Preparing method of composite tungsten cobalt oxide powder

A technology of cobalt oxide and composite tungsten, which is applied in the powder preparation of composite tungsten-cobalt oxide and the preparation of cemented carbide powder. Errors and measurement analysis errors are difficult to accurately analyze the tungsten and cobalt content of the composite solution, etc., to achieve the effects of saving production consumption, shortening the production cycle, and no ammonia nitrogen wastewater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

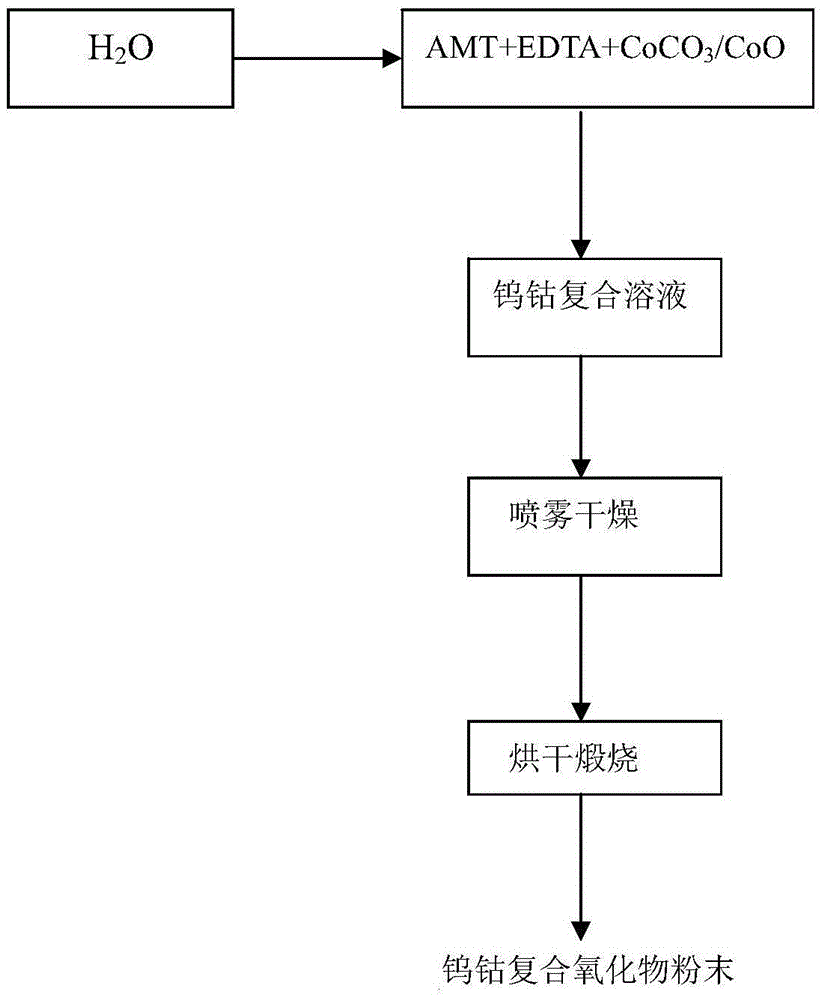

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 7.00kg of ammonium metatungstate (AMT) powder, CoCO 3 Powder 0.74kg, EDTA powder 0.91kg, and mix well.

[0023] (2) Heat 12 liters of deionized water to 50-80° C., slowly add the above powder, make it fully react, and obtain a tungsten-cobalt composite solution. Wherein: the molar ratio of Co and EDTA is 1.86:1, the molar ratio of W and Co is 4.74:1; the pH value of the solution is 3-5.

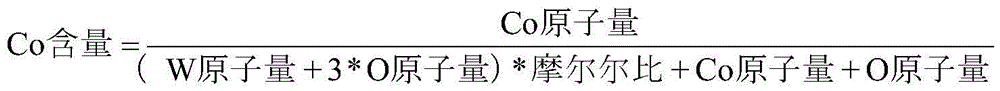

[0024] (3) The obtained tungsten-cobalt composite solution is spray-dried, dried and calcined to obtain tungsten-cobalt composite oxide powder, wherein: the spray drying outlet temperature is 160-190°C, and the drying and calcination is carried out in a rotary furnace at a temperature of 570-680°C ℃, the obtained tungsten-cobalt composite oxide powder, its cobalt content detection method is the volumetric method (the following examples are the same), the result is 5.02%, the theoretical calculation method is as follows (the following examples are the same), the theoretical v...

Embodiment 2

[0029] (1) Weigh 14.00kg of ammonium metatungstate powder, CoCO 3 Powder 5.50kg, EDTA powder 6.86kg, and mix well.

[0030] (2) Heat 26 liters of deionized water to 50-80° C., slowly add the above-mentioned powder to make it fully react, and obtain a tungsten-cobalt composite solution. Wherein: the molar ratio of Co and EDTA is 1.84:1, the molar ratio of W and Co is 1.28:1; the pH value of the solution is 3-5.

[0031] (3) The obtained tungsten-cobalt composite solution is spray-dried, dried and calcined to obtain tungsten-cobalt composite oxide powder, wherein: the spray drying outlet temperature is 160-190°C, and the drying and calcination is carried out in a rotary furnace at a temperature of 570-680°C °C, the obtained tungsten-cobalt composite oxide powder has a cobalt content of 15.87%, a theoretical value of 15.86%, and a cobalt content error of 0.01%.

Embodiment 3

[0033] (1) Weigh 30.00kg of ammonium metatungstate powder, 15.32kg of CoO powder and 31.60kg of EDTA powder, and mix them evenly.

[0034] (2) Heat 60 liters of deionized water to 50-80° C., slowly add the above powder, make it fully react, and obtain a tungsten-cobalt composite solution. Wherein: the molar ratio of Co and EDTA is 1.89:1, the molar ratio of W and Co is 0.58:1; the pH value of the solution is 3-5.

[0035](3) The obtained tungsten-cobalt composite solution is spray-dried, dried and calcined to obtain tungsten-cobalt composite oxide powder, wherein: the spray drying outlet temperature is 160-190°C, and the drying and calcination is carried out in a rotary furnace at a temperature of 570-680°C °C, the obtained tungsten-cobalt composite oxide powder has a cobalt content of 28.16%, a theoretical value of 28.15%, and a cobalt content error of 0.01%.

[0036] As in the above example, the cobalt content of the composite tungsten-cobalt oxide powder prepared by the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com