Combined pile supporting structure in deep and thick peat soil layer

A technology of supporting structure and peat material, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of poor hole quality of bored piles and excessive concrete filling coefficient, and achieves the solution to the problem of excessive concrete filling coefficient, high Solve the effect of poor hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

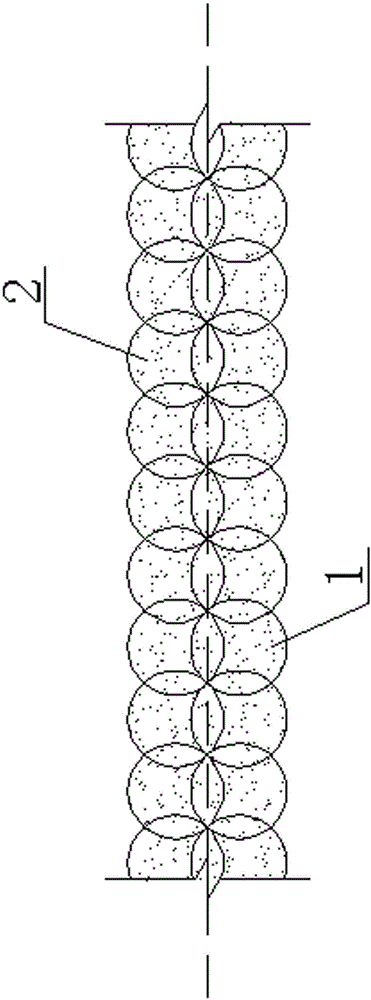

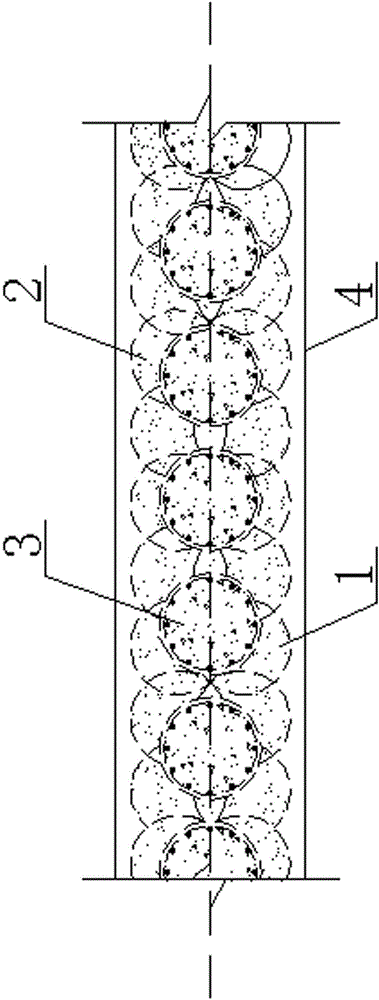

[0031] Example 1 :Such as figure 1 , 2 , 3, 4, and 6 show a combined pile support structure in a deep peaty soil layer, which consists of a front row of jet grouting piles 1, a rear row of jet grouting piles 2, bored piles 3 and crown beams 4. The design pile lengths of the front row jet grouting piles 1 and the rear row jet grouting piles 2 and the bored cast-in-place pile 3 are equal. Firstly, according to the construction axis and design pile position of the front row of rotary grouting piles 1 and the rear row of rotary grouting piles 2, the cement clay slurry with a cement dry mixing ratio of less than 8% is injected through high-pressure jet grouting (in the cement dry powder, mixed with The mixed slurry of cement and clay with content less than 8%) is used for the construction of rotary grouting piles, and the two rows of rotary grouting piles are guaranteed to interlock and be arranged in parallel to improve the engineering characteristics of peaty soil; after the p...

Embodiment 2

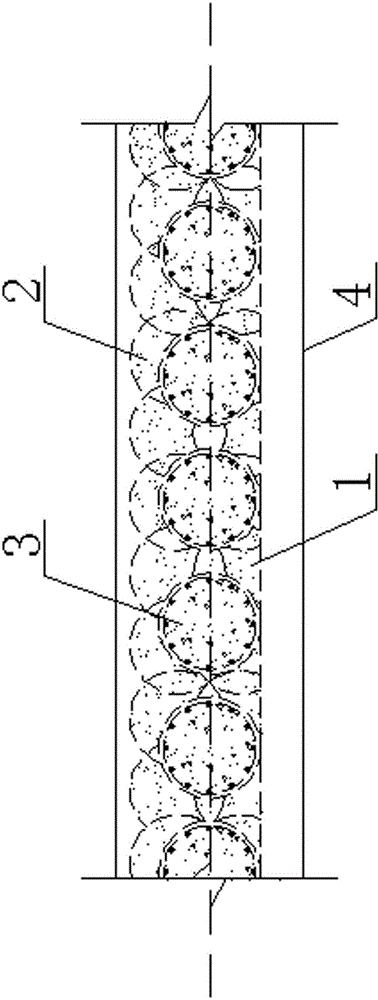

[0032] Example 2: Such as figure 1 , 2 , 3, 5, and 7 show a combined pile support structure in a deep peaty soil layer, which consists of a front row of jet grouting piles 1, a rear row of jet grouting piles 2, bored piles 3 and crown beams 4. The design pile lengths of the front row of jet grouting piles 1 and the back row of jet grouting piles 2 and bored piles 3 are not equal. Firstly, according to the construction axis and design pile position of the front row of rotary grouting piles 1 and the rear row of rotary grouting piles 2, inject the cement clay slurry with a cement dry mixing ratio of less than 8% through high-pressure jet grouting to carry out the construction of the rotary grouting piles, and ensure that the two Rows of jet grouted piles are interlocked and arranged in parallel to form a water-stop curtain and improve the engineering properties of peaty soil; after the pile body of the jet grouted piles tends to be stable, drill holes along the centerline of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com