Method for improving TiO2 cathode deoxidizing process by utilizing carbonaceous additive

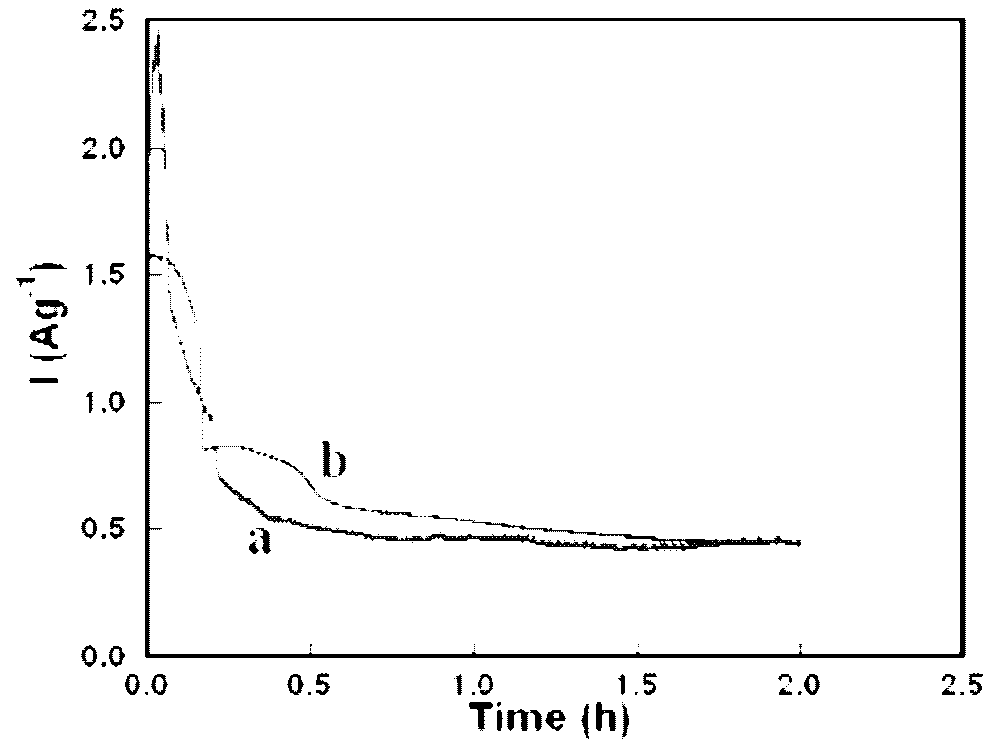

A cathode deoxidation and additive technology, which is applied in the field of carbonaceous additives to improve the deoxidation rate of TiO2 molten salt cathodes, can solve the problems of incomplete deoxidation and decreased current efficiency, and achieve the effects of shortening electrolysis time, improving the deoxidation process, and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] cathode preparation

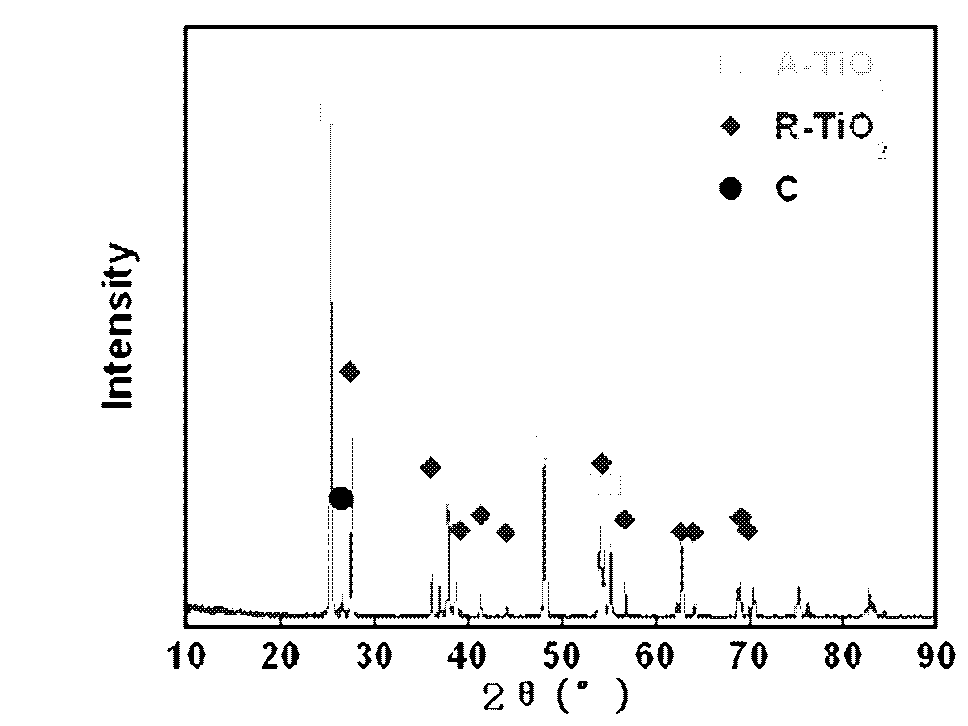

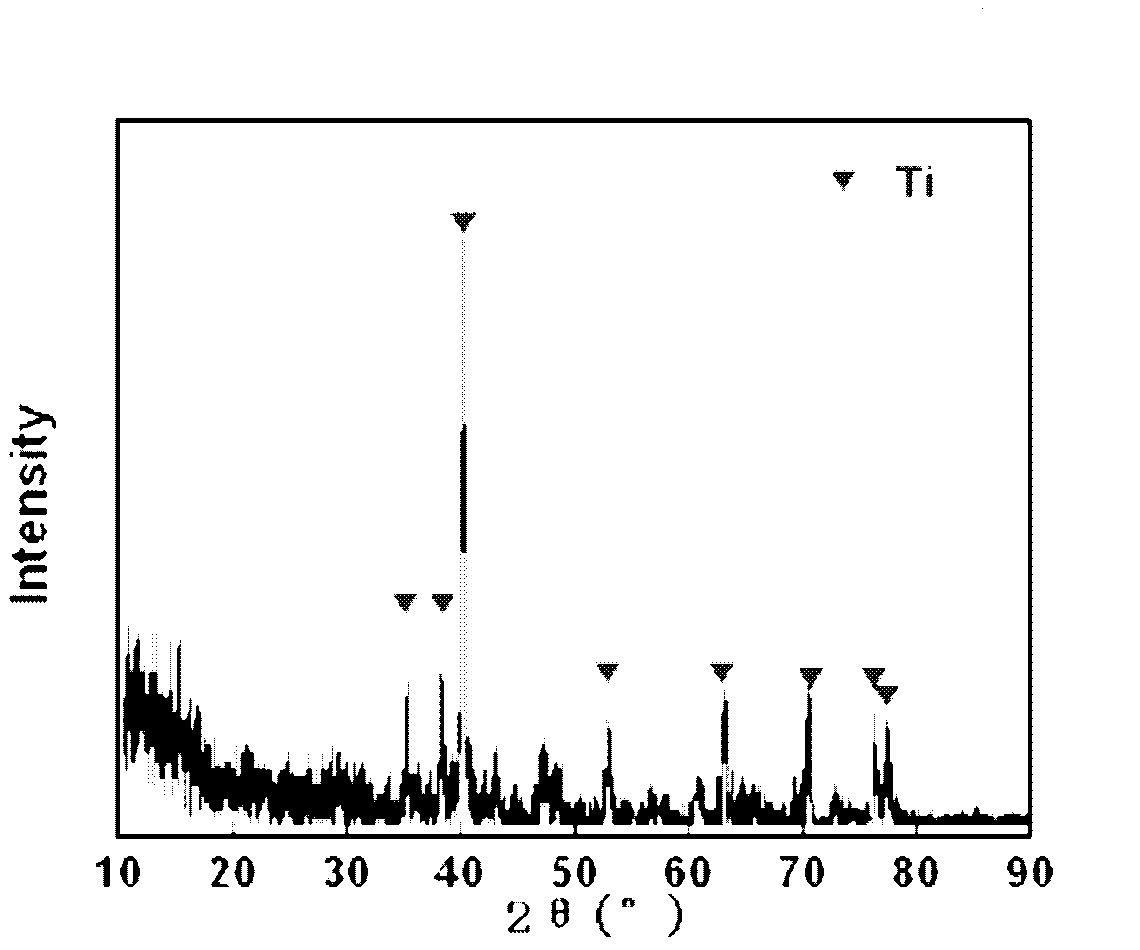

[0022] 1.1 Raw materials: carbon powder, titanium dioxide. Mix the raw materials evenly according to the set ratio, press and sinter the bulk TiO with the following ratio 2 :C=19:1.

Embodiment 2

[0024] 1.2 Raw materials: graphite, titanium dioxide. Mix the raw materials evenly according to the set ratio, press and sinter the bulk TiO with the following ratio 2 :C=9:1.

Embodiment 3

[0026] 1.3 Raw materials: pitch, titanium dioxide. Mix the raw materials evenly according to the set ratio, press and sinter the bulk TiO with the following ratio 2 :C=2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com