Preparation method of large-domain graphene single crystal

A graphene and single crystal technology, applied in the field of large-domain graphene single crystal preparation, can solve the problems of large wrinkle density, small domain size defect density distribution, and limit the application of graphene, so as to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The application provides a method for preparing a large domain graphene single crystal, comprising the following steps:

[0025] 1) Anneal the sapphire / metal substrate in a small amount of oxidizing atmosphere;

[0026] 2) providing a growth gas in a manner of increasing the proportion of the growth gas in a gradient manner, and growing on the sapphire / metal substrate to obtain the large-domain graphene single crystal.

[0027] The preparation method of the large-domain graphene single crystal of the present invention adopts a chemical vapor deposition method and is carried out in a chemical vapor deposition device. The chemical vapor deposition equipment used can be various equipments known in the art, which will not be repeated here.

[0028] The method of the present application uses a sapphire / metal substrate as the growth substrate of the large-domain graphene single crystal, and the substrate can be prepared by a magnetron sputtering process. In the sapphire / met...

Embodiment 1

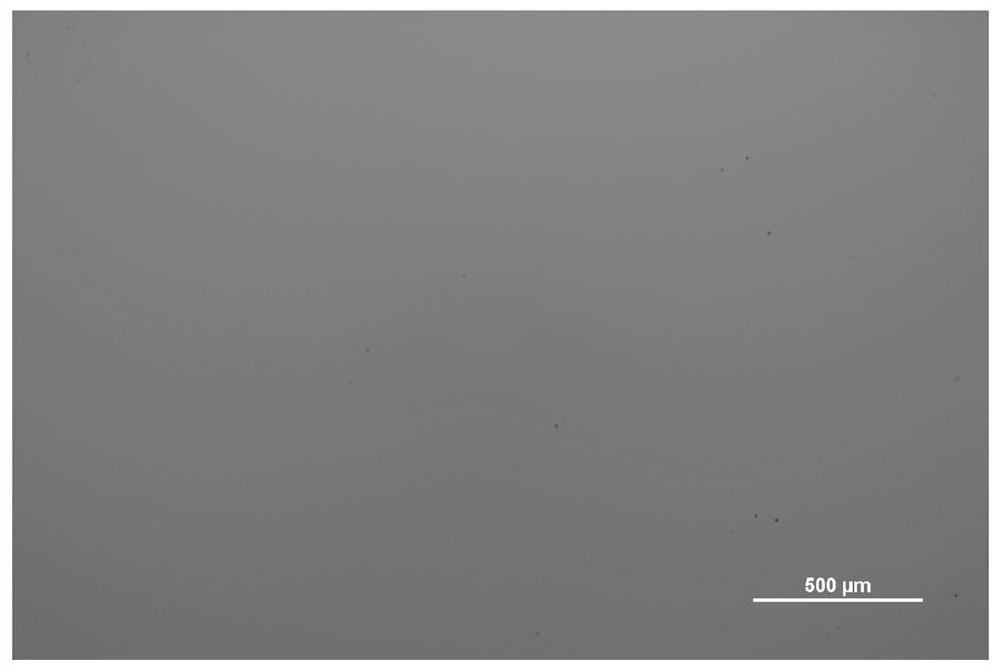

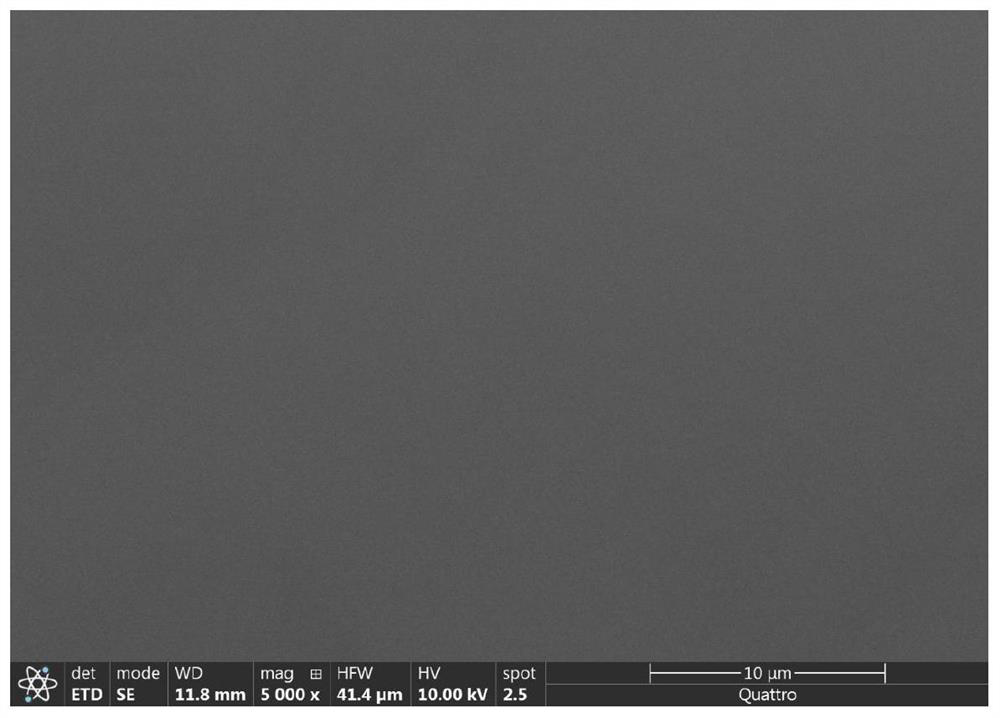

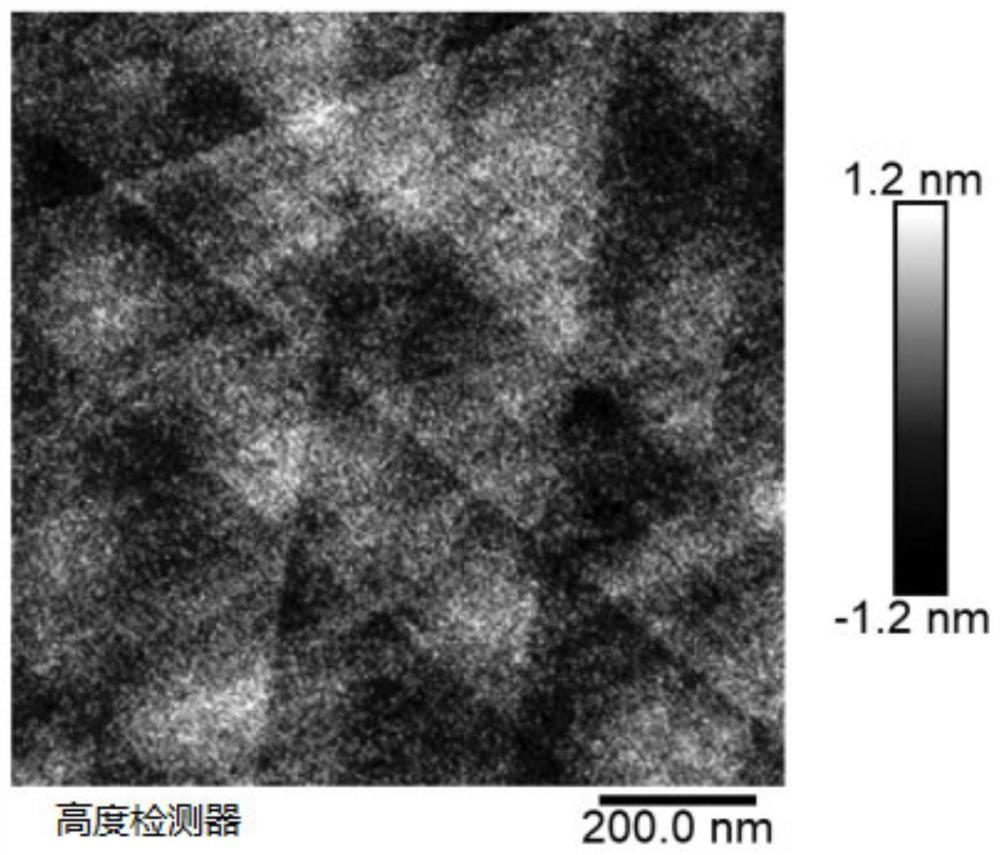

[0037] Example 1 Preparation of large domain graphene single crystal wafer on 4-inch Cu / sapphire single crystal substrate

[0038] Step (1): single crystal copper is prepared according to the method disclosed in the patent application with the application number of 201710522321.1, and a copper (111) single crystal with a thickness of 500 nm is obtained on a 4-inch sapphire single crystal substrate;

[0039] Step (2): The copper (111) single crystal thin film / sapphire was first subjected to a carrier gas flow rate of 4000 sccm Ar (wherein the oxygen content was 10 -5%, based on the total mass of argon), raised from room temperature to 1000°C for 1 hour, and annealed at 1000°C for 0.5h. After that, 20 sccm of diluted methane and 40 sccm of hydrogen were passed in, and the volume percentage of methane in the diluted carbon source gas was 0.1%. After 30 minutes of growth, the diluted methane was increased to 40sccm, and after 30 minutes of continued growth, the diluted methane wa...

Embodiment 2

[0040] Example 2 Preparation of large domain graphene single crystal wafer on 4-inch CuNi / sapphire single crystal substrate

[0041] Step (1): single crystal copper-nickel is prepared according to the method disclosed in the patent application with the application number of 201710522321.1, and a copper-nickel (111) single crystal with a thickness of 500 nm is obtained on a 4-inch sapphire single crystal substrate;

[0042] Step (2): The copper-nickel (111) single-crystal thin film / sapphire was first subjected to a carrier gas flow rate of 4000 sccm Ar (wherein the oxygen content was 10 -5 %, based on the total mass of argon), increased from room temperature to 1000 °C in 1 hour, and annealed at 1000 °C for 0.5h, passed 20sccm of diluted methane and 40sccm of hydrogen, the volume percentage of methane in the diluted carbon source gas was 0.1 %. After 3 minutes of growth, the diluted methane was increased to 40 sccm, and after 3 minutes of continued growth, the diluted methane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com