Device for blending etching solution and device for determinating concetration of etching solution

An etching solution and concentration technology, which is applied in control/regulation systems, semiconductor/solid-state device testing/measurement, instruments, etc., can solve problems such as the reduction of nitric acid concentration and the lack of continuous measurement of the concentration of etching solution components, so as to improve the yield and accuracy Good and constant, direct supply reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. However, unless otherwise specified, the shapes of the structural devices described in these embodiments, their corresponding arrangements, and the like are not limited thereto, and are merely illustrative examples.

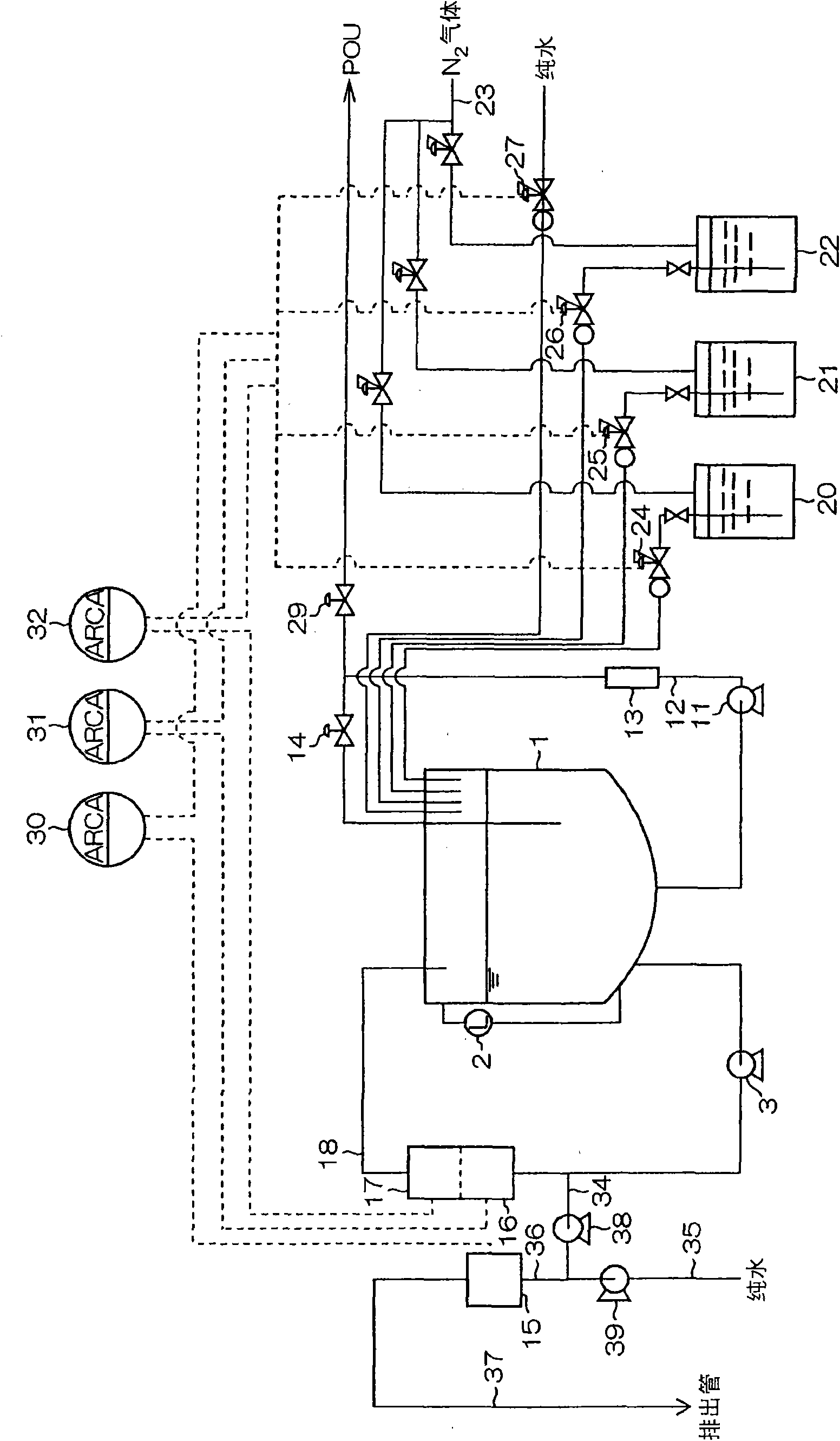

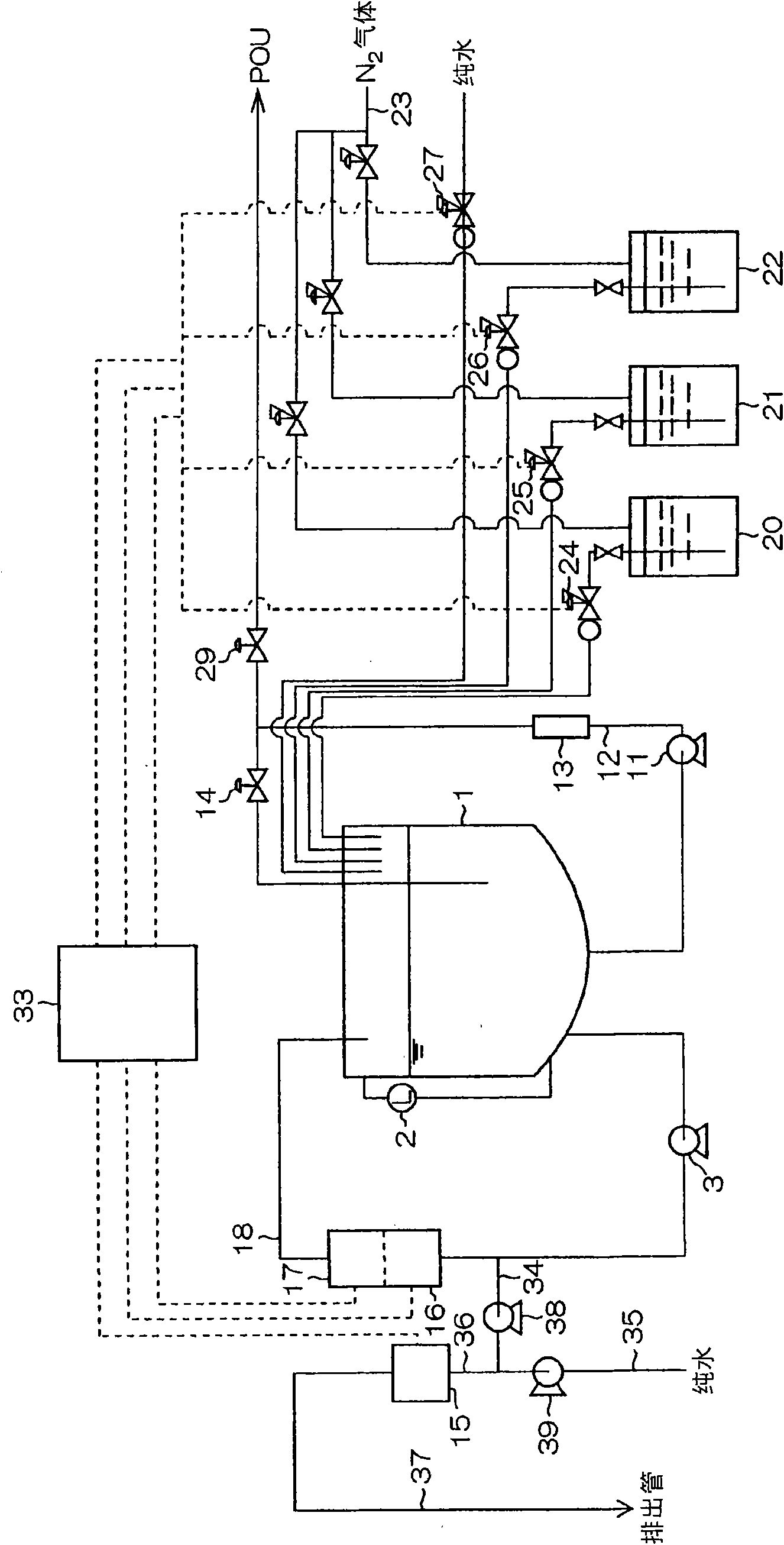

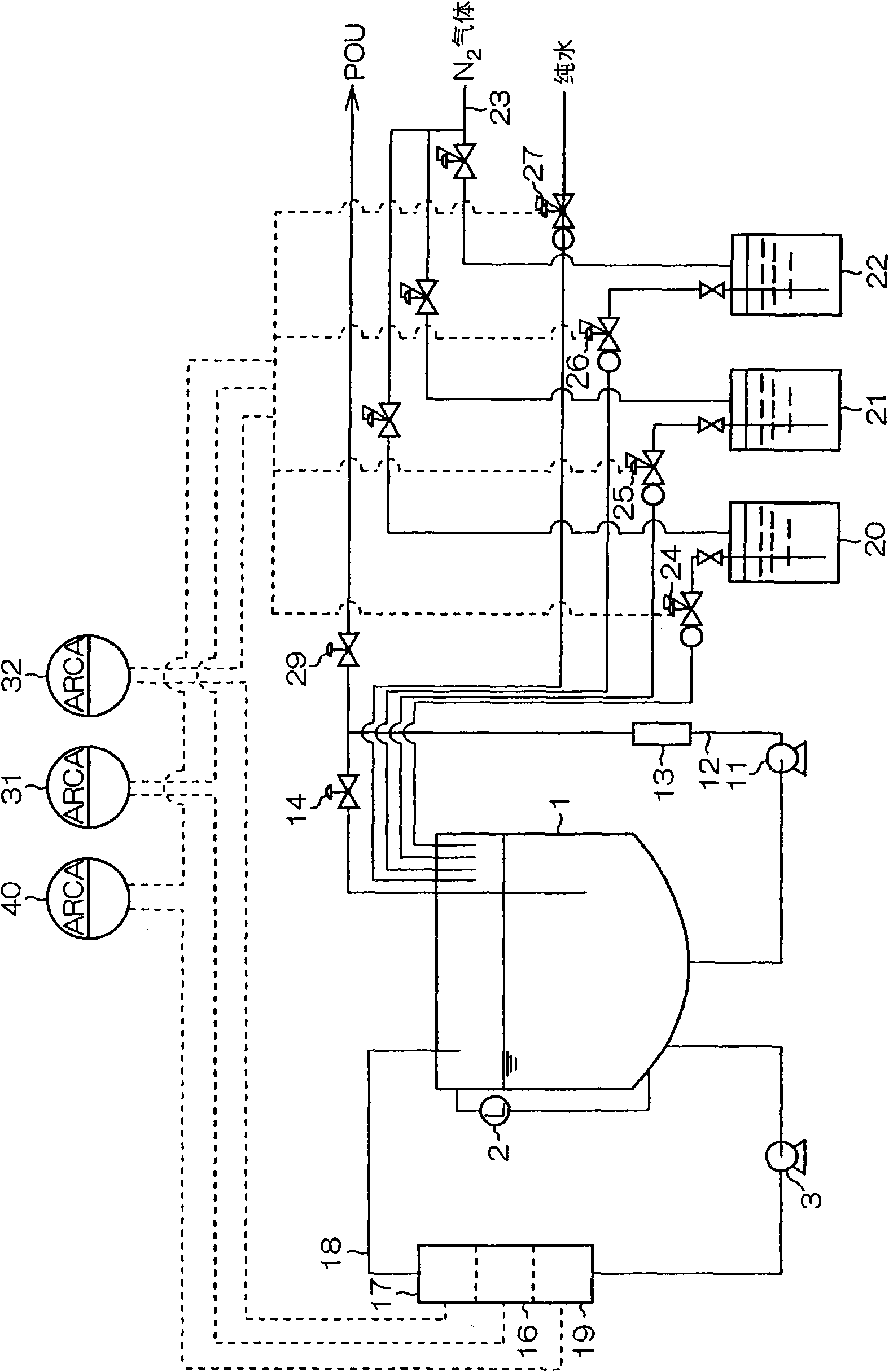

[0043] figure 1 It is a device system diagram showing the first embodiment of the present invention. The reference symbols in the figure are the equipment and components constituting the etchant mixing device. That is, the etchant mixing device includes: a mixing tank 1 for mixing the etching solution, a liquid level gauge 2, a circulation pump 11 for cleaning and stirring the etching solution (also transporting to the etching device at the same time), a pipeline 12. Filter 13 for removing fine particles in etching solution, gas valve 14 for circulating stirring, phosphoric acid stock solution supply tank 20, flow regulating valve 24 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com