Preparation methods of gold and silver embedded target and film thereof

A technology of inlaying targets and gold and silver, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of complex melting and casting process, uneven composition of coating samples, low utilization rate of precious metals in target materials, etc. Overcome the effects of unstable film composition, dense and uniform film structure, and reduced target cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Gold and silver mosaic target material and preparation method thereof

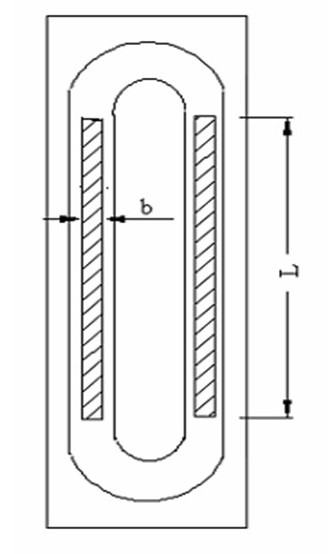

[0048] 1. First, use a silver target with a purity of 99.99% in a clean room to conduct a sputtering experiment in a magnetron sputtering device to accurately obtain the dimensions of its sputtering runway. During the sputtering process, record the difference between the sputtering runway when it glows and the sputtering runway under normal working conditions, and make statistical analysis. After the sputtering is completed, measure and calculate the precise size of the sputtering runway, and then determine the shape and area of the groove on the silver target runway according to the composition of the gold-silver alloy film to be designed (see figure 1 , figure 2 , image 3 ).

[0049] 2. According to the composition of the target material and the area of the slot, determine the size of the slot length L and width b. The target material composition in this example: gold 10%,...

Embodiment 2

[0053] Example 2: The gold and silver mosaic target material and its preparation method are basically the same as in Example 1, the difference being:

[0054] Target composition: 20% gold, 80% silver; the length L of the gold groove is 50 mm, and the width b is 4 mm.

Embodiment 3

[0055] Example 3: The gold and silver mosaic target material and its preparation method are basically the same as in Example 1, the difference being:

[0056] Target composition: 30% gold, 70% silver; the length L of the gold slot is 60mm, and the width b is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com