Sealing structure of angle grinder gear box lubricated by lubricating oil and angle grinder

A technology of sealing structure and lubricating oil, which is applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problems of poor fluidity and poor lubricating effect of semi-solid lubricating oil, so as to ensure long-term lubrication, The effect of reducing operating noise and accelerating the transfer of frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

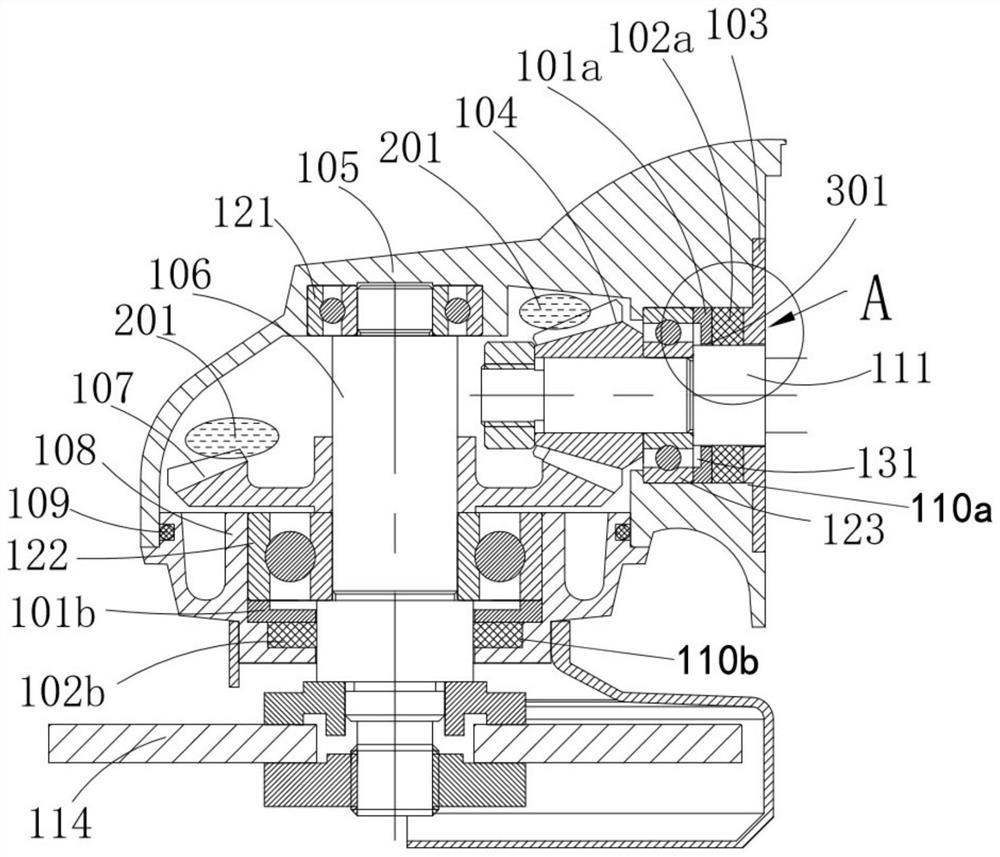

[0039] This embodiment provides an angle grinder gearbox filled with liquid lubricating oil, see Figure 1-Figure 4 , is a schematic structural diagram of the gearbox of this embodiment.

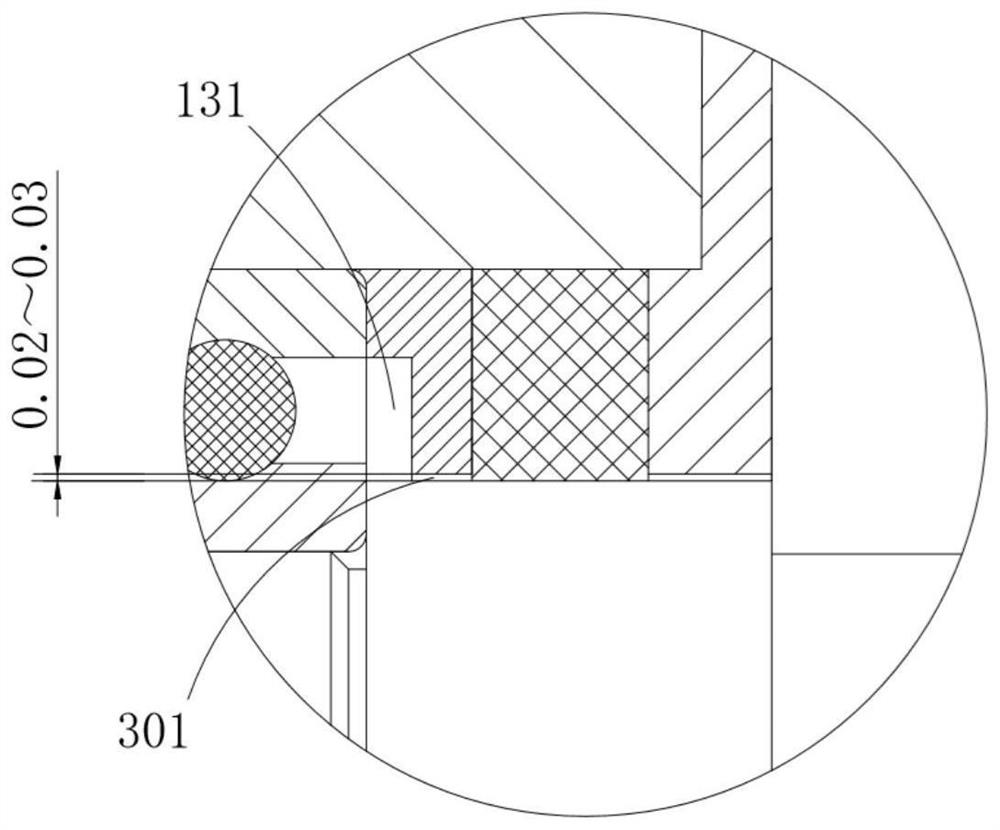

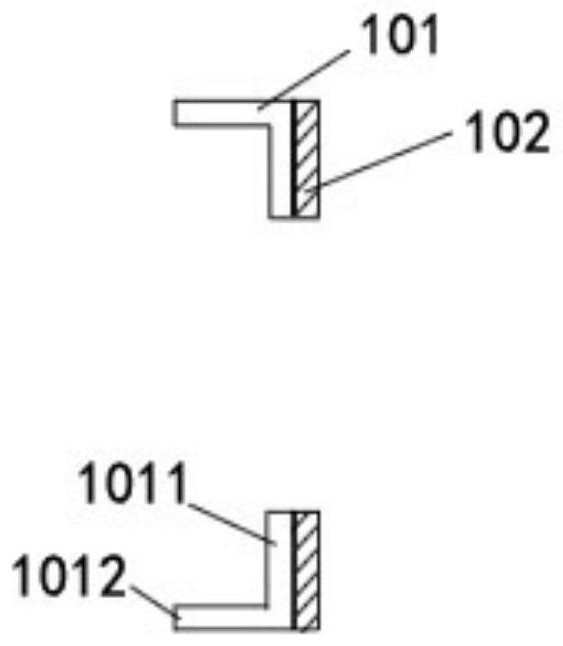

[0040] In this embodiment, the gearbox includes a housing 100, a transmission mechanism assembled in the housing 100, and a sealing assembly; the housing 100 has a first assembly hole 110a and a second assembly hole 110b, and the transmission mechanism includes a motor shaft for driving a motor 112 111, the driving gear 104, the driven gear 107, the drive output shaft 106, the motor shaft 111 passes through the first assembly hole 110a and is rotatably supported in the housing 100, the drive output shaft 106 passes through the second assembly hole 110b and is rotatably supported in the In the housing 100; the driving gear 104 is assembled on the end of the motor shaft 111, the driven gear 107 is assembled on the drive output shaft 106, and the driving gear 104 and the driven gear 107 are mes...

Embodiment 2

[0058] This embodiment provides an angle grinder filled with liquid lubricating oil, see Figure 5 , Image 6 It is a schematic structural view of the angle grinder of this embodiment, wherein the angle grinder of this embodiment includes the gear box described in Embodiment 1, the drive motor 112 and the grinding head 114, the drive motor 112 is a drive motor, and the drive motor can be It is a brushed motor, or a brushless motor with electronic drive. The drive motor 112 is installed in the motor housing 113 , and the motor shaft 111 is rotatably supported in the main housing 105 . A grinding head 114 is fixed at the end of the drive output shaft 106, and the grinding head 114 works for cutting or grinding tools such as cutting discs and friction discs.

[0059] In this embodiment, an auxiliary handle 116 is configured on the angle grinder for easy handling during work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com