Metal wire straightening and cutting machine

A metal wire and cutting machine technology, applied in the field of metal wire straightening and cutting machines, can solve the problems of scratching the surface of the metal wire, reducing the roughness level of the metal wire, affecting the processing, use and price of the metal wire, and achieving the appearance of wear and scratches. Less damage, good follow-up processing performance, and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

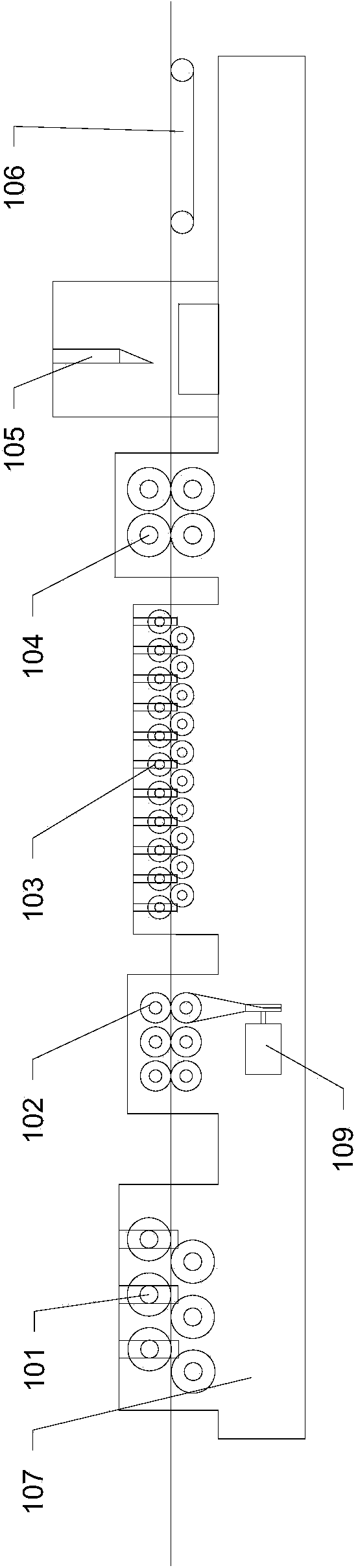

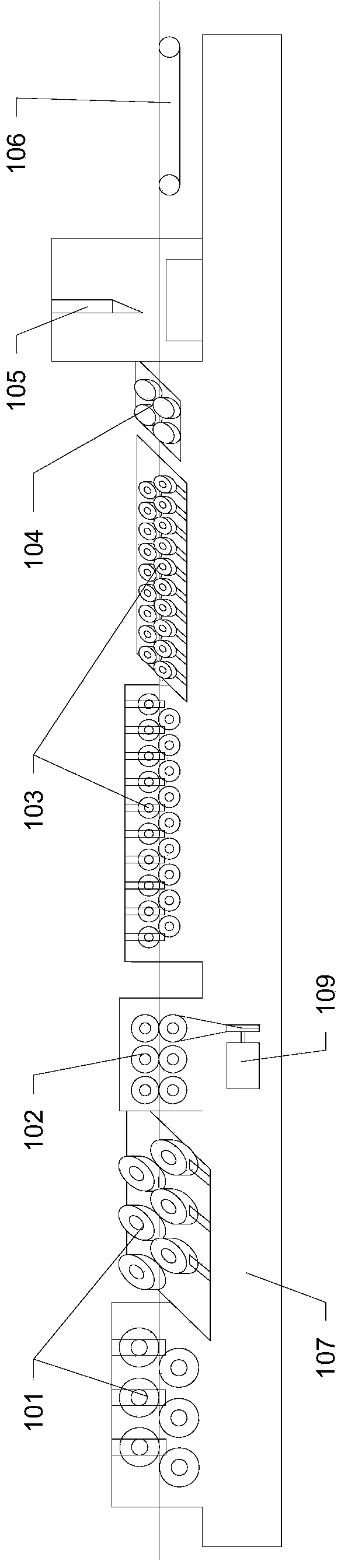

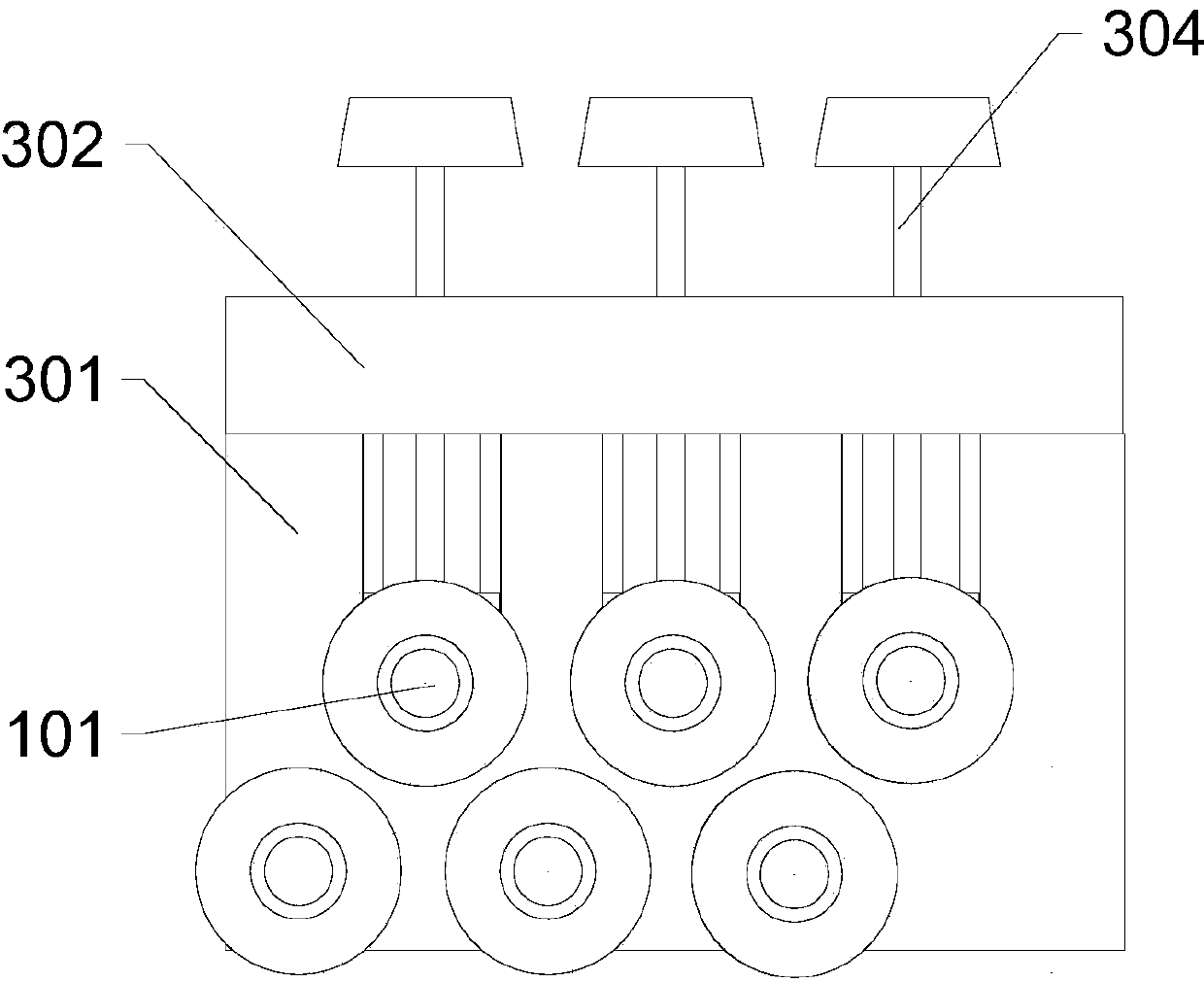

[0033] Such as figure 1 Shown is the metal wire straightening and cutting machine provided by the first embodiment of the present invention, including a roller set 101, a transmission wheel set 102, a straightening wheel set 103, a roller set 104, a cutting mechanism 105, a transmission mechanism 106 and a machine tool 107, the transmission mechanism 106 is arranged on one end of the machine tool 107, and the cutting mechanism 105 is arranged on the machine tool 107 adjacent to the transmission mechanism 106. The set 102 and the set of rollers 101 are successively arranged adjacently on the machine tool 107 , and the power source 109 is connected to the set of transmission wheels 102 . That is, the cutting mechanism 105 is arranged on the machine tool 107 adjacent to the conveying mechanism 106, and the roller gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com