A pressureless sintering process for silicon carbide ceramics

A silicon carbide ceramic and process technology, applied in the field of silicon carbide ceramics, can solve problems such as low friction coefficient and other workpiece wear, and achieve the effects of reducing defects, improving hardness and toughness, and improving friction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

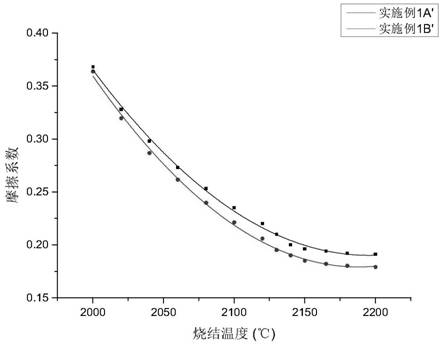

[0054] as attached figure 1 As shown, the pressureless sintering process of silicon carbide ceramics includes the following steps:

[0055] Step 1: Weigh and mix the silicon carbide powder and additive powder, and obtain a premix after mixing evenly;

[0056] Step 2: Weighing the graphite powder and adding it to the pre-mixture obtained in Step 1 and mixing, and mixing uniformly to obtain a raw material mixture;

[0057] Step 3: Mix sodium alginate and water to obtain a hydrogel, then add the raw material mixture to the hydrogel, stir while adding the materials, and stir it evenly to obtain a dispersion mixture; place the dispersion mixture in a spray drying tower for spray granulation , the pumping pressure is 3.2MPa, the inlet temperature is controlled at 215°C, and the outlet temperature is 45°C to obtain raw material powder; the raw material powder is put into a mixer and then stirred and mixed evenly, put into a barrel and sealed for 10 hours; the mixed The uniform and ...

Embodiment 2

[0084] A pressureless sintering process for silicon carbide ceramics, based on the first embodiment, the difference is that in step four, water washing and drying are performed after the green body is sintered and cooled.

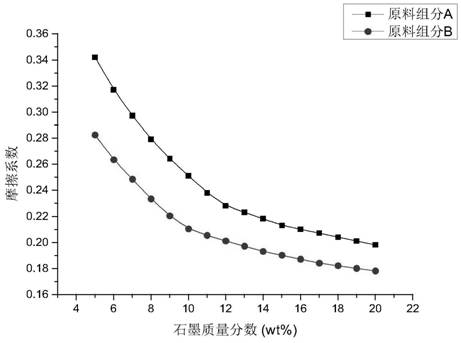

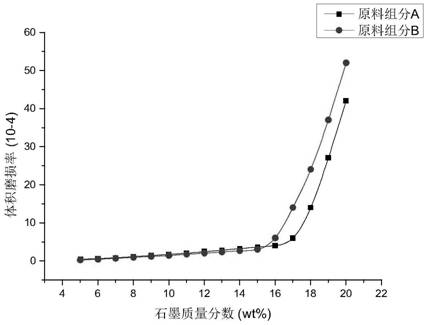

[0085] Embodiments 2A-2B were designed according to the above-mentioned pressureless sintering process of silicon carbide ceramics, and the specific parameters are shown in the table below.

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com