Tungsten trioxide/polymer nano core-shell microsphere and preparing process thereof

A tungsten trioxide and nano-core-shell technology, which is applied in the field of tungsten trioxide/polymer nano-core-shell microspheres and its preparation, can solve thermal and chemical stability needs to be improved, strict material system requirements, and complex processes and other issues, to achieve the effect of improving photoelectric performance or processing performance, preventing effect, and changing optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

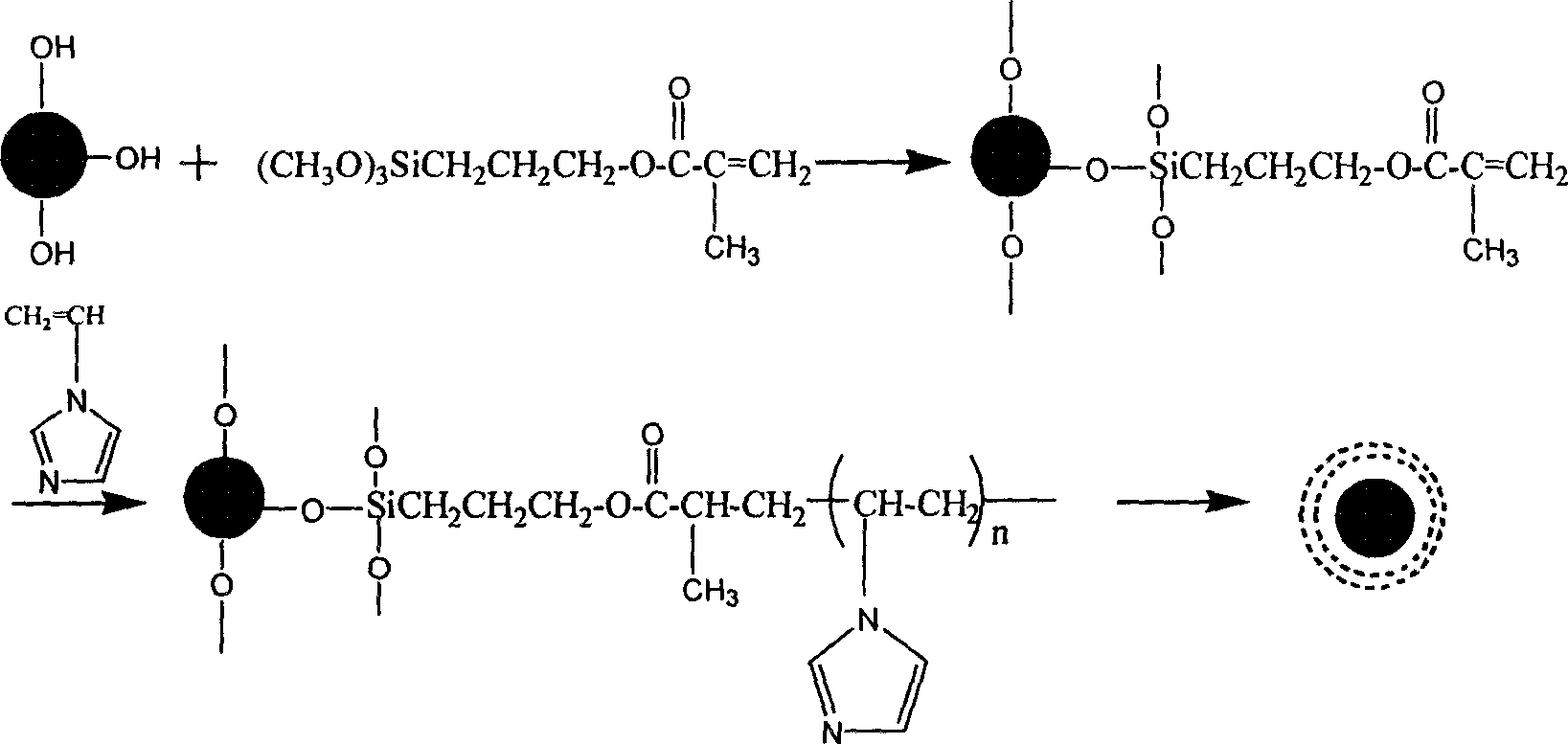

Method used

Image

Examples

Embodiment 1

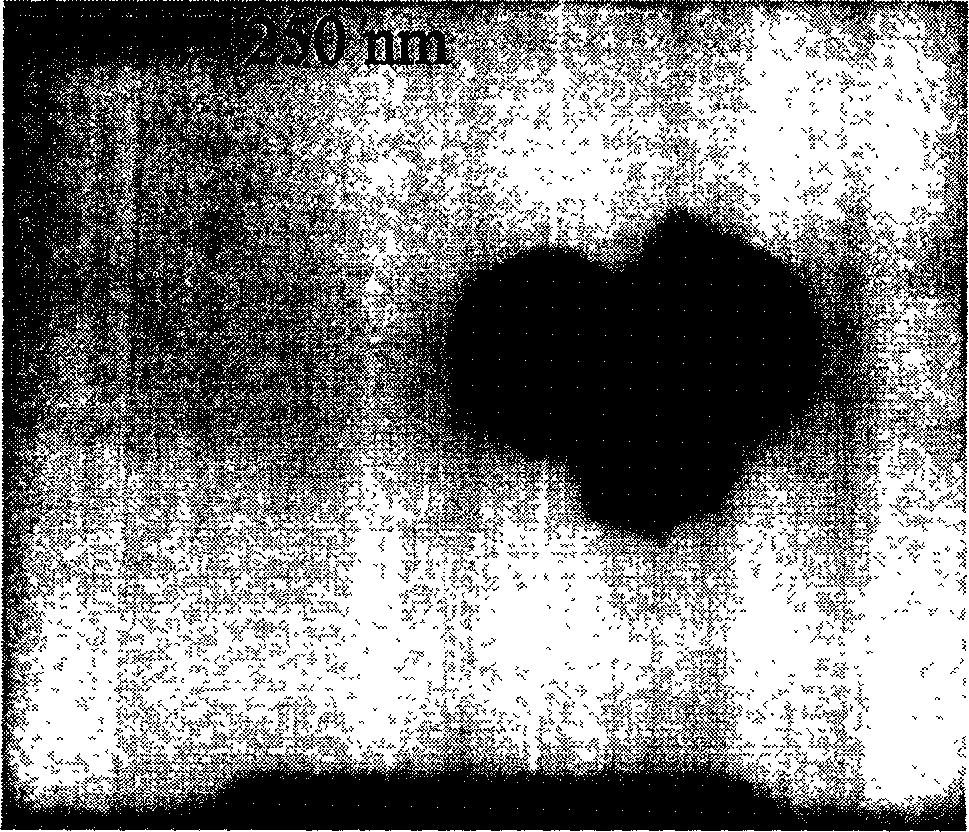

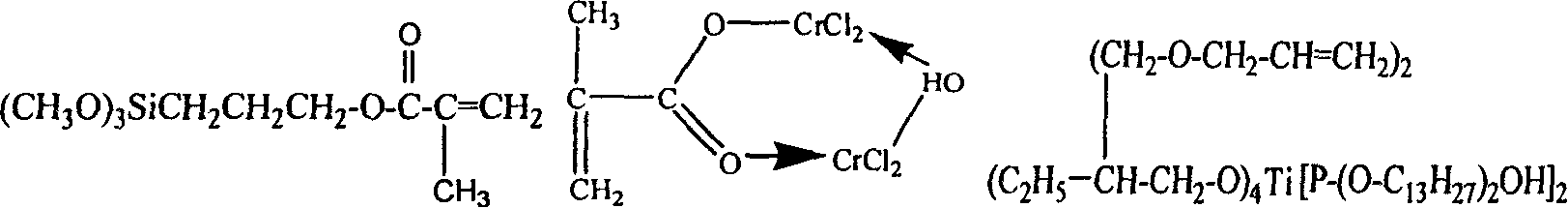

[0022] Make 2.5g tungstic acid and 6.35g citric acid into an aqueous solution at a molar ratio of 3:1, continuously stir at 60°C, and then adjust the pH to 9 with ammonia water to form a tungsten trioxide / citric acid chelate solution . The solution was heated at 60° C. for 24 hours to generate a gel-like precursor, and was calcined in air in a muffle furnace at a high temperature of 700° C. for 6 hours to generate tungsten trioxide nanopowder. Accurately weigh 1.2g of tungsten trioxide nanospheres and disperse them in 25ml of absolute ethanol, and add 20ml of an ethanol solution of KH-570 silane coupling agent dropwise (concentration: 0.05g / ml). Then, under the condition of a water bath at 35° C., after reacting for 36 hours, vacuum drying at 40° C. overnight, the purified tungsten trioxide nanopowder treated with the coupling agent was obtained. In a three-necked flask equipped with a reflux condensing device, ultrasonically disperse 1.0 g of tungsten trioxide nanopowder tre...

Embodiment 2

[0025] Same as Example 1, but the concentration of KH-570 was changed to 0.05 g / ml, and the amount of vinylimidazole monomer was changed to 15 ml.

Embodiment 3

[0027] Same as Example 1, but the concentration of KH-570 was changed to 0.1 g / ml, and the amount of vinylimidazole monomer was changed to 30 ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com