Preparation method for copper nanowire

A copper nanowire and copper source technology, which is applied in the field of preparation of new functional nanomaterials, can solve the problems of high preparation cost, difficulty in recycling and reuse, and achieve the effect of reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

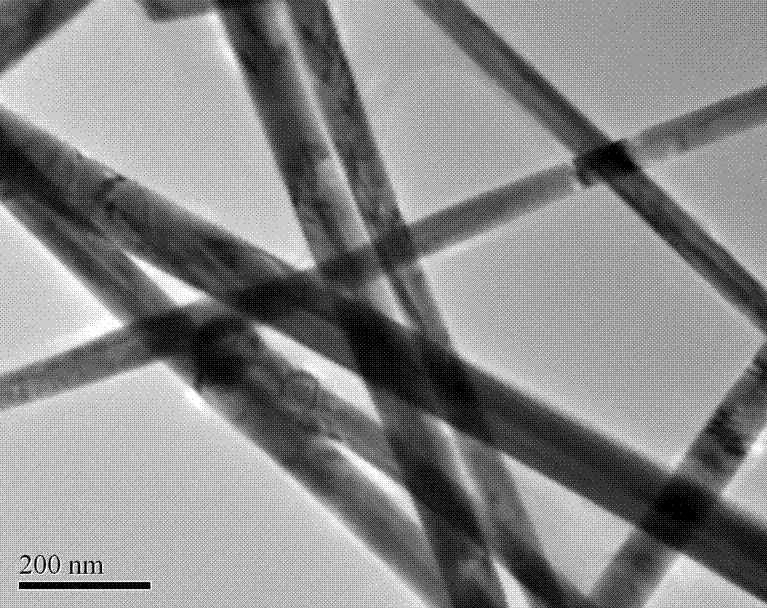

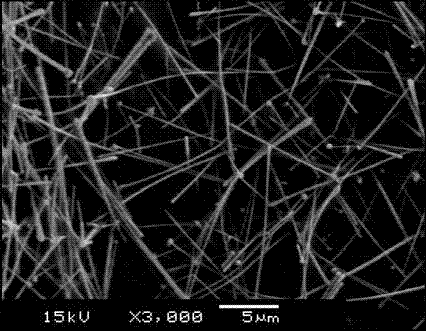

[0017] Add 300ml of 7M NaOH solution into a 500mL flask, then add 3g of triethylenetetramine, 1.5g of Cu(OH) under slow stirring 2 React with 1.5ml 80% (mass fraction, the same below) aqueous solution of hydrazine hydrate in a water bath at 80°C for 1 hour at constant temperature. The solution gradually changed from blue to brownish-red, and a large amount of solids floated on the liquid surface. The flask was taken out from the water bath, cooled to room temperature, filtered to obtain a brownish-red solid, and washed 3 times with 5% hydrazine hydrate aqueous solution, and then 60 °C Dry under vacuum to obtain the copper nanowire product.

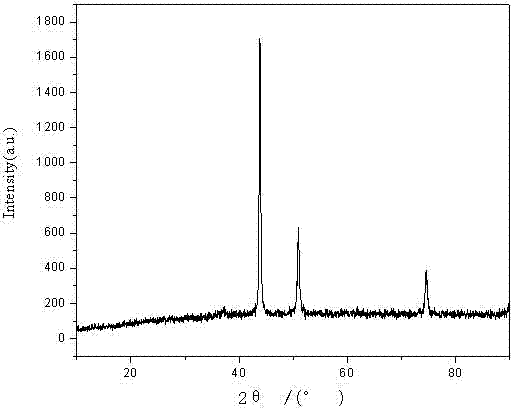

[0018] The XRD pattern of copper nanowires is shown in figure 1 , as can be seen from the figure, the XRD result shows that the prepared product is metallic copper with a pure face-centered cubic structure, and there is no diffraction peak of cupric hydroxide, cuprous oxide or cupric oxide, indicating that the product prepared by this met...

Embodiment 2

[0022] Add 300ml of 7M NaOH solution into a 500mL flask, then add 1g of triethylenetetramine, 1.5g of Cu(OH) under slow stirring 2 and 1.5ml of 80% hydrazine hydrate aqueous solution, and reacted at constant temperature in a water bath at 80°C for 1 hour. The solution gradually changed from blue to brownish-red, and a large amount of solids floated on the liquid surface. The flask was taken out from the water bath, cooled to room temperature, filtered to obtain a brownish-red solid, and washed 3 times with 5% hydrazine hydrate aqueous solution, and then 60 °C Dry under vacuum to obtain the copper nanowire product. The prepared nano copper wire has a length of 5-20um and a diameter of 50-100nm.

Embodiment 3

[0024] Add 300ml of 7M NaOH solution into a 500mL flask, then add 9g of triethylenetetramine, 1.5g of Cu(OH) under slow stirring 2 and 1.5ml of 80% hydrazine hydrate aqueous solution, and reacted at constant temperature in a water bath at 80°C for 1 hour. The solution gradually changed from blue to brownish-red, and a large amount of solids floated on the liquid surface. The flask was taken out from the water bath, cooled to room temperature, filtered to obtain a brownish-red solid, and washed 3 times with 5% hydrazine hydrate aqueous solution, and then 60 °C Dry under vacuum to obtain the copper nanowire product. The prepared nano copper wire has a length of 5-20um and a diameter of 50-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com