Magnesium alloy plate serving as battery cathode and preparation method thereof

A battery negative electrode and magnesium alloy technology, which is applied in the field of magnesium alloy plates and its preparation, can solve the problems of magnesium polarization, corrosion, and failure to meet application standards, and achieve the effects of increased strength and plasticity, excellent performance, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

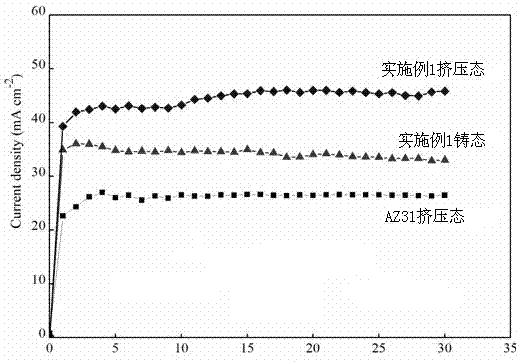

Embodiment 1

[0027] The magnesium alloy plate used as the negative electrode of the battery in this embodiment consists of the following components in terms of mass percentage:

[0028] Li 5.0%;

[0029] Al 1.0%;

[0030] Impurities ≤0.3%;

[0031] Magnesium balance.

[0032] The preparation method of the magnesium alloy plate used as the negative electrode of the battery in this embodiment is to heat the formulated amount of pure magnesium, pure lithium and pure aluminum to 720° C. under the condition of vacuuming and passing in an inert gas. After the alloy is completely melted, Keep the temperature at 700°C for 15 minutes, then pour the melted alloy liquid into the mold to obtain the as-cast magnesium alloy; heat the as-cast magnesium alloy at 380°C for 3 hours, and then extrude it into a magnesium alloy plate with a thickness of 2mm and a width of 120mm (The tonnage of the extrusion machine is 1250T, the diameter of the extrusion barrel is 165mm, and the extrusion ratio: 89).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com