Floor plate truss pouring structure

A floor slab and truss technology, which is applied to floor slabs, building components, building structures, etc., can solve the problems of low labor efficiency, insufficient use of concrete beam support, and difficult construction, so as to improve labor efficiency and reduce construction difficulty. , Improve the effect of coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

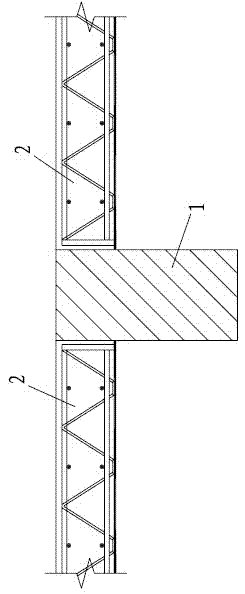

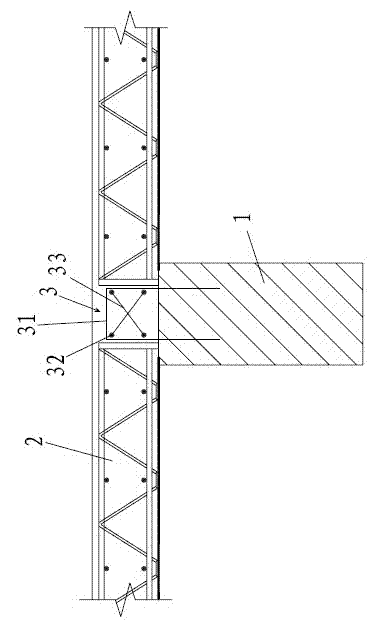

[0015] Embodiment: a floor slab truss pouring structure, such as figure 2 As shown, it includes a concrete beam 1 and a floor deck 2, the floor deck 2 is arranged above the concrete beam 1, and the floor deck 2 has a connecting portion 3 connected to the concrete beam 1; the connecting portion 3 includes four pieces divided into two rows The connecting ribs 32 arranged in parallel are fixedly connected with fixed ribs 33 between the diagonally distributed connecting ribs 32 , and the connecting ribs 32 are fixedly connected with a U-shaped stirrup 31 inserted into the concrete beam 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com