Lubrication system for rotating shuttle components of embroidery machines

A lubricating system and embroidery machine technology, applied to embroidery machines, embroidery machine mechanisms, sewing machine components, etc., can solve the problems of not being able to refuel, oil stains on embroidery products, not being able to refuel the hook shaft and the hook sleeve, and achieve improved The effect of improving the rotation speed, improving the operating efficiency, and improving the working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments:

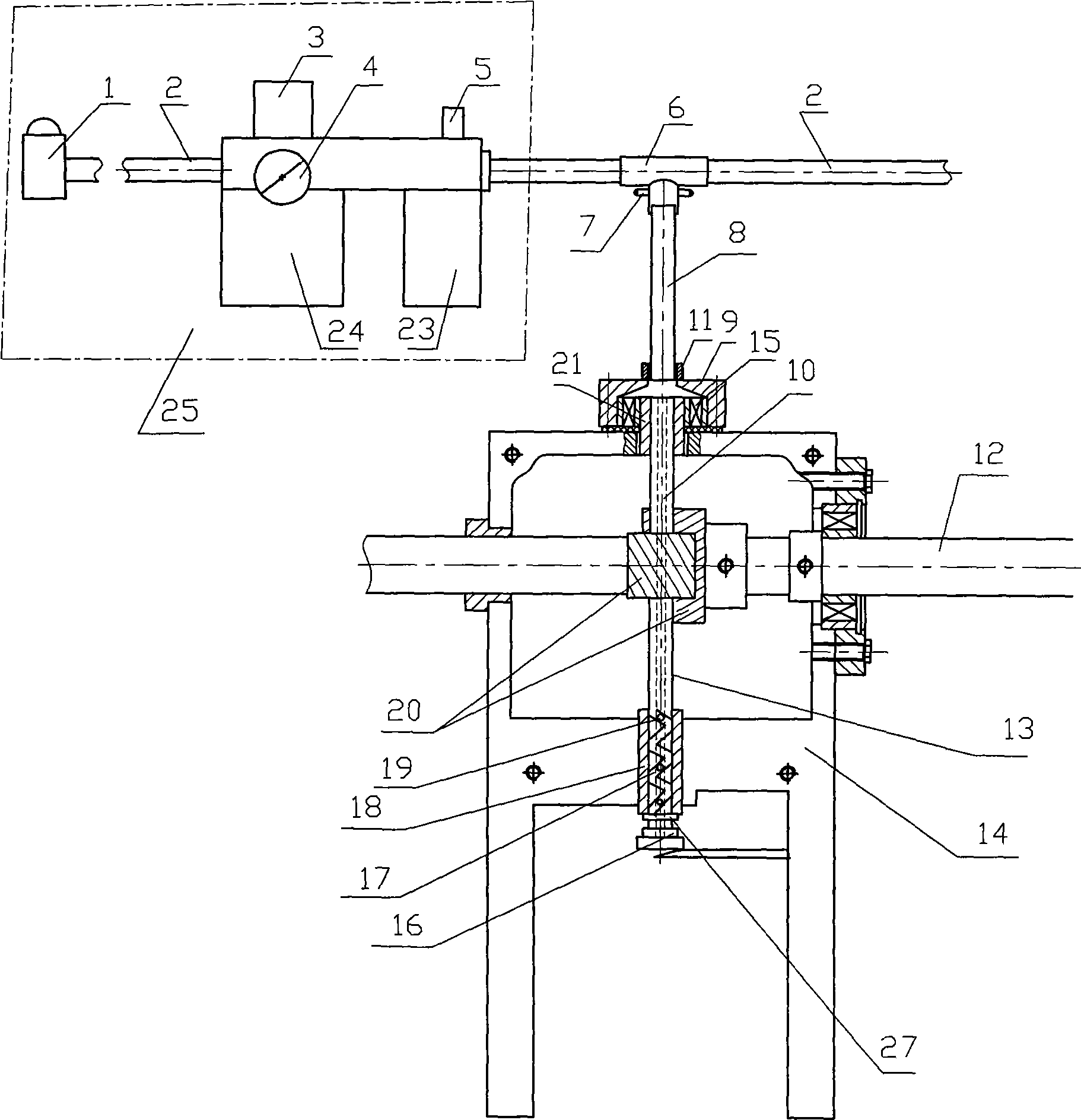

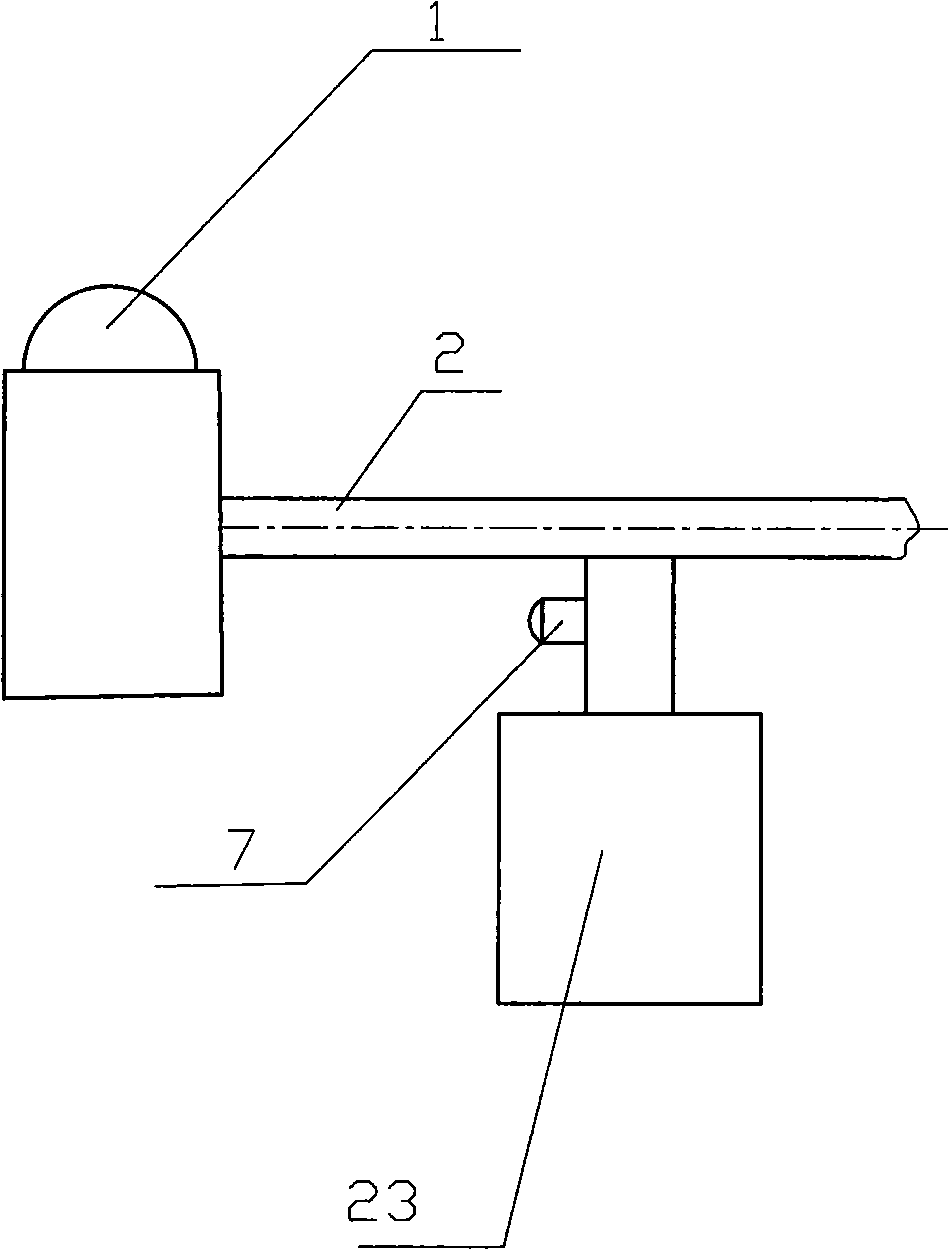

[0022] Such as figure 1 As shown, the lubrication system for the rotary hook assembly of the embroidery machine of the present invention is applicable to both single-head embroidery machines and multi-head embroidery machines. The main pipe 2 is connected to multiple branch pipes 8, and each branch pipe 8 is connected to a set of rotary hook components. , So as to realize the lubrication of multiple sets of rotary hook components. The lubricating system of the rotary hook component of the embroidery machine of the present invention includes a rotary hook component oil supply device and a rotary hook component. The rotary hook assembly includes a rotary hook 16, a rotary hook shaft 13, and a rotary hook sleeve 18. One end of the rotary hook shaft 13 is fixedly connected with the rotary hook 16, and the other end is connected with the main drive shaft 12 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com