Metal sputtering low-temperature preparation method for crystallization TiO2 film

A metal sputtering and crystallization technology, applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problems of high oxygen partial pressure, reduce the speed of TiO2 film, etc., and achieve simple equipment and substrate selection The effect of widening the scope and reducing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

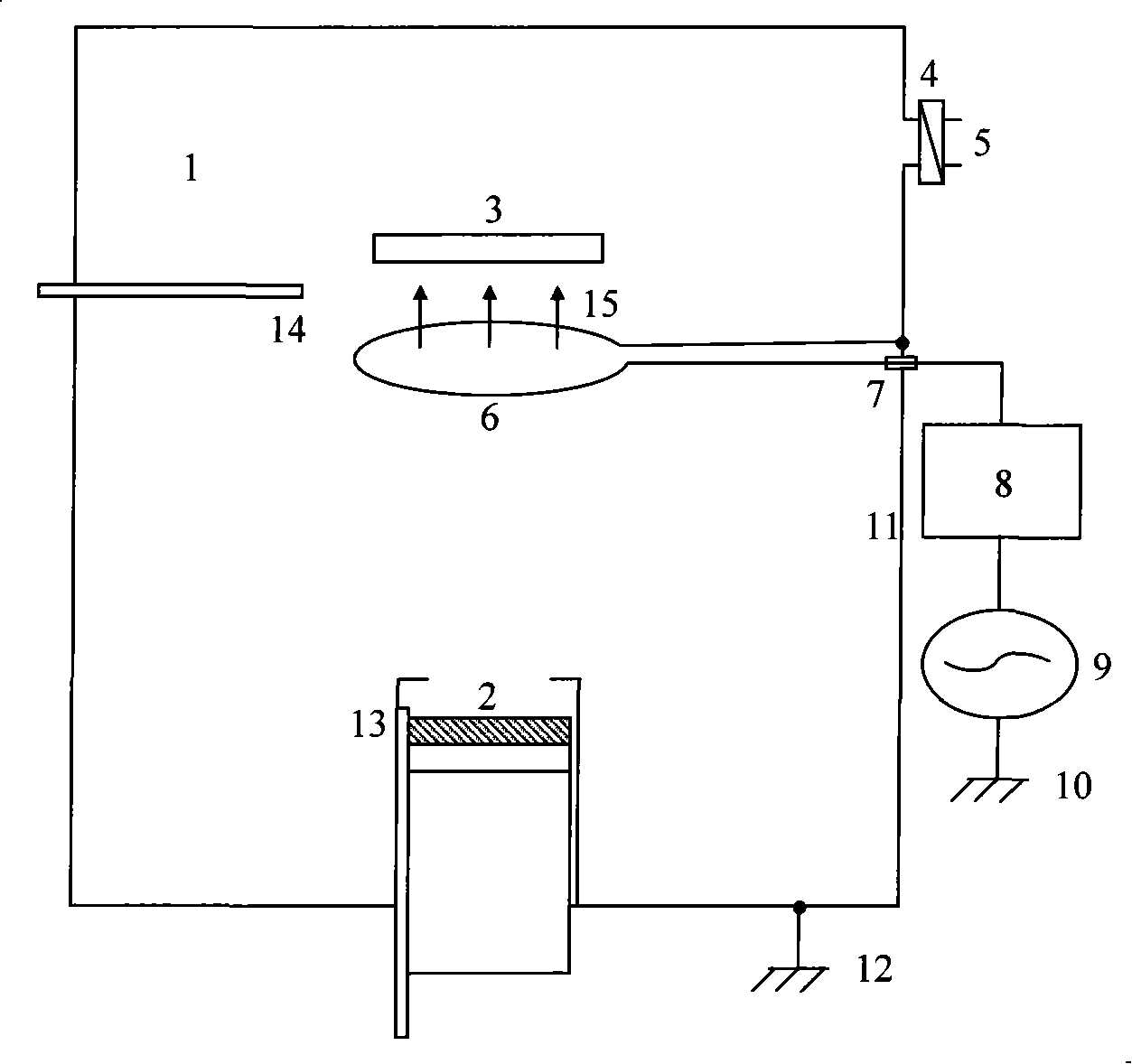

Method used

Image

Examples

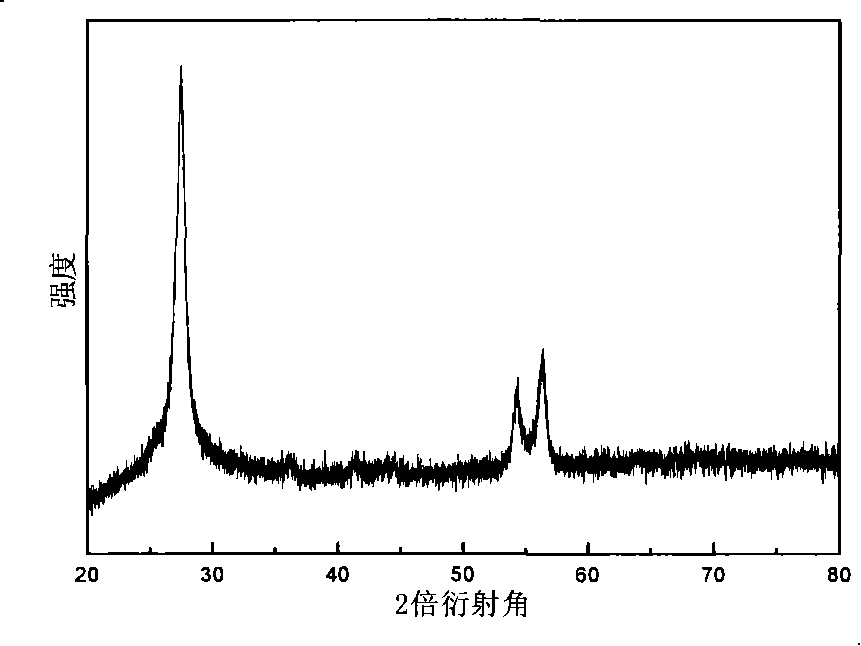

Embodiment 1

[0029] Rutile TiO 2 Examples of low-temperature preparation of films by metal sputtering. The working pressure is 0.5Pa, of which the partial pressure of argon is 0.37Pa, and the partial pressure of oxygen is 0.13Pa. The gas is fed separately. The magnetron sputtering target is titanium metal with a purity of 99.98%, the DC sputtering current is 0.8A, the voltage is about negative 400 volts, and the constant current control mode, the established magnetron sputtering plasma sputters the titanium atoms of the metal titanium target shot out, part of which moves toward the substrate. The substrate is glass and grounded. The RF power input to the RF coil is 500 watts, and the ion beam density of the incident glass substrate is 3.0mA / cm 2 , with an average energy of 20eV. The time to prepare the film was 150 minutes.

[0030] When coating, the glass substrate is not deliberately heated, and the temperature rise caused by high-density ion beam irradiation is lower than 200°C. The...

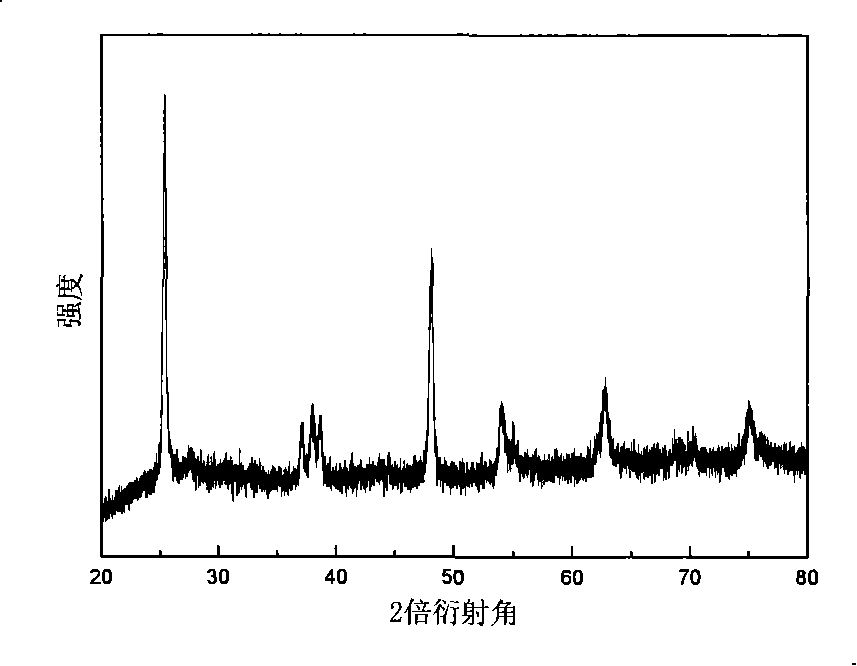

Embodiment 2

[0032] Anatase TiO 2 Examples of low-temperature preparation of films by metal sputtering. The working pressure is 0.5Pa, of which the partial pressure of argon is 0.34Pa, and the partial pressure of oxygen is 0.16Pa. The gas is fed separately. The magnetron sputtering target is titanium metal with a purity of 99.98%, the DC sputtering current is 0.8A, the voltage is about negative 400 volts, and the constant current control mode, the established magnetron sputtering plasma sputters the titanium atoms of the metal titanium target shot out, part of which moves toward the substrate. The substrate is glass and grounded. The RF power input to the RF coil is 500 watts, and the ion beam density of the incident glass substrate is 3.0mA / cm 2 , with an average energy of 20eV. The time to prepare the film was 150 minutes.

[0033] When coating, the glass substrate is not deliberately heated, and the temperature rise caused by high-density ion beam irradiation is lower than 200°C. ...

Embodiment 3

[0035] Examples of thin film preparation without separate gas feeding and mixed gas feeding of argon and oxygen. The working pressure is 0.5Pa, of which the partial pressure of argon is 0.34Pa, and the partial pressure of oxygen is 0.16Pa. The gas is mixed and fed, and the argon and oxygen are mixed through the quality control flowmeter respectively, and then introduced into the figure 1 Next to the medium metal titanium target. The magnetron sputtering target is titanium metal with a purity of 99.98%, the DC sputtering current is 0.8A, the voltage is about negative 400 volts, and the constant current control mode, the established magnetron sputtering plasma sputters the titanium atoms of the metal titanium target shot out, part of which moves toward the substrate. The substrate is glass and grounded. The RF power input to the RF coil is 500 watts, and the ion beam density of the incident glass substrate is 3.0mA / cm 2 , with an average energy of 20eV. The film preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com