Method for preparing nano composite multiple layer hard film

A nano-composite, hard technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of high requirements for synthesis equipment, time-consuming, low sputtering efficiency, etc., and achieve low cost, Effect of reducing noise and improving sputtering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

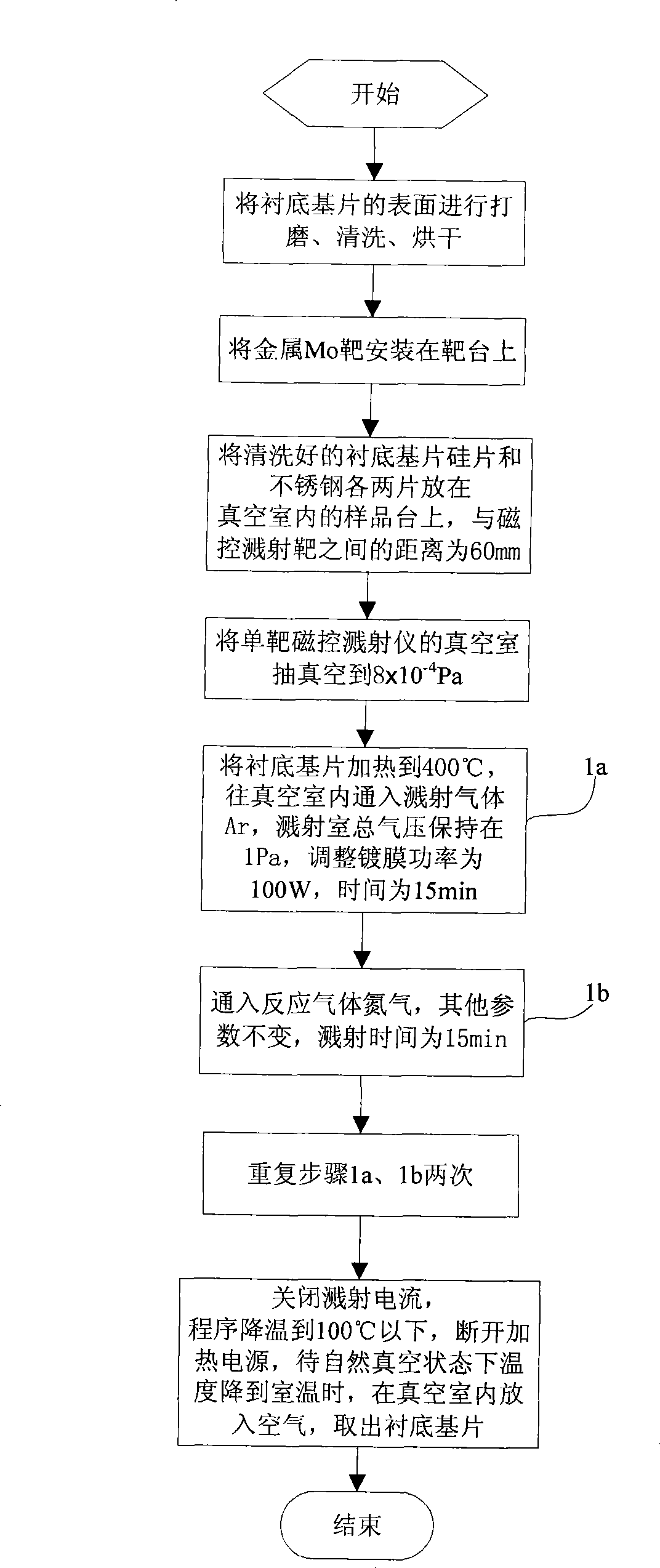

[0034] Embodiment one: prepare MoNx / Mo composite multi-layer hard film, see figure 1 shown

[0035] (1), the surface of the substrate substrate is polished, cleaned and dried;

[0036]The substrate substrate can choose to cut the steel sheet used in the industry, that is, the wire-cut or laser-cut high-speed steel / stainless steel sheet (10mm in diameter, 3mm in thickness) with metallographic sandpaper from coarse to fine, from 300 mesh to 3000 The objects are polished in turn, and polished with diamond paste on the polishing machine until the surface is smooth without scratches, and then degreased with acetone or ethanol solution to dissolve impurities attached to the surface of the substrate, and then mixed with hydrochloric acid, hydrogen peroxide and deionized water. Soak in liquid (volume ratio 1:2:5) for 6 hours, take it out, wash it with deionized water, and then ultrasonically clean it, then dry it on a desktop glue homogenizer for use.

[0037] The substrate substrat...

Embodiment 2

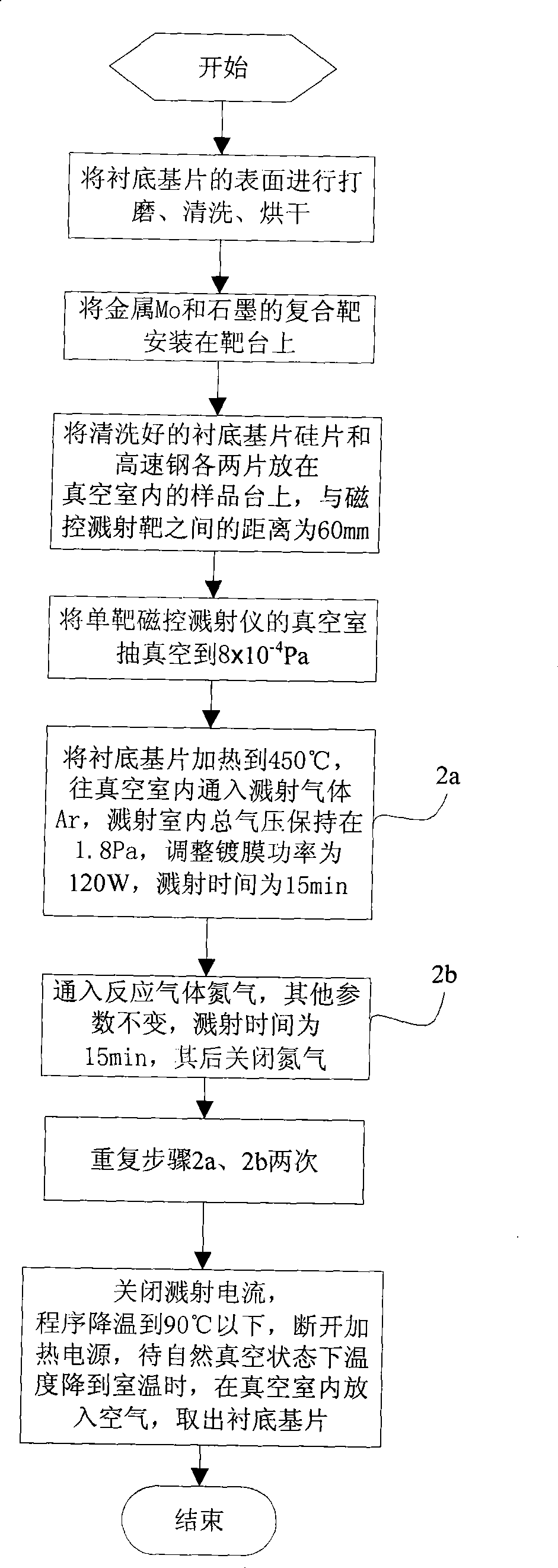

[0046] Embodiment two: prepare MoCx / MoCNx nanocomposite multi-layer hard film, see appendix figure 2 shown;

[0047] (1) The substrate substrate is made of high-speed steel sheet (10mm in length and 2mm in width) that is wire-cut or laser-cut, and polished with metallographic sandpaper from coarse to fine, from 300 mesh to 3000 mesh , polished with diamond paste on a polishing machine until the surface is smooth without scratches, then degreased with acetone or ethanol solution to dissolve impurities attached to the surface of the substrate, and then in a mixed solution composed of hydrochloric acid, hydrogen peroxide and deionized water (volume ratio 1:2:5) for more than 6 hours, wash off the residual liquid with deionized water, then use ultrasonic cleaning, and dry it on a desktop glue homogenizer before use. The substrate substrate also uses a silicon wafer with a purity of 99.99%, which is cut into 8 x 8mm with a glass knife 2 size, wash and tumble dry ready to use.

...

Embodiment 3

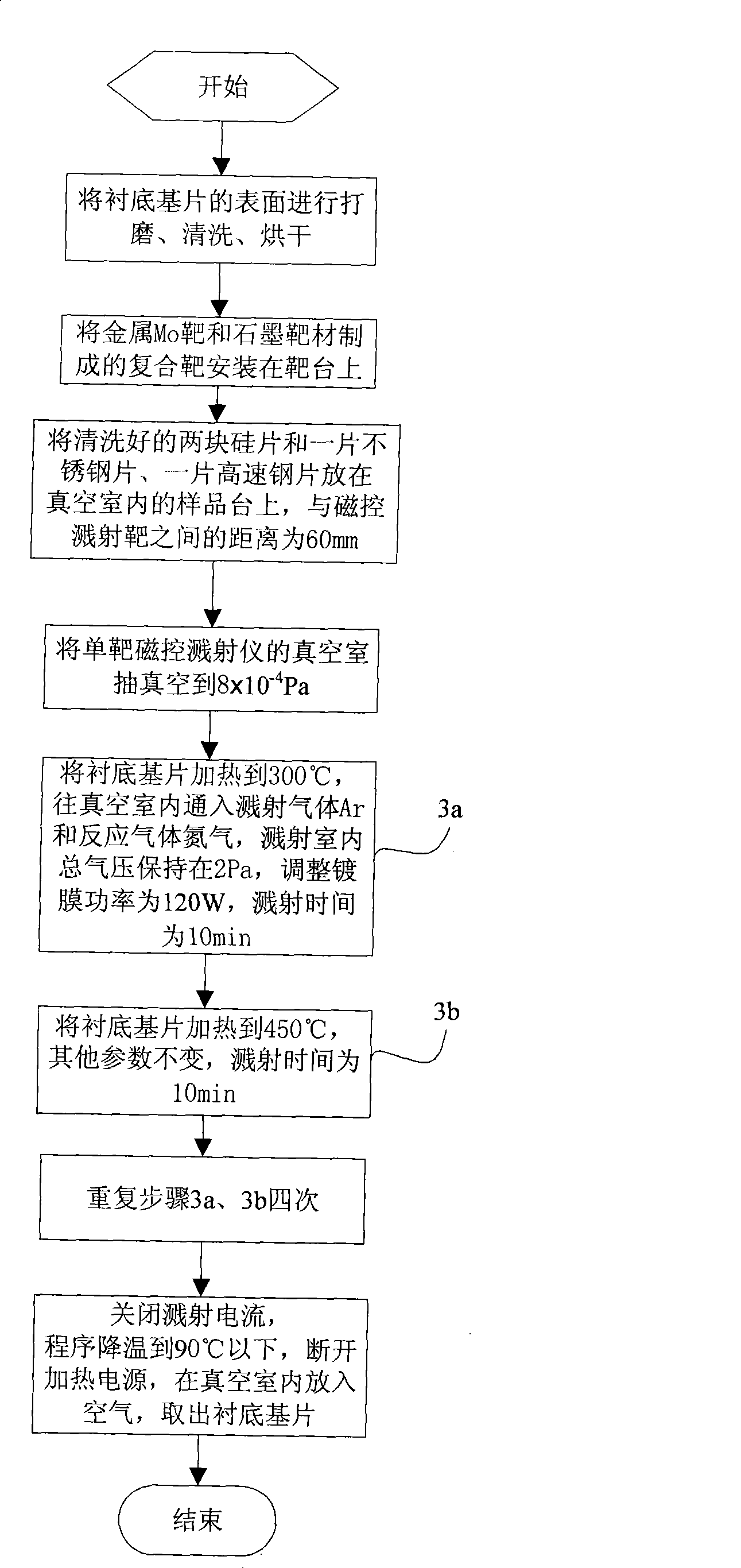

[0055] Embodiment Three: Preparation of MoCNx nanocomposite homogeneous multilayer film, see attached image 3 shown

[0056] (1), the surface of the substrate substrate is polished, cleaned and dried;

[0057] The substrate substrate selects the steel sheet used in the cutting knife and cutting tool industry, that is, the wire-cut or laser-cut high-speed steel / stainless steel sheet (10mm in diameter, 3mm in thickness) with metallographic sandpaper from coarse to fine, from 300 Grind in sequence from mesh to 3000 mesh, and polish with diamond nano-scale abrasive paste on the polishing machine until the surface is smooth without scratches, then degrease with acetone or ethanol solution to dissolve impurities attached to the surface of the substrate, and then wash with hydrochloric acid, hydrogen peroxide and Soak in a mixture of deionized water (volume ratio 1:2:5) for more than 6 hours, wash with deionized water, and then use ultrasonic cleaning for 15 minutes, then dry it on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com