Film coating system for depositing metal on plastic substrate surface on basis of glow discharge principle

A glow discharge and substrate surface technology, which is applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems that the coating effect needs to be improved, so as to improve the application range and sputtering efficiency , The uniform effect of the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

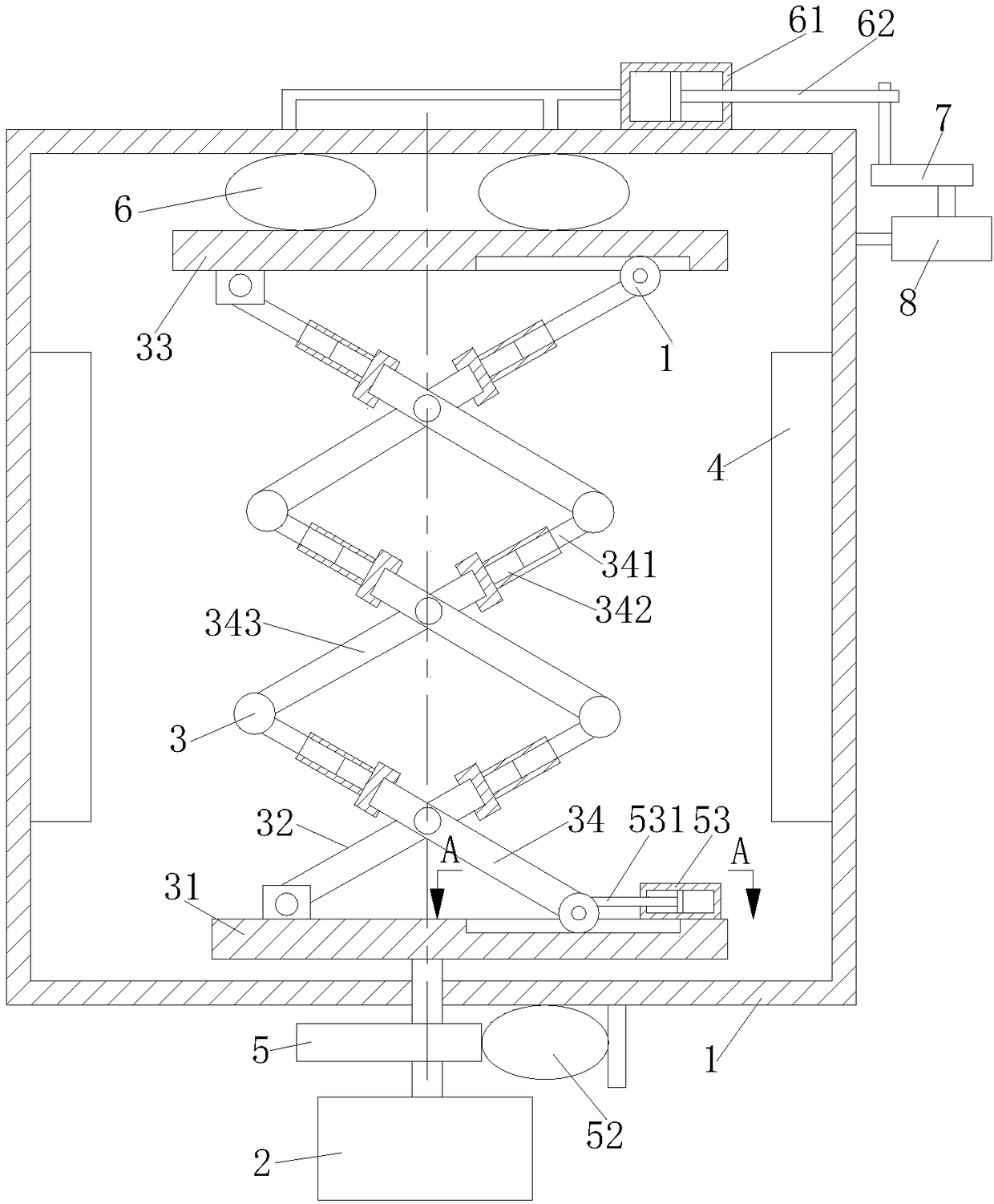

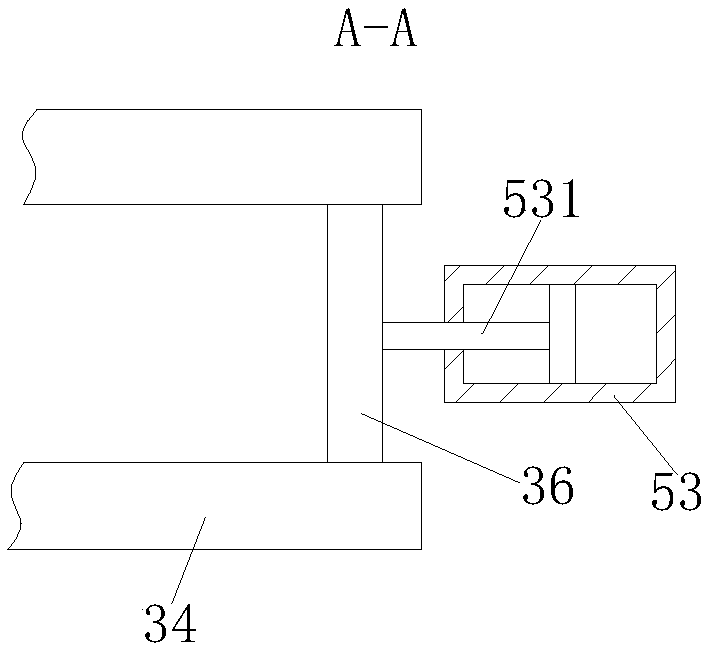

[0021] As an embodiment of the present invention, the box body 1 is rectangular. During work, since the workpieces to be plated have different shapes, such as plates and rings, the workpieces to be plated with better plasticity can be placed on the material rod of the scissor mechanism 32 for coating, while the plate-shaped workpieces with poor plasticity can be coated by The box 1 is set as a rectangle, the target 4 can be placed on the scissor mechanism 32, and the workpiece to be plated can be placed on the inner wall around the box 1, thereby avoiding damage to the workpiece, so that the device can coat different plastics and shapes The workpiece, thereby improving the range of use of the device.

[0022] As an embodiment of the present invention, a second airbag 6 is provided between the upper support plate 33 and the inner wall of the box body 1 . During work, when the scissor mechanism 32 rises and rotates, the No. 2 air bag 6 is set between the upper support plate 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com