Disulfide single crystal and preparation method and application thereof

A disulfide, single crystal technology, applied in the fields of electronics and optoelectronics, can solve problems such as the unrealized preparation of disulfide single crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

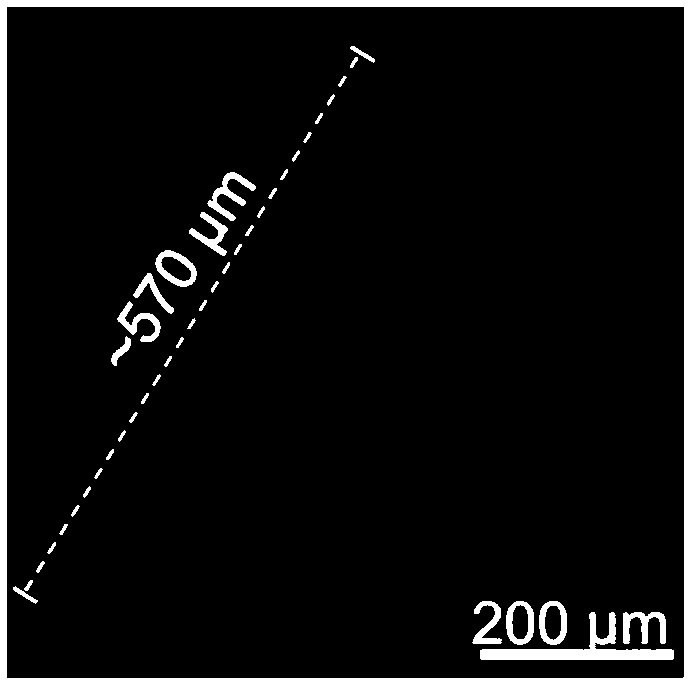

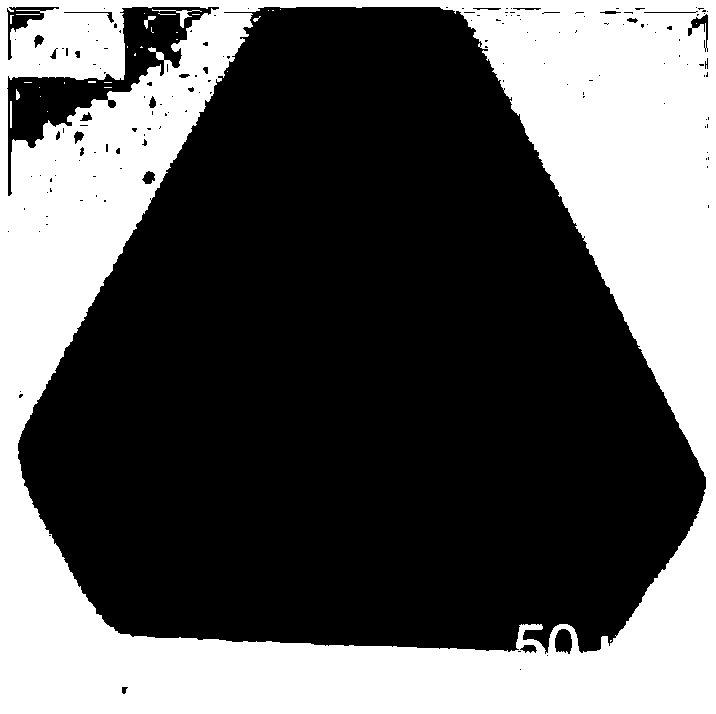

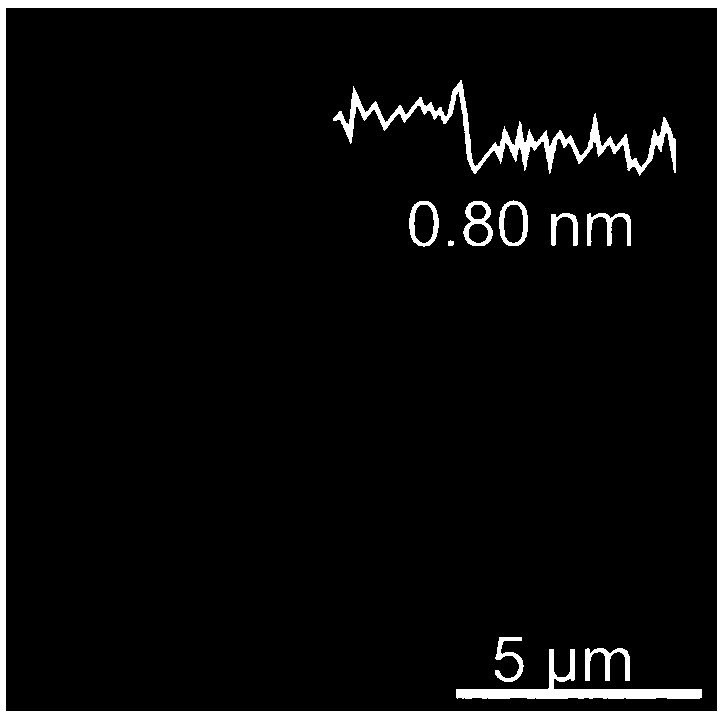

[0068] Preparation of disulfide single crystals:

[0069] (1) In the tube furnace with a heating device in the middle, along the direction of the air flow, 50 mg of Se elemental substance with a particle size of 200 mesh is placed at a distance of 30% of the total length of the tube furnace from the inlet end of the tube furnace. The quartz crucible of powder is placed at the place where the distance from the inlet end of the tube furnace accounts for 50% of the total length of the tube furnace, and the particle size containing sodium chloride is 100 mesh WO 3 Powder (among them, sodium chloride 1mg, WO 3 9mg) of the cubic ceramic crucible, the surface will contain a layer of 300nm thick amorphous S i o 2 A silicon substrate is covered above the cubic ceramic crucible, and a gap accounting for 15% of the cubic crucible mouth area is reserved for airflow to enter;

[0070] (2) Into the tube furnace, the flow rate is 5sccm of hydrogen and 20sccm of argon, the tube furnace is...

Embodiment 2

[0074] The difference from Example 1 is that the temperature of the tube furnace was raised to 1150°C.

Embodiment 3

[0076] The difference from Example 1 is that the tube furnace is heated to 800°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com