Processing method for refining crystal grains and improving texture of double surface layers of magnesium alloy plate strip

A magnesium alloy plate and grain refinement technology, applied in the field of magnesium alloy processing, can solve problems such as low efficiency, high equipment requirements, and unfavorable costs, and achieve the effects of reasonable process design, high processing efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

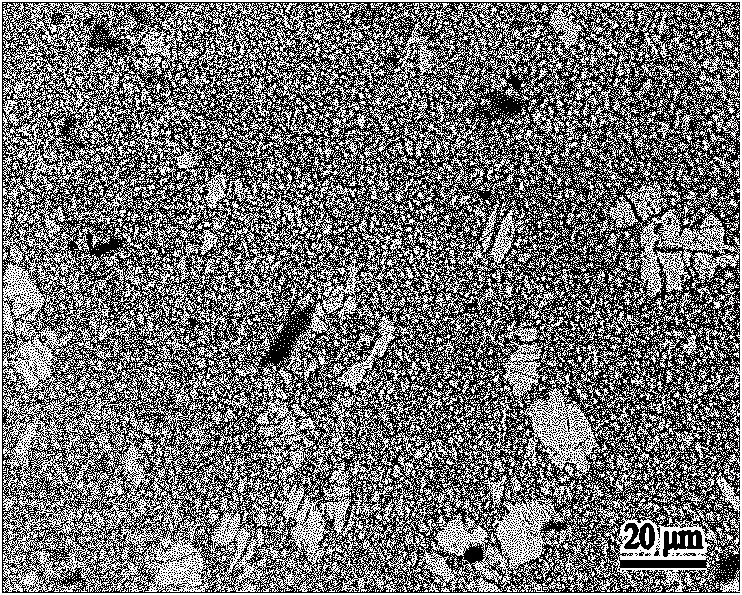

[0025] Bidirectional repeated bending of AZ31 magnesium alloy sheets was performed at 250 °C. First, place the AZ31 plate between a set of bending rolls, adjust the distance between the upper and lower sets of bending rolls h=1.8r, and the distance between the same set of bending rolls L=3.8r, so that the bending radius R of the strip and the plate thickness The ratio R / t of t is 9, and then the driving roller drives the strip to move in one direction once, so that the strip is bent and deformed when it passes through the bending roller. Repeat the above steps to control the deformation pass to 30 times. attached by figure 1 It can be seen that after two-way repeated bending, the surface grains of the plate are refined to less than 1 μm, and the integral fraction of fine crystals is as high as 90%.

Embodiment 2

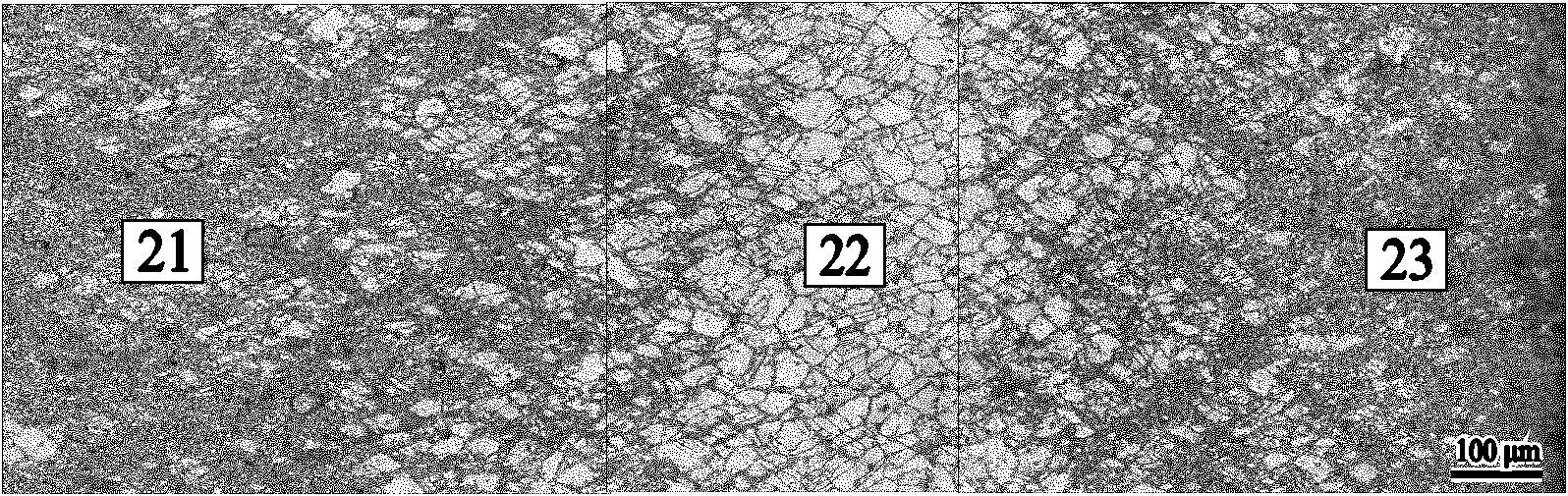

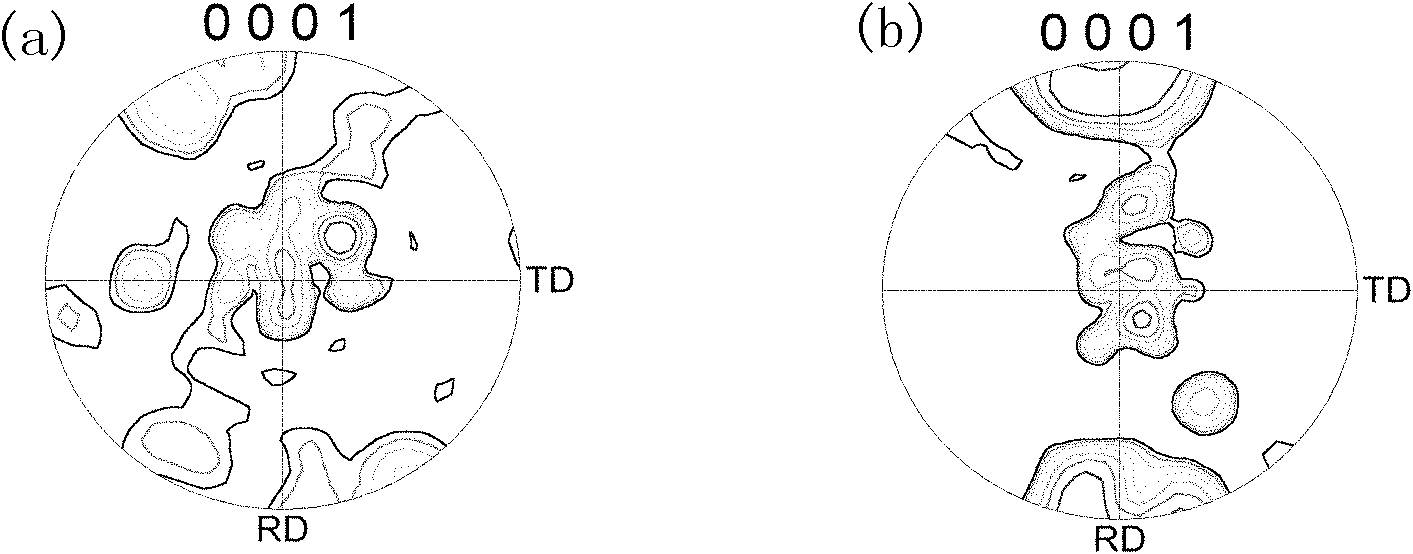

[0027] Bidirectional repeated bending of AZ61 magnesium alloy sheets was performed at 350 °C. Firstly, place the AZ61 plate between a set of bending rolls, adjust the distance between the upper and lower sets of bending rolls h=1.8r, and the distance between the same set of bending rolls L=2.2r, so that the bending radius R of the strip and the plate thickness The ratio R / t of t is 6.5, and then the driving roller drives the strip to move in one direction once, so that the strip is bent and deformed when it passes through the bending roller. Repeat the above steps to control the deformation pass to 10 times. attached by figure 2 and 3 The microstructure observation and texture analysis show that after bidirectional repeated bending, the double surface grains of the plate are refined to less than 3 μm, and the thickness of the fine grain layer is 0.6-0.7 mm; the surface texture of the plate is obviously deflected, and most of the grains (0001 ) The base surface is turned to...

Embodiment 3

[0029] AZ61 magnesium alloy sheets were subjected to bidirectional repeated bending at 400 °C. First, place the AZ61 plate between two sets of bending rolls, adjust the distance h between the upper and lower sets of bending rolls to h=1.5r, and the distance between the same set of bending rolls to L=3r, so that the bending radius R of the strip and the plate thickness t The ratio R / t is 3, and then the driving roller drives the strip to move in one direction once, so that the strip is bent and deformed when it passes through the bending roller. Repeat the above steps to control the deformation pass to 6 times. attached by Figure 4 It can be seen that after deformation, the surface grains of the plate are refined to less than 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com