Nickel-vanadium alloy magnetron sputtering rotating target containing trace rare earth elements and preparation method

A technology of rare earth elements and nickel-vanadium alloys, applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problem of poor oxidation resistance and corrosion resistance, no sharing of production equipment, sputtering rate Instability and other issues, to achieve high throughput, save labor costs, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

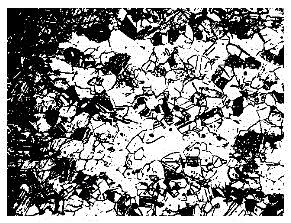

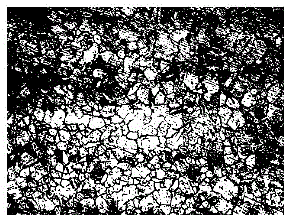

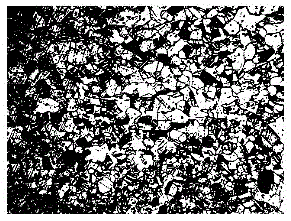

Image

Examples

Embodiment 1

[0042] A nickel-vanadium alloy magnetron sputtering rotary target containing trace rare earth elements and a preparation method thereof, the preparation steps are as follows:

[0043] ⑴Raw material preparation: by weight percentage, the alloy composition is: 0.05% RE, 9% V, the balance is Ni and unavoidable impurities, the impurity content is less than 0.1%, and the total input is 180 kg, including electrolytic nickel 163.71 kg, sponge Vanadium 16.2 kg, mixed rare earth 0.09 kg;

[0044] (2) Vacuum smelting: use industrial alcohol to remove the dirt on the surface of electrolytic nickel, remove oxides with dilute nitric acid, put the treated electrolytic nickel into a melting crucible after drying, and smelt with electricity at a melting temperature of 1600°C for 80 minutes. Vacuumize during the process to make the vacuum degree less than 8Pa. Before casting the ingot, first pass argon gas 4Mpa in the vacuum state, then add the sponge vanadium into the crucible from the small ...

Embodiment 2

[0053] A nickel-vanadium alloy magnetron sputtering rotary target containing trace rare earth elements and a preparation method thereof, the preparation steps are as follows:

[0054] ⑴Raw material preparation: by weight percentage, the alloy composition is: 0.002% RE, 5% V, the balance is Ni and unavoidable impurities, the impurity content is less than 0.1%, and the total input is 180 kg, including electrolytic nickel 170.9964 kg, sponge Vanadium 9 kg, mixed rare earth 0.0036 kg;

[0055] (2) Vacuum smelting: use industrial alcohol to remove the dirt on the surface of electrolytic nickel, remove oxides with dilute nitric acid, put the treated electrolytic nickel into a melting crucible after drying, and smelt with electricity at a melting temperature of 1550°C and a melting time of 80 minutes. Vacuumize during the process to make the vacuum degree less than 8Pa. Before ingot casting, first pass argon gas 4Mpa in the vacuum state, then add the sponge vanadium into the crucible...

Embodiment 3

[0064] A nickel-vanadium alloy magnetron sputtering rotary target containing trace rare earth elements and a preparation method thereof, the preparation steps are as follows:

[0065] ⑴Raw material preparation: by weight percentage, the alloy composition is: 0.026% RE, 7% V, the balance is Ni and unavoidable impurities, the impurity content is less than 0.1%, and the total feed is 180 kg, of which electrolytic nickel is 167.3532 kg, sponge Vanadium 12.6 kg, mixed rare earth 0.0468 kg;

[0066] (2) Vacuum smelting: use industrial alcohol to remove the dirt on the surface of electrolytic nickel, remove oxides with dilute nitric acid, put the treated electrolytic nickel into a melting crucible after drying, and smelt with electricity. The melting temperature is 1610 °C and the melting time is 80 minutes. Vacuumize during the process to make the vacuum degree less than 8Pa. Before ingot casting, first pass argon gas 4Mpa in the vacuum state, then add the sponge vanadium into the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com