Liquid state hydrogen-replacing thinning solidifying tissue method in Ti-6Al-4V alloy induction shell smelting process

A technology of solidification structure and ti-6al-4v, which is applied to the field of liquid hydrogen in the process of induction smelting of titanium alloys, can solve the problems of not being widely used in production, slow hydrogen permeation rate of titanium alloy atmosphere, etc., to improve the subsequent processing performance, The effect of grain size reduction and mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

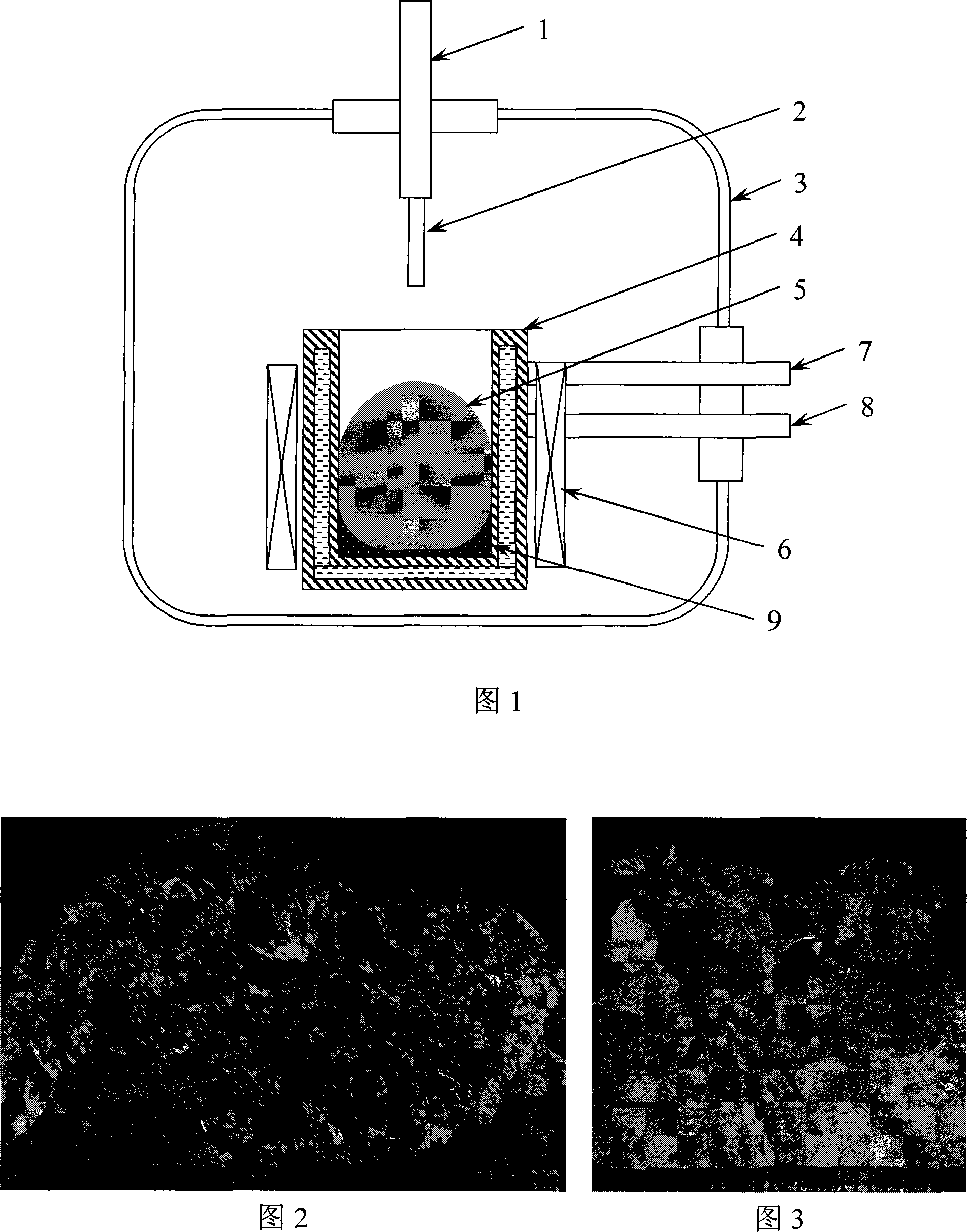

[0017] Specific implementation mode 1: The method for refining the solidification structure by placing hydrogen in the liquid state during the Ti-6Al-4V alloy induction shell melting process of the present embodiment is as follows:

[0018] Step 1, loading the charge of Ti-6Al-4V alloy into the crucible 4 of the induction shell melting furnace;

[0019] Step 2. Weigh TiH containing 0.09% to 0.2% of the mass of charge described in step 1. 2 preform2;

[0020] Step 3, fastening the preform 2 obtained in step 2 to the lower end of the feeding rod 1 above the crucible 4 in the induction shell melting furnace;

[0021] Step 4, close the door of the melting chamber 3 of the induction shell melting furnace, and vacuumize to 10 -1 ~10 -2 Pa, backfill high-purity argon to 300-600Pa, repeat 3 times;

[0022] Step 5: Control the pressure of the high-purity argon gas in the melting chamber 3 at 400-700 Pa.

[0023] Step 6, switch on the power supply of the induction heating coil 6 in...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and the Ti-6Al-4V alloy induction shell smelting process described in specific embodiment 1 is that:

[0031] The prefabricated rod 2 described in step 2 contains 0.09% to 0.11% of TiH by mass of charge described in step 1 2 ;

[0032] In step 6, after heating until the furnace charge is completely melted, continue heating to a superheated temperature of 40°C to 80°C;

[0033] In step seven, after the preform rod 2 is completely immersed in the molten pool 5 and the feeding rod 1 is lifted, keep the temperature for 60s-90s, and then stop heating.

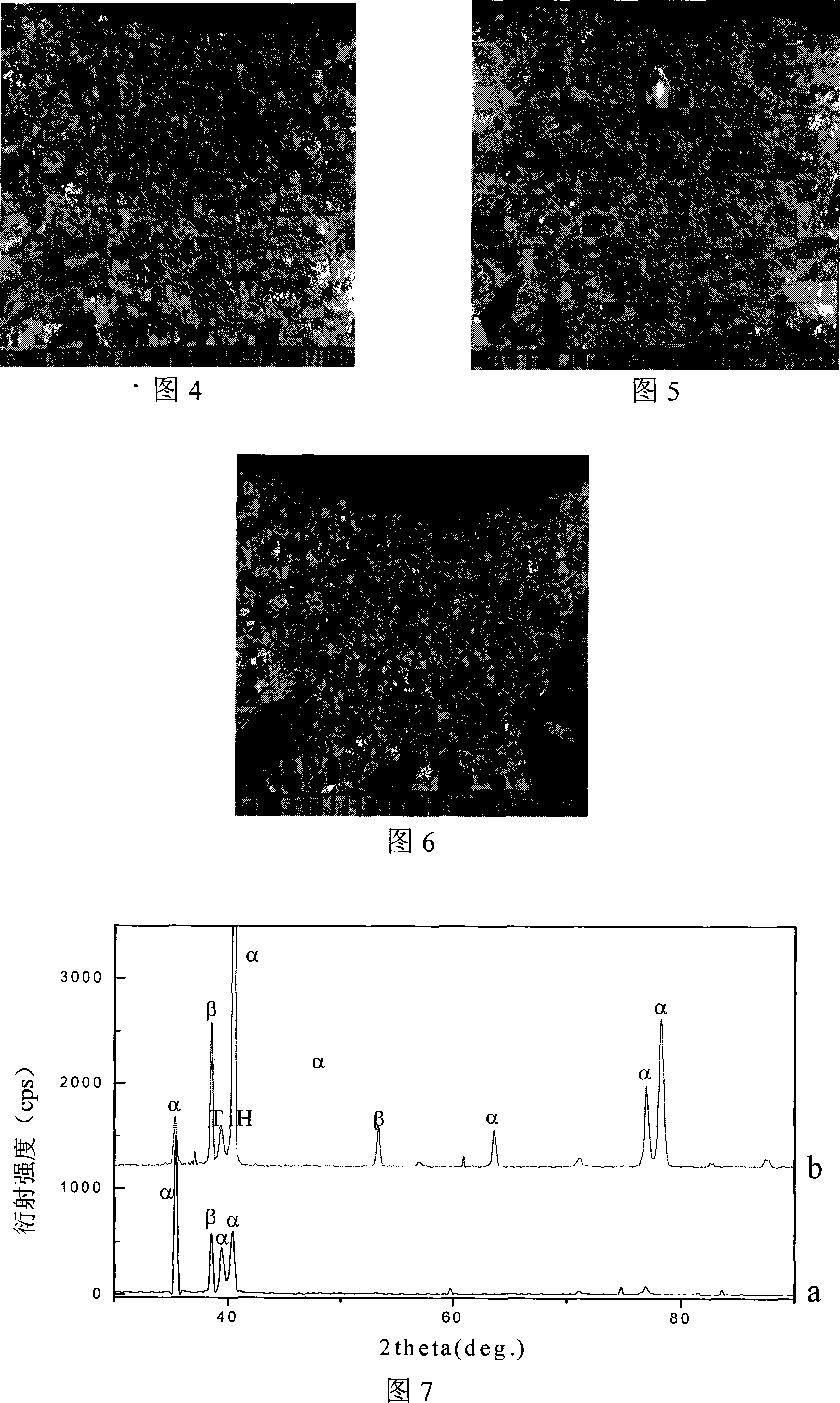

[0034] Referring to FIG. 3 , the average grain size of the macrostructure of the Ti-6Al-4V alloy material prepared by the method of this embodiment is 771 μm.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and the method for refining the solidified structure by adding liquid hydrogen in the Ti-6Al-4V alloy induction shell smelting process described in Embodiment 1 is that:

[0036] The prefabricated rod 2 described in step 2 contains 0.12% to 0.14% of TiH by mass of charge described in step 1 2 ;

[0037] In step 6, after heating until the furnace charge is completely melted, continue heating to a superheated temperature of 40°C to 80°C;

[0038] In step seven, after the preform rod 2 is completely immersed in the molten pool 5 and the feeding rod 1 is lifted, keep the temperature for 60s-90s, and then stop heating.

[0039] Referring to FIG. 4 , the average grain size of the macrostructure of the Ti-6Al-4V alloy material prepared by the method of this embodiment is 612 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com