A kind of preparation method of rare earth tantalate or niobate thermal barrier coating

A thermal barrier coating, tantalate technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of low thermal expansion coefficient, low operating temperature of 6-8YSZ, and high thermal conductivity. Low thermal conductivity, weak interface effect, satisfying diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation method of rare earth tantalate or niobate powder to prepare YNbO 4 As an example, the following steps are included:

[0031] Step 1: Follow YNbO 4 The structural formula of Y 2 o 3 Dissolve in concentrated nitric acid to react, and adjust the pH to about 1, then the prepared NbOCl 3 Add the solution drop by drop (dropping speed is 200mL / min), keep stirring, add ammonia water at the same time to stabilize the pH of the system at 9-10, stir for 1 hour, continue stirring for 120min in a 60°C water bath environment, and then use deionized water The precipitate was continuously washed until pH = 7, and the obtained filter cake was dried in an oven at 120°C for 5 hours, then passed through a 500-mesh sieve and sintered at 900°C for 5 hours, and the sintered powder was passed through a 500-mesh sieve again for use.

[0032] Step 2: Mix the powder prepared in step 1 with 30wt.% water by mass to obtain slurry A, and mix slurry A with powder mass fraction of 0.5% ...

Embodiment 2

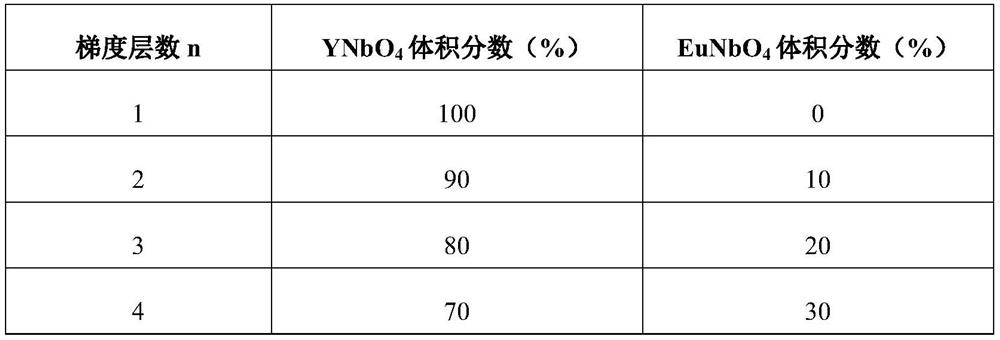

[0039] The difference with Example 1 is that, as shown in Table 2, the number of gradient layers n=11, the thickness of the rare earth niobate coating is 200 μm, and YNbO in each gradient layer 4 and EuNbO 4 The volume fraction of the powder is shown in Table 2 below.

[0040] Table 2 is YNbO in each gradient layer of embodiment 2 4 and EuNbO 4 Powder Volume Fraction Table

[0041]

[0042]

Embodiment 3

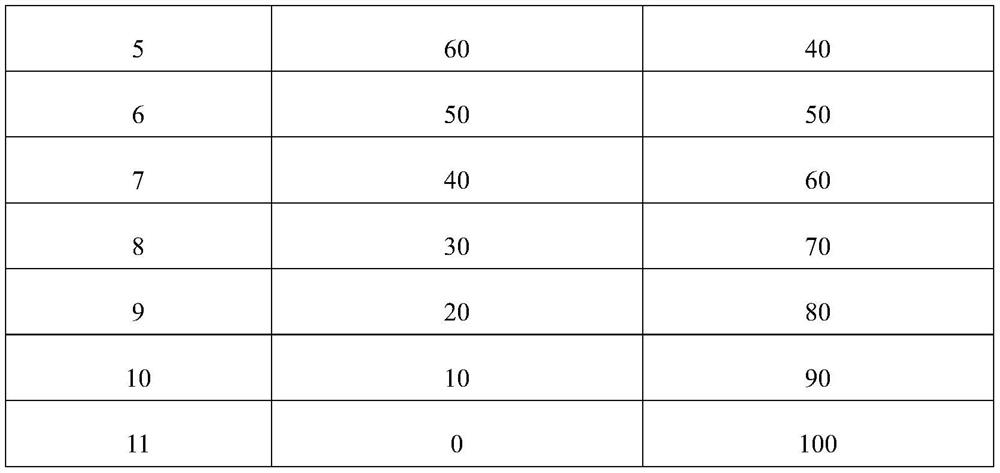

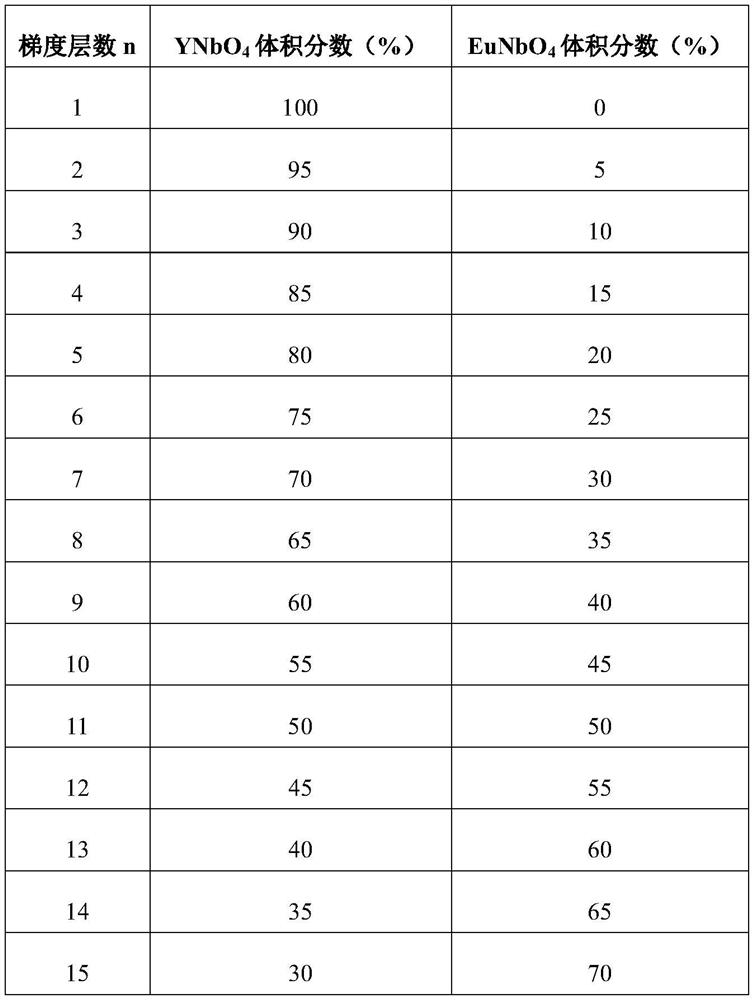

[0044] The difference with Example 1 is that, as shown in Table 3, the number of gradient layers of the ceramic coating n=21, the thickness of the rare earth niobate coating is 300 μm, and YNbO in each gradient layer 4 and EuNbO 4 The volume fraction of the powder is shown in Table 3 below.

[0045] Table 3 is YNbO in each gradient layer of embodiment 3 4 and EuNbO 4 Powder Volume Fraction Table

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com