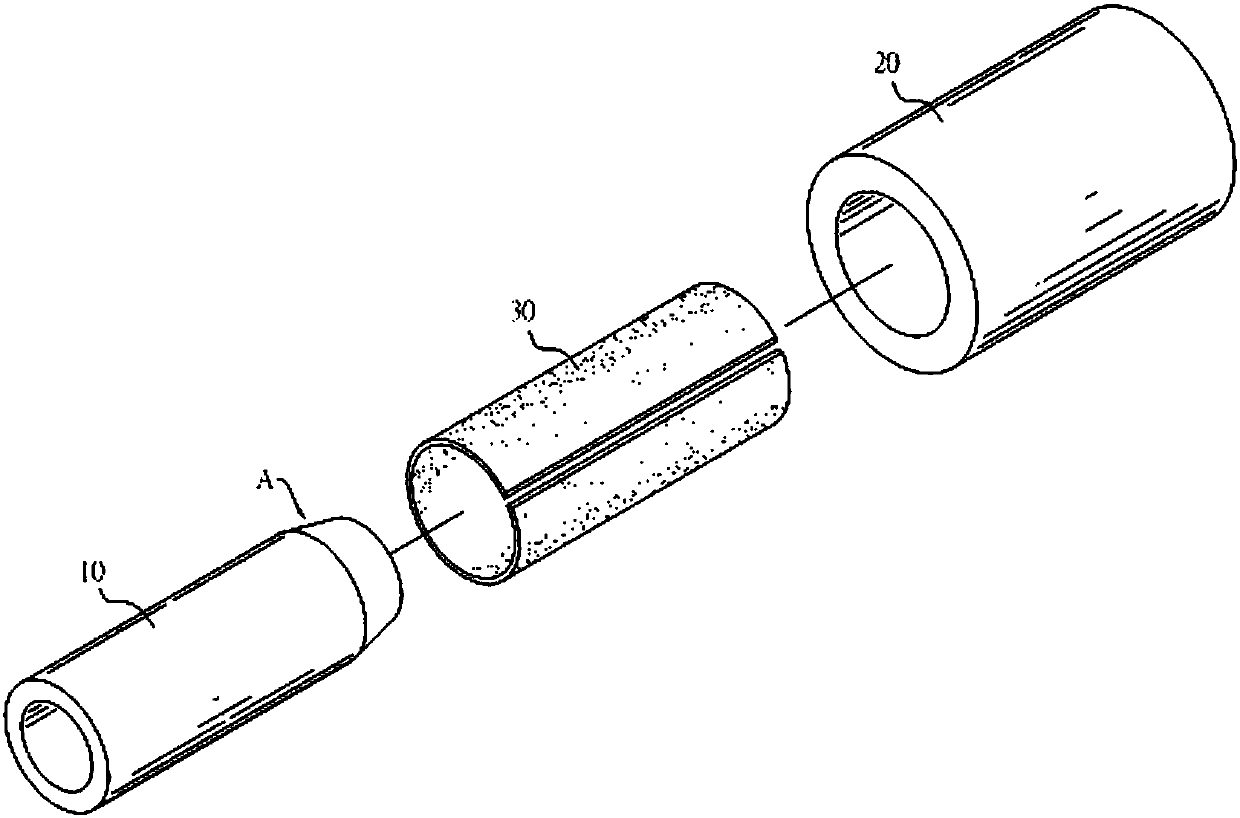

Rotating target material

A technology of rotating target and target material, applied in the field of sputtering, can solve the problems of poor power tolerance of rotating target material, difficult to rotate target material service life, inability to take away heat, etc., so as to improve the resistance of sputtering power. efficiency, shortening time and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

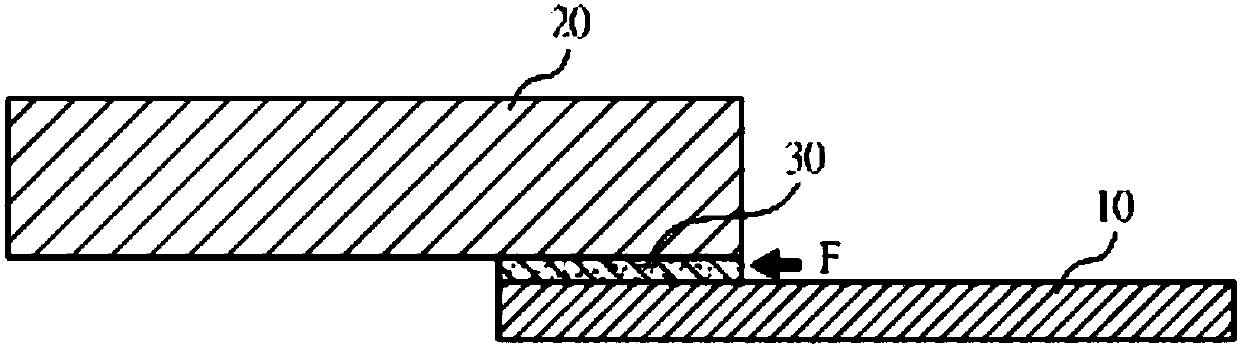

Method used

Image

Examples

Embodiment 1 and 2

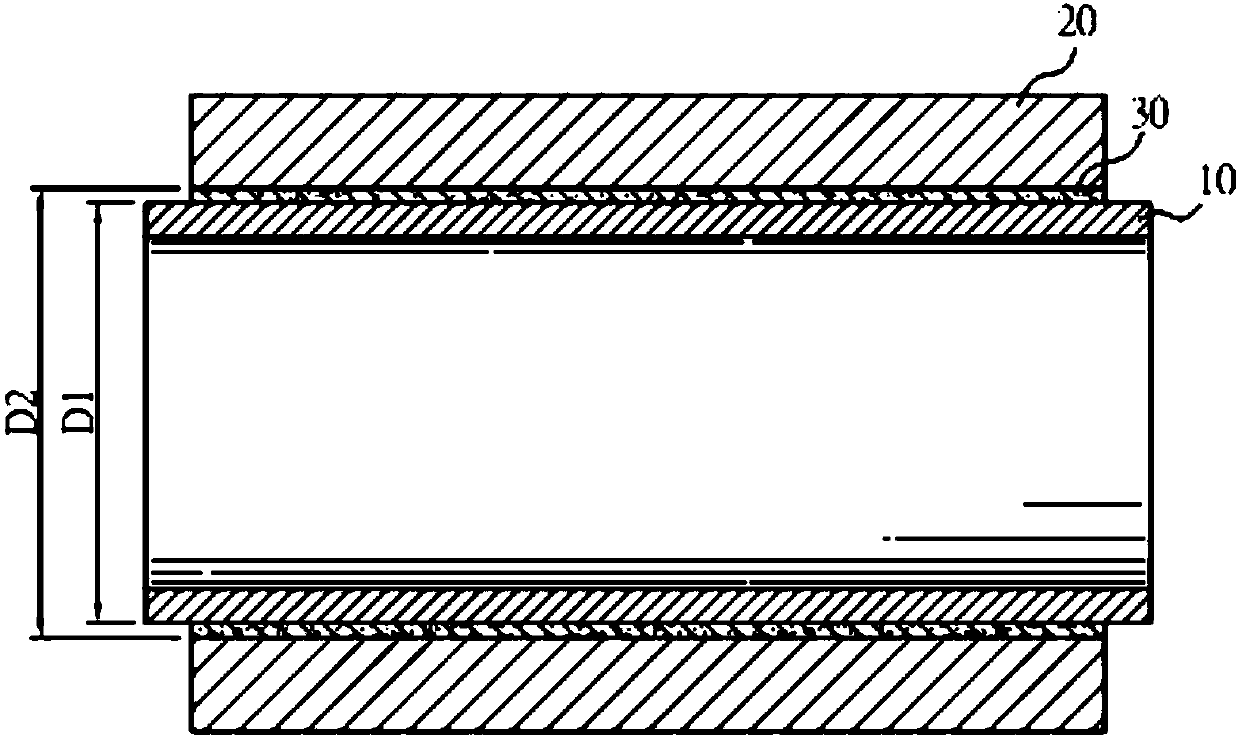

[0031] First, a backing tube having an inner diameter of 125 mm, an outer diameter of 133 mm, and a length of 1500 mm was prepared. The materials of the backing tubes of the various examples and comparative examples are shown in Table 1 below.

[0032] Next, the raw material of the target body is formed into a hollow target body with an inner diameter of 142 mm, an outer diameter of 154 mm, and a length of 700 mm after sintering, melting, casting, processing and other processes. The materials of the target body in each example and comparative example are shown in Table 1 below. When making the hollow target body of the rotating target of Example 1, the aforementioned hollow target body is formed by indium tin oxide (ITO) through processes such as sintering and processing; when making the rotating target of Example 2 In the case of a hollow target body, molybdenum (Mo) is used to form the aforementioned hollow target body through processes such as melting, casting and processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com