Multifunctional grinding head mechanism and main shaft

A multi-functional grinding head and grinding head technology, applied in the field of polishing machines, can solve the problems of shortening the service life of the chuck, difficult to replace the brush, difficult to operate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

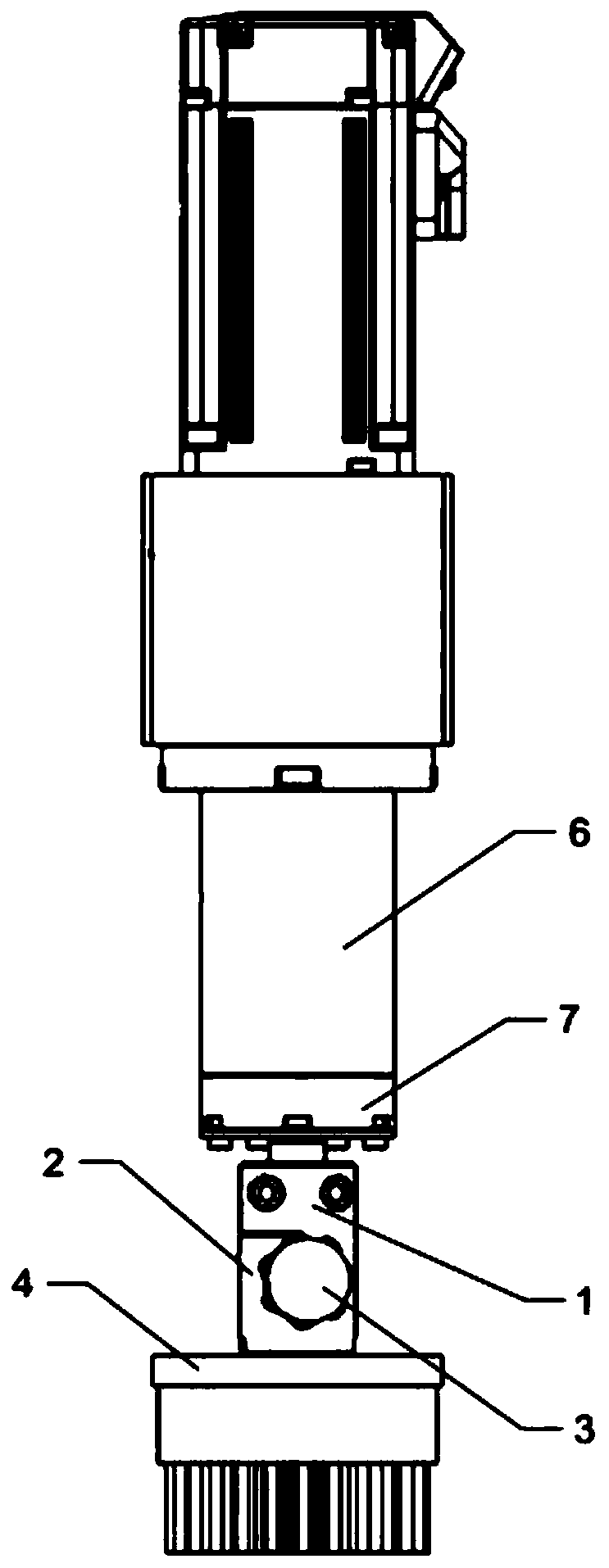

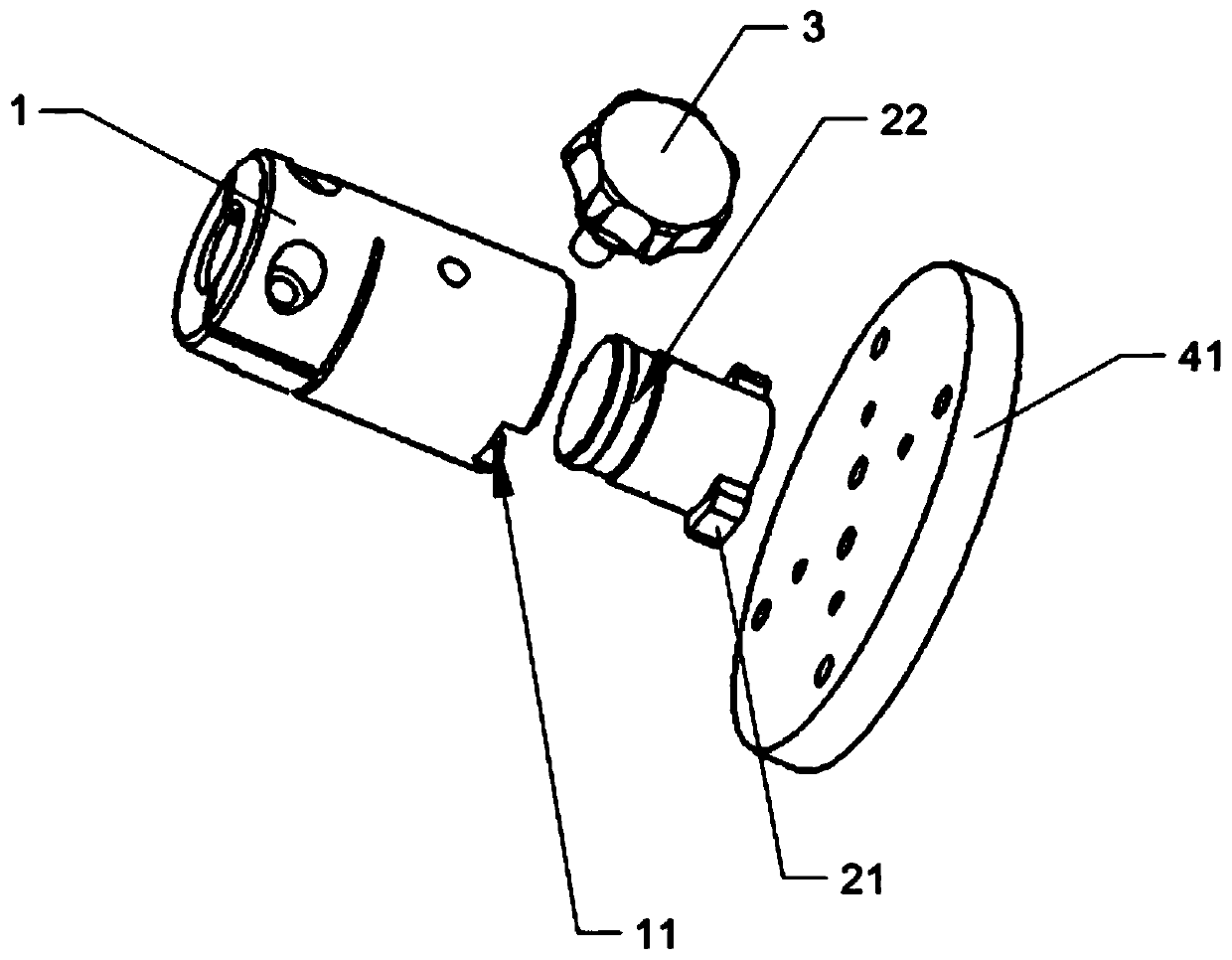

[0025] Refer to attached Figure 1-4 , this embodiment includes: a chuck handle 1, a grinding head handle 2 and a handle 3, the grinding head handle 2 is inserted into the chuck connecting handle 1, the outer wall of the grinding head handle 2 is provided with lugs 21, and the chuck handle 1 is provided with The first limiting groove 11 matching the lug 21, the outer peripheral wall of the grinding head handle 2 is provided with a second limiting groove 22 matching the handle 3, the handle 3 is threadedly connected with the chuck handle 1, and One end is inserted into the second limiting groove 22 to lock the grinder handle 2 . The end of the grinding head handle 2 away from the chuck handle 1 is provided with a first grinding assembly or a second grinding assembly 4 , and the grinding head handle 2 is detachably connected to the first grinding assembly or the second grinding assembly 4 .

[0026] The second grinding assembly 4 includes a brush plate 41, and the brush plate 4...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, the difference is:

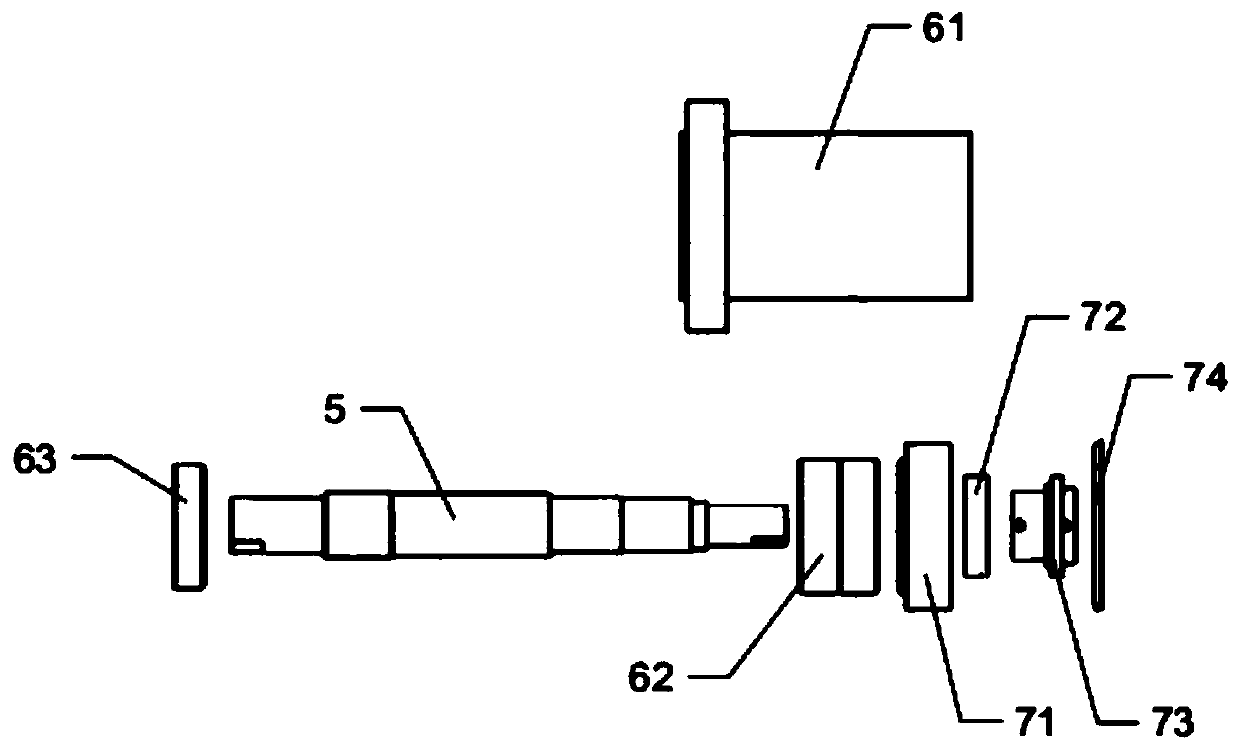

[0035] Refer to attached Figure 4-5 , the first grinding assembly includes a grinding head and a fixing bolt, the grinding head handle 2 has a first mounting hole 23 suitable for the grinding head, the fixing bolt is threaded with the grinding head handle 2, and one end is inserted into the first mounting hole 23 and The grinding head abuts to fix the grinding head in the first mounting hole 23 . The grinding head is inserted into the first installation hole 23, and the fixing bolt locks the grinding head. In this embodiment, the fixing bolt is an inner hexagon screw, and when the inner hexagon screw is installed on the grinding head handle 2, it can avoid affecting the insertion of the grinding head handle 2 into the collet adapter 1.

[0036] In the present invention, by setting the lugs 21 and the handle 3, the grinding head handle 2 can be quickly installed on or disassembled from the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com