Preparation method of biomass boiler heating surface protection coating

A biomass boiler and protective coating technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of affecting the service life of biomass boilers, poor corrosion resistance, coating cracking, etc. The effect of improving the density, enhancing the corrosion resistance and enhancing the bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

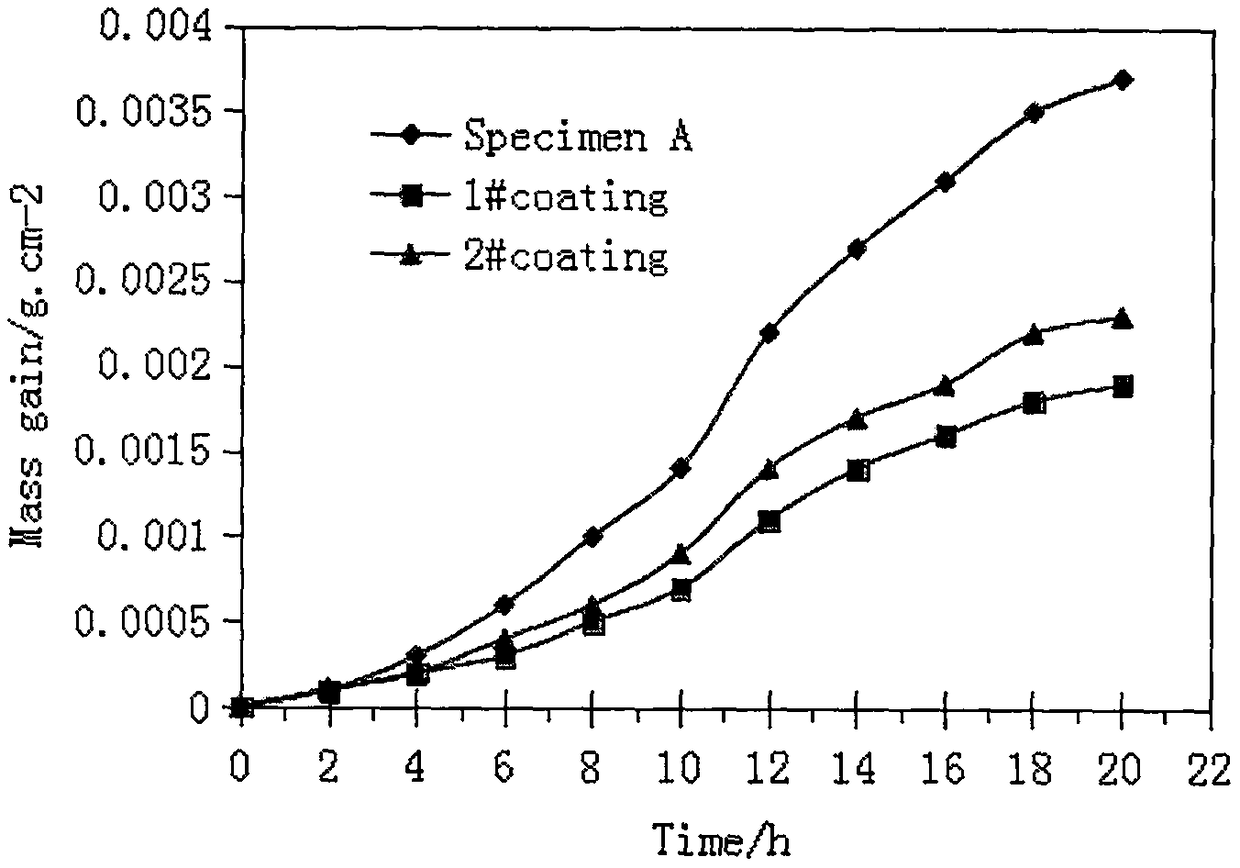

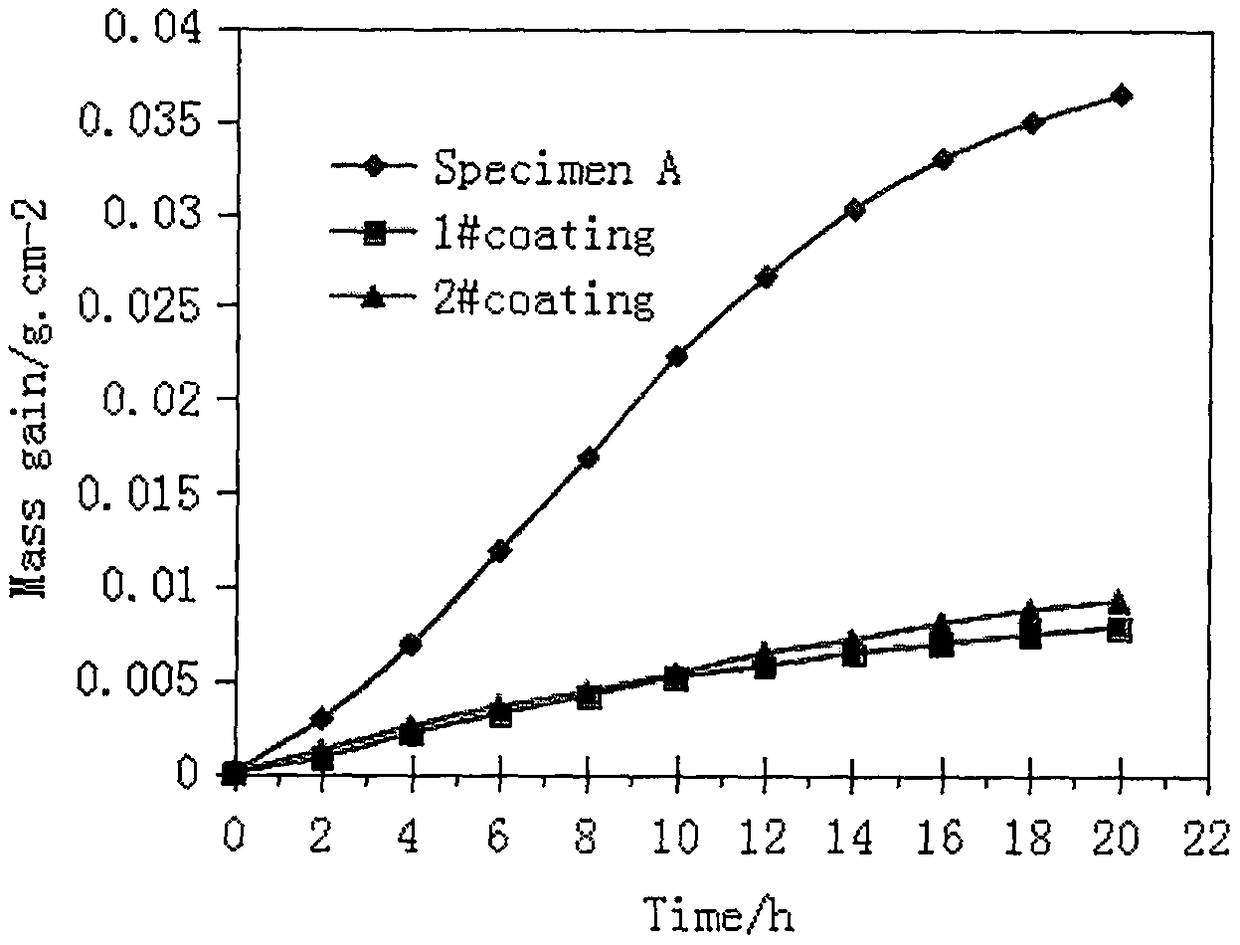

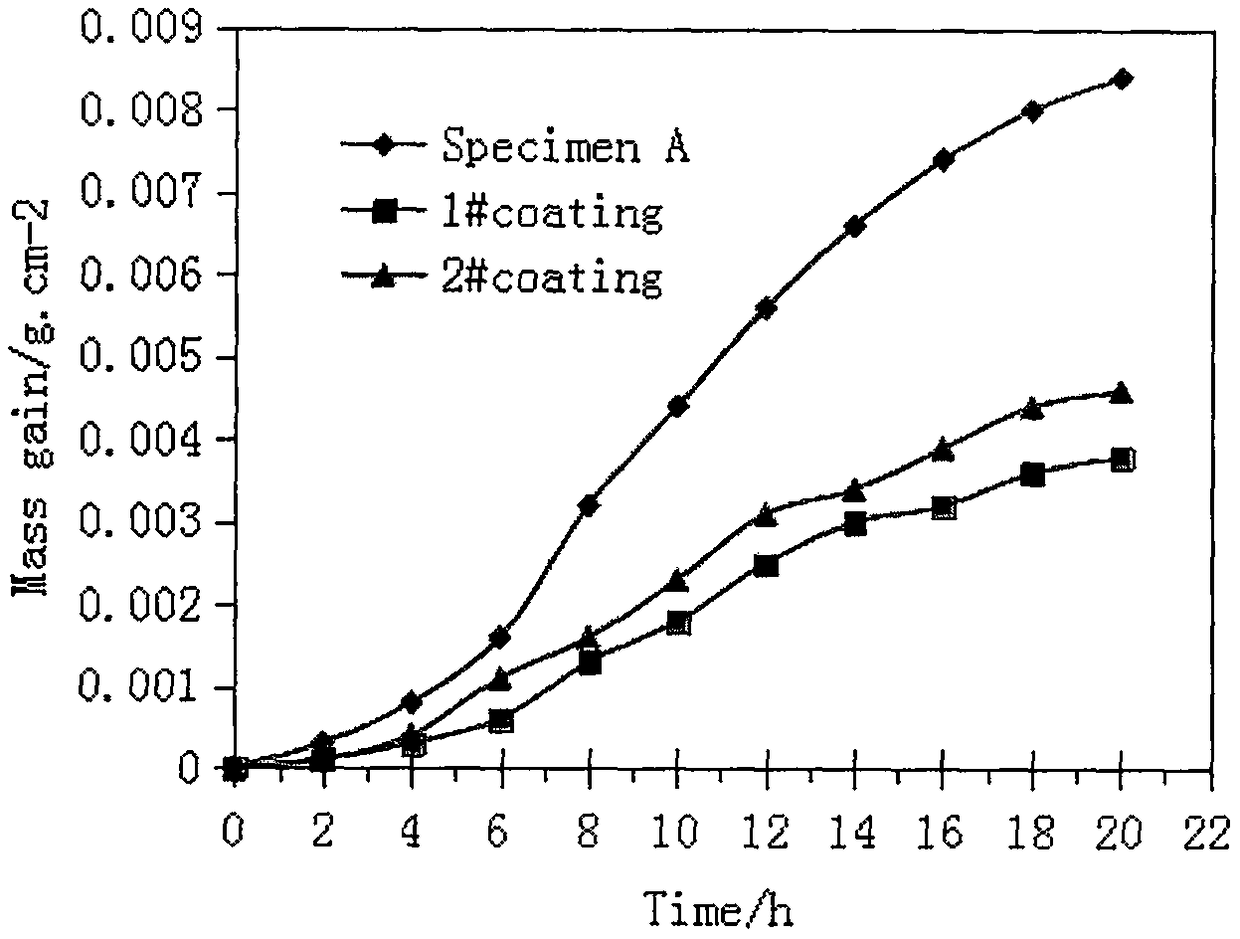

Examples

Embodiment 1

[0028] A method for preparing a protective coating on a heating surface of a biomass boiler, comprising the following steps:

[0029] (1) Preparation of powder core wire

[0030] Put the core powder into the powder feeder of the wire rolling machine, roll the stainless steel strip on the rolling machine to form grooves, the powder feeder sends the mixed core powder into the groove, and the rolling machine passes through the rollers The steel strip is gradually closed into a circular wire by rolling, and then the rolled and formed wire is drawn on a wire drawing machine, gradually reduced in diameter, and finally reaches the required size of φ2.00mm for arc spraying, and the powder core wire is obtained, of which The powder core powder is made of the following components by weight: 45 parts of nickel powder, 28 parts of chromium powder, 4 parts of molybdenum powder, 4 parts of aluminum powder, 1 part of indium powder, 1 part of aluminum silicon powder, and 8% of rare earth:

...

Embodiment 2

[0041] A method for preparing a protective coating on a heating surface of a biomass boiler, comprising the following steps:

[0042] (1) Preparation of powder core wire

[0043] Put the core powder into the powder feeder of the wire rolling machine, roll the stainless steel strip on the rolling machine to form grooves, the powder feeder sends the mixed core powder into the groove, and the rolling machine passes through the rollers The steel strip is gradually closed into a circular wire by rolling, and then the rolled and formed wire is drawn on a wire drawing machine, gradually reduced in diameter, and finally reaches the required size of φ2.00mm for arc spraying, and the powder core wire is obtained, of which The powder core powder is made of the following components by weight: 55 parts of nickel powder, 32 parts of chromium powder, 6 parts of molybdenum powder, 6 parts of aluminum powder, 3 parts of indium powder, 3 parts of aluminum silicon powder, and 12% of rare earth; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com