Connecting structure for vertically fixing probe rod and probe rod fixing method

A connection structure and probe technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the difficulty of adjusting the verticality of the probe axis, affecting the quality of the needle tip of the probe, and difficult to achieve short Probe rod vertical and other problems, to achieve the effect of small resistance torque, improved verticality, simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

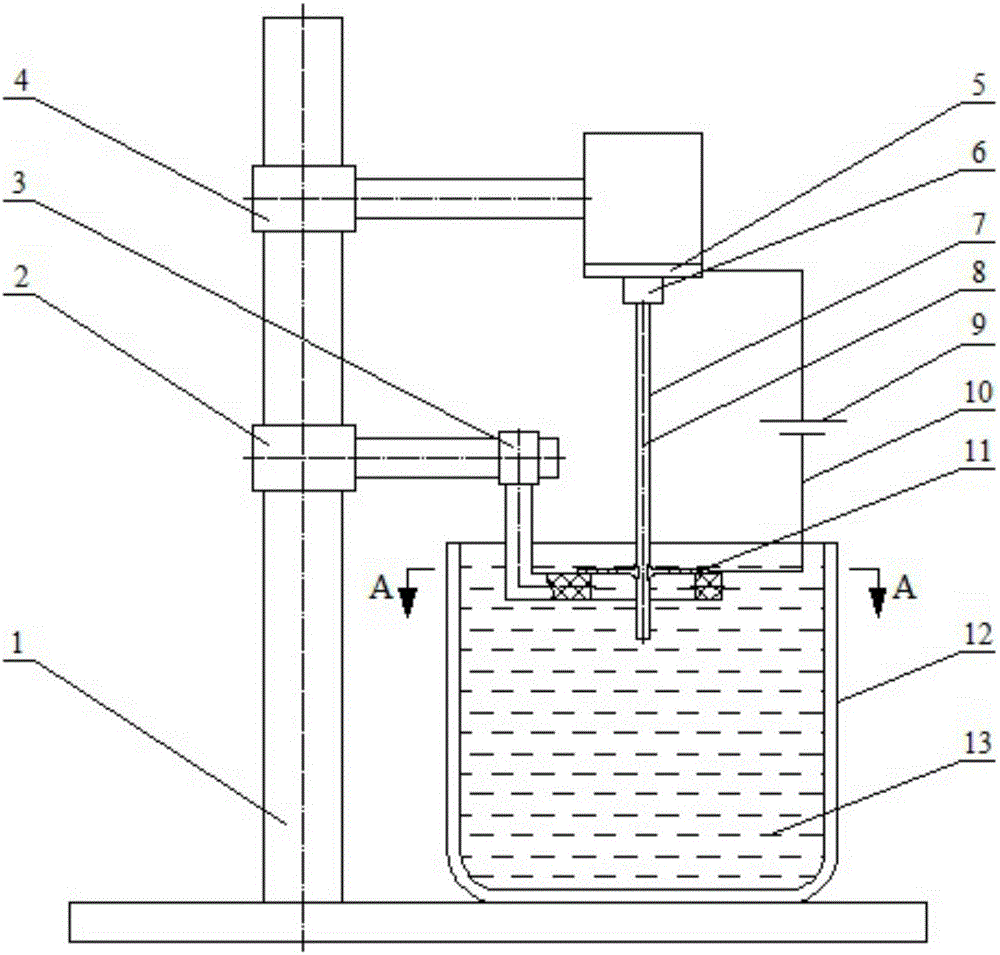

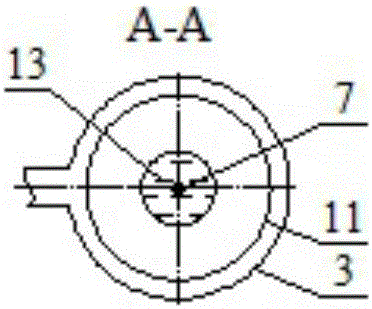

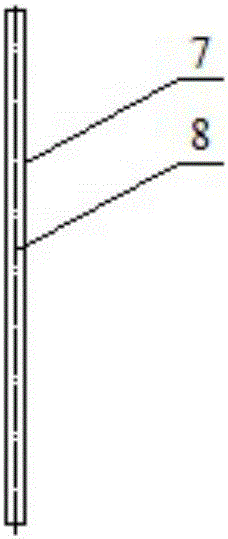

[0041] In the accompanying drawings of the manual: 1 bracket; 2 lower adjustment frame; 3 lower adjustment tray; 4 upper adjustment frame; 5 conductive plate; 6 probe clip; 7 short probe rod; 8 probe axis; Conductive ring; 12 beaker; 13 electrolyte; 14 short probe at one end; 15 long probe rod; 16 long probe rod at one end; 17 long probe rod with magnetic end; 18 magnet; 19 conductive glue; 20 two Tip short probe; a height of magnetic material.

[0042] In the present invention, the short probe rod, the long probe rod, the long probe rod with a pointed end and the long probe rod with a magnetic one end are all probe rods, and the short probe with one end and the short probe with both ends are both probe rods. for the probe.

[0043] A common device for making scanning tunneling microscope probes and making a short-pointed probe such as figure 1 ~shown in 4; make one end pointed long probe stick as Figure 5 ~7 shown; a long probe stick with a magnetic end as shown in Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com