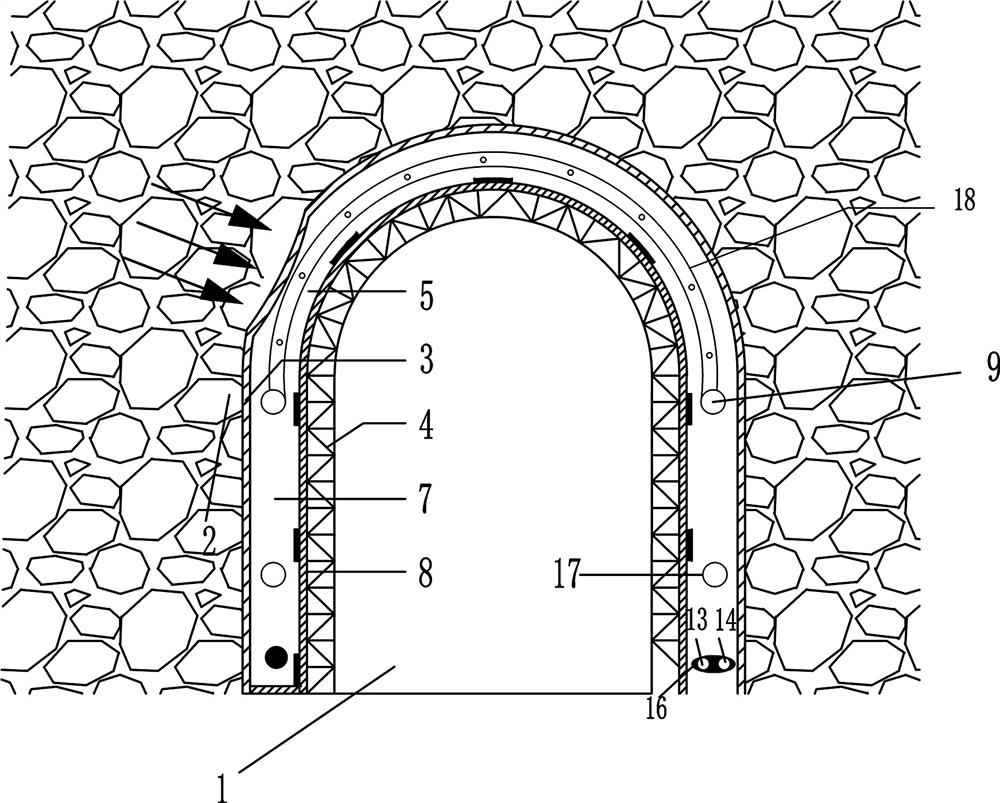

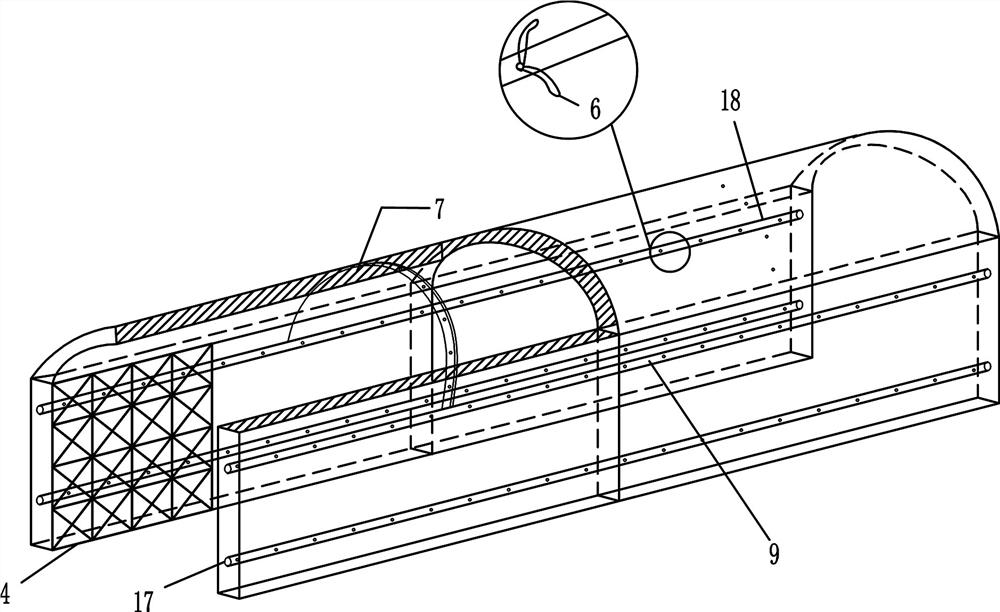

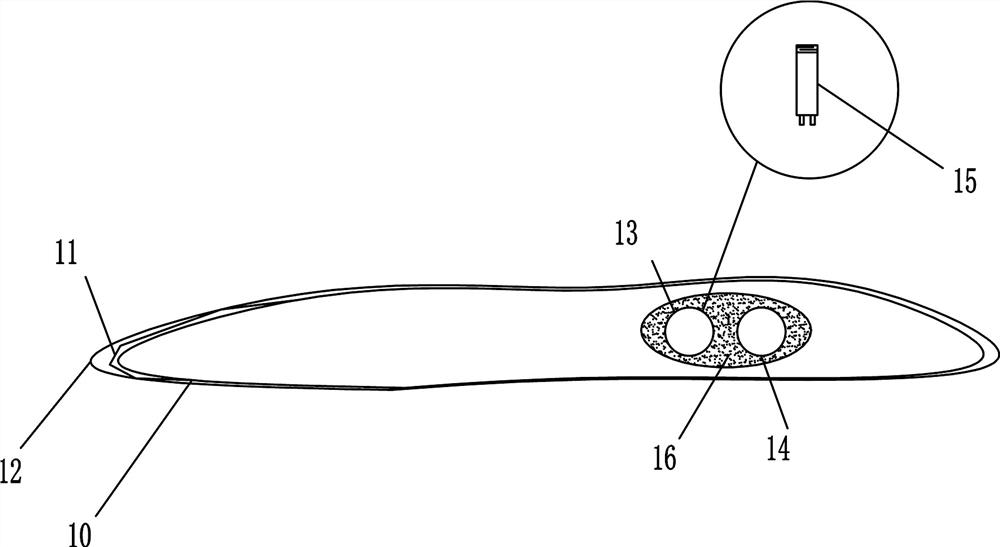

[0036] Such as Figure 1-Figure 3 As shown, a non-Newtonian fluid lining support structure, including the tunnel primary lining body 3 formed by inserting anchor rods, hanging nets, and shotcrete on the surrounding rock 2 of the tunnel 1, the outer surface of the tunnel primary lining body 3 is provided with a tunnel second The secondary lining body 4, a certain space is set between the tunnel primary lining body 3 and the tunnel secondary lining body 4 to form a reserved deformation layer 5, and a non-Newtonian fluid filling material 7 is placed in the reserved deformation layer 5; the non-Newtonian fluid filling material 7 includes a fully-enclosed bag 10 filled with non-Newtonian fluid. The outer surface of the fully-enclosed bag 10 corresponding to the surrounding rock 2 is provided with a rubber valve 16. The rubber valve 16 is provided with a water injection hole 13 and pressure relief / grouting In the hole 14, the non-Newtonian fluid inside the non-Newtonian fluid fillin...

Embodiment 2

[0050] A construction method of the above-mentioned support structure, the method comprises the following steps:

[0051] Step 1: Make the polyethylene geomembrane into a bag shape by hot pressing to obtain a closed bag body 10, set a rubber valve 16 on one side of the closed bag body 10, and connect the first main water injection pipe 17 and the second main water injection pipe 9 through the water injection hole. And the arched sub-water injection pipe 18 is placed inside the closed bag body 10, the detection end of the moisture content detector 15 is placed inside the closed bag body 10 through the water injection hole, and the grouting / pressure relief is connected to the pressure relief / grouting hole 14 Pipe, inject non-Newtonian fluid into the closed bag body 10 through the grouting / pressure relief pipe, and stop the injection until the reserved deformation layer 5 is filled;

[0052] Step 2: Wrap the geotextile 11 and the barbed wire 12 on the outside of the fully enclose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com