Small-scale spiral bevel gear CNC worm disc grinding wheel grinding machine and its processing steps

A technology of spiral bevel gears and gear grinding machines, which is applied to gear tooth manufacturing tools, gear tooth manufacturing devices, gear cutting machines, etc., can solve the problems of low gear machining accuracy and insufficient surface roughness, and achieves simple structure and improved efficiency. Processing efficiency, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

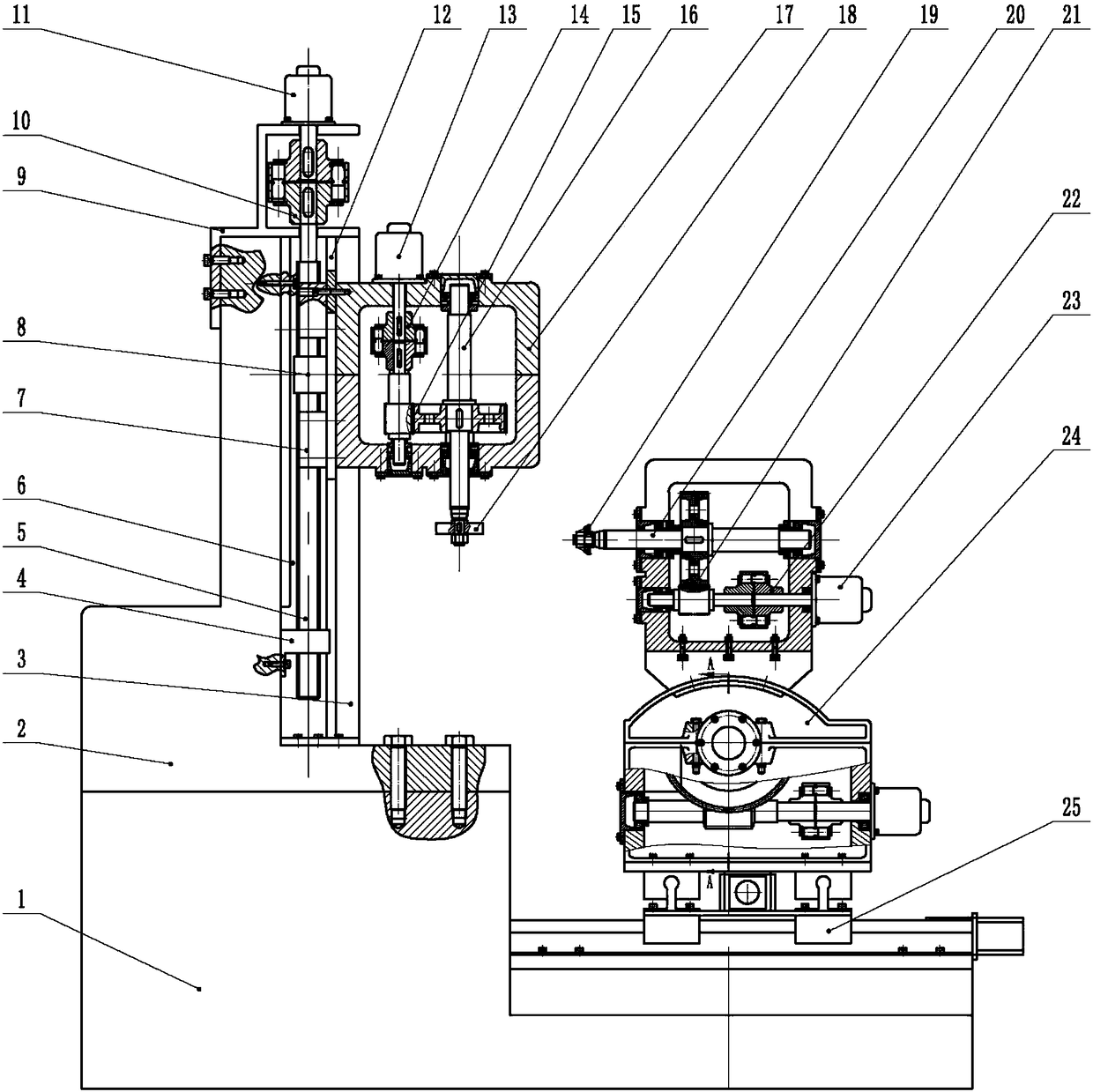

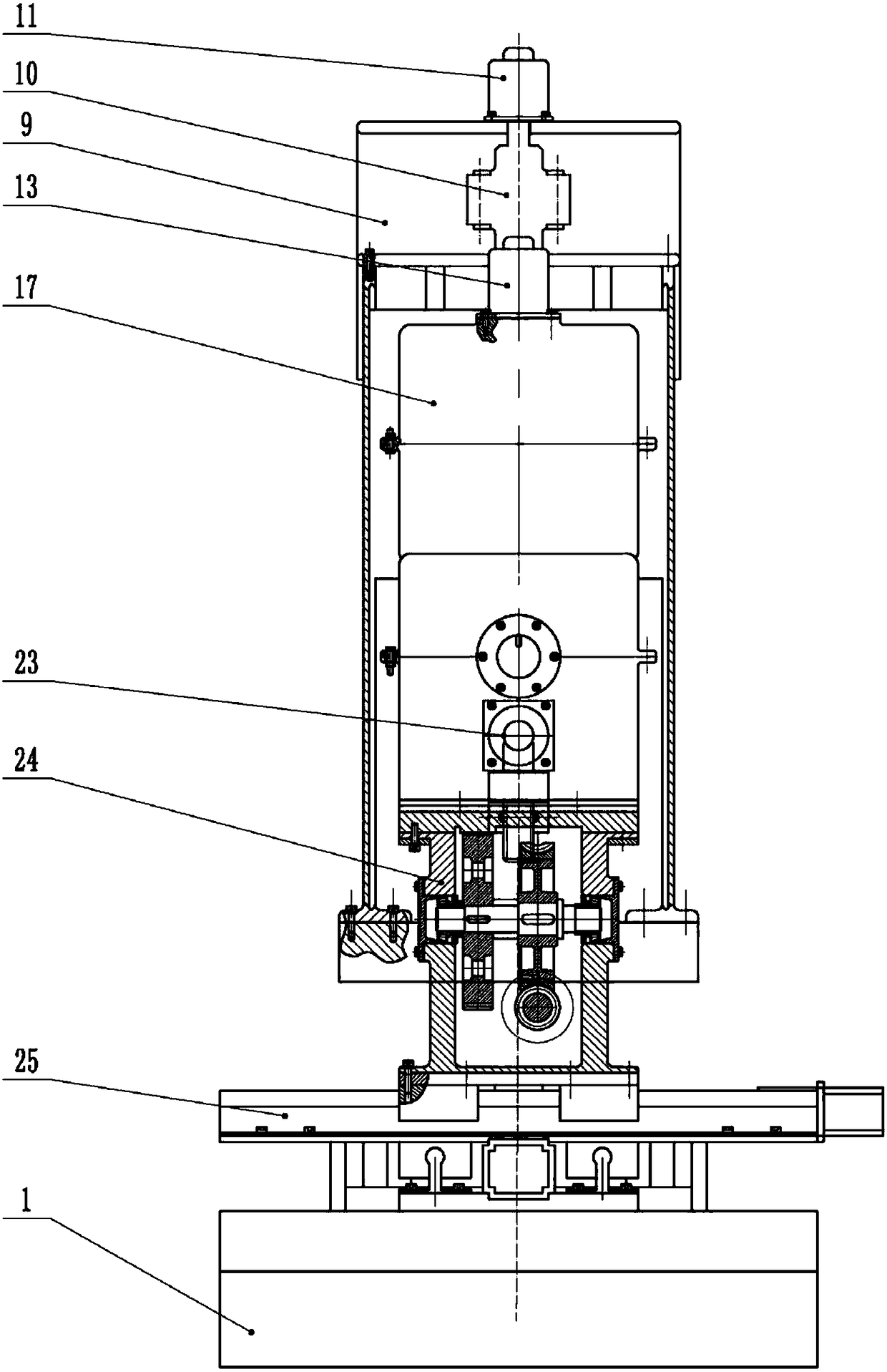

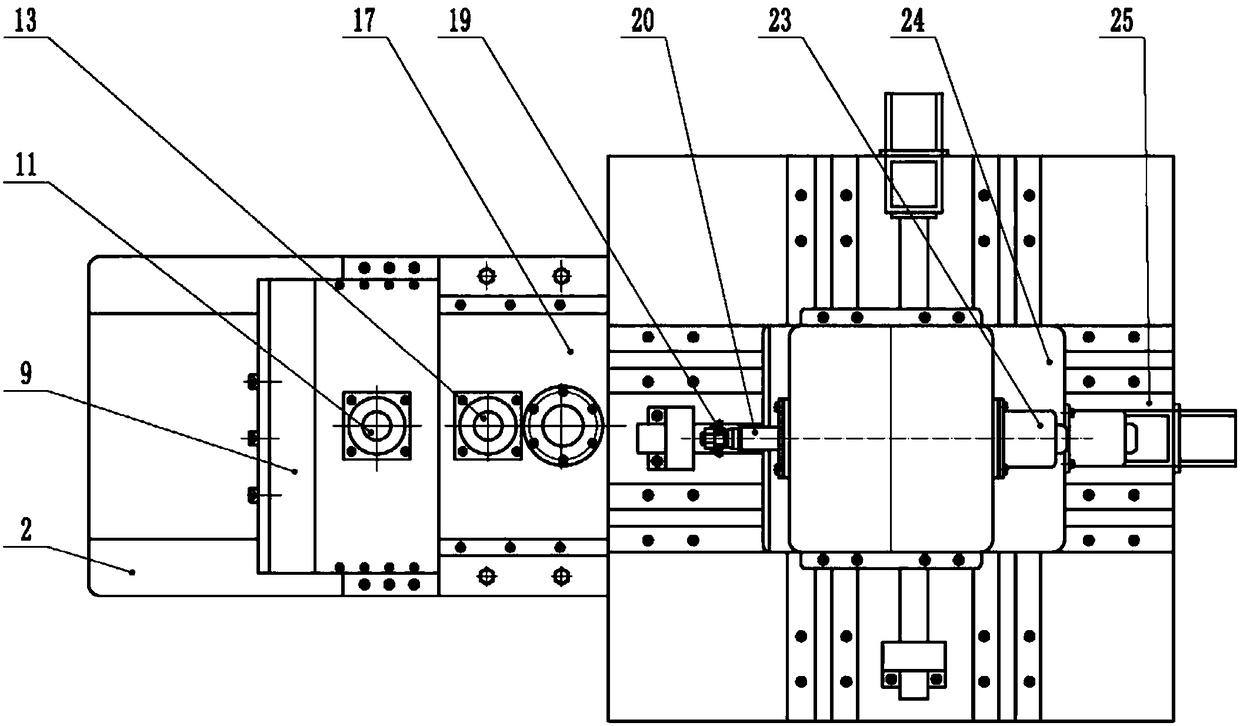

[0032] The specific embodiment of the present invention is shown in the accompanying drawings, a small-scale spiral bevel gear CNC worm disc grinding wheel grinding machine, including a bottom plate 1, a base 2, a vertical plate 3, a support block 4, a ball screw 7, a guide rail 6, and a slider 7 , ball screw pair 8, F-type support plate 9, coupling I10, servo motor I11, connecting plate 12; base 2 is installed on the upper left side of base plate 1; vertical plate 3 is installed on base 2; ball screw 7 passes through The support block 4 is installed on the side wall of the base 2; the guide rail 6 is installed on the side wall of the base 2; the servo motor I11 is installed on the top of the base 2 through the F-shaped support plate 9, and the servo motor I11 is connected with the ball wire through the coupling I10 The rod 7 is connected; the connecting plate 12 is connected with the ball screw 7 through the ball screw pair 8, and at the same time the connecting plate 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com