Novel electrolysis structure device for wastewater treatment

A new type of wastewater treatment technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problems of dead corners of wastewater, low work efficiency, no collection structure, etc., to reduce resources waste, improve work efficiency, and reduce the effect of excess space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

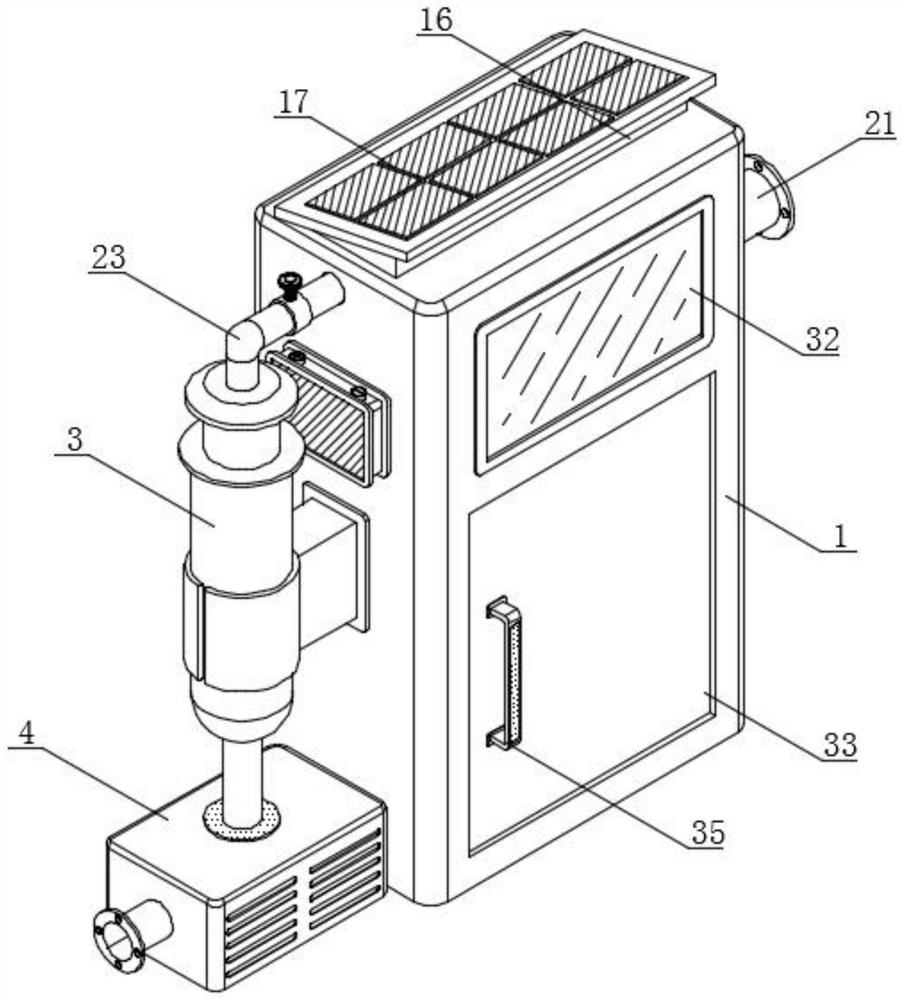

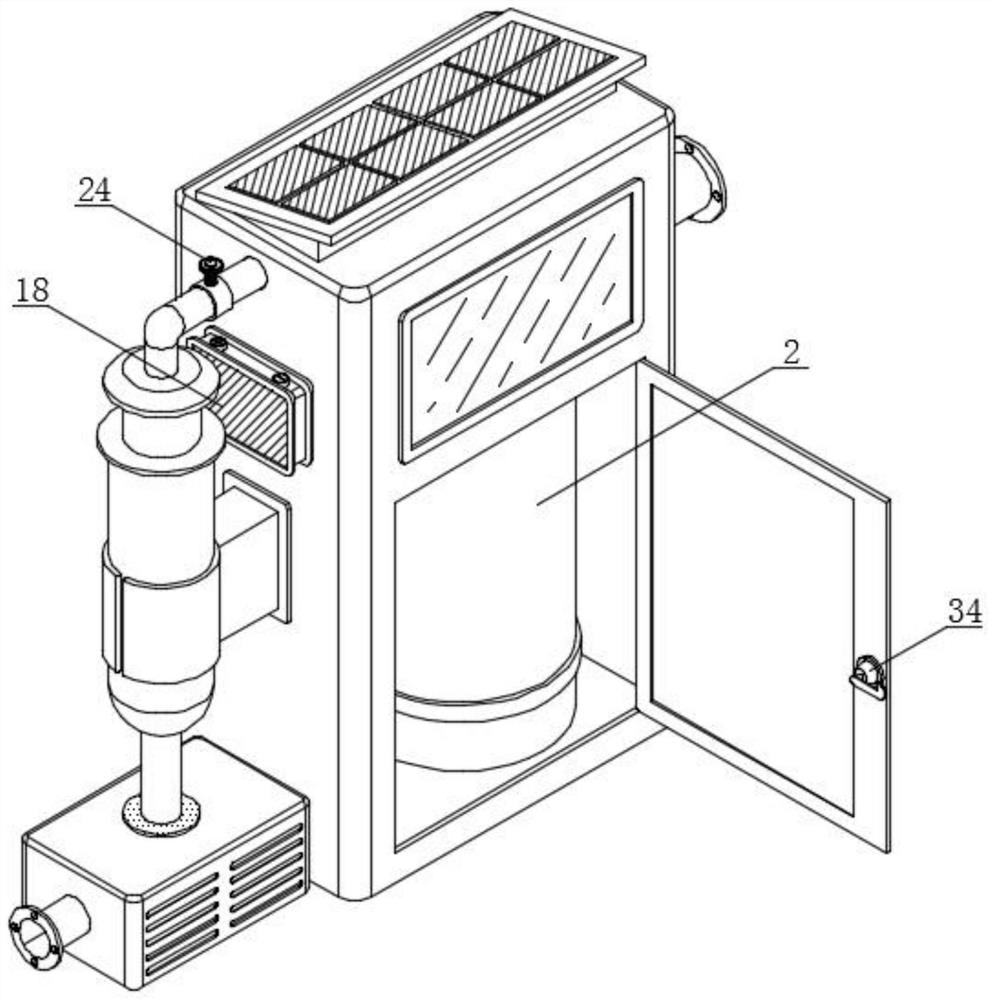

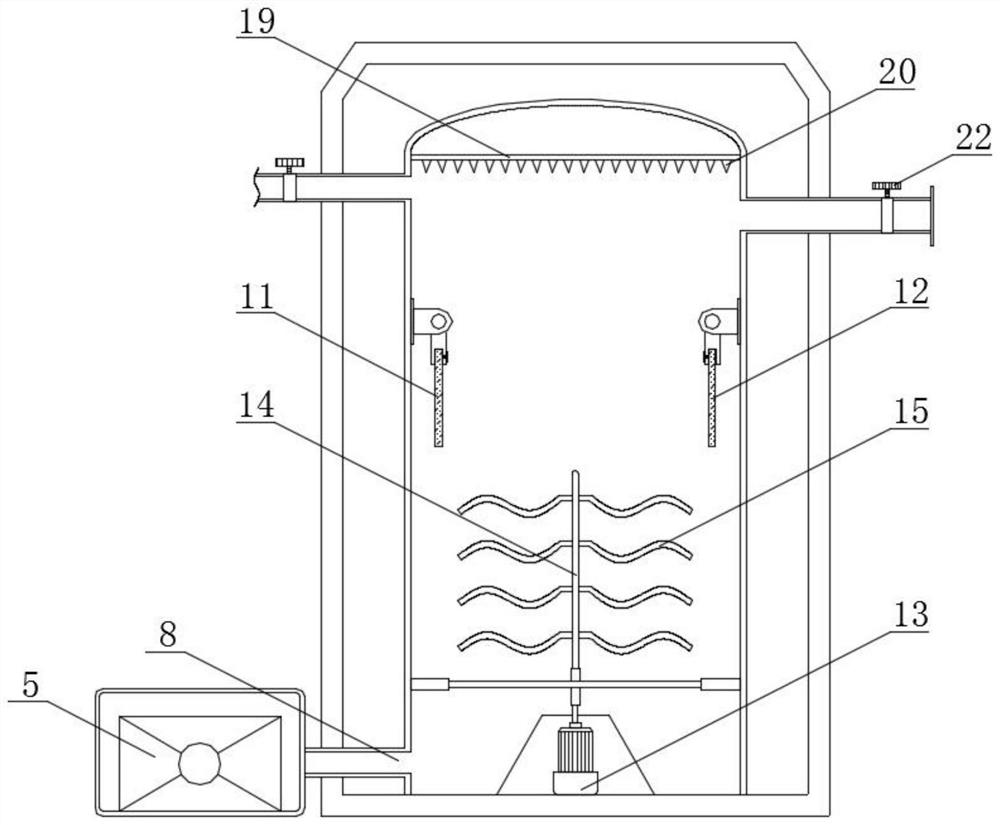

[0043] see figure 1 , figure 2 , image 3 with Image 6 , an embodiment provided by the present invention: a novel electrolytic structural device for wastewater treatment, comprising a work box 1, a treatment tank 2 and a purification tank 3, the inside of the work box 1 is provided with a treatment tank 2, and a part of the work box 1 The side is provided with a purification tank 3; the bottom of one side of the working box 1 is provided with a storage box 4, and the inside of the storage box 4 is provided with a water pump 5; Fixed clip 7 is arranged, and purification tank 3 is positioned at the inside of fixed clip 7, and the bottom of processing tank 2 surface is provided with water inlet pipe 8, and the top of water inlet pipe 8 is connected to the output end of water pump 5, and the inner side wall of processing tank 2 is installed with The connecting plate, the surface of the connecting plate is equipped with a fixed rod 9, the top of the fixed rod 9 is connected wi...

Embodiment 2

[0046] see figure 1 , figure 2 with Figure 4 , an embodiment provided by the present invention: a novel electrolytic structural device for wastewater treatment, comprising a work box 1, a support block 16 is installed on the top of the work box 1, a solar panel 17 is installed on the top of the support block 16, and the work box One side of 1 is provided with a battery box 18, and the inside of the solar panel 17 is electrically connected to the battery box 18, and the battery box 18 is located above the fixed block 6;

[0047] Through the setting of the working box 1, when the staff needs to reduce the occupied area of the device, the collocation of the fixing block 6, the fixing clip 7 and the purification tank 3 can effectively reduce the redundant space of the device by adopting an integrated connection method. , the supporting block 16, the solar panel 17 and the battery box 18 work together, and the inside of the solar panel 17 is electrically connected to the batt...

Embodiment 3

[0049] see image 3 , an embodiment provided by the present invention: a novel electrolytic structural device for wastewater treatment, including crushing teeth 20 and an air outlet pipe 21, a limiting plate 19 is installed on the top of the treatment tank 2, and several A crushing tooth 20, the top of the treatment tank 2 side is provided with an air outlet pipe 21, and the surface of the air outlet pipe 21 is provided with a sealing valve 22;

[0050] Through the setting of the crushing teeth 20 and the air outlet pipe 21, when the staff needs to deal with the air bubbles that appear during electrolysis, the limit plate 19 and the crushing teeth 20 work together, and the crushing teeth 20 can puncture larger air bubbles, thereby The device can better control the generated air bubbles, and the collocation of the air outlet pipe 21 and the sealing valve 22 can make the inside of the device maintain a good seal, thereby making the reaction in the treatment tank 2 more sufficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com