Thermosetting resin composition having good coatability and re-coatability

A thermosetting and resin technology, applied in coatings, nonlinear optics, instruments, etc., can solve problems such as limited use of surfactants, no effect of surfactants, damage to recoating properties, etc., to ensure coatability , Coatability improvement, and the effect of promoting subsequent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

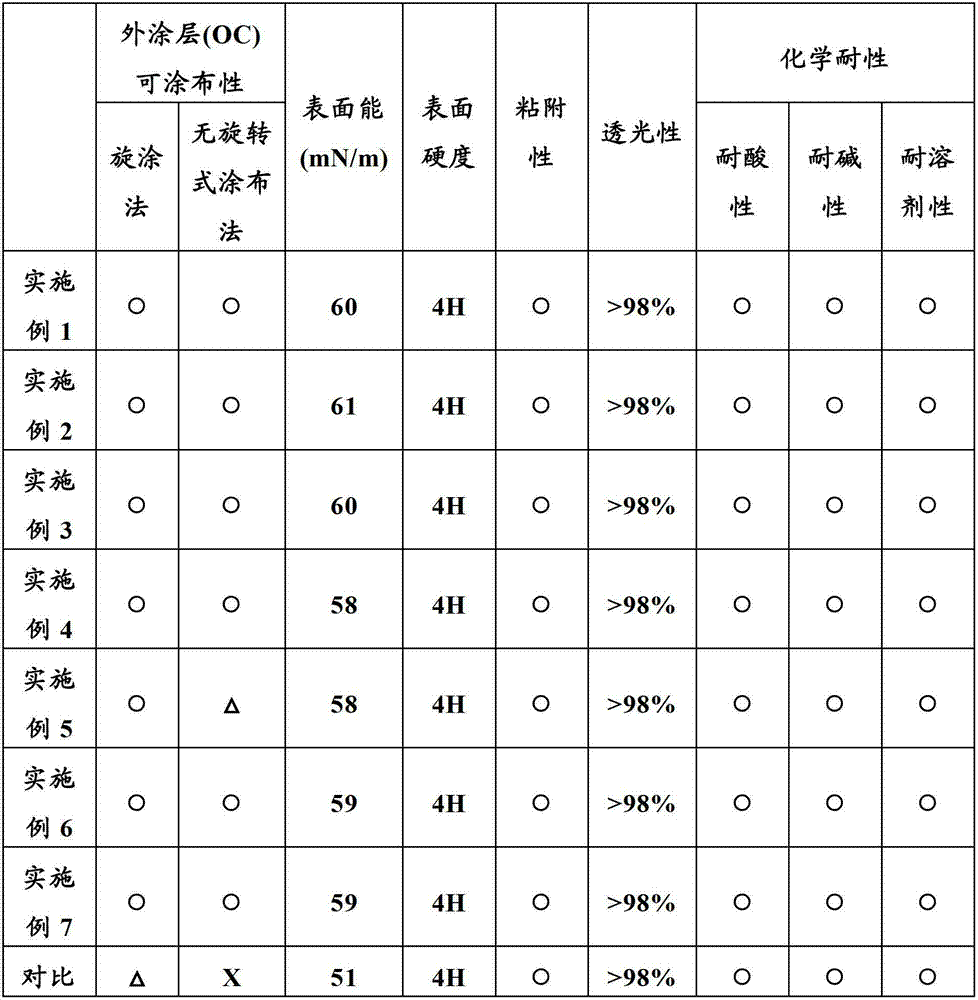

Embodiment 1

[0081] 1-1. Thermosetting binder resin

[0082] A monomer composed of 15 parts by weight of 2-tetrahydropyranyl methacrylate, 40 parts by weight of glycidyl methacrylate, 20 parts by weight of methoxydiethylene glycol monomethacrylate and 25 parts by weight of styrene And 200 parts by weight of propylene glycol methyl ether acetate as solvent respectively add in the flask with nitrogen inlet, this flask is heated to 90 DEG C, and in this flask, add 3.0 parts by weight of azobisvaleronitrile (AVN), And maintain this temperature for 9 hours. The reacted resin solution was added dropwise to excess hexane to form a precipitate and vacuum dried to obtain a thermosetting binder resin (A1). The resin (A1) had a weight average molecular weight (Mw) of 12,500 according to polystyrene standards.

[0083] 1-2. Thermosetting resin composition

[0084] 100 parts by weight of the synthesized copolymer (A1) are dissolved in 400 parts by weight of propylene glycol methyl ether acetate ...

Embodiment 2

[0088] Except using methoxytriethylene glycol monomethacrylate instead of methoxydiethylene glycol monomethacrylate, proceed in the same manner as in Example 1-1 to obtain a thermosetting binder resin (A2 ), according to polystyrene standard, its weight average molecular weight (Mw) is 12,900. Using the resin (A2) and proceeding in the same manner as in Examples 1-2 and 1-3, a composition and a cured film were prepared.

Embodiment 3

[0090] Except using methoxyethylene glycol monomethacrylate instead of methoxydiethylene glycol monomethacrylate, proceed in the same manner as in Example 1-1 to obtain a thermosetting binder resin (A3) , according to polystyrene standard, its weight average molecular weight (Mw) is 12,000. Using the resin (A3) and proceeding in the same manner as in Examples 1-2 and 1-3, a composition and a cured film were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com