Method for assembling screw rod and rolling bearing assembly

A technology of rolling bearing and assembly method, applied in the direction of rolling contact bearings, bearing components, shafts and bearings, etc., can solve problems such as permanent damage, achieve continuous lubrication, simple assembly method, and prevent dust from entering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment further illustrate the present invention.

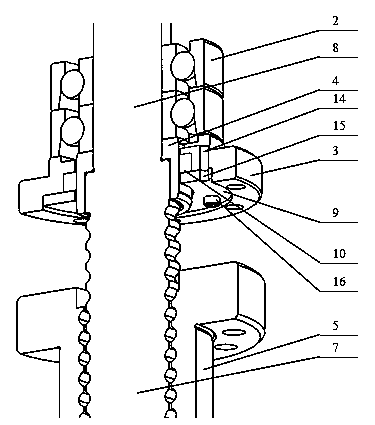

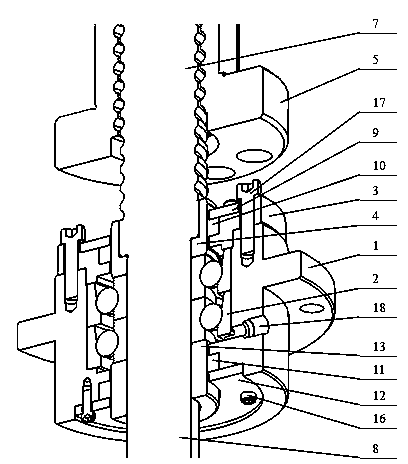

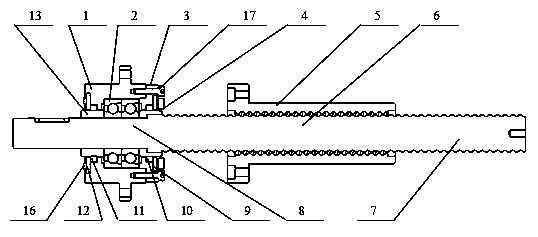

[0033] A screw and rolling bearing assembly assembly method of the present invention, said screw and rolling bearing assembly comprises screw fixing sleeve 1, rolling bearing 2, screw flange 3, screw cover 14, ball nut 5, ball screw 6 , Gland I 9, rubber sealing ring I 10, rubber sealing ring II 11, gland II 12, screw cover II 13, screw I 16, screw II 17, screw fixing sleeve oil hole 18. Ball screw 6 is divided into leading screw raceway section 7 and leading screw connection section 8, leading screw flange oil leakage hole 14 is arranged on leading screw flange 3, gland oil leakage hole 15 is arranged on gland 19. The method steps are as follows.

[0034] (1) Preparations

[0035] (1.1) Selection of parts such as rolling bearings

[0036] According to the requirements of load capacity and transmission accuracy, select the appropriate rolling bearing 2 matching the ball screw 6, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com