Patents

Literature

64results about How to "Optimal Assembly Method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

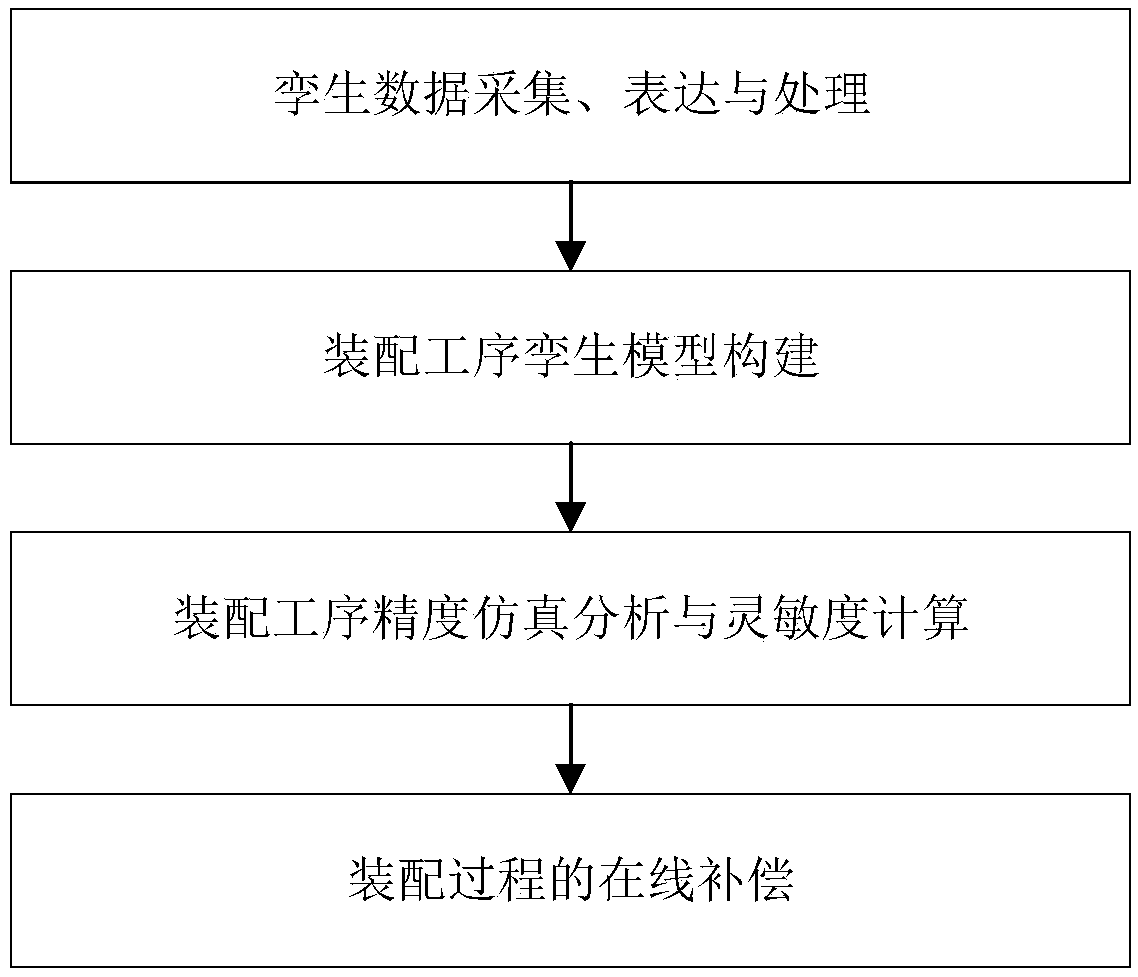

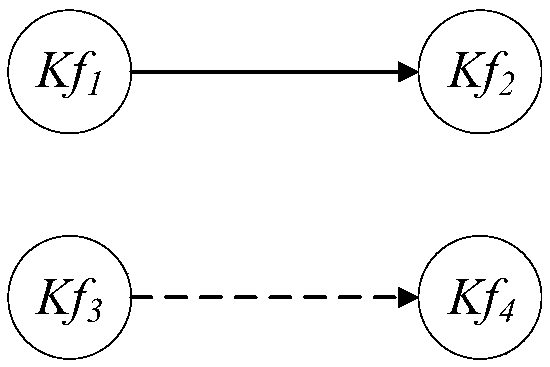

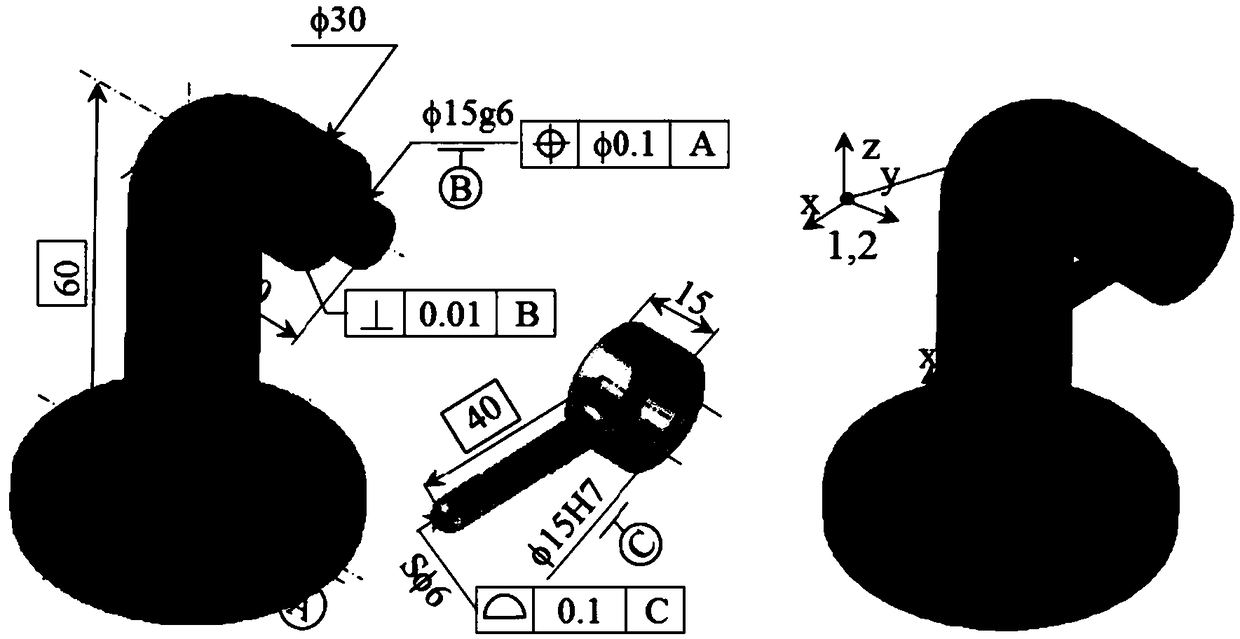

Digital twinning-based assembly precision simulation analysis method and system

InactiveCN109445305ARealize scientific assemblyQuality improvementSimulator controlInformation spacePhysical space

The invention discloses a digital twinning-based assembly precision simulation analysis method and system. According to the digital twinning-based assembly precision simulation analysis method and system, as for key processes in complex product assembly, the twin data of a physical assembly site are collected and processed, and twin data information is expressed and stored; an assembly process model is obtained in a 3D assembly process design system, and the assembly process model is reconstructed based on the twin data, so that an assembly process twin model is generated; the assembly processtwin model is introduced into commercial assembly tolerance analysis software, so that assembly precision simulation and sensitivity calculation can be performed; and the online compensation and precise control of the assembly process are performed according to assembly process precision simulation analysis results. With the digital twinning-based assembly precision simulation analysis method andsystem of the invention adopted, the deep fusion of the physical space and information space of the assembly site can be realized. The method and system are of great significance for realizing the intelligent closed-loop control of a complex product assembly process and improving assembly quality and efficiency.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

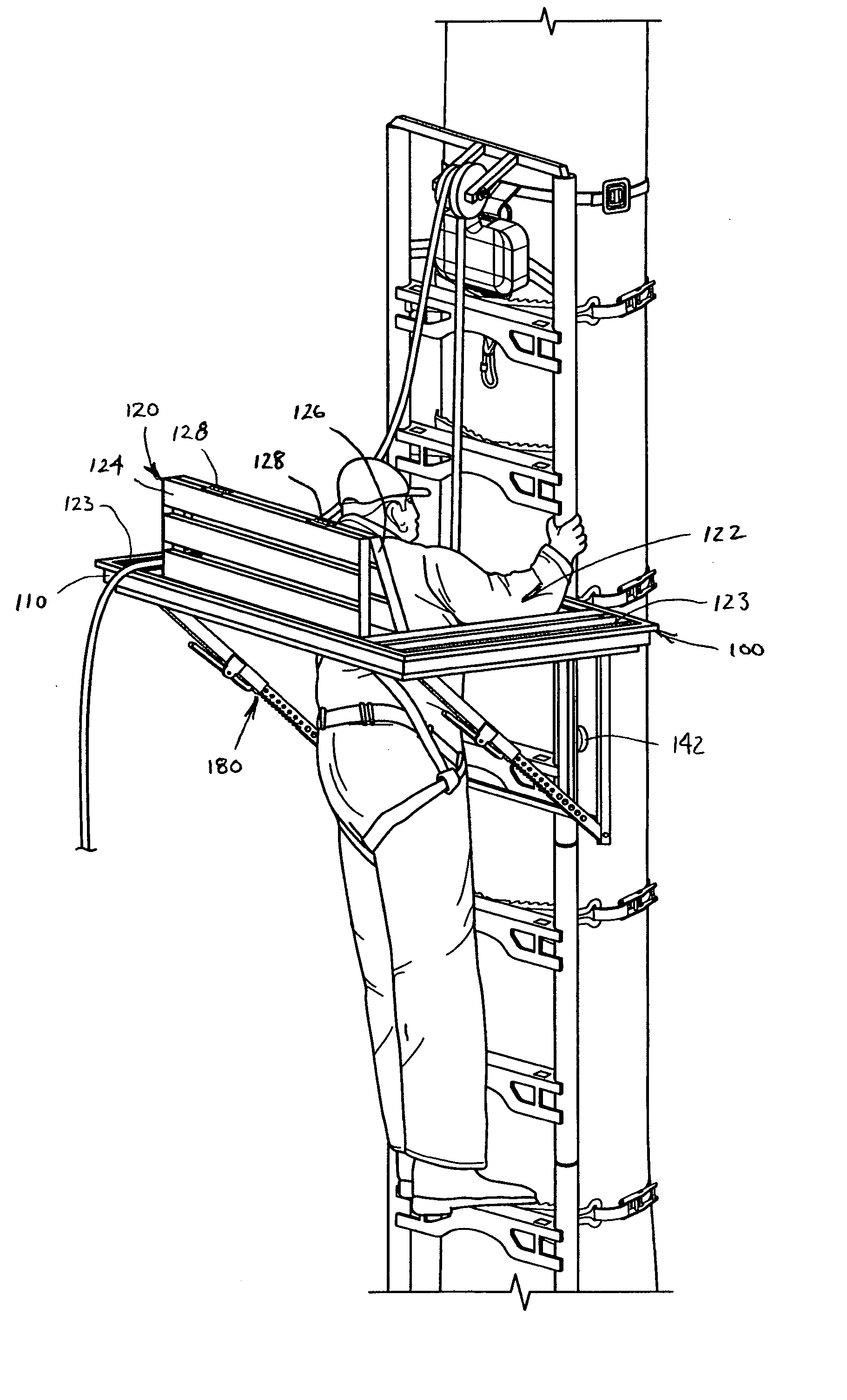

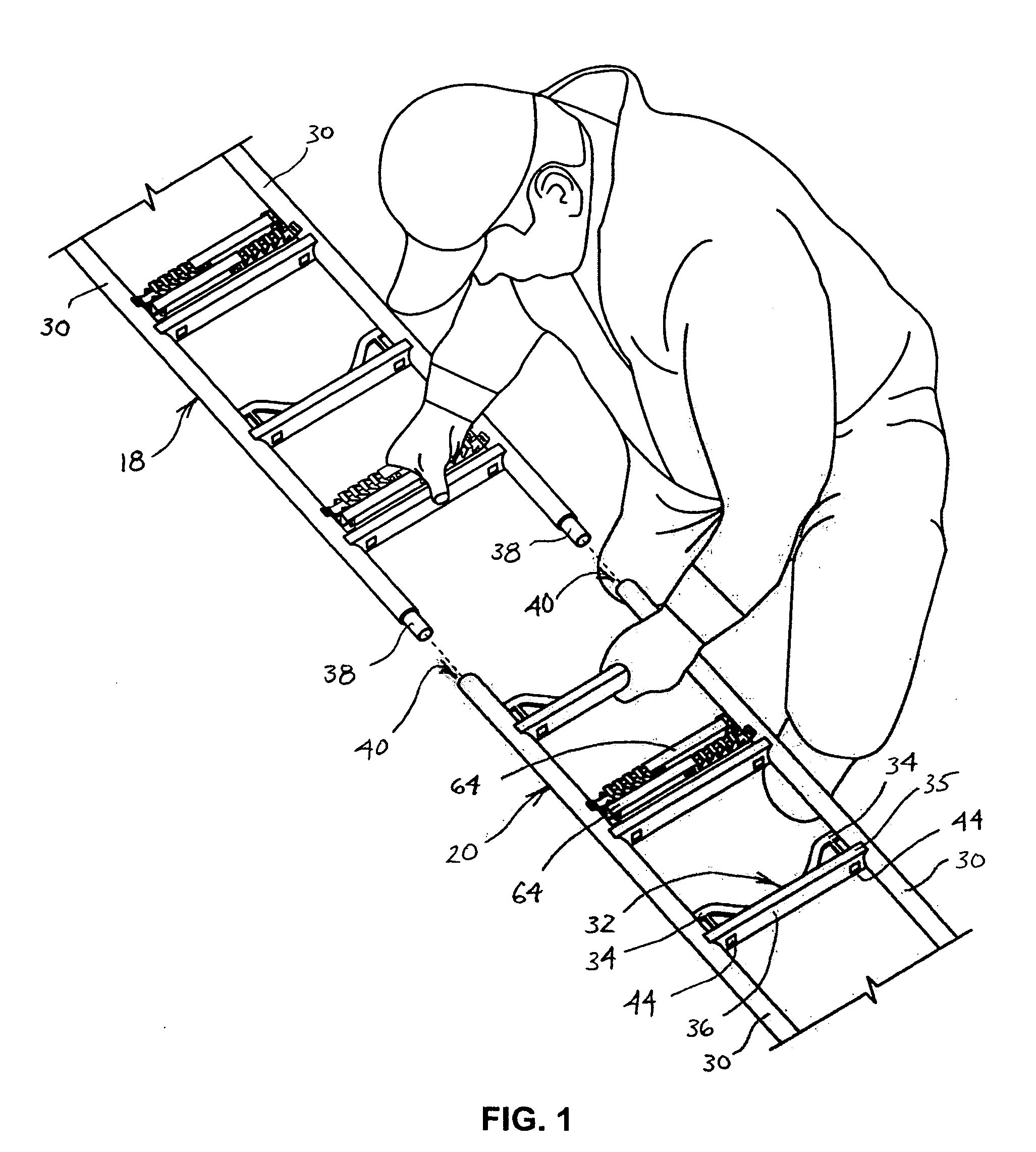

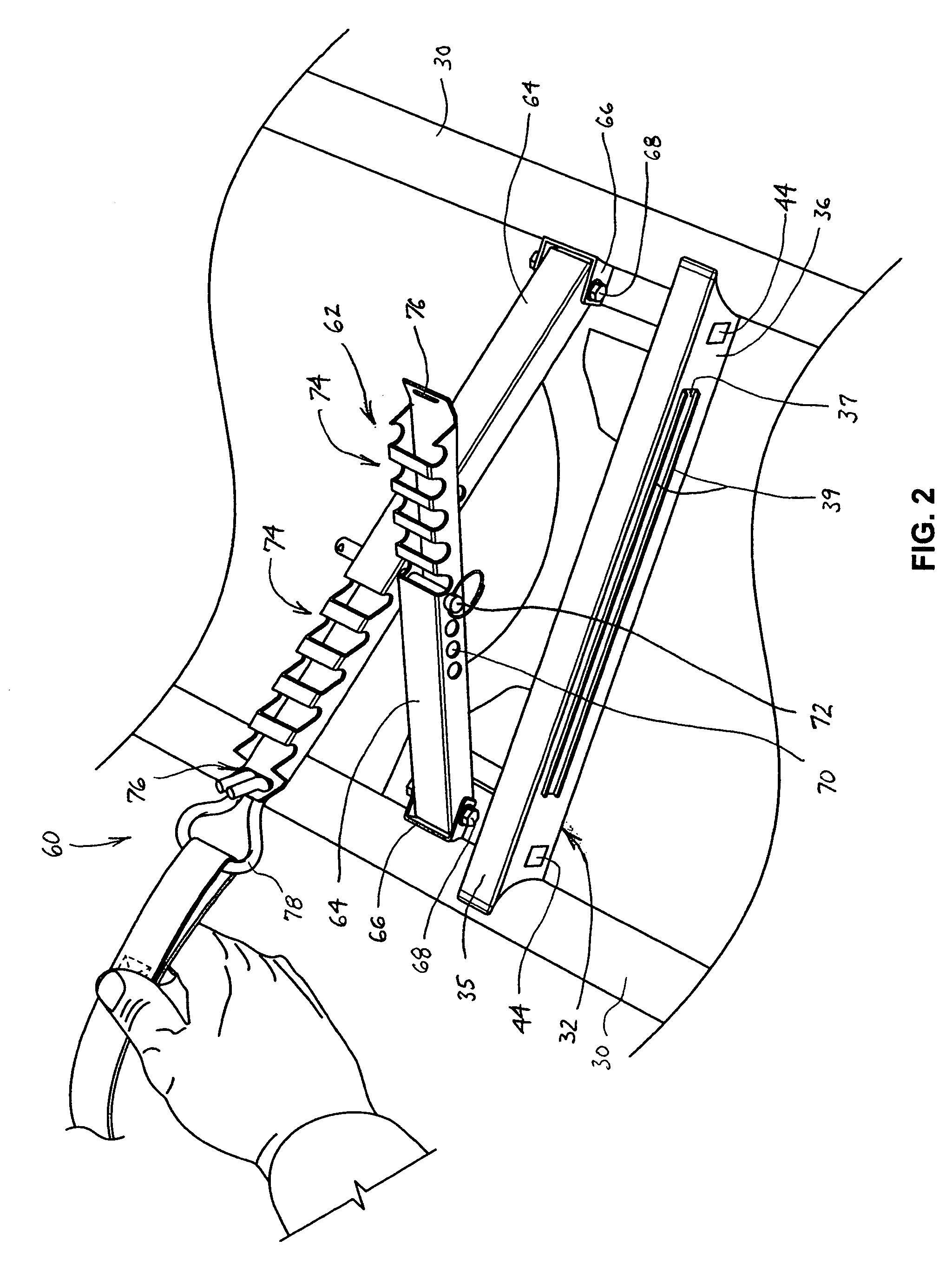

Ladder stand with platform hoist and method of assembling same

InactiveUS20070256892A1Easy to assembleSafely and conveniently assembled by a single personAnimal huntingLaddersMechanical engineeringEngineering

Owner:BREEDLOVE MICHAEL G SR

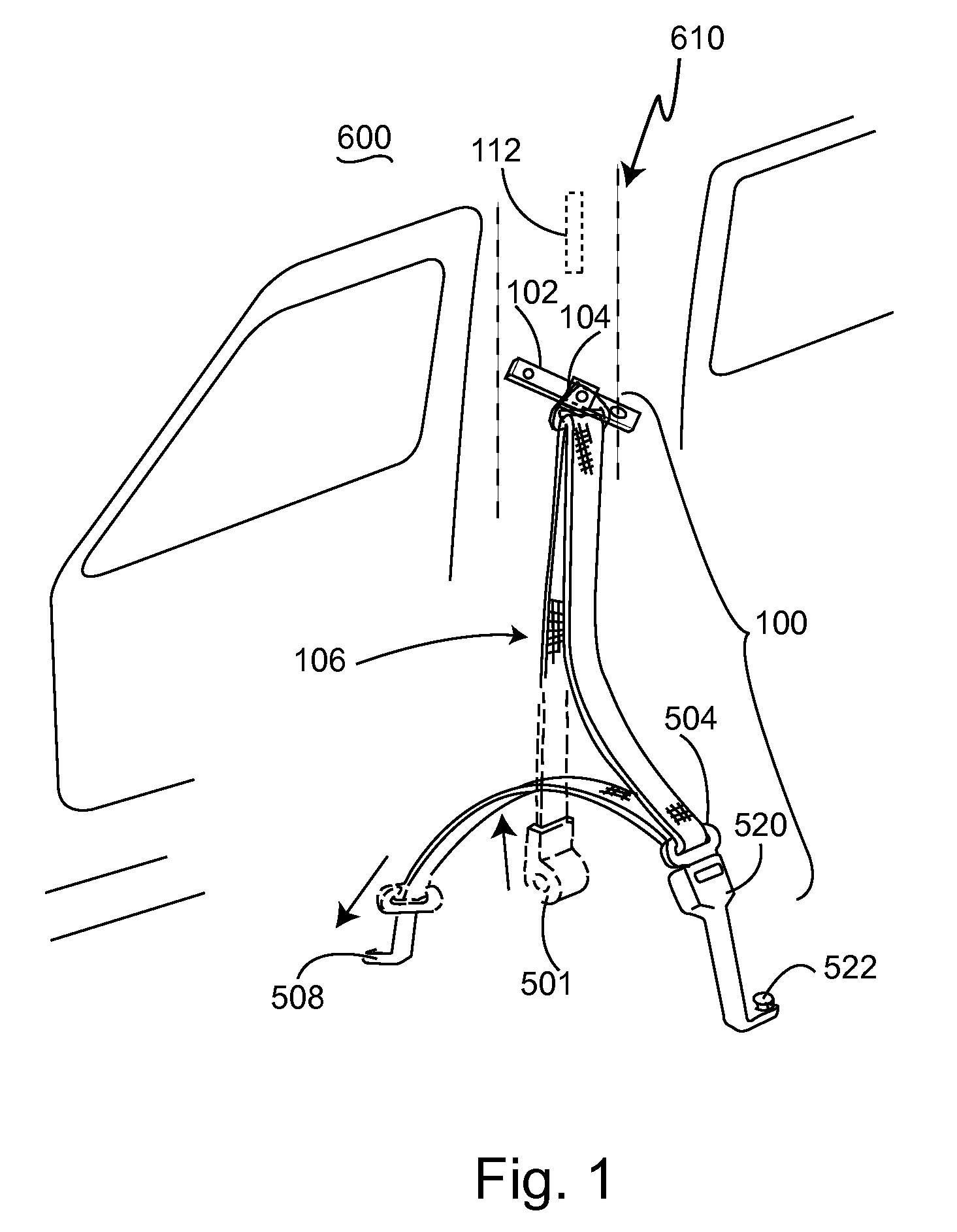

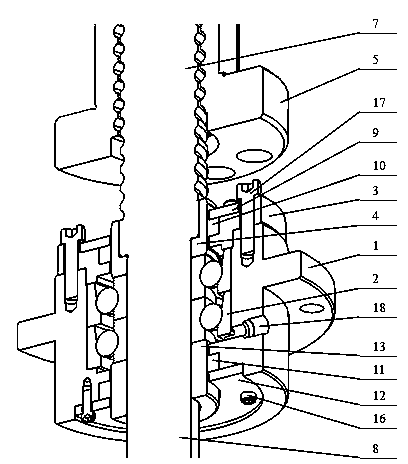

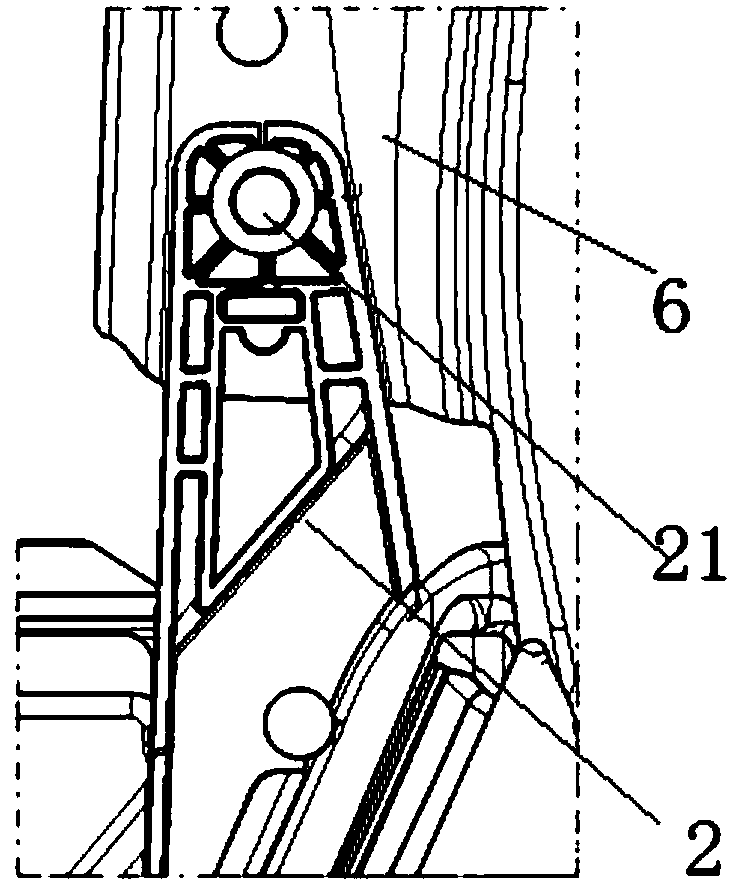

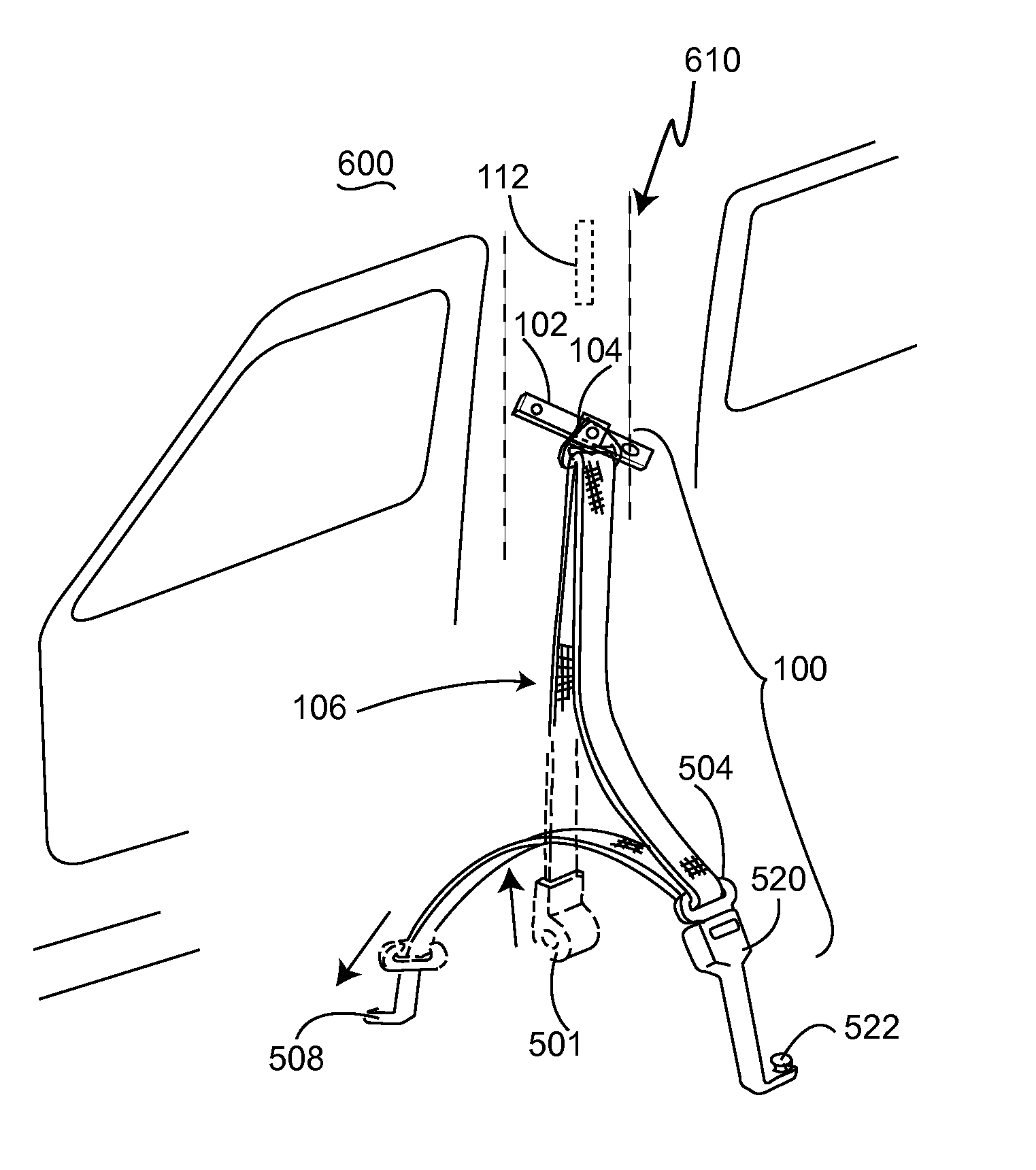

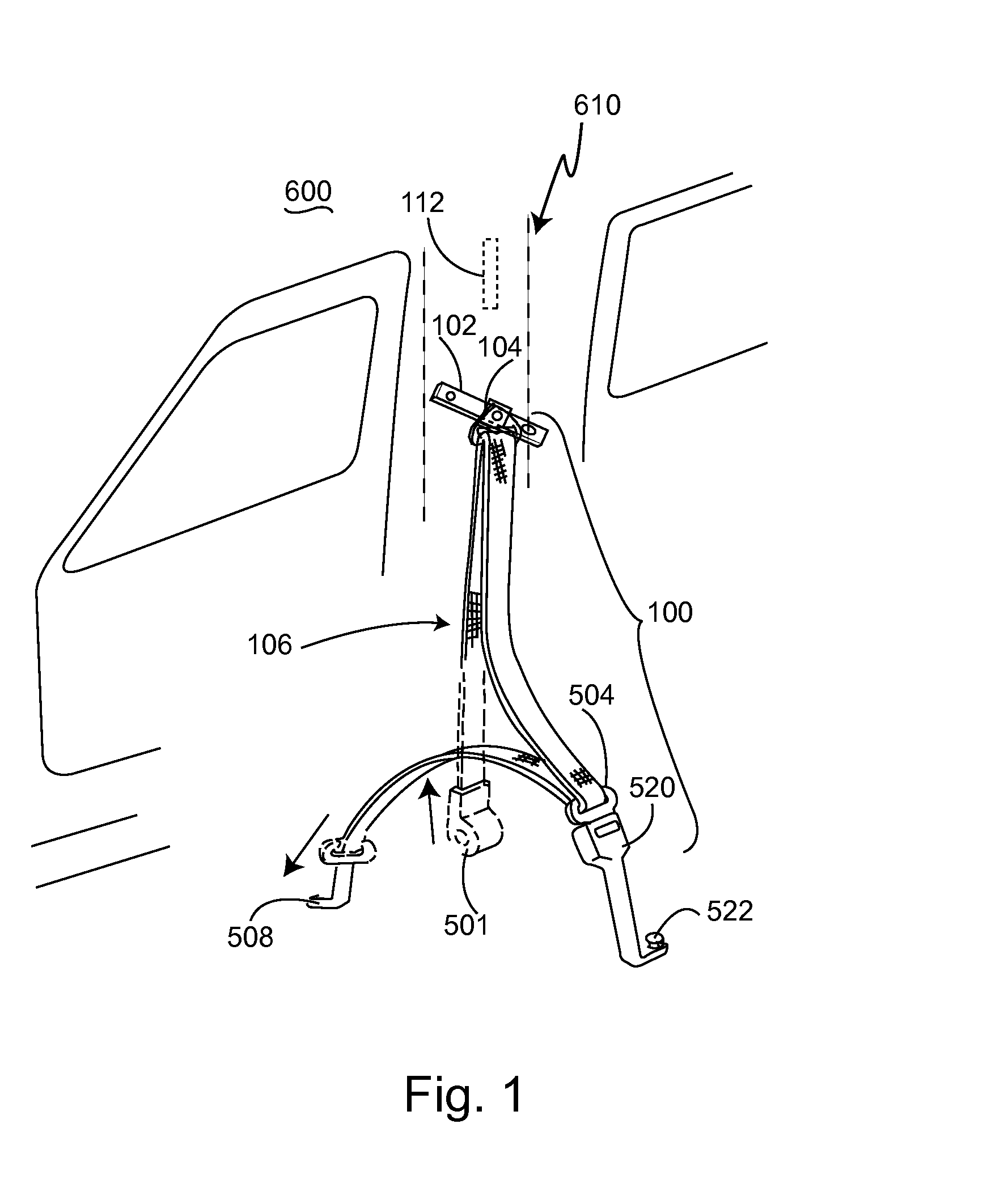

Seat belt assembly and method of installation

InactiveUS7367590B2Easy to assembleOptimal Assembly MethodBelt anchoring devicesSeat beltControl theory

A method of installing a seat belt system (100) into a passenger compartment of a vehicle, the system of the type including a seat belt retractor (501), a height adjuster (102) and a web guide (104), the method including the steps of: a) providing a height adjusting mechanism having a bar or track and a carrier; b) securing the web guide to the carrier so the height adjuster and web guide form a subassembly; c) locating and securing the retractor to a desired location within the vehicle and; d) lifting the subassembly and manipulating the height adjuster to a desired location in the vehicle and securing the height adjuster to the desired location, wherein the step of lifting the subassembly simultaneously locates the web guide to its desired location.

Owner:KEY SAFETY SYST

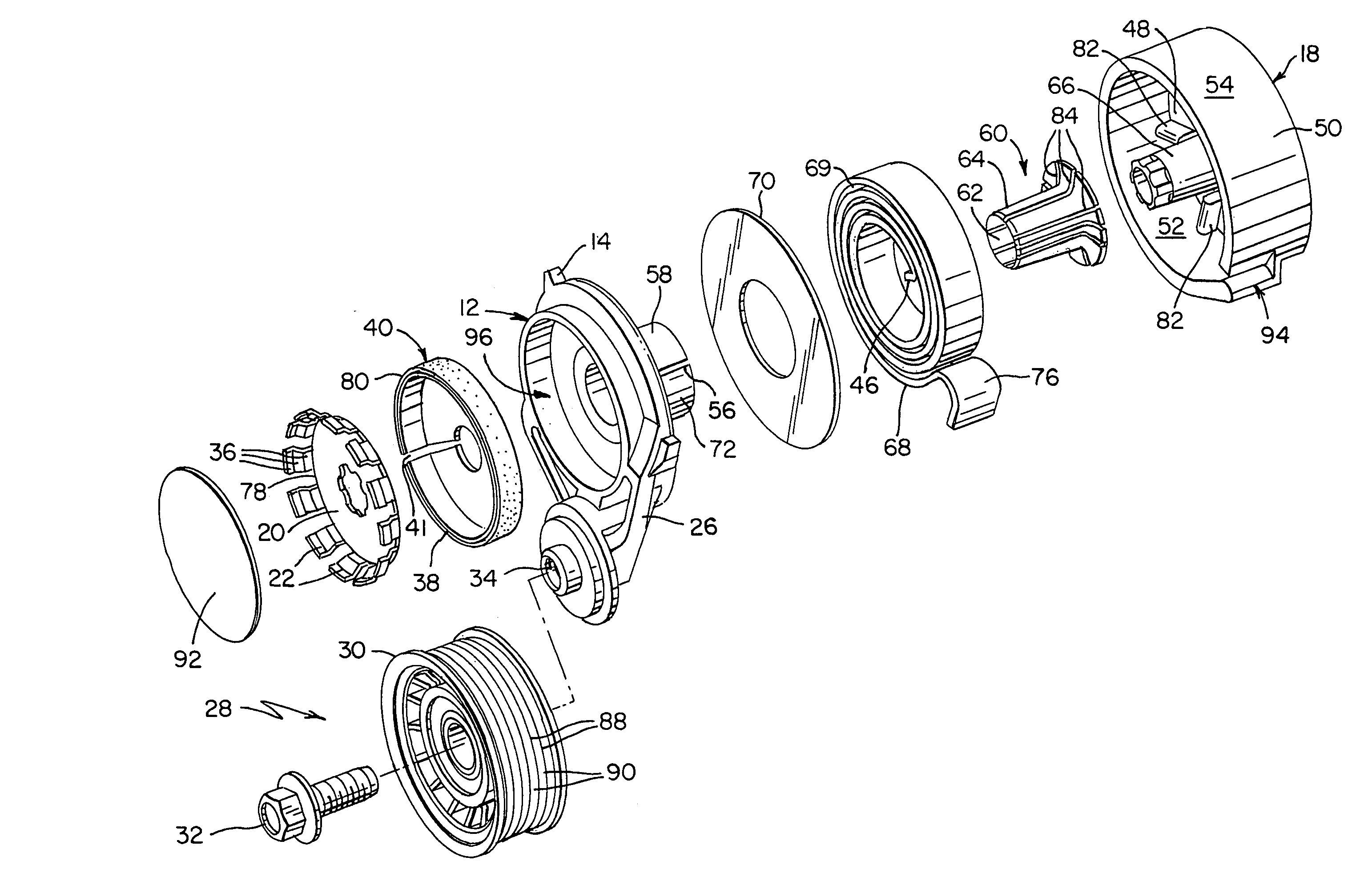

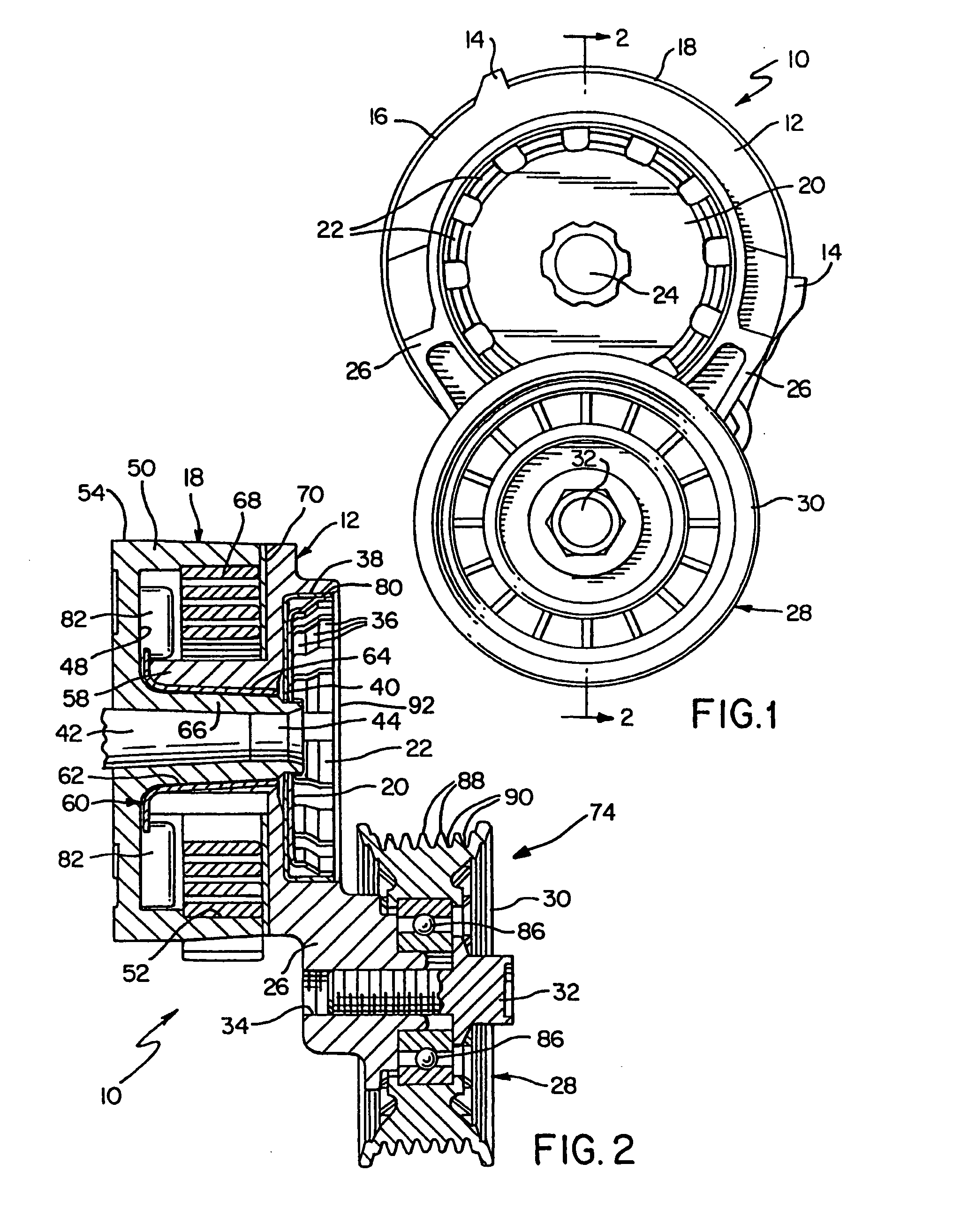

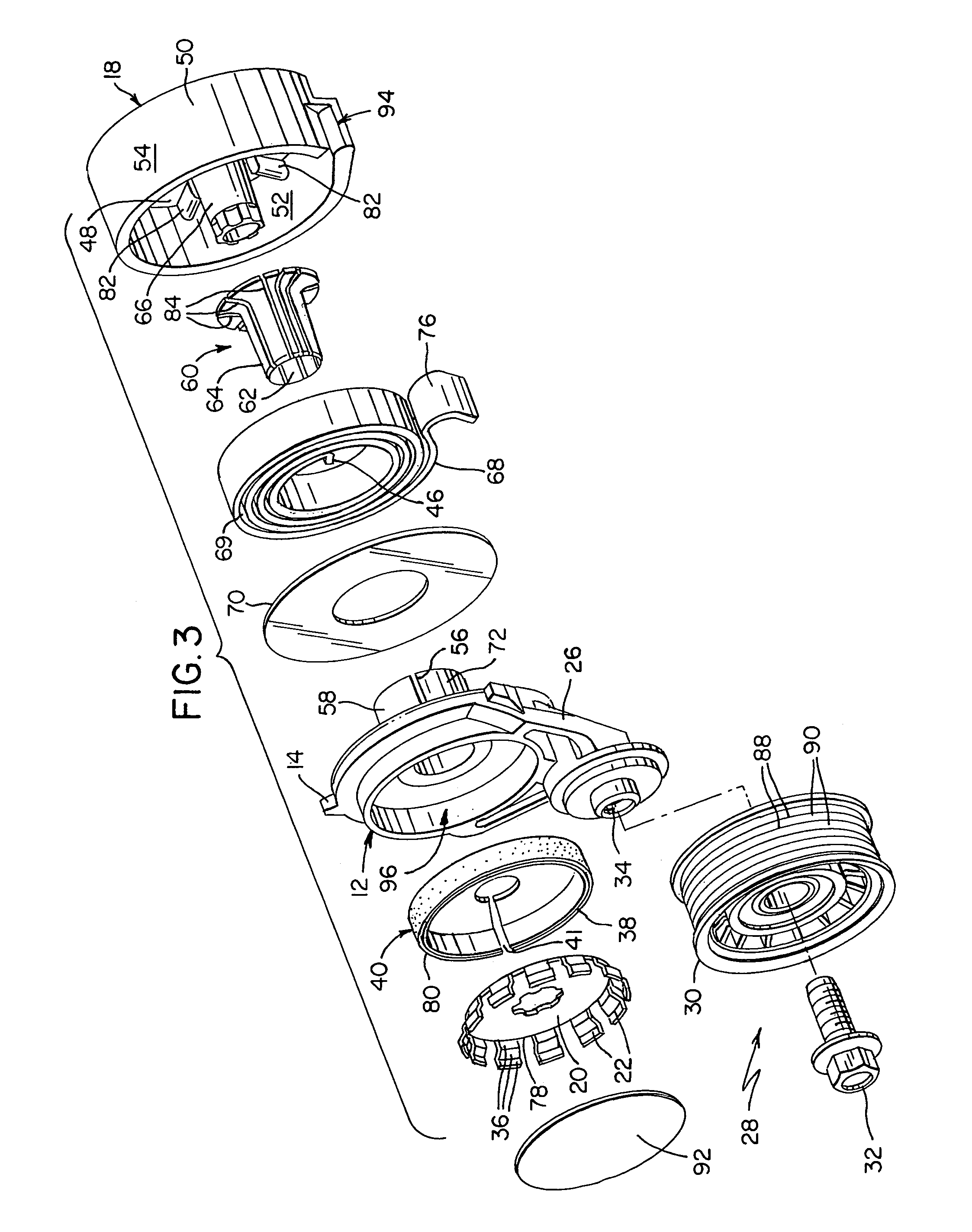

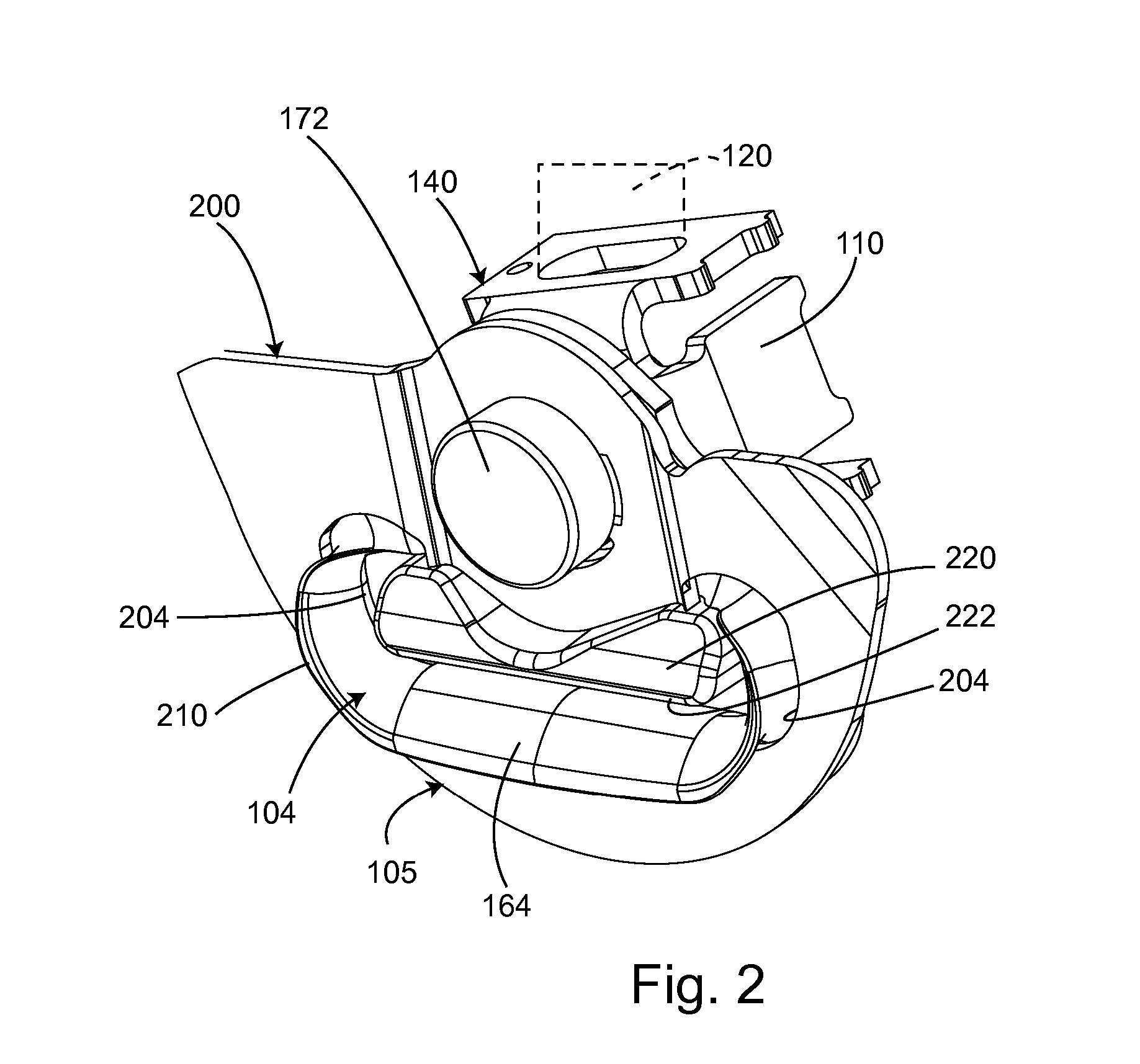

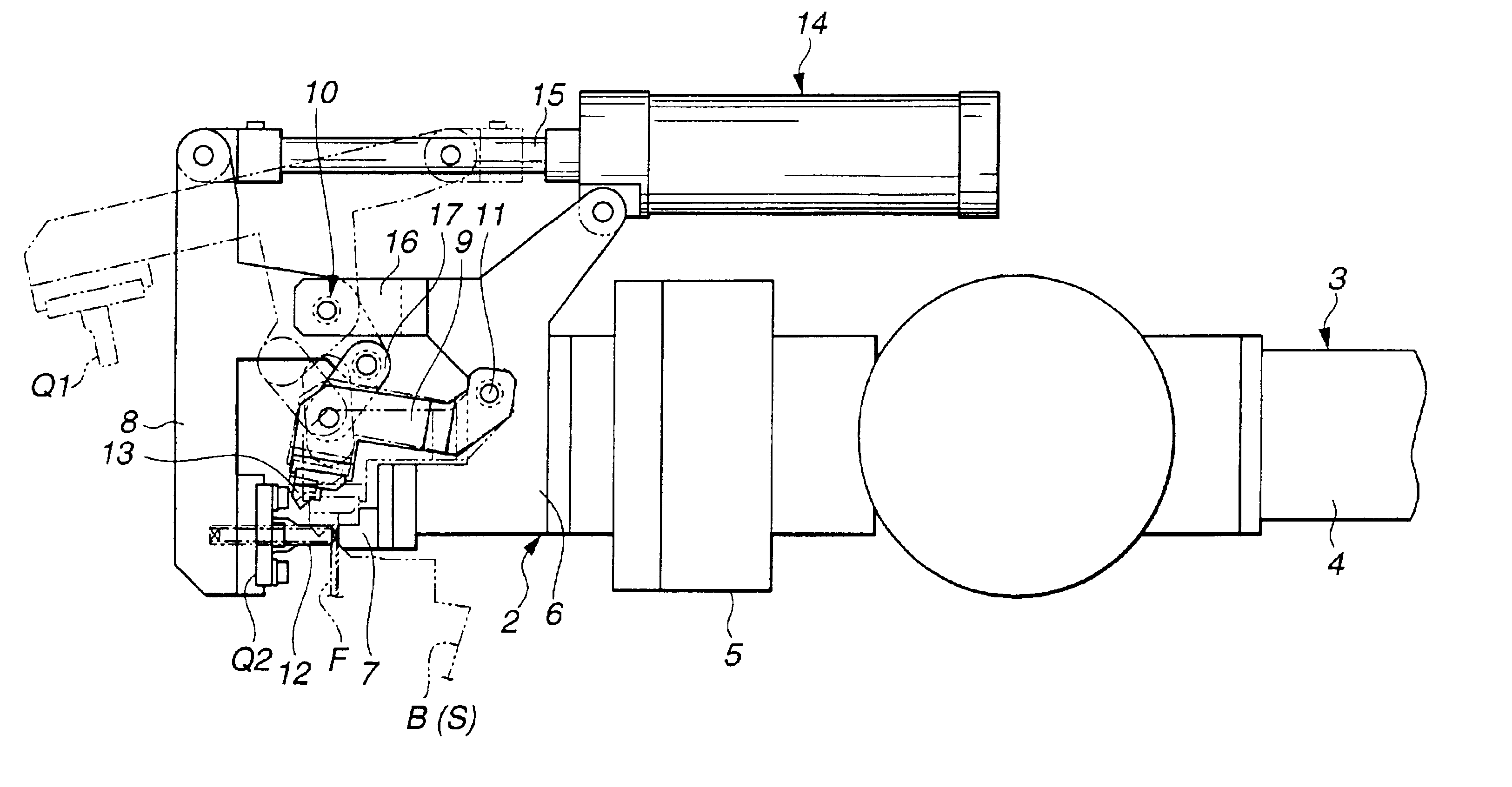

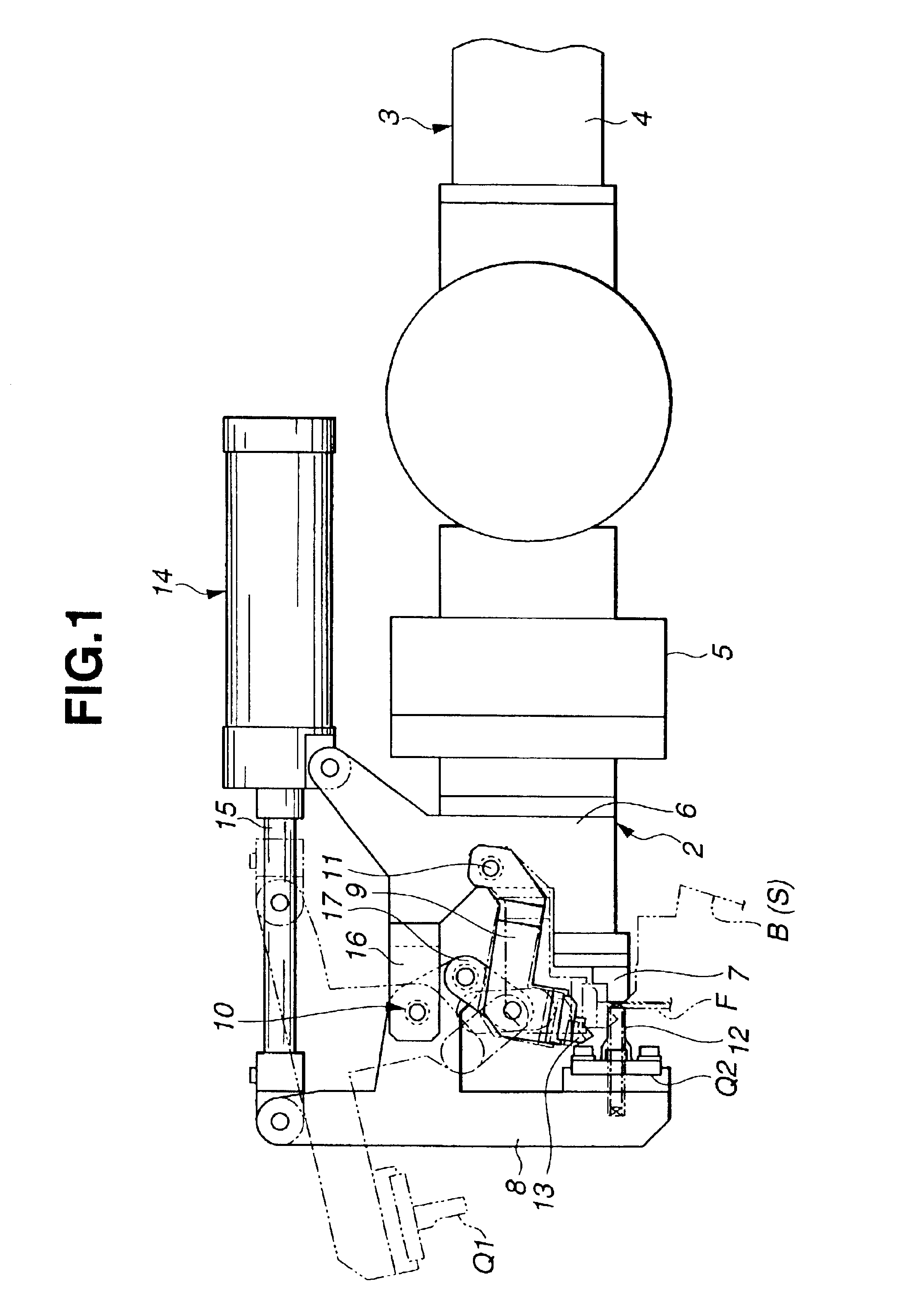

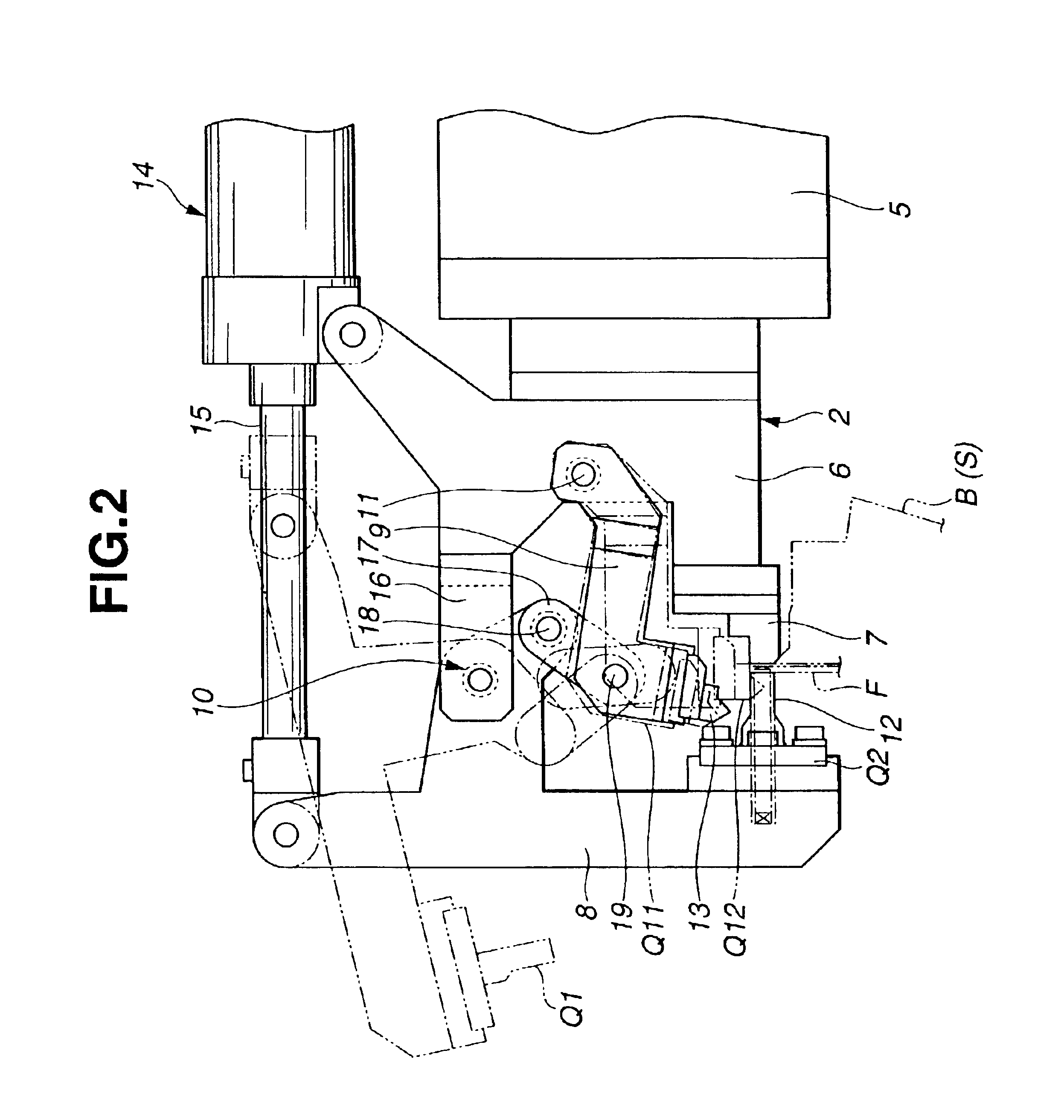

Belt tensioner with integral damping

A belt tensioner with integral damping comprising a housing, a pivot bushing, a spring element, a disc-shaped spring bushing, a lever arm assembly, a pulley assembly, an armplate assembly including an armplate and a friction element; wherein the armplate assembly comprises an armplate having a cup-shaped cavity including a circumferential edge and a plurality of spaced apart finger elements extending from said circumferential edge wherein the finger elements are configured to provide a high degree of damping in a radial direction., and a friction element disposed between the fingers elements and the armplate, the friction element providing at least one contact area having increased friction between the lever arm and the armplate.

Owner:DAYCO IP HLDG

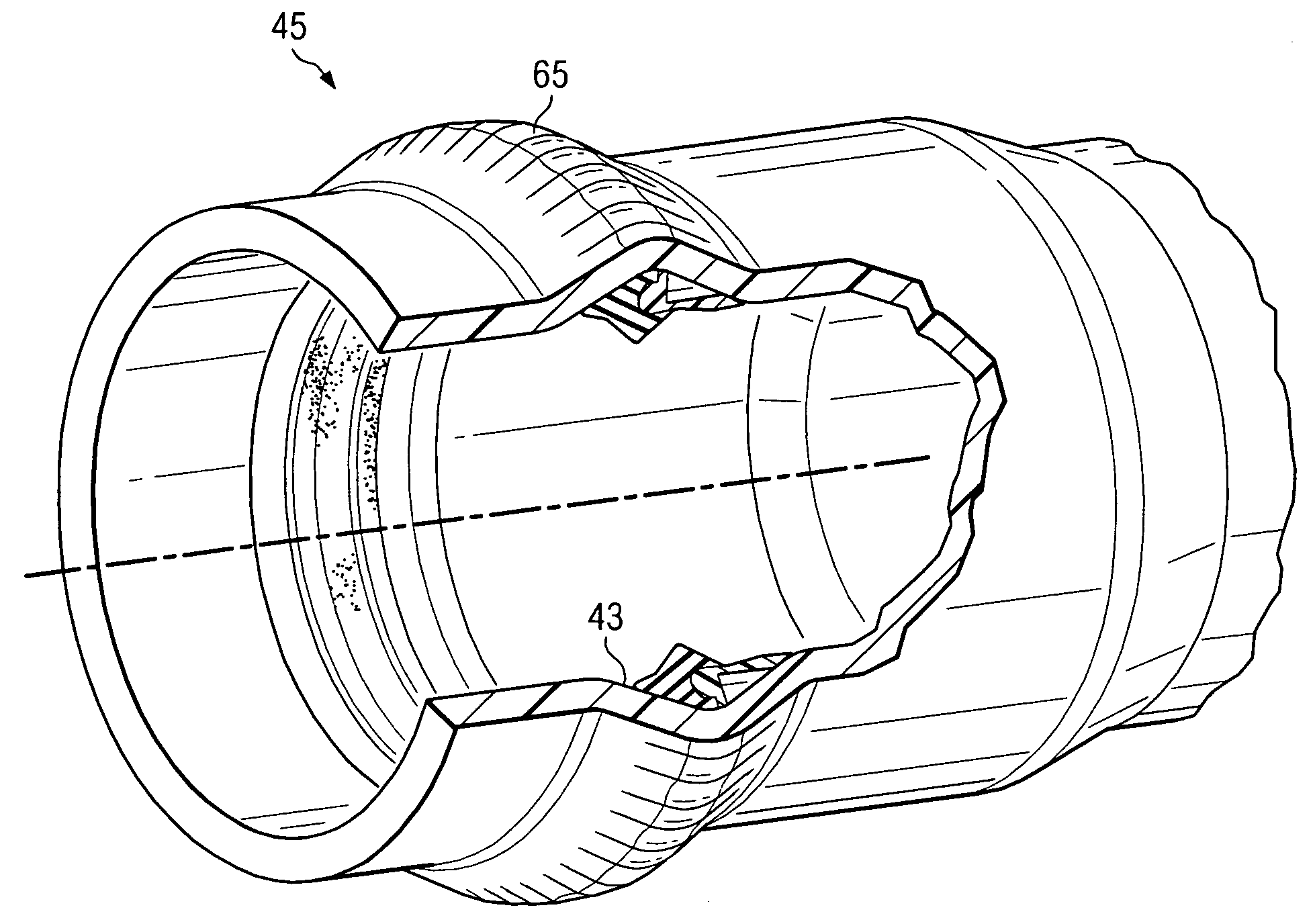

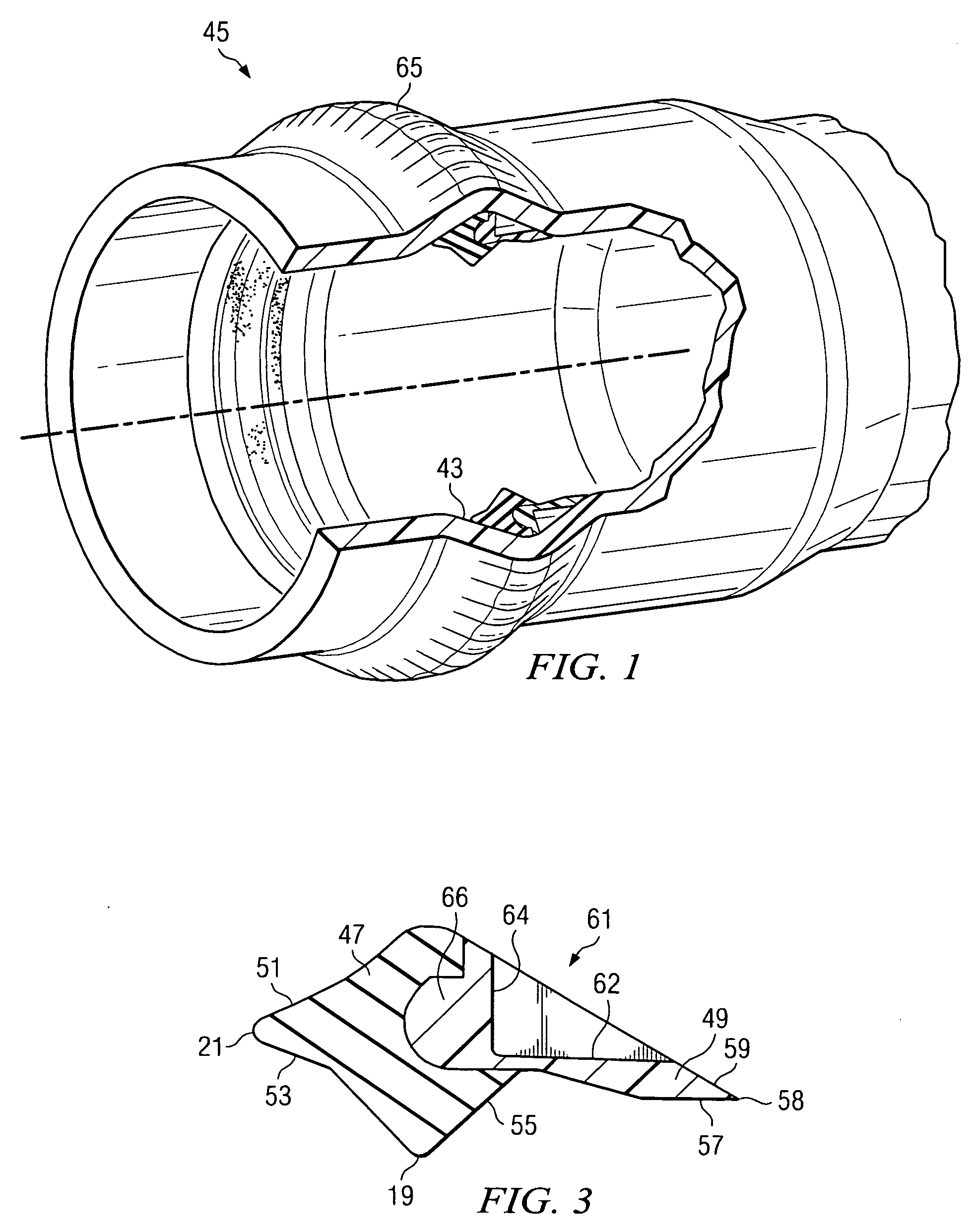

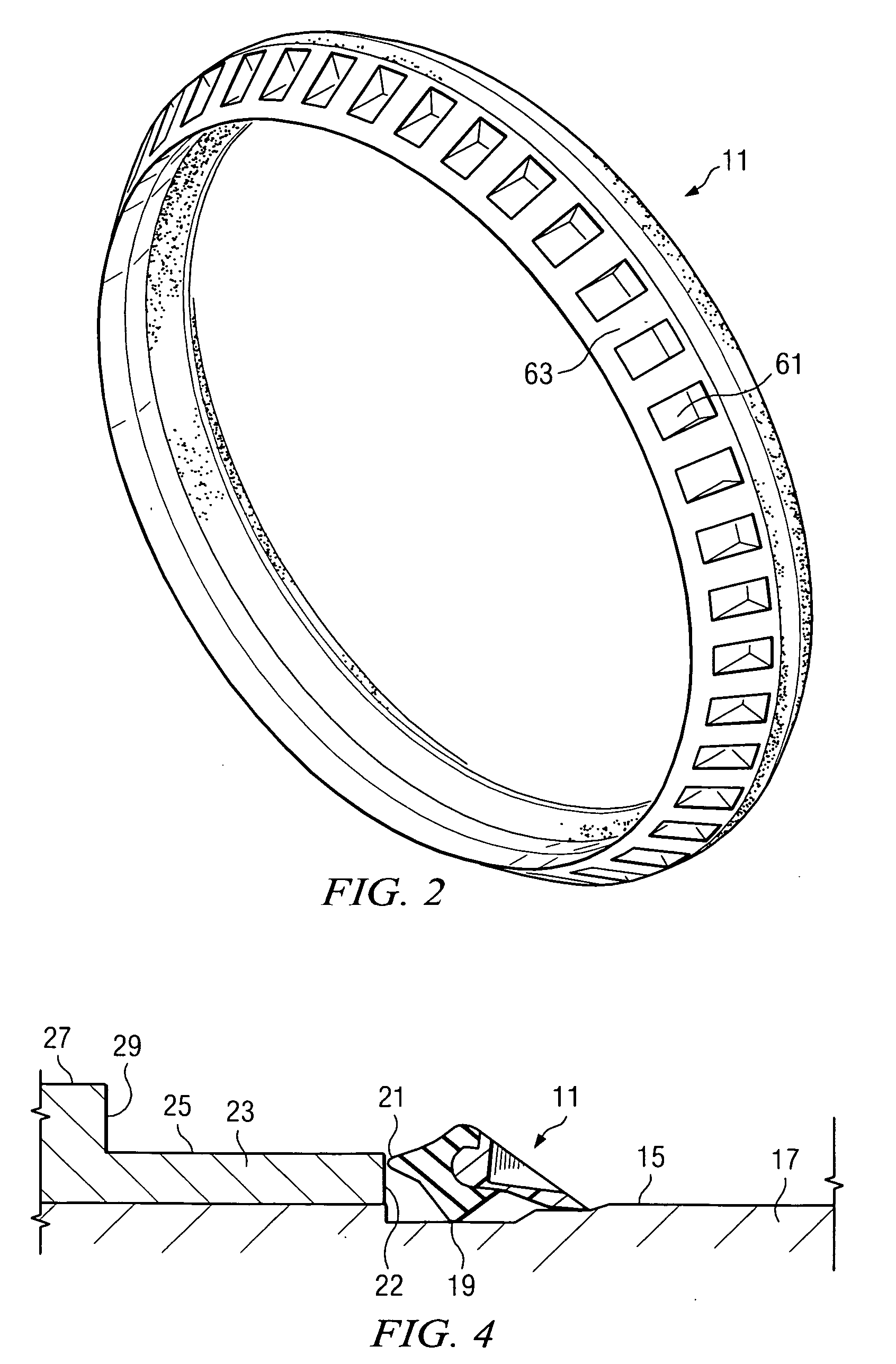

Composite Sealing Gasket and Process for Belling Plastic Pipe

InactiveUS20100059940A1Optimal Assembly MethodSimple designSleeve/socket jointsEngine sealsThermoplastic elastomerPlastic materials

An sealing gasket is shown for use in forming joints of plastic pipe. The gasket is formed as a composite elastomeric body with a leading region formed of a thermoplastic elastomer material and with a trailing region formed of a synthetic plastic material. The gasket body has an outer circumferential region provided with a series of recessed pocket which give it a scallop-like appearance. The relatively harder plastic region of the gasket body deforms the associated pipe socket end during manufacture of the pipe end, whereby the gasket is integrally locked within an internal pipe groove in the pipe socket end upon completion of the pipe belling operation.

Owner:S & B TECHN PRODS

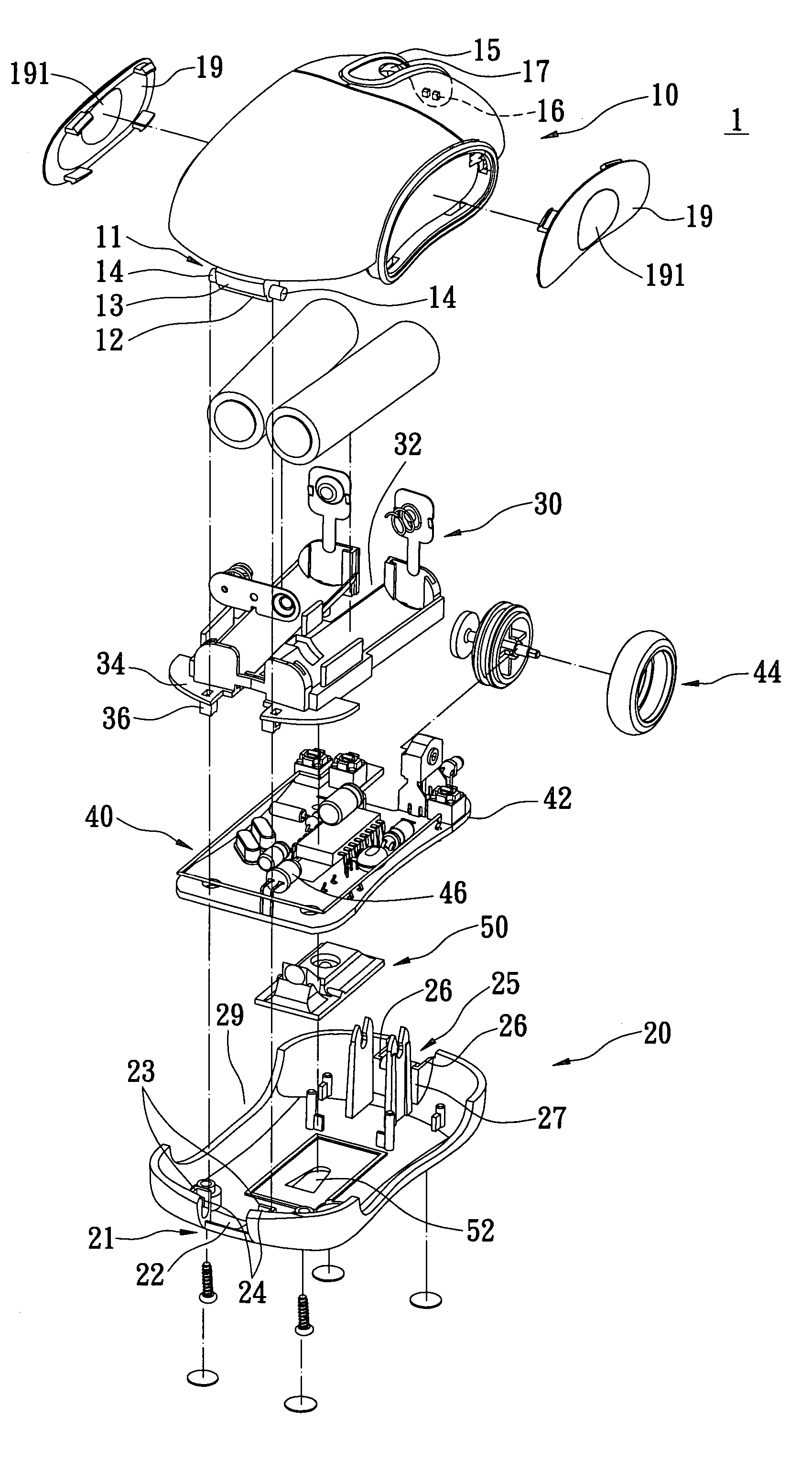

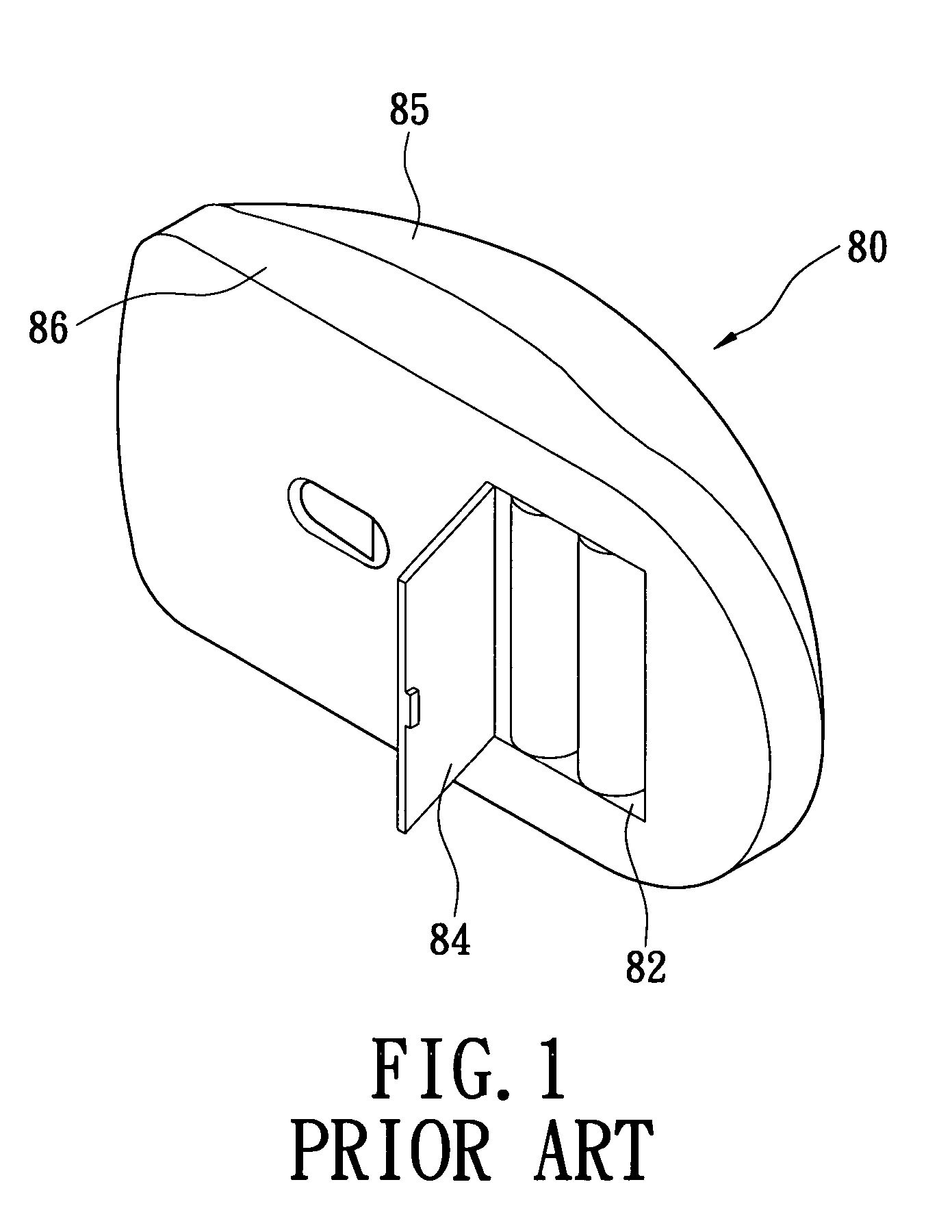

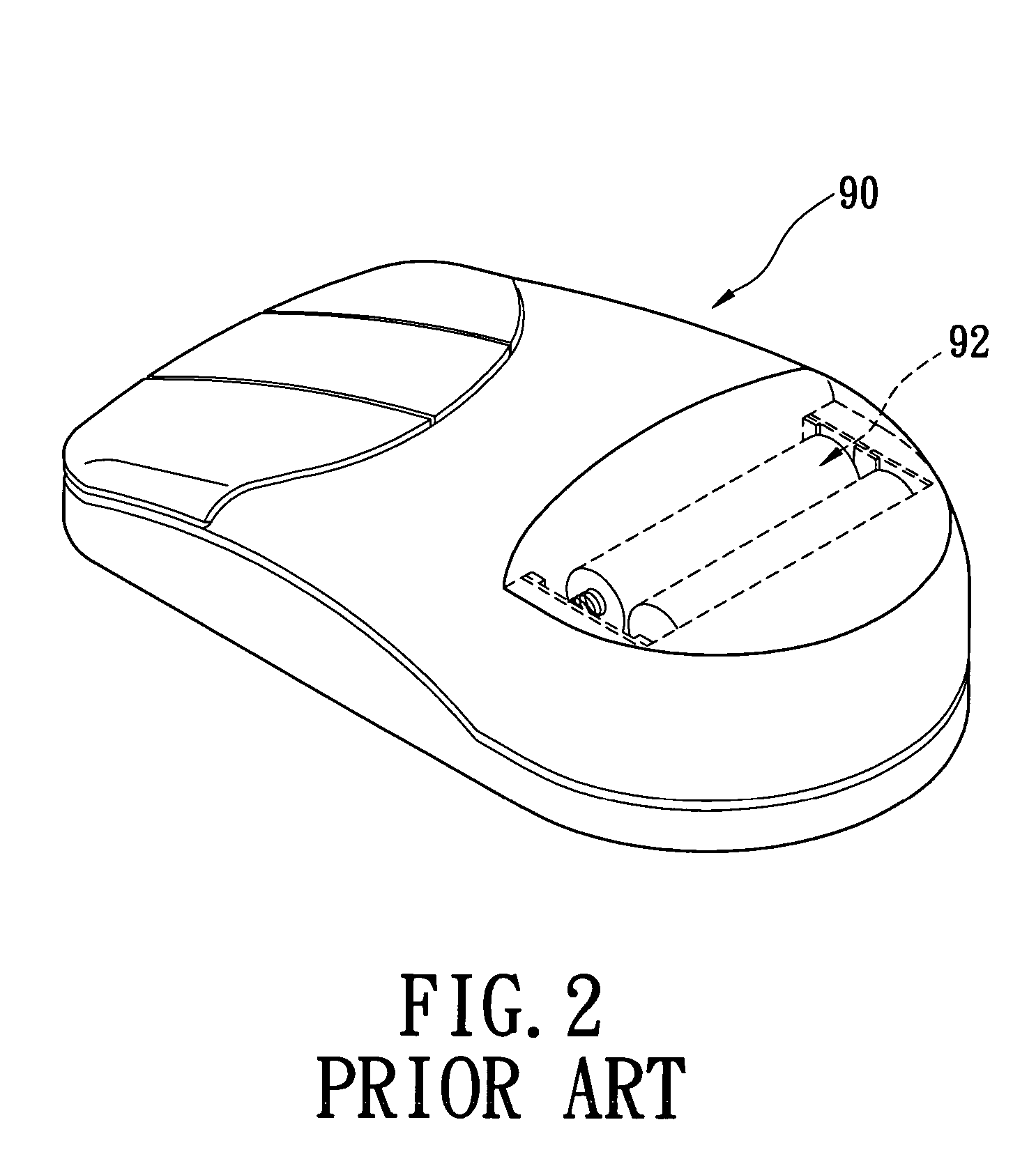

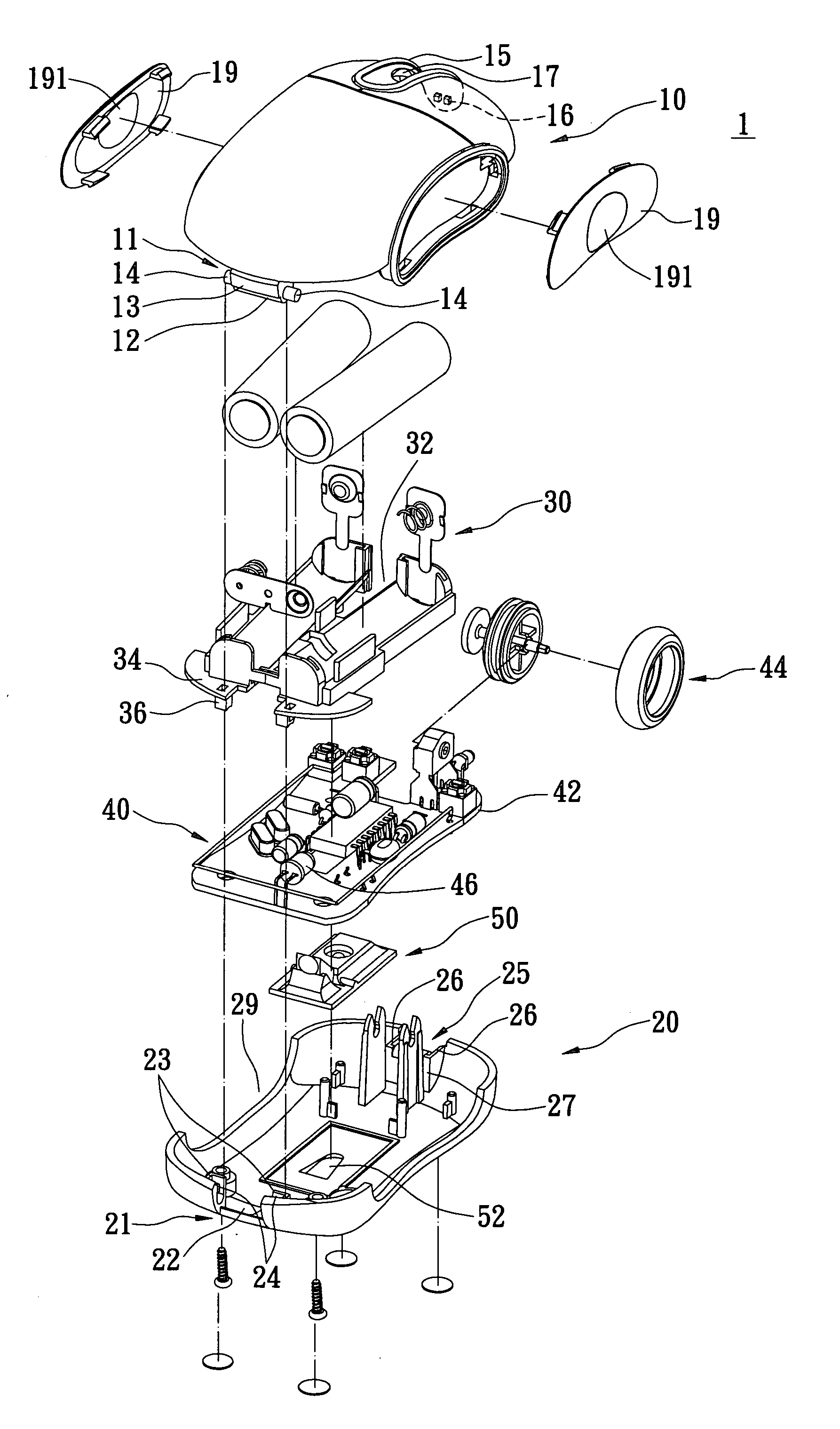

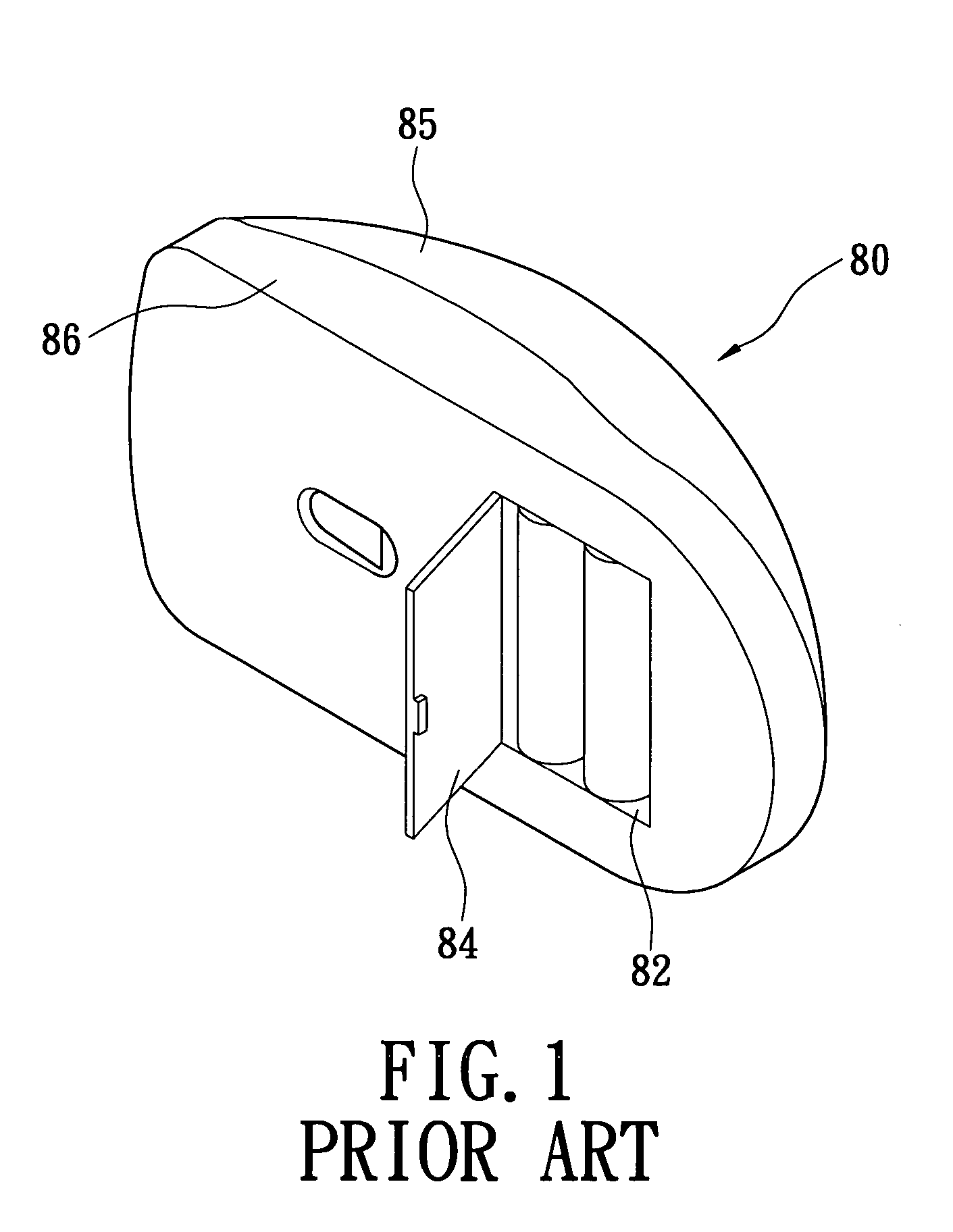

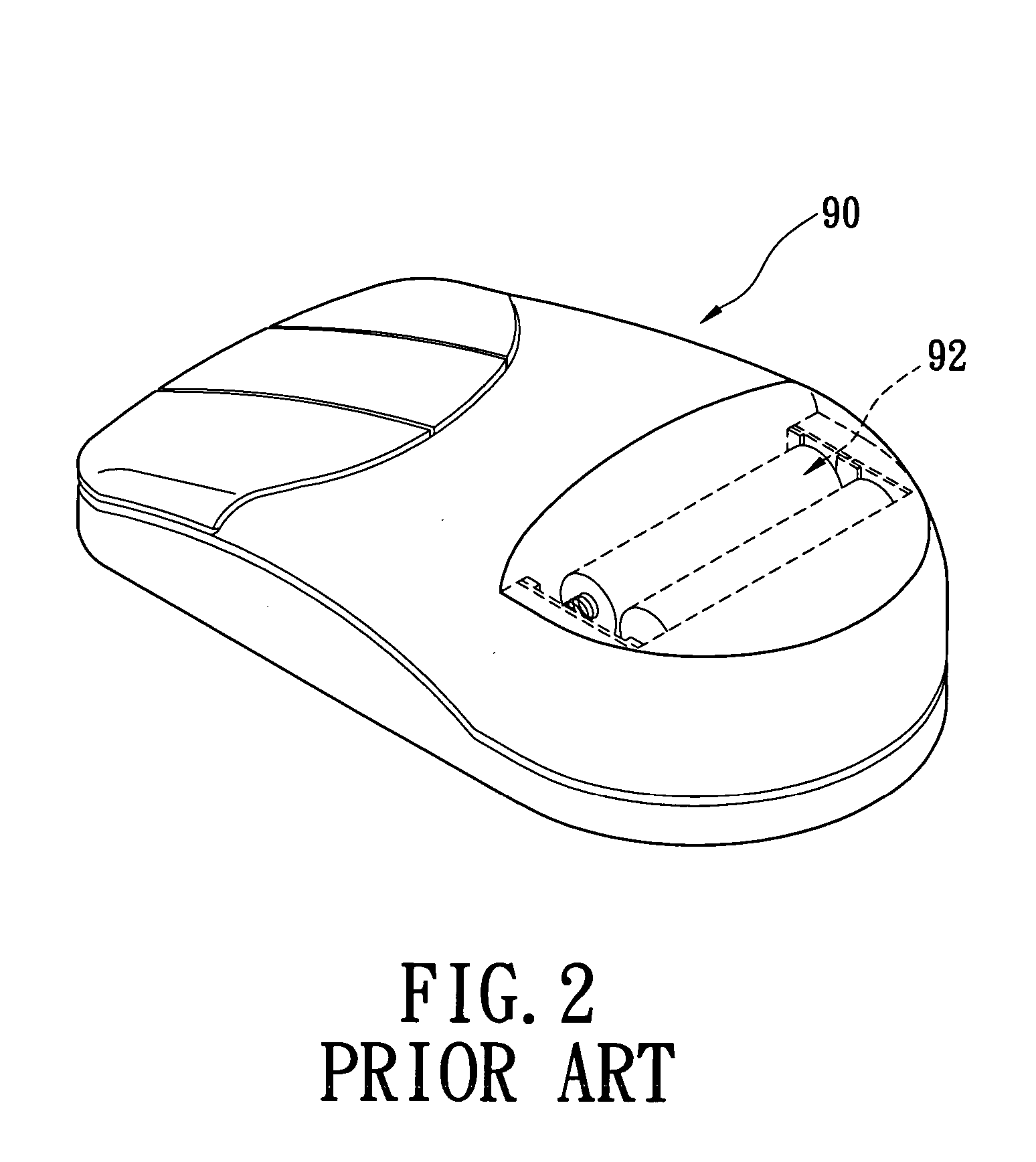

Mouse structure

InactiveUS7119793B2Convenient ArrangementSimple structureCathode-ray tube indicatorsInput/output processes for data processingEngineeringMechanical engineering

Owner:CHEN CLIFF

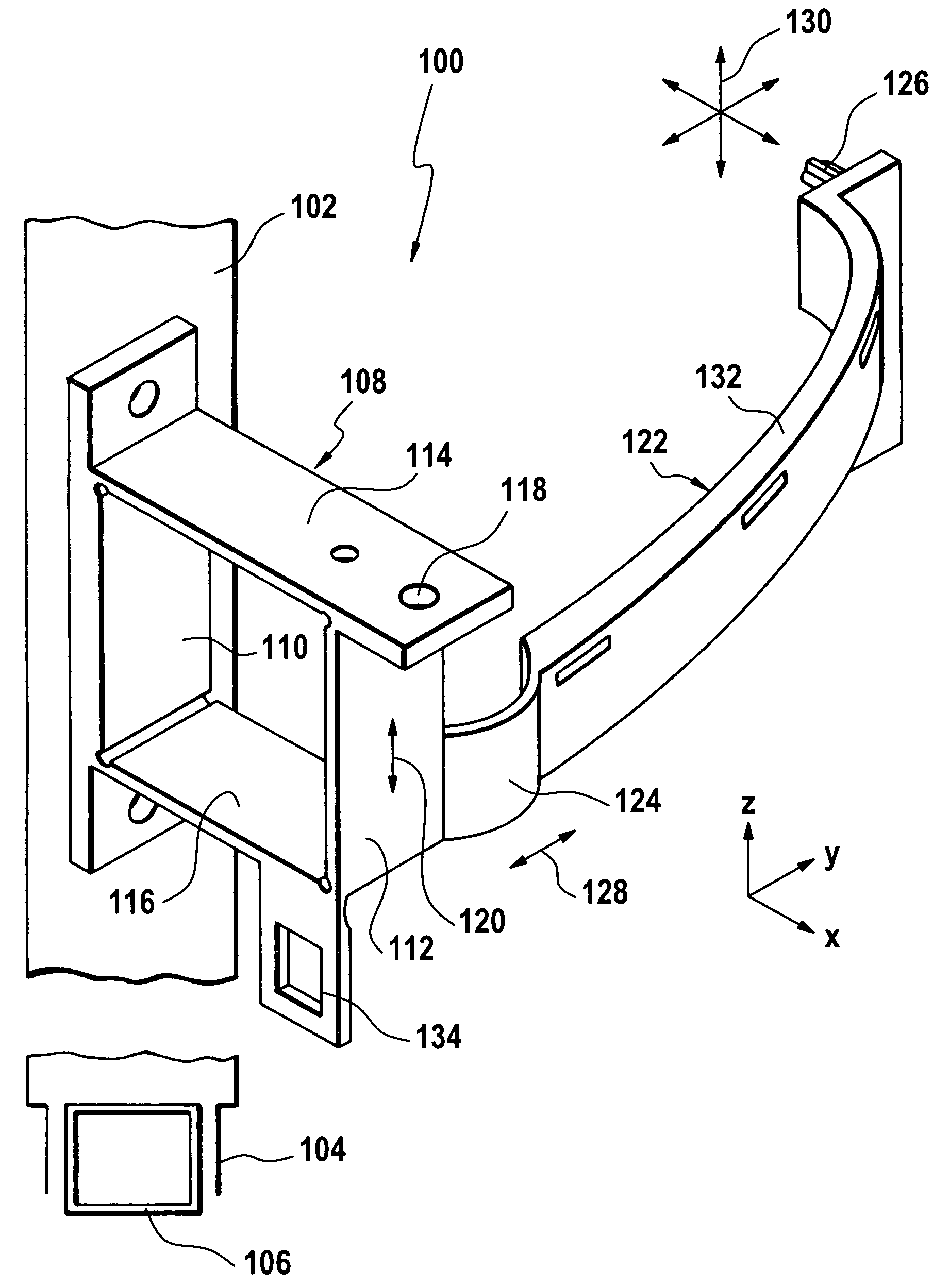

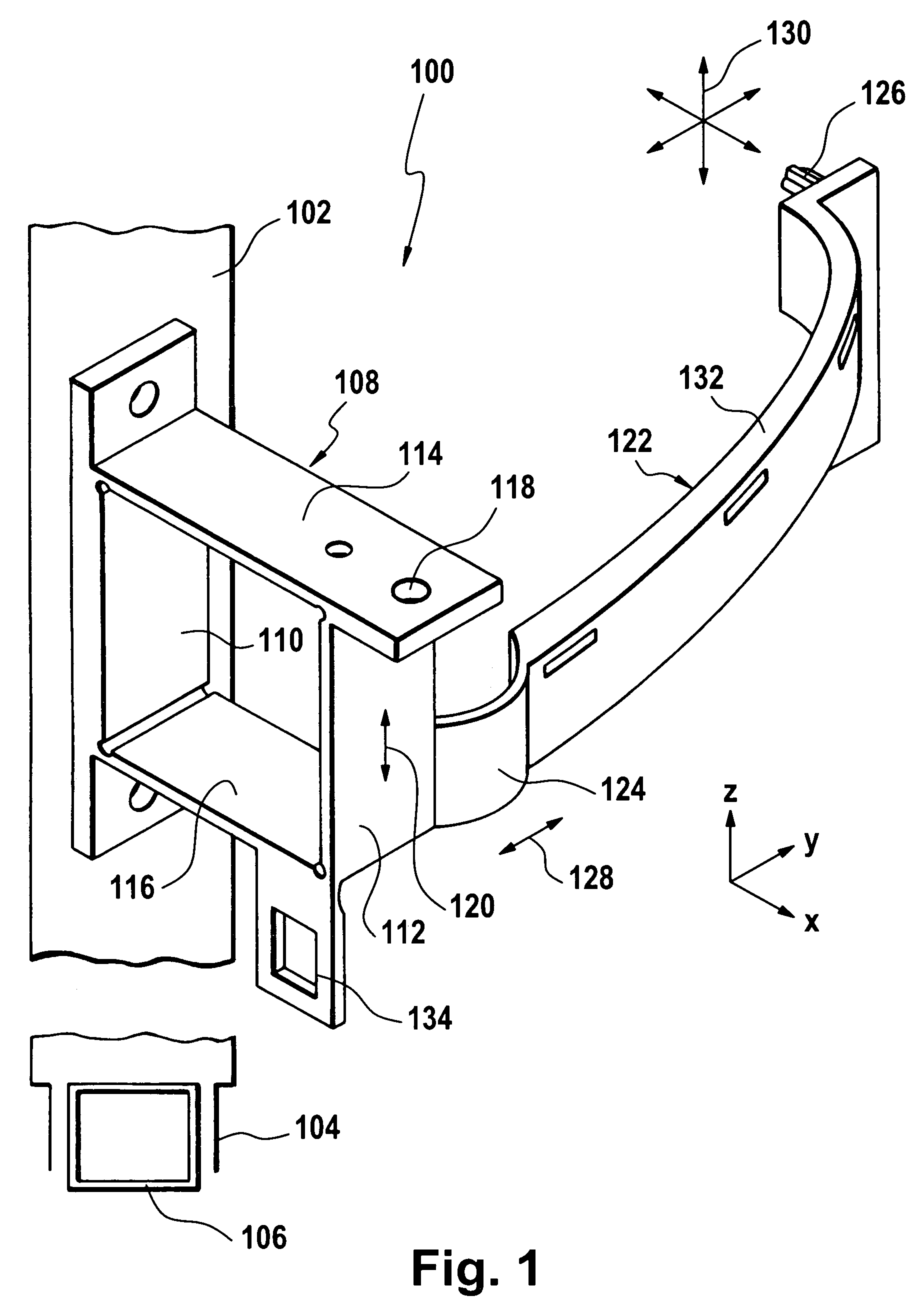

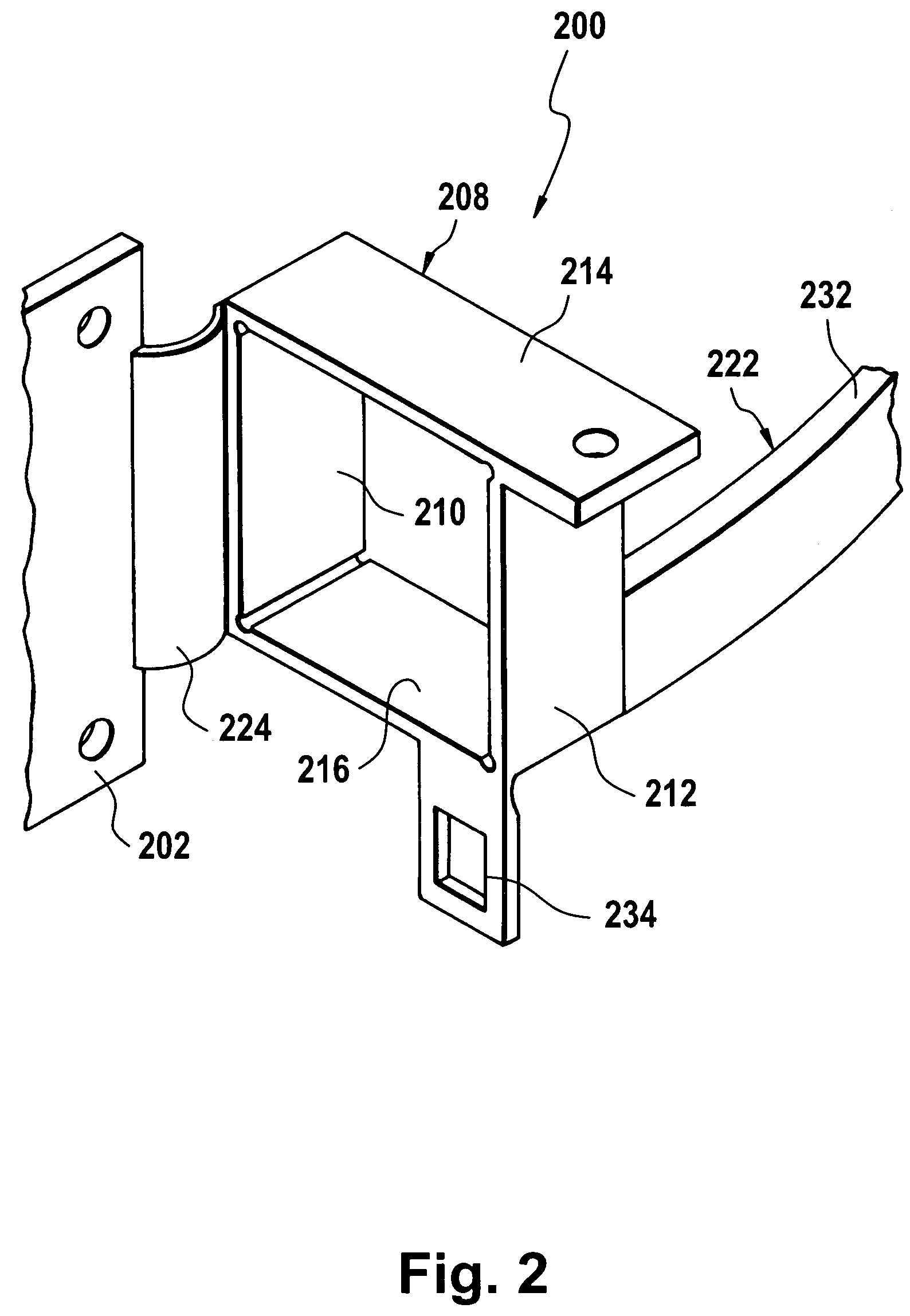

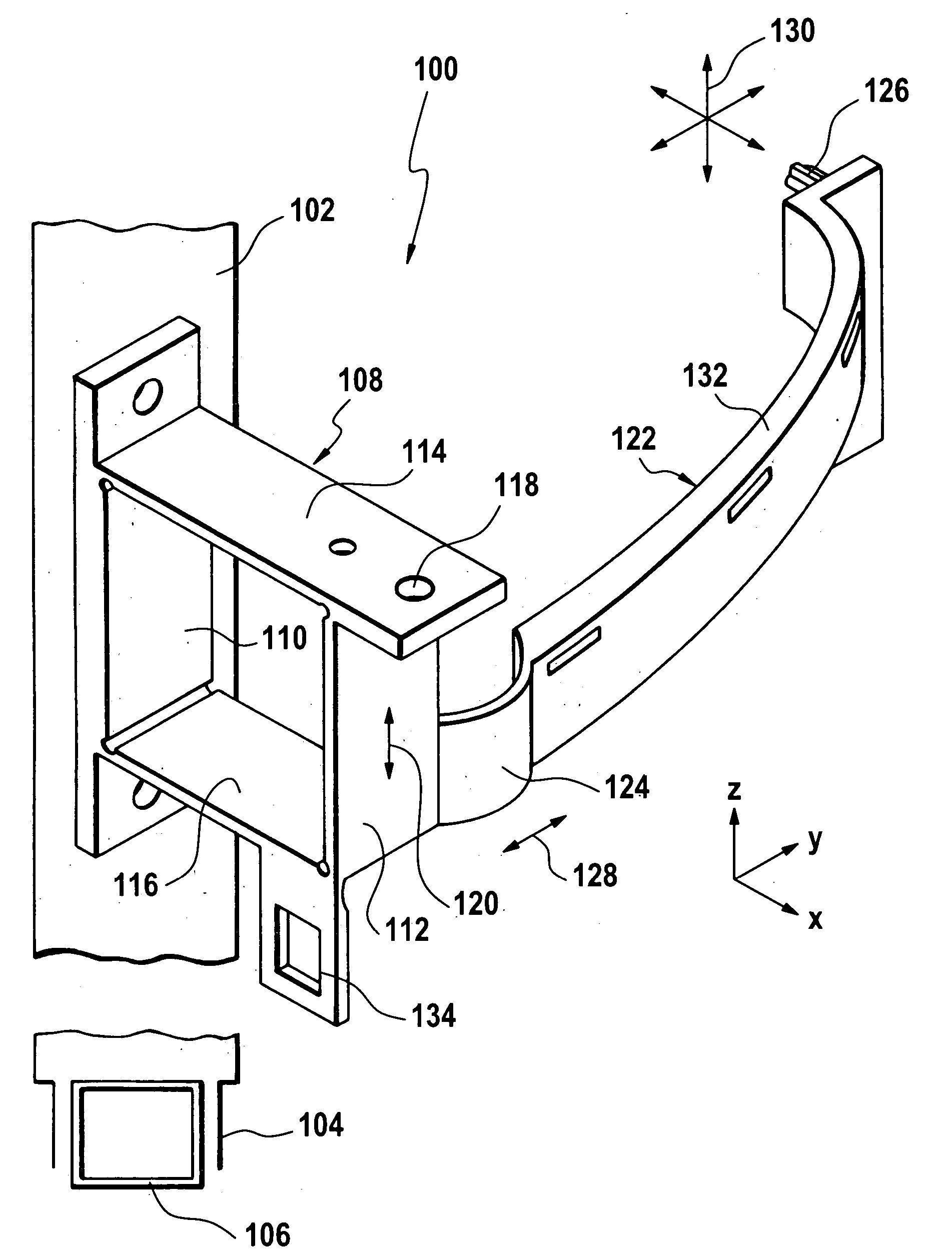

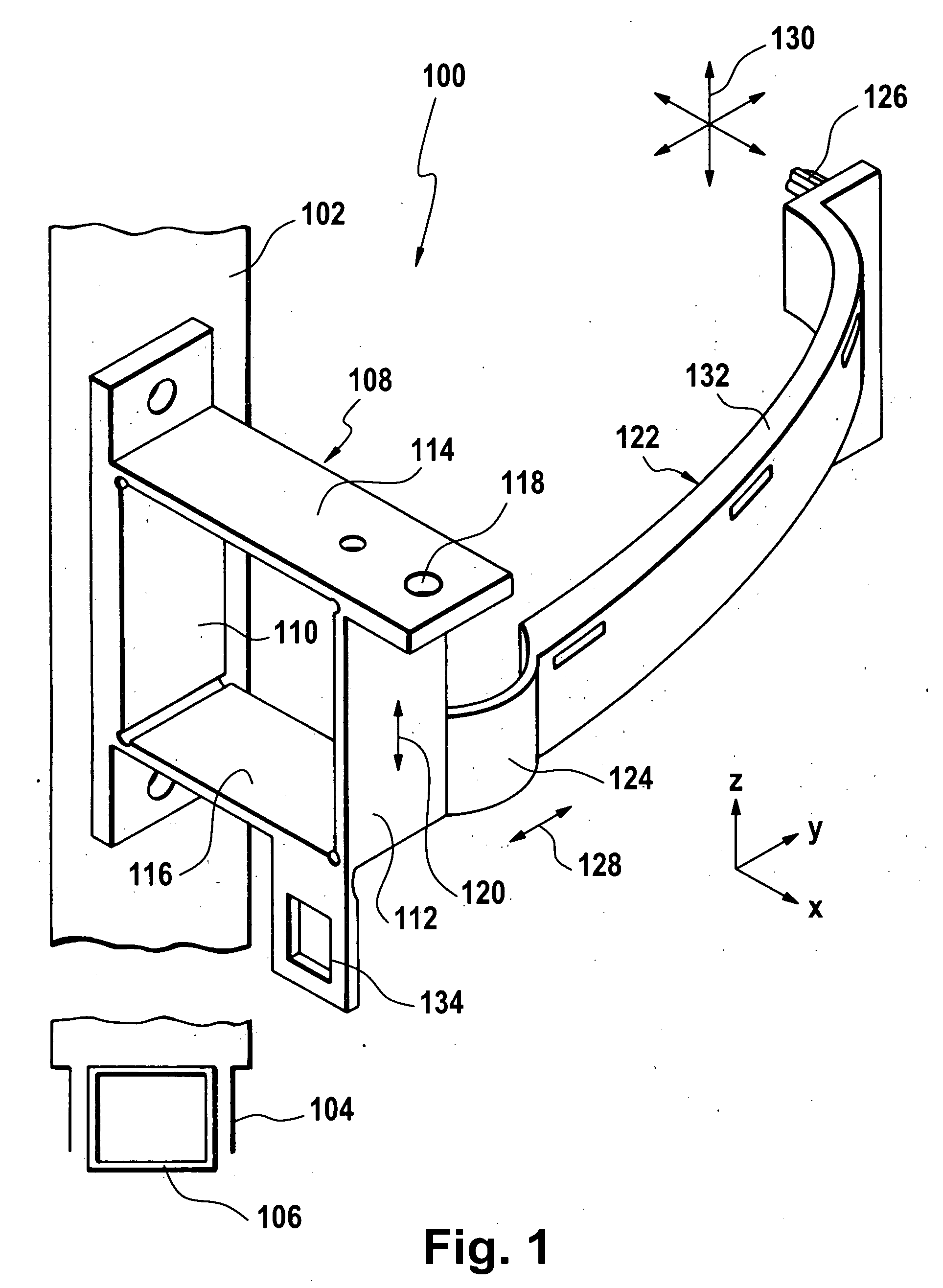

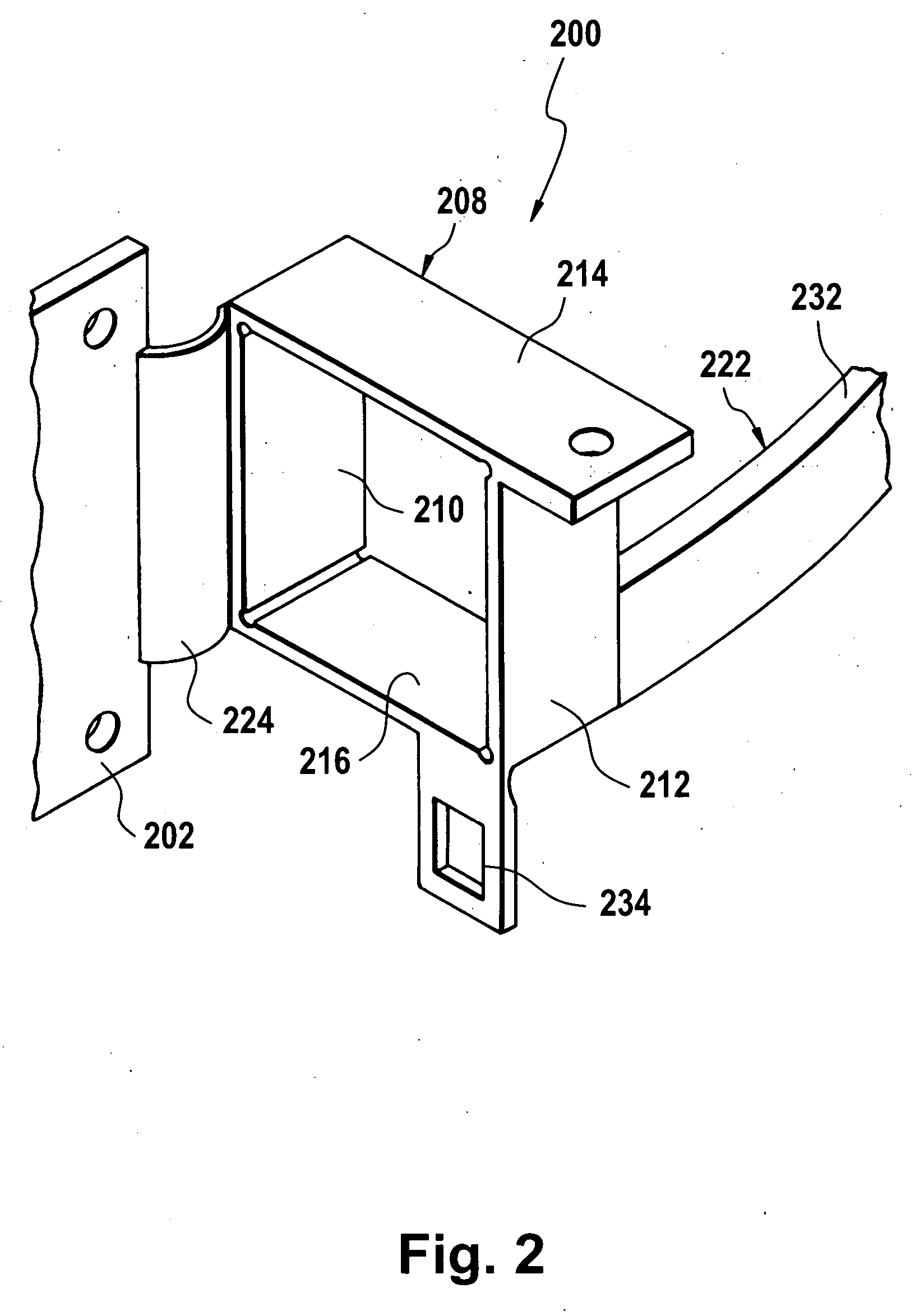

Support for the front module of a motor vehicle and assembly method

ActiveUS7410209B2Optimal Assembly MethodHigh-quality joint patternVehicle seatsSuperstructure subunitsMobile vehicleMotor vehicle part

Owner:FAURECIA KUNSTSTOFFE AUTOMOBILSYSTEME GMBH

Mouse structure

InactiveUS20050083302A1Improved mouse structureConvenient ArrangementCathode-ray tube indicatorsInput/output processes for data processingEngineeringMechanical engineering

Owner:CHEN CLIFF

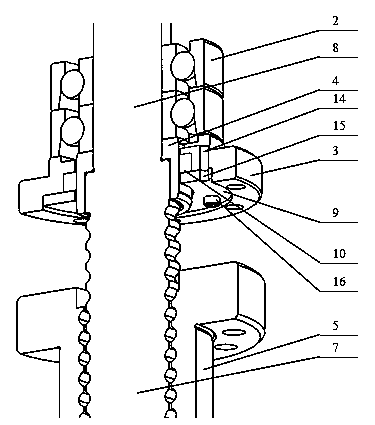

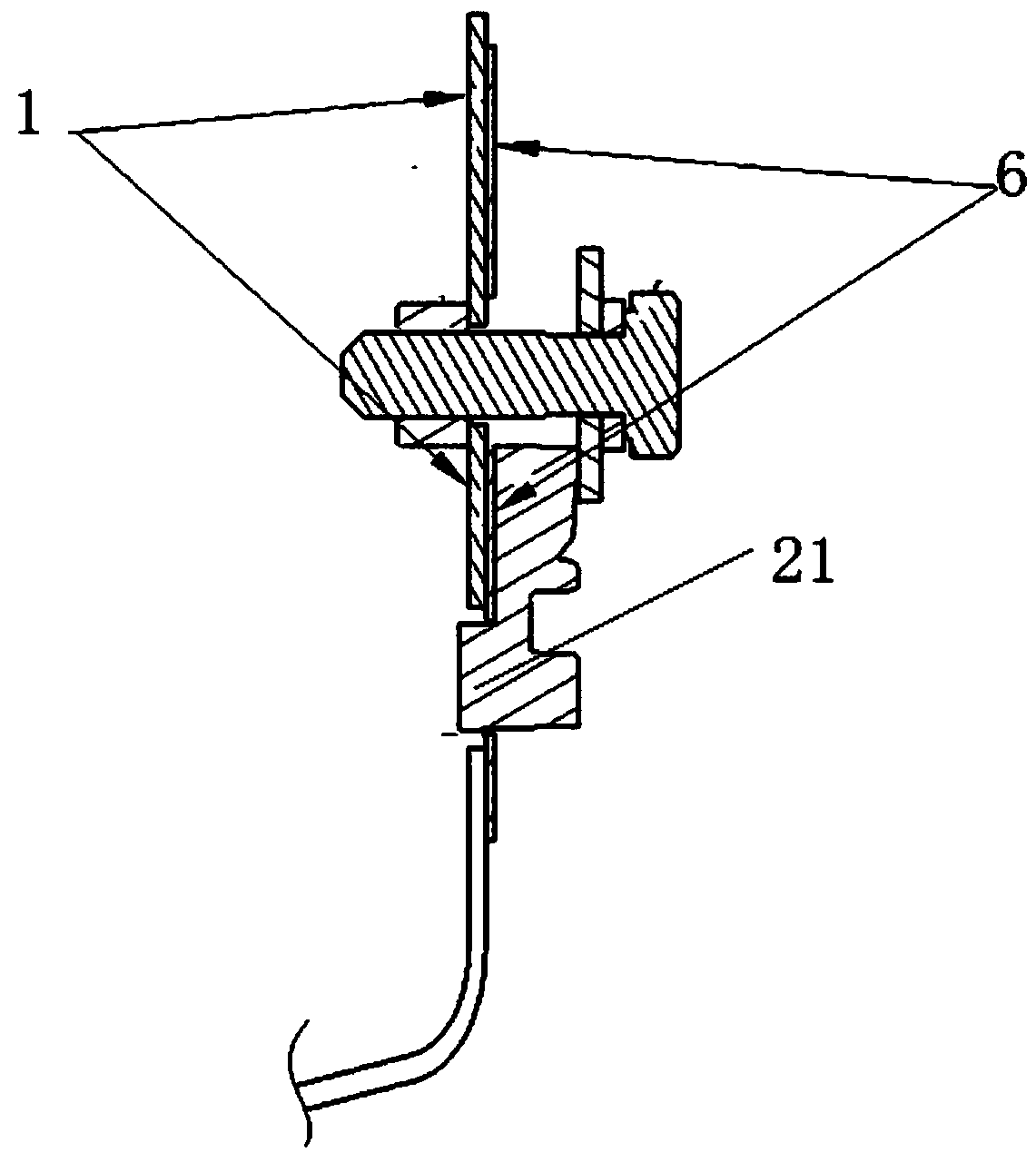

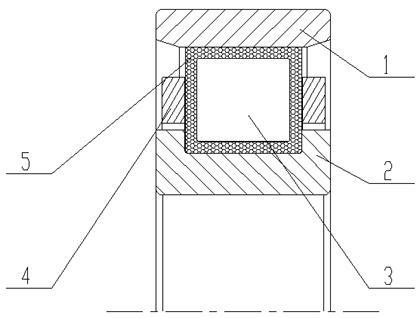

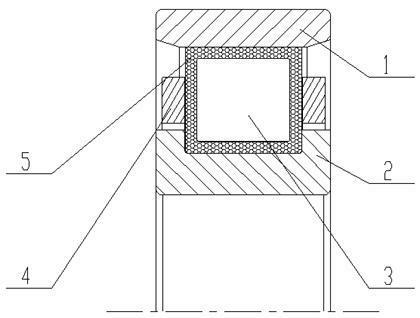

Method for assembling screw rod and rolling bearing assembly

InactiveCN104029001AGuaranteed levelGuaranteed coaxialityRolling contact bearingsMetal working apparatusBall screwEngineering

The invention discloses a method for assembling a screw rod and rolling bearing assembly. The method comprises the steps of mounting a screw rod flange, mounting a rolling bearing, mounting a screw rod fixing sleeve, fixing a screw rod flange and the screw rod fixing sleeve and finally obtaining the assembled screw rod and rolling bearing assembly. The method is simple, convenient and easy to achieve, and the assembled screw rod and rolling bearing assembly is tight, firm and clean. The parallelism between the screw rod and a working table linear guide rail in the horizontal and vertical directions, the coaxiality between a bearing seat and a ball nut and the rotating precision of a ball screw are guaranteed, namely, radial runout precision and axial float precision are guaranteed, continuous lubrication can be achieved, leakage of lubricating oil inside is avoided, external dust is prevented from entering the assembly, and long-term stable work of parts is facilitated.

Owner:ZHEJIANG UNIV

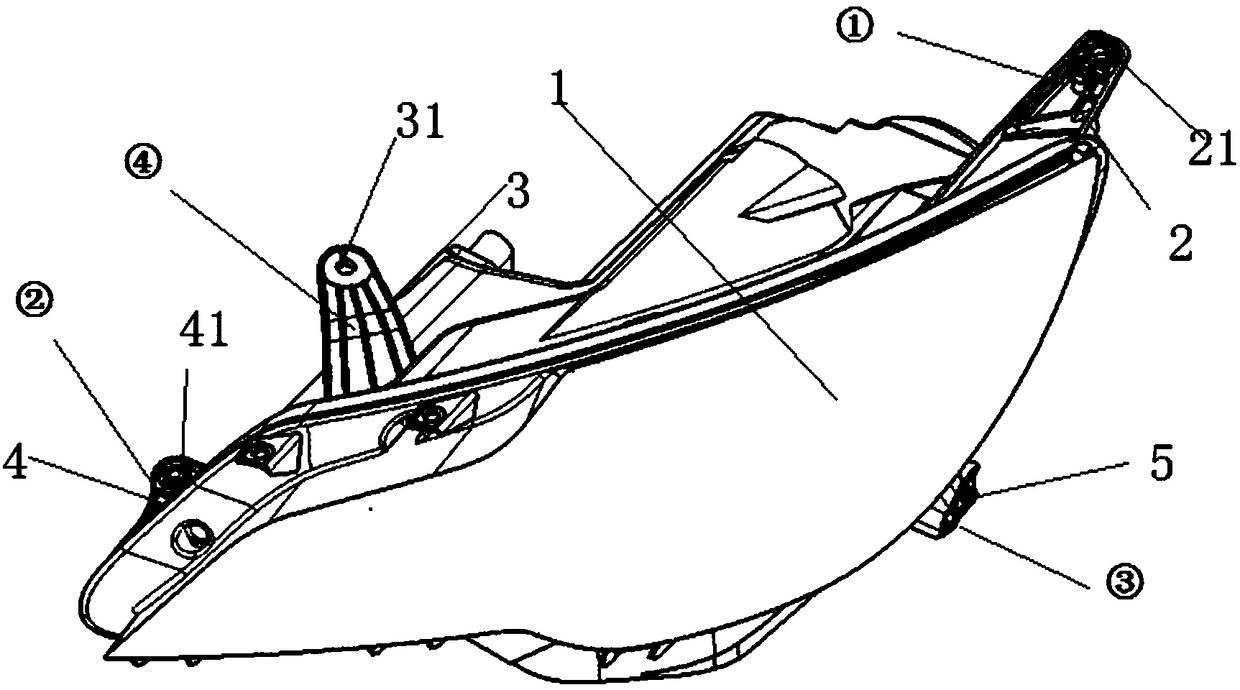

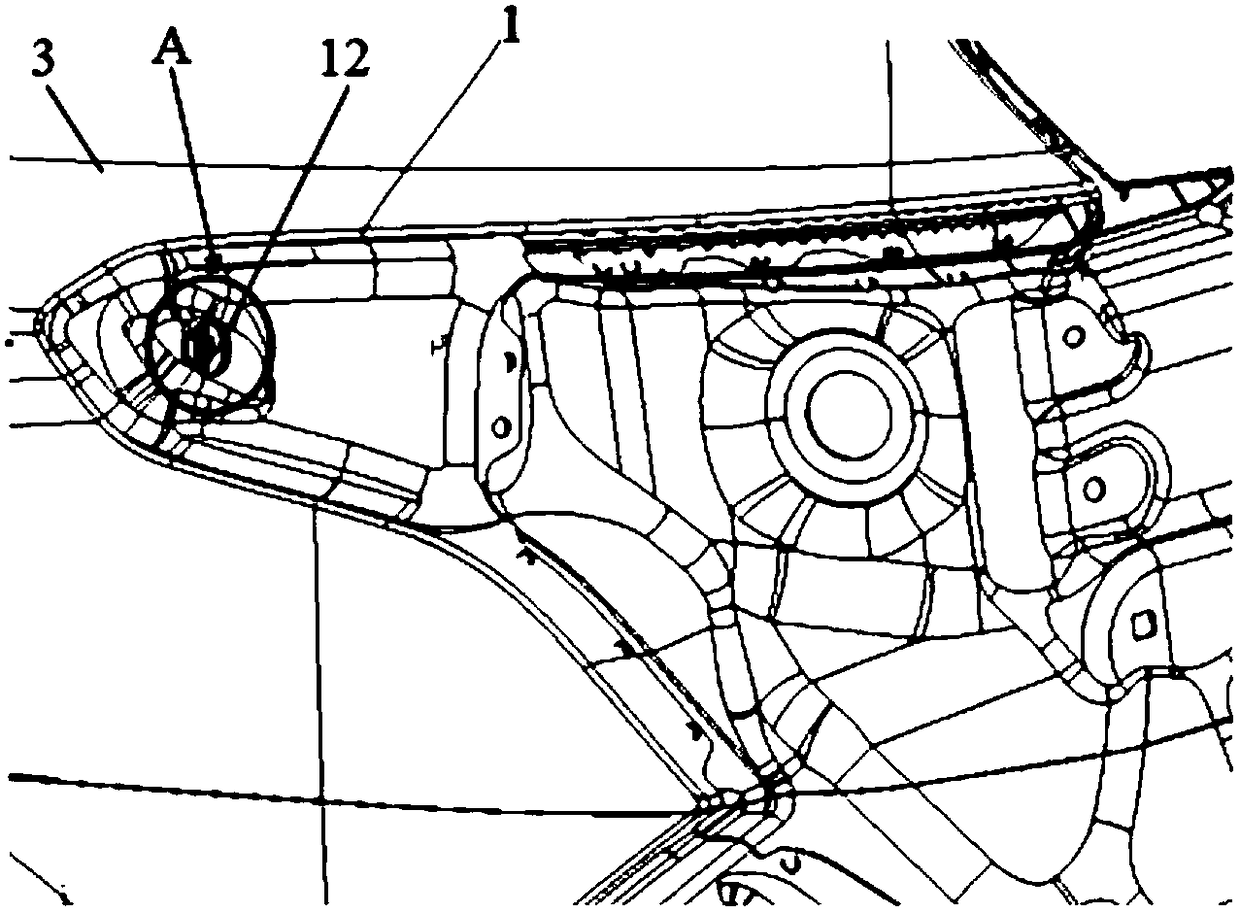

Automotive headlight fixing structure and headlight assembling method based on same

ActiveCN108116303ARealize the fastening of the connectionLimited rotational freedomOptical signallingAssembly lineLight fixture

The invention relates to the field of automotive lamps, particularly to an automotive headlight fixing structure and a headlight assembling method based on the same. The automotive headlight fixing structure comprises a headlight body, which is provided with a fixing unit for fixing a headlight onto a vehicle body; the fixing unit is composed of a main positioning unit, an auxiliary positioning unit and an auxiliary fixing unit, wherein the main positioning unit is composed of a first positioning unit for connecting a wheel fender and a second positioning unit for connecting a headlight lowersupport, and the auxiliary positioning unit comprises a third positioning unit for connecting the headlight body and a headlight beam. The automotive headlight fixing structure and the headlight assembling method based on the same can well meet visual requirements on the headlight as well as the sensory quality demands of customers, optimize assembling methods, and on the basis of thoroughly ensuring the matched state of the headlight and surrounding parts, improve the assembling efficiency of an assembly line and greatly save the assembling time.

Owner:CHERY COMML VEHICLE ANHUI

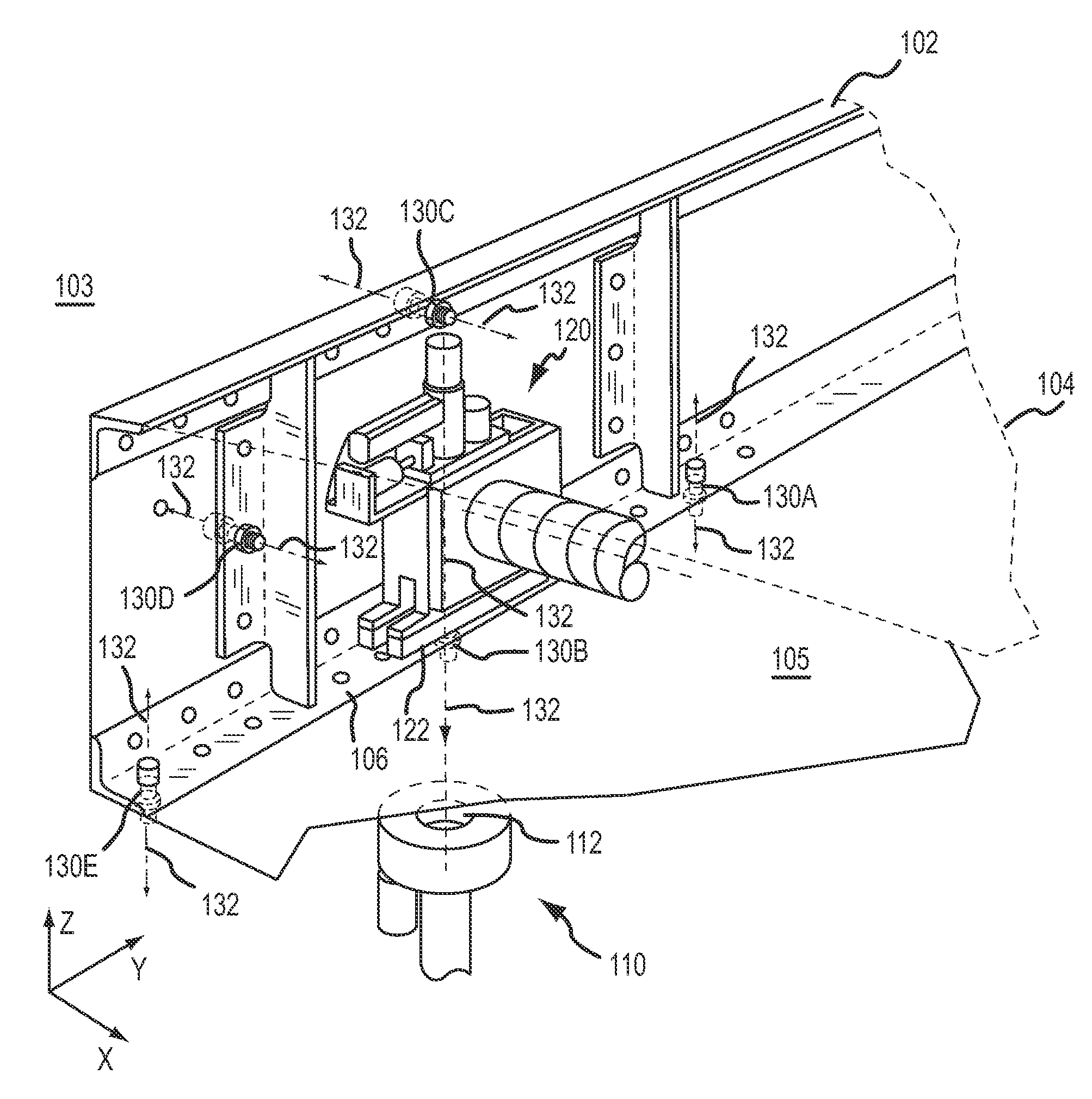

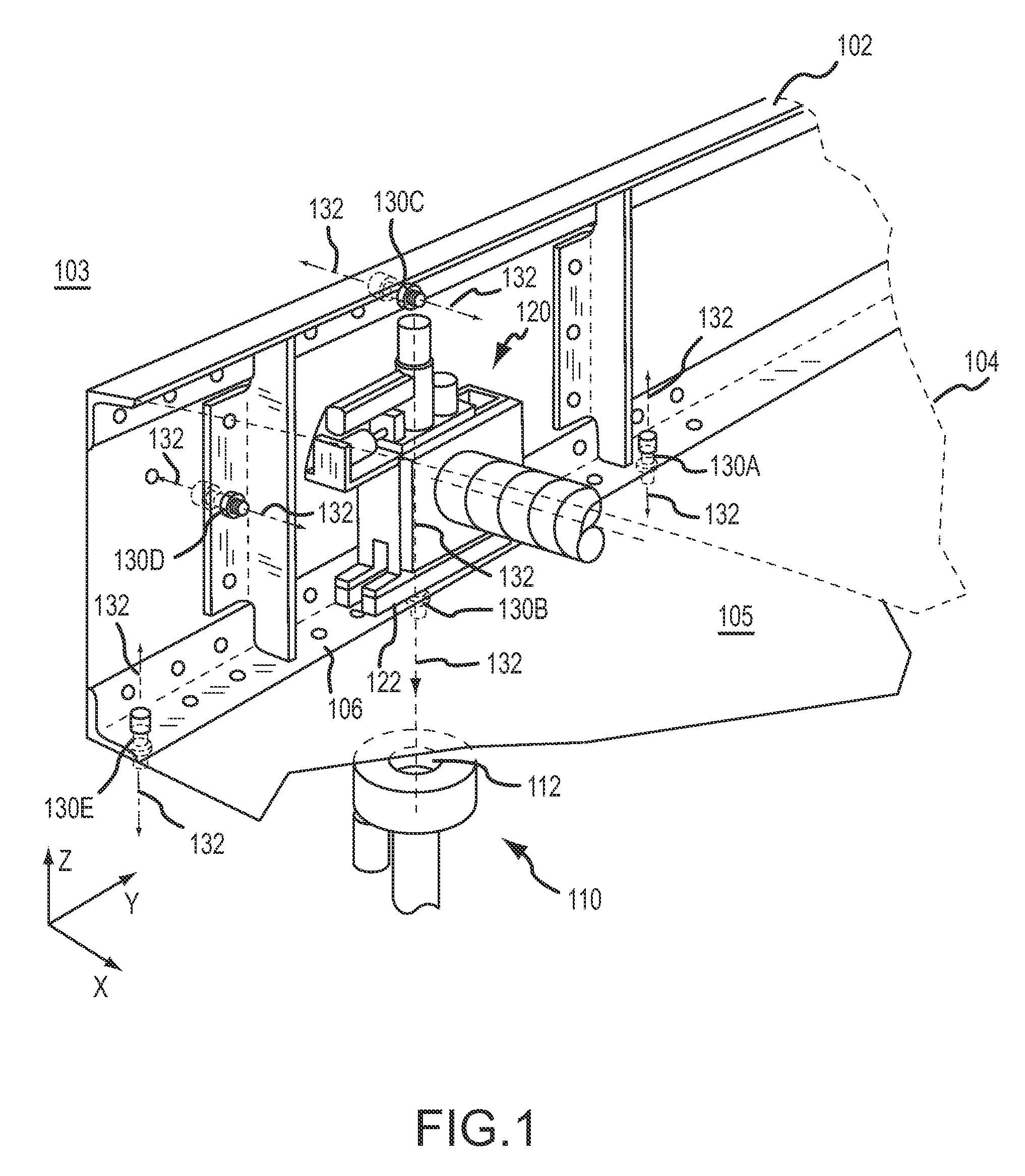

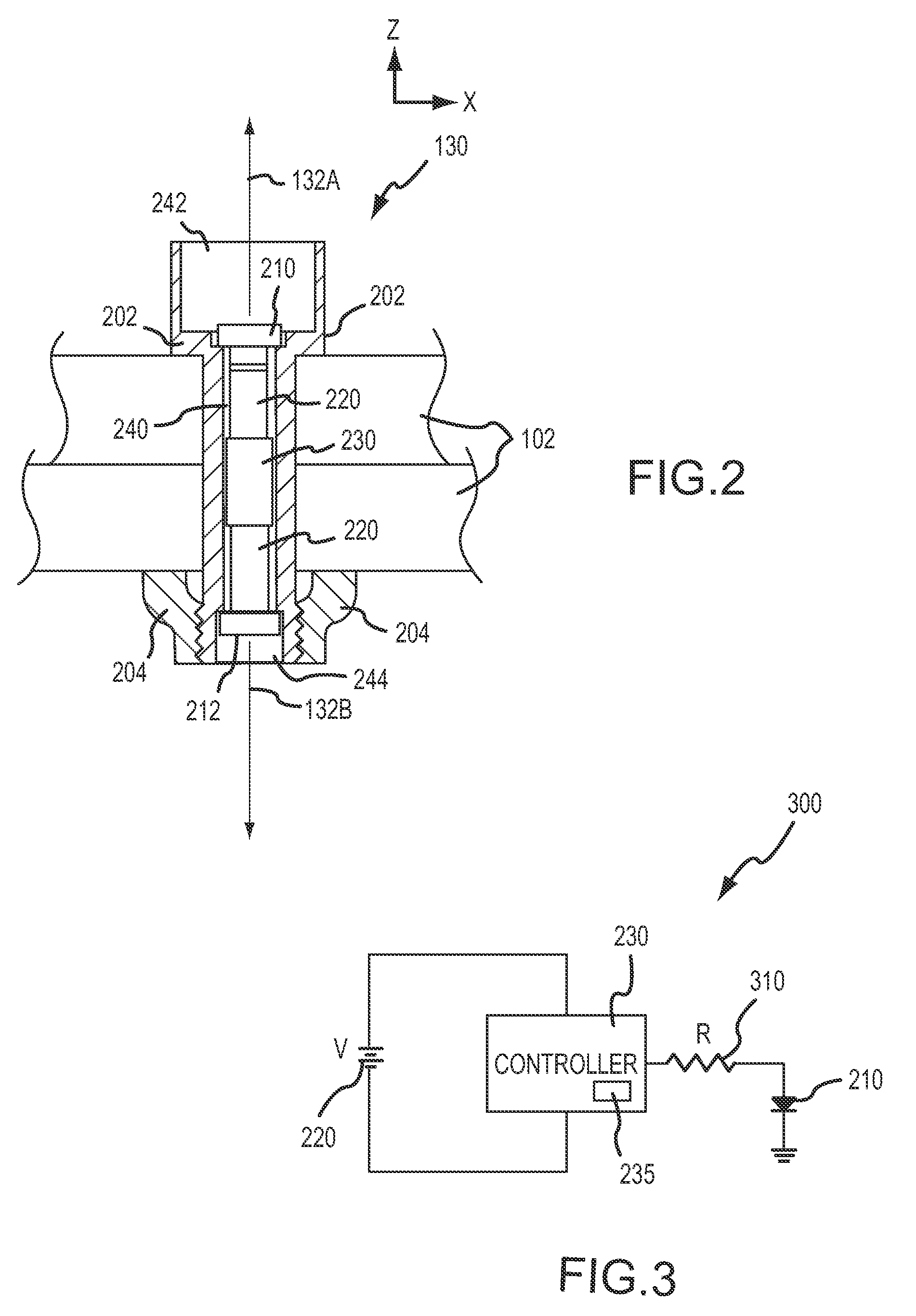

Methods and apparatus for an instrumented fastener

ActiveUS20080295314A1Optimal Assembly MethodProgramme controlOptical rangefindersEngineeringLight-emitting diode

An instrumented fastener (e.g., a “tack” fastener) includes one or more light sources (e.g., light-emitting diodes) configured to produce a light beacon that includes encoded information regarding the instrumented fastener (e.g., part number), wherein the direction of the light beacon can be used to align external and / or internal assembly systems to the instrumented fasteners. The light beacon may be activated automatically, or via an instruction received from an external system. Once aligned, the assembly system may, for example, proceed with installing permanent fasteners between neighboring tack fasteners.

Owner:THE BOEING CO

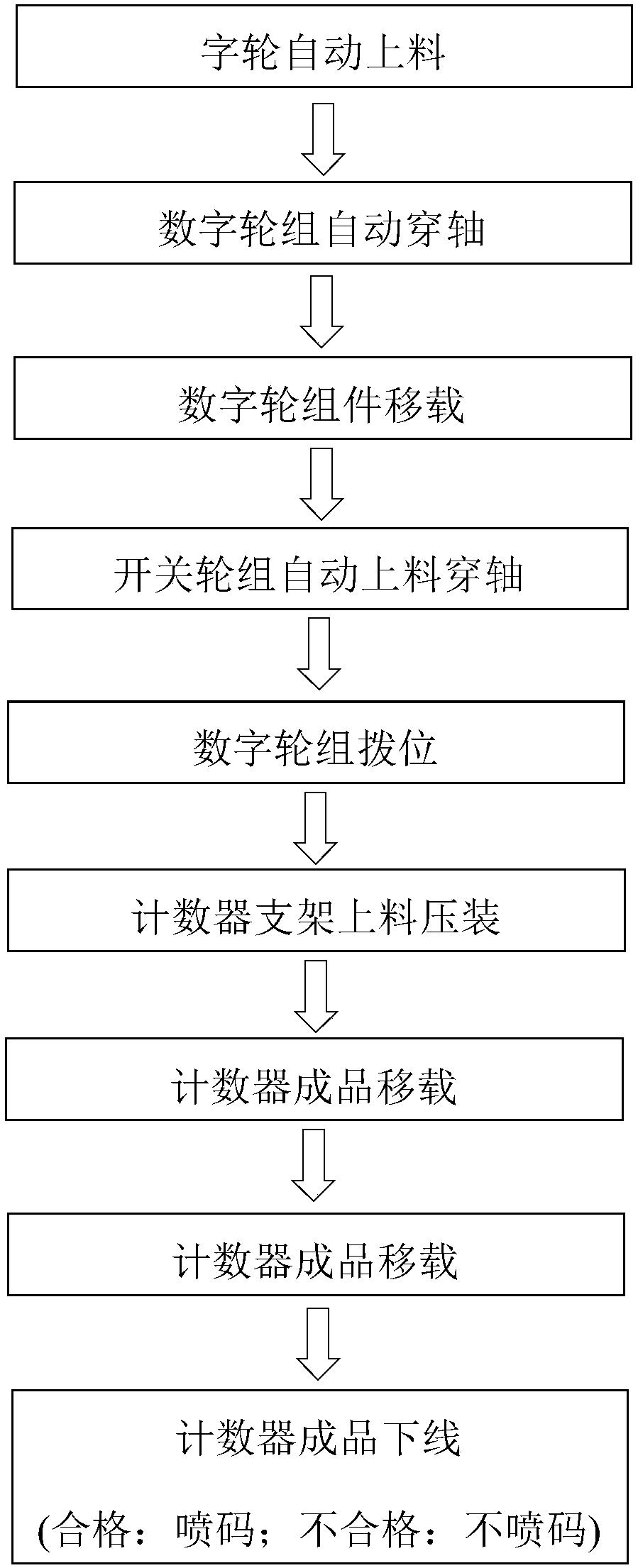

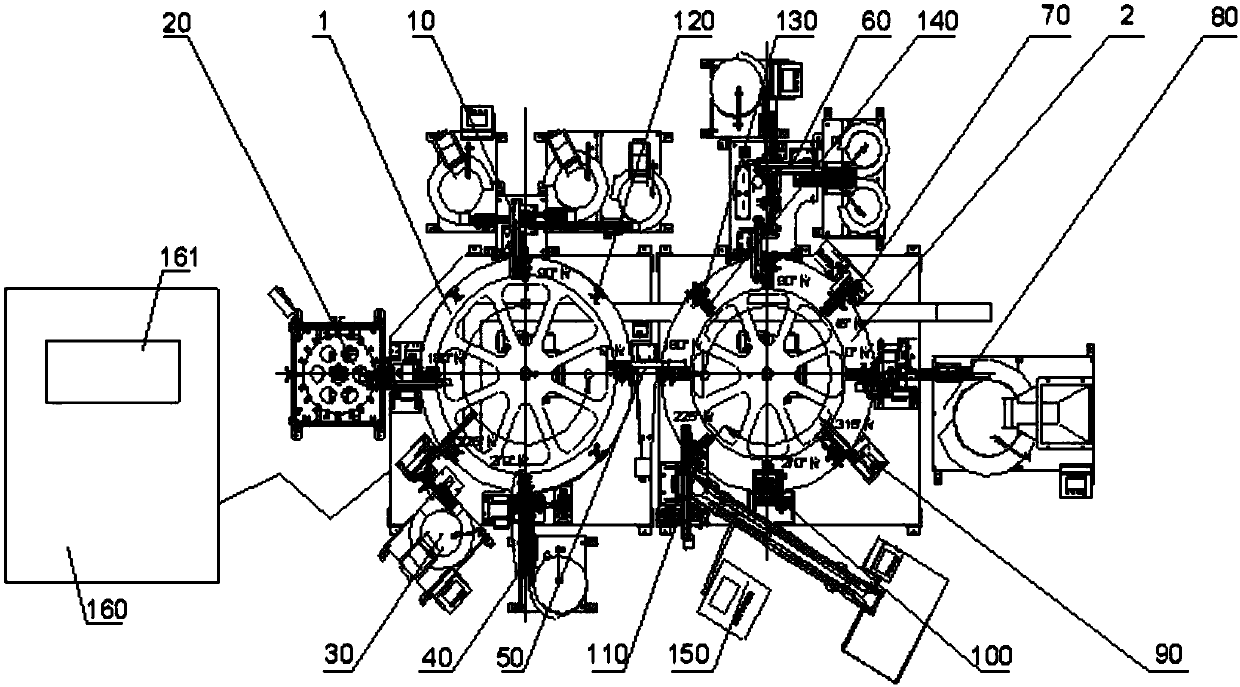

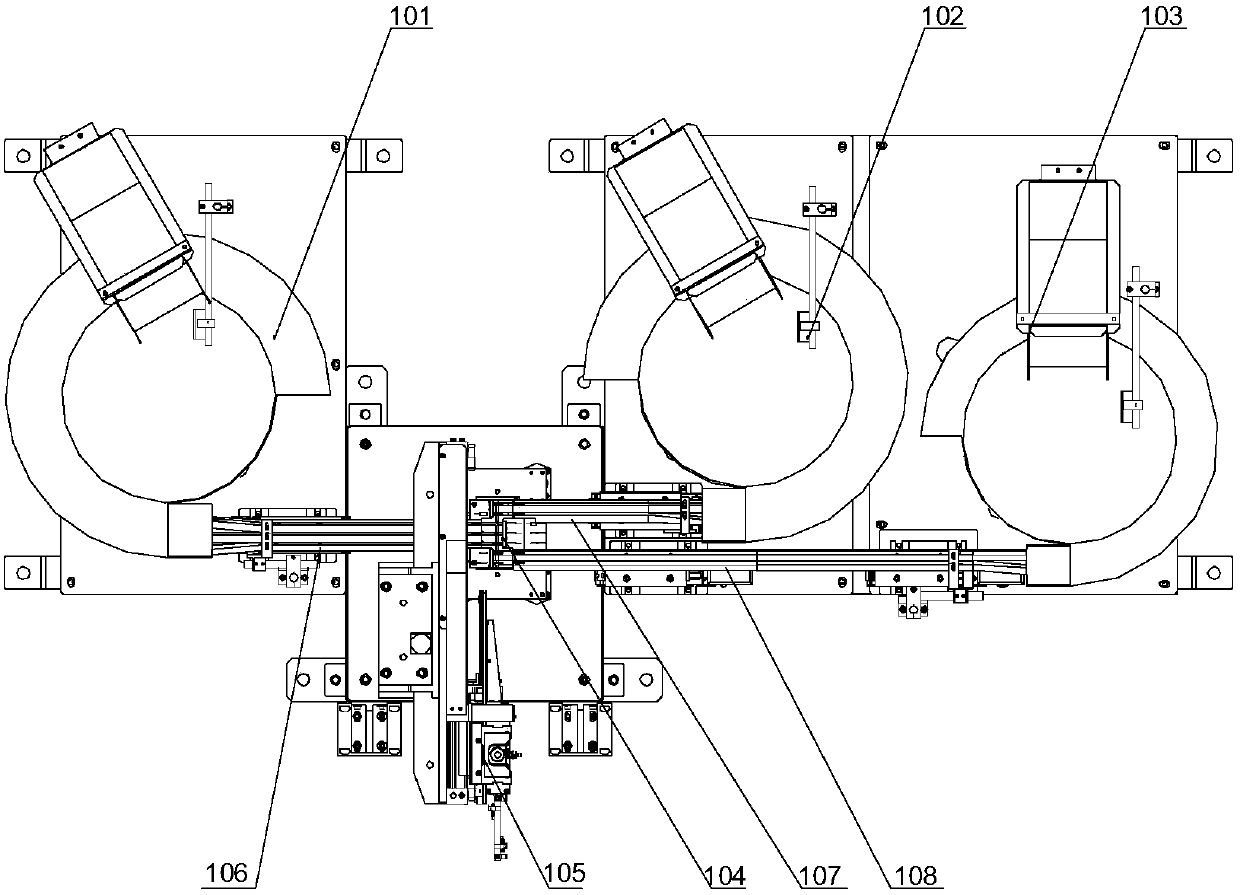

Fully-automatic assembly equipment and method for mechanical digital counter of meter

ActiveCN108044333AOptimal Assembly MethodSave assembly timeMetal working apparatusAutomatic test equipmentTerra firma

The invention discloses fully-automatic assembly equipment and method for a mechanical digital counter of a meter. Effective optimization for an assembly method is carried out on the basis of the existing manual assembly procedures and steps, so that the assembly method is adaptive to fully-automatic assembly and production for a machine. The fully-automatic assembly equipment for the mechanical digital counter of the meter is formed through development of an automatic loading device for a digit wheel, an automatic loading device for a magnetic steel wheel, a loading device for a first-place character wheel, a shaft penetrating device for the digit wheel, a transferring device for the digit wheel, a shaft penetrating loading device for a switch wheel group, a shifting device for the digitwheel, and the like. The equipment provided by the invention is high in automation degree, greatly increases the assembly efficiency for the counter of the meter, ensures the consistency of product quality, lowers the production cost, and remarkably increases economic benefits. The equipment is provided with an Ethernet interface capable of being networked with an information-based system of a workshop to accept the control of an MES and other systems, so that a solid foundation is laid for establishment for a digitized manufacturing workshop for the mechanical digital counter of the meter.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

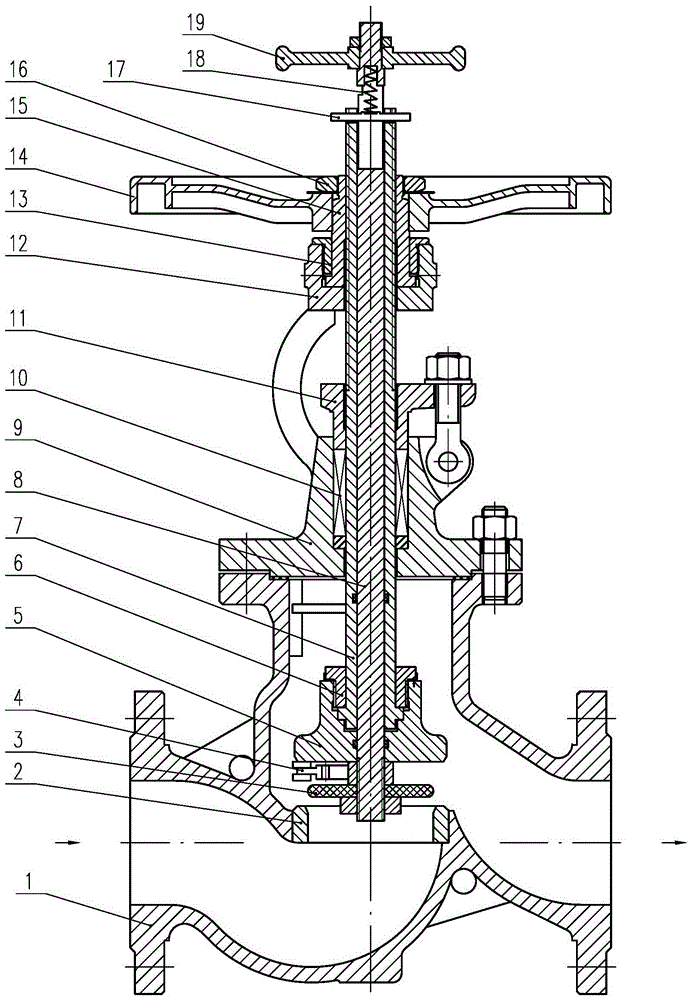

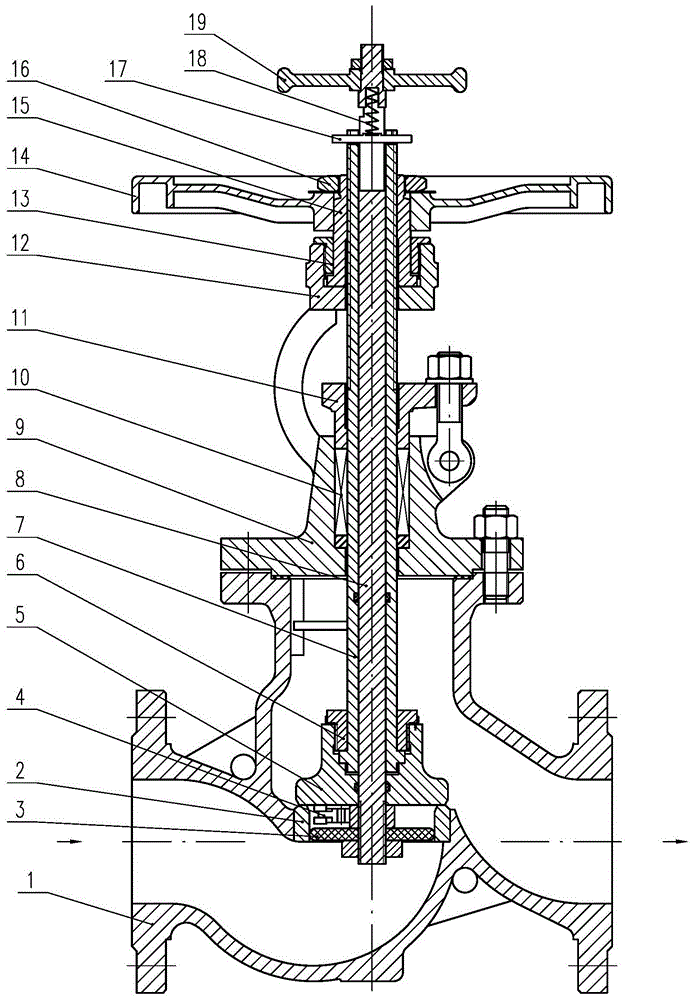

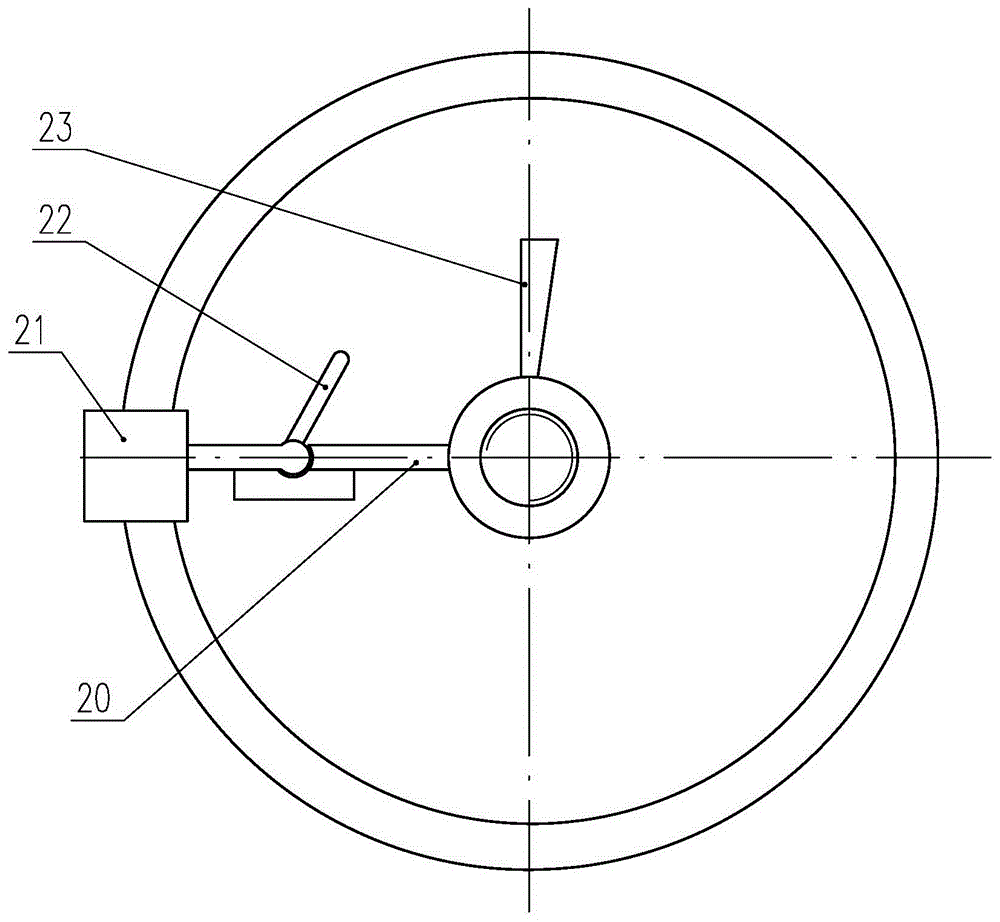

Using method of scraper stop valve

The invention relates to a using method of a scraper stop valve. The using method comprises the following steps: from an open state to a closed state, lifting a positioning pin till the two ends of the positioning pin are clamped into a concave seam allowance respectively, clockwise rotating a small hand wheel to drive an internal valve rod and a scraper assembly to rotate, outwardly moving a cutter head, and moving an upper scraper to a valve clack sealing surface; anticlockwise and outwardly rotating a big hand wheel to drive a valve clack, the scraper assembly, a plug head and other components to move downward till a lower scraper contacts a valve seat sealing surface, continuing rotating the small hand wheel for a round clockwise, then anticlockwise rotating the small hand wheel till the head of an inclined rod contacts a baffle block, continuing rotating the small hand wheel anticlockwise to drive the cutter head to move inward, moving the upper scraper and the lower scraper away from the valve clack sealing surface and the valve seat sealing surface respectively, and stopping rotating the small hand wheel; moving the positioning pin away from the concave seam allowance, moving downwardly, and clamping the two ends of the positioning pin into a clamping slot; continuing rotating the big hand wheel anticlockwise till the valve clack sealing surface presses against the valve seat sealing surface, and closing the valve. The using method of the scraper stop valve is simple; by the using method, wear of sealing surfaces is low and the service life of the scraper stop valve is prolonged.

Owner:李祥庆

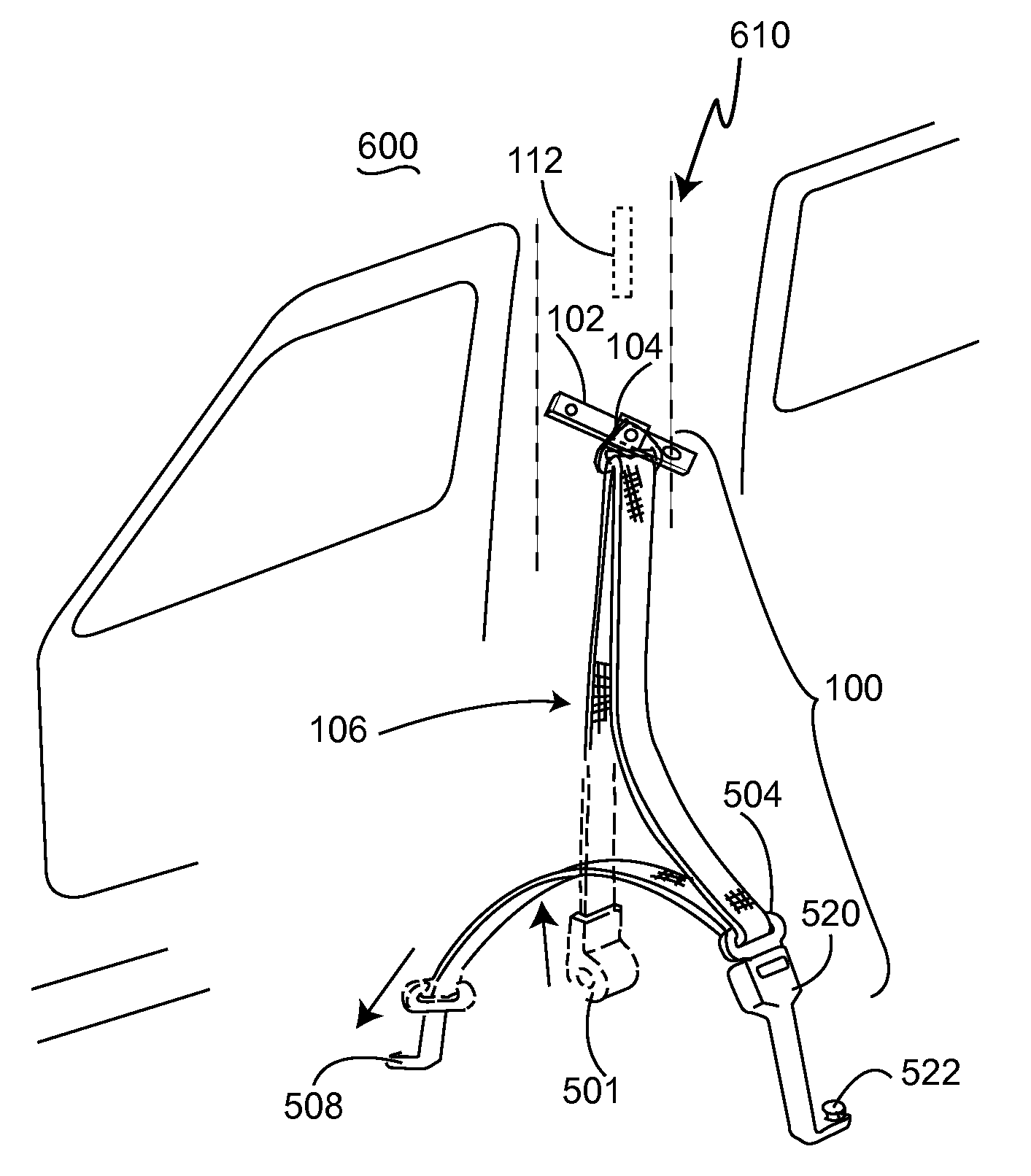

Seat Belt Assembly and Method of Installation

InactiveUS20070029773A1Improve methodImprove assemblyBelt control systemsMetal working apparatusSeat beltEngineering

A method of installing a seat belt system (100) into a passenger compartment of a vehicle, the system of the type including a seat belt retractor (501), a height adjuster (102) and a web guide (104), the method including the steps of: a) providing a height adjusting mechanism having a bar or track and a carrier; b) securing the web guide to the carrier so the height adjuster and web guide form a subassembly; c) locating and securing the retractor to a desired location within the vehicle and; d) lifting the subassembly and manipulating the height adjuster to a desired location in the vehicle and securing the height adjuster to the desired location, wherein the step of lifting the subassembly simultaneously locates the web guide to its desired location.

Owner:KEY SAFETY SYST

Support for the front module of a motor vehicle and assembly method

ActiveUS20060250899A1Optimal Assembly MethodHigh-quality joint patternSuperstructure subunitsTransmissionEngineeringMotorized vehicle

The invention relates to a support for a front module of a motor vehicle comprising a first support part for connection to a chassis of the motor vehicle and left and right brackets, wherein the left and right brackets are configured to receive a headlight unit and for connection to a bumper of the motor vehicle, respectively, wherein the left and right brackets with the left and right elastic elements are connected to the first support part, and comprising means for fixing the elastic elements relative to the chassis when the elastic elements have assumed an assembly position following elastic deformation.

Owner:FAURECIA KUNSTSTOFFE AUTOMOBILSYSTEME GMBH

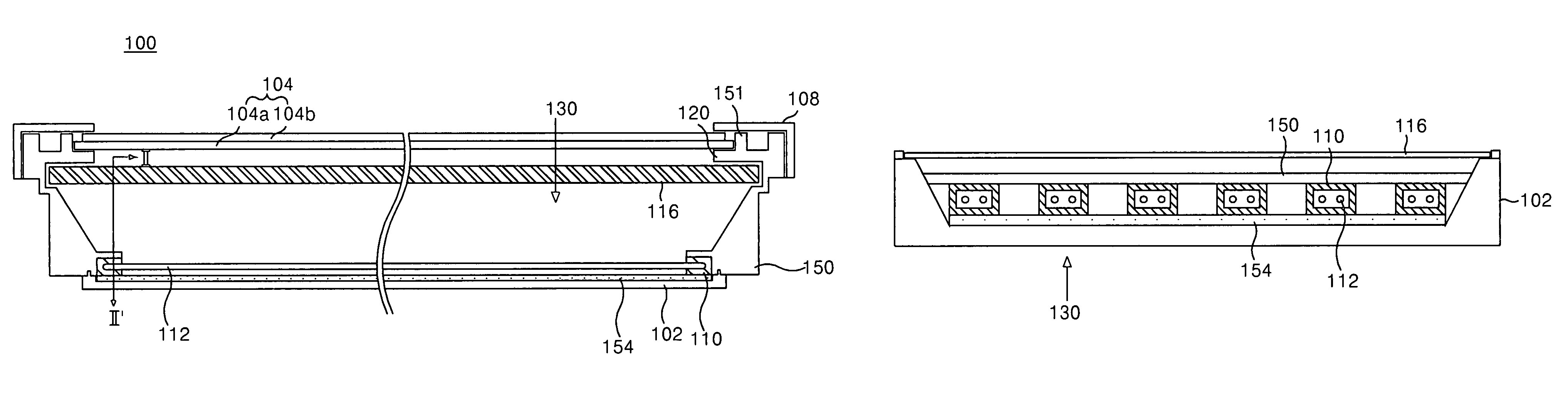

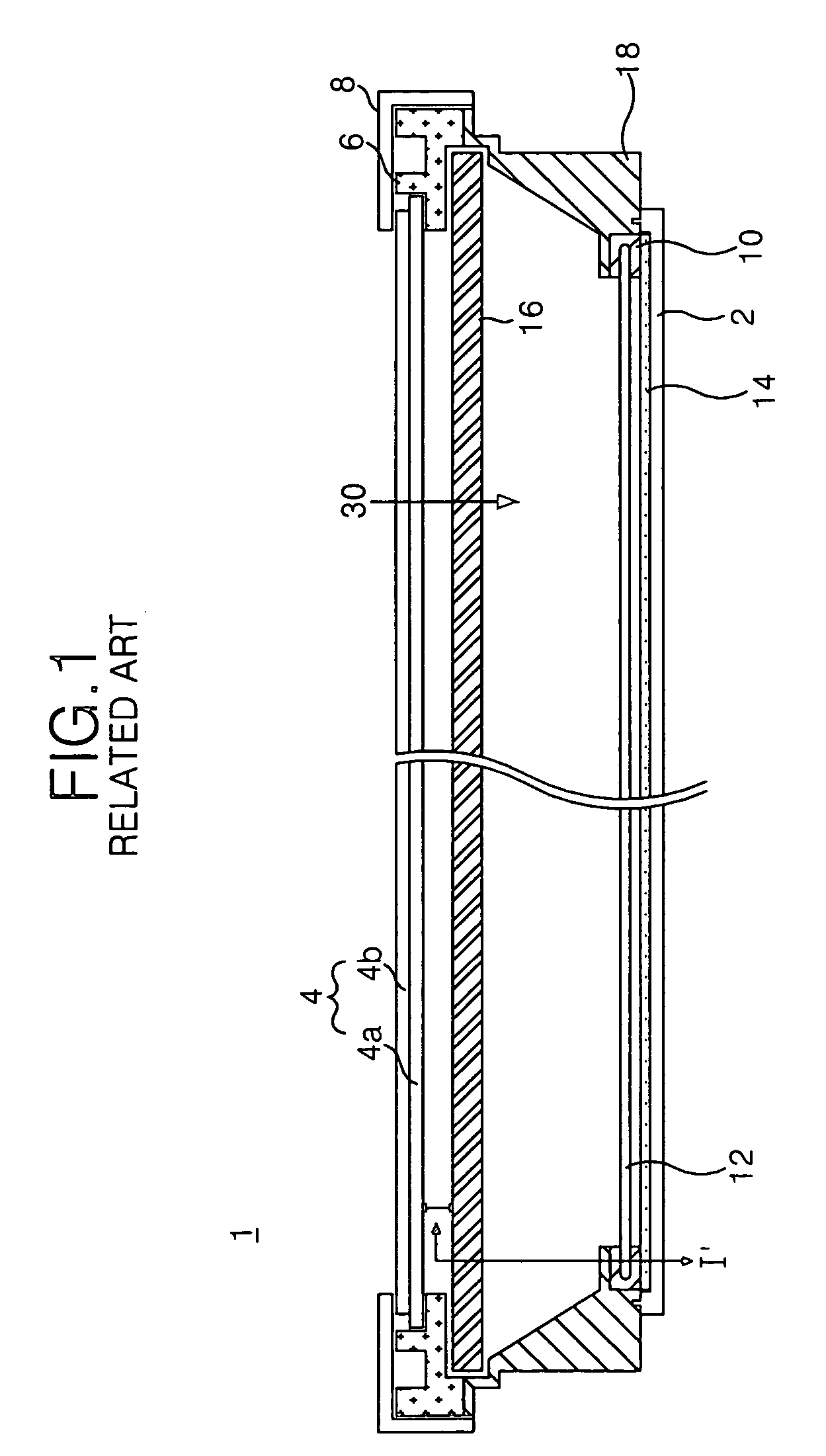

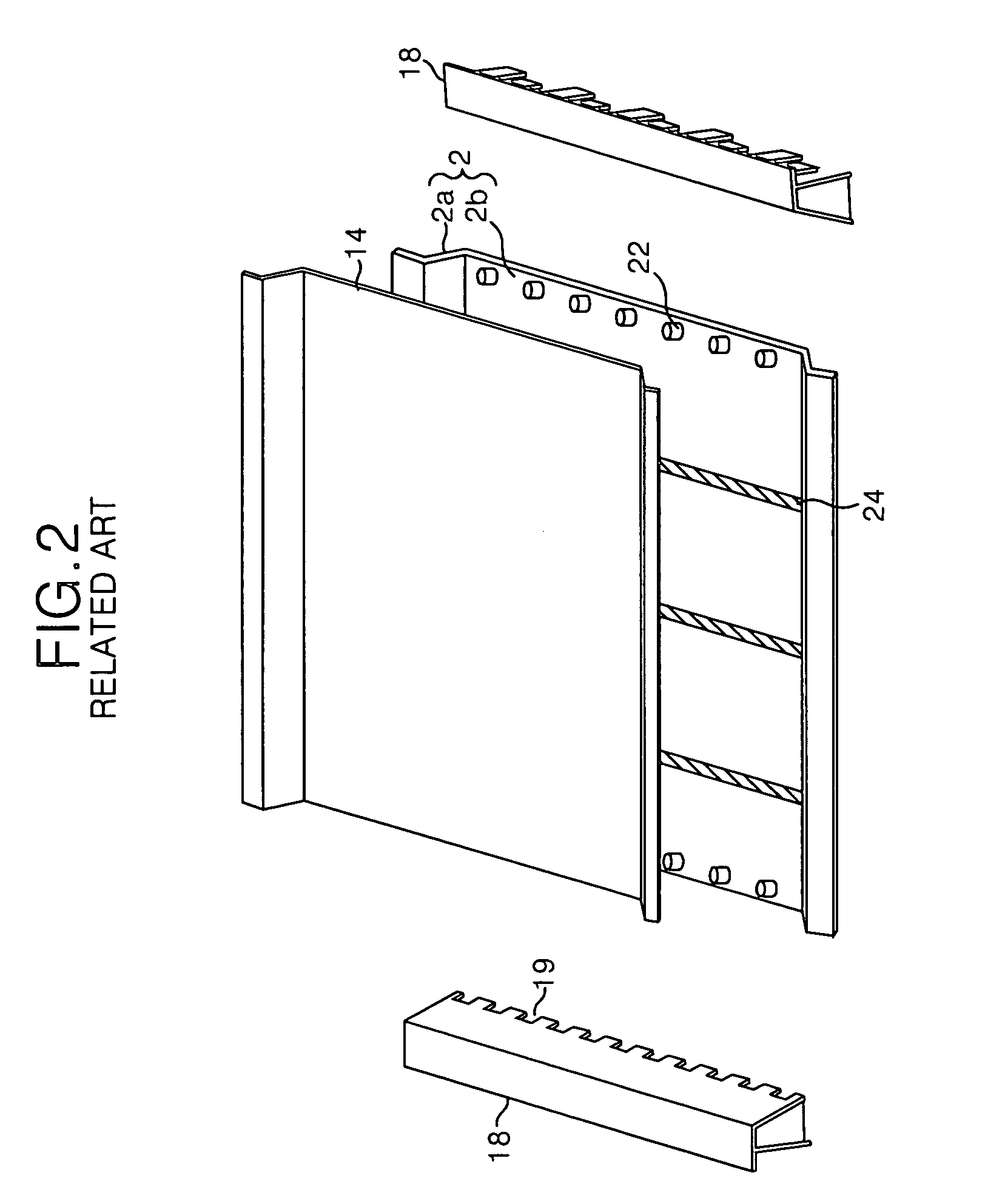

Liquid crystal display module and assembling method thereof

A liquid crystal display module includes a liquid crystal panel, a bottom cover having a plurality of lamps installed thereabove, a reflection sheet for reflecting the light generated from the lamps and a main support having openings in which the lamps are inserted, an extension part extending from the openings, and a supporting member for supporting the liquid crystal panel.

Owner:LG DISPLAY CO LTD

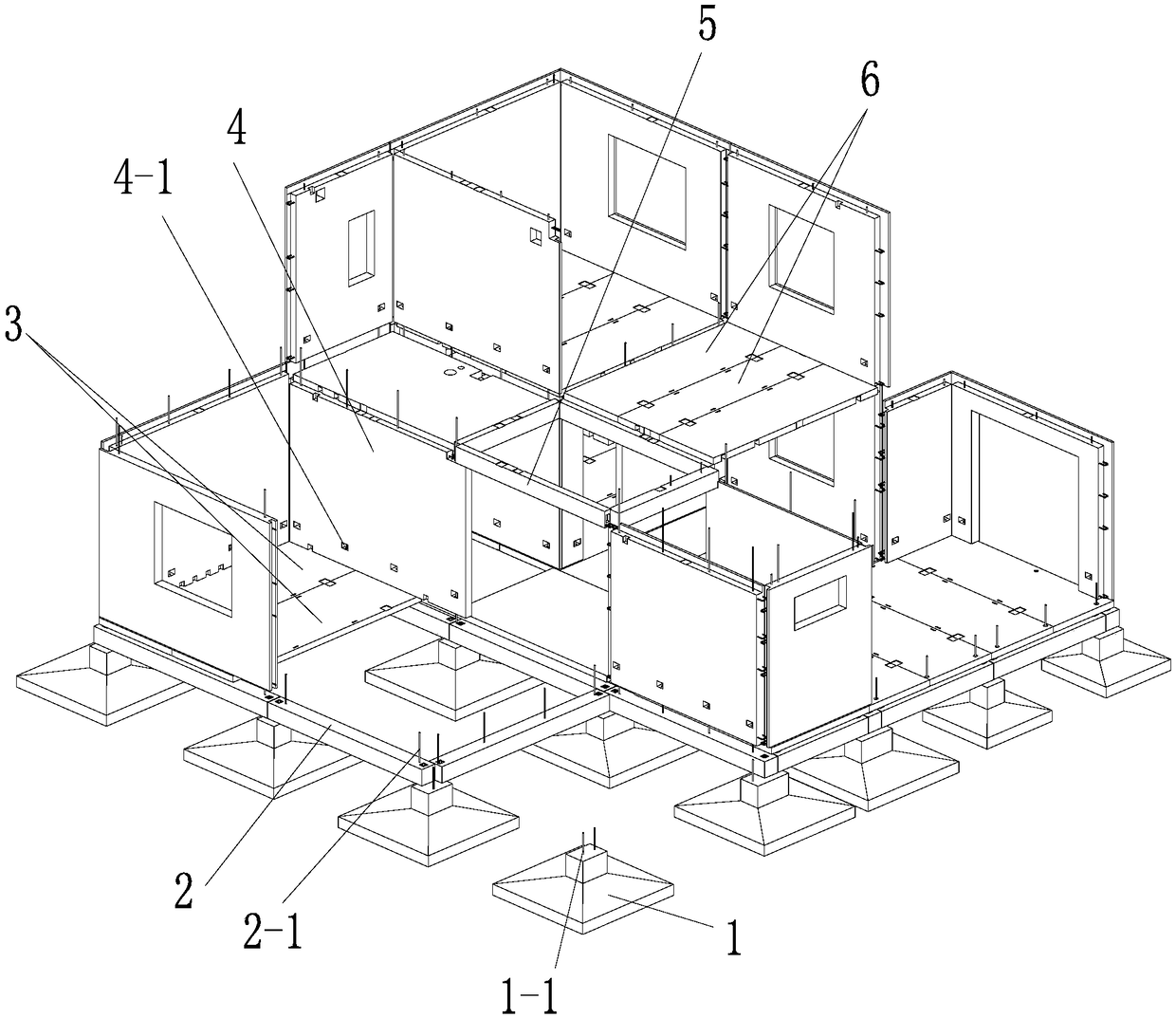

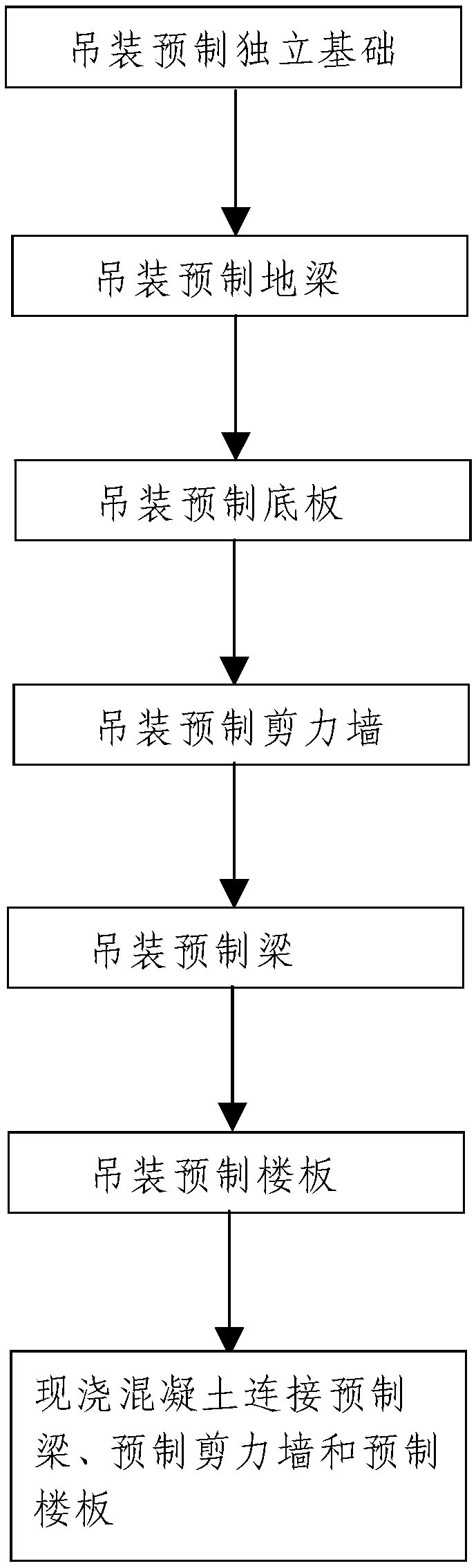

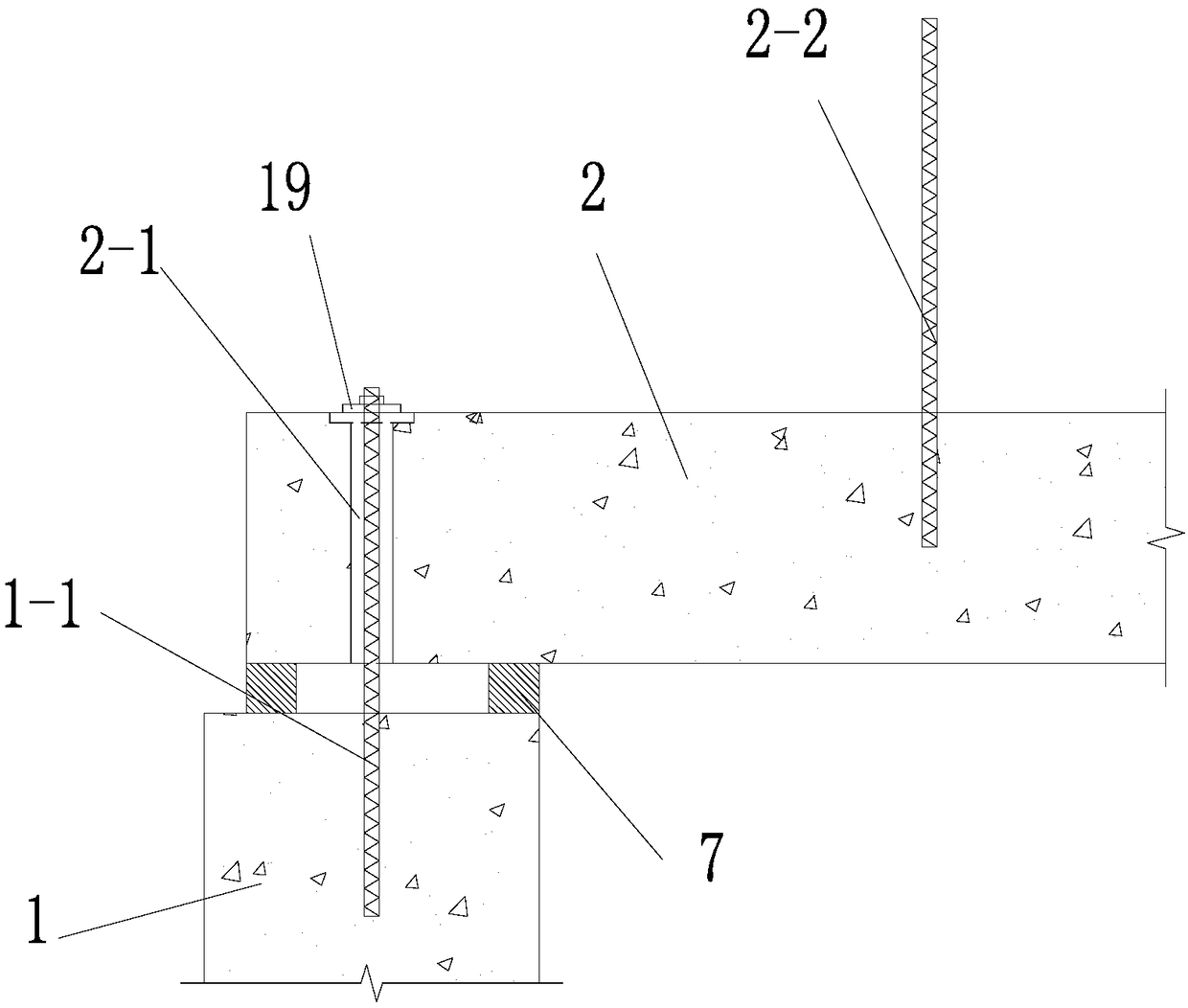

Construction method of low-rise fully-fabricated concrete shear wall structure system

ActiveCN108951870AImprove the level of construction industrializationImprove construction efficiencyBuilding constructionsFloor slabStructure system

The invention discloses a construction method of a low-rise fully-fabricated concrete shear wall structure system. The low-rise fully-fabricated concrete shear wall structure system comprises precastindependent foundations, precast ground beams mounted on the precast independent foundations, precast bottom plates mounted on the precast ground beams, precast shear walls vertically mounted on the precast bottom plates, precast beams and precast floor slabs laid on the precast shear walls and the precast beams. The construction method comprises the steps that firstly, the precast independent foundations are hoisted; secondly, the precast ground beams are hoisted; thirdly, the precast bottom plates are hoisted; fourthly, the precast shear walls are hoisted; fifthly, the precast beams are hoisted; sixthly, the precast floor slabs are hoisted; and seventhly, concrete is cast in situ to connect the precast beams, the precast shear walls and the precast floor slabs. According to the construction method of the low-rise fully-fabricated concrete shear wall structure system, the problems that an existing fabricated concrete structure is low in fabrication rate and large in site wet operationamount are solved, site construction mainly refers to site fabrication between precast structural members, connection is safe and reliable, and the construction efficiency can be greatly improved.

Owner:陕西建筑产业投资集团有限公司

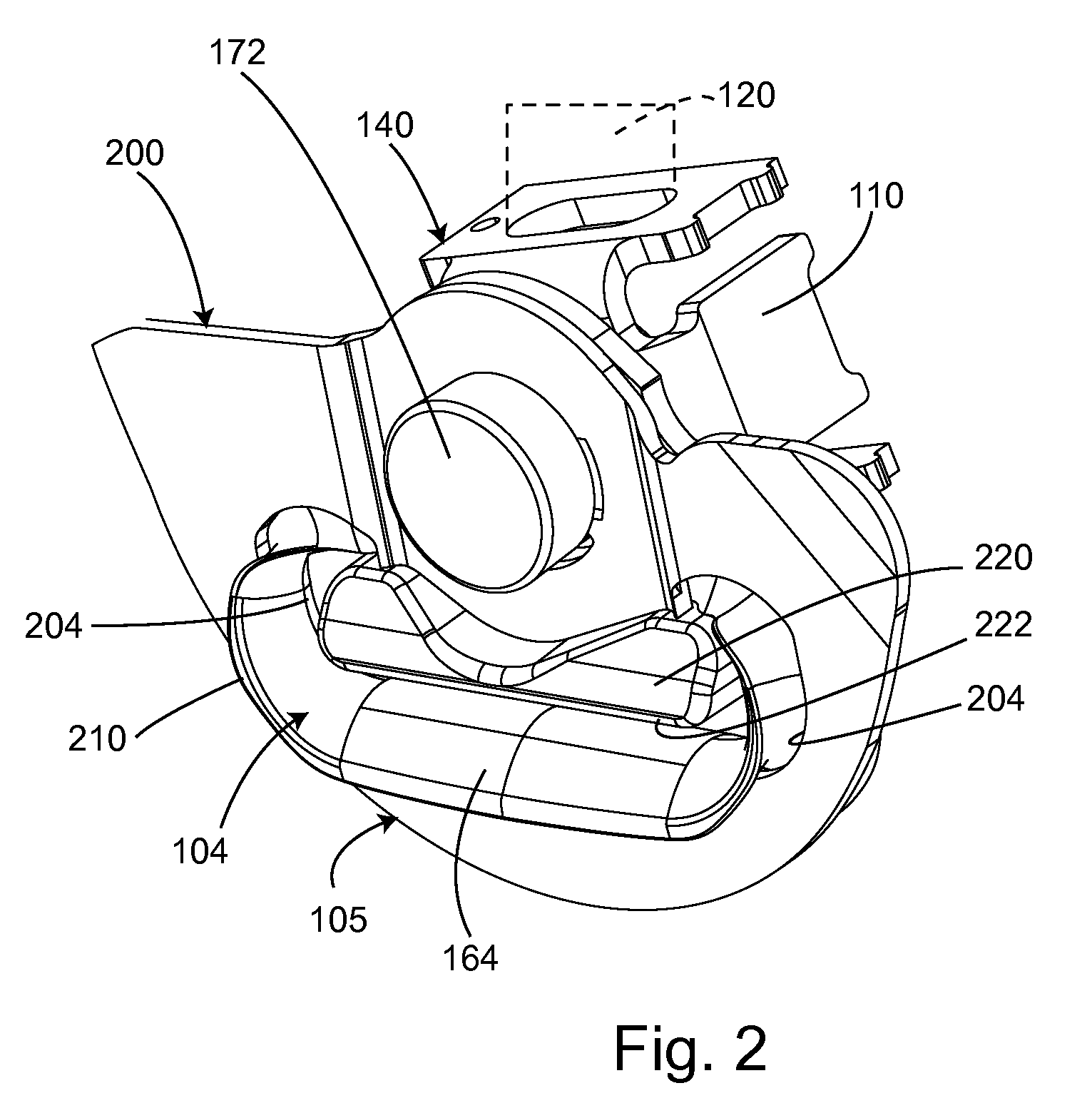

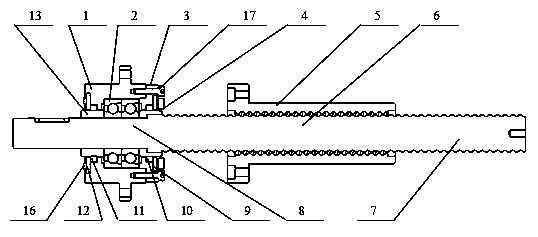

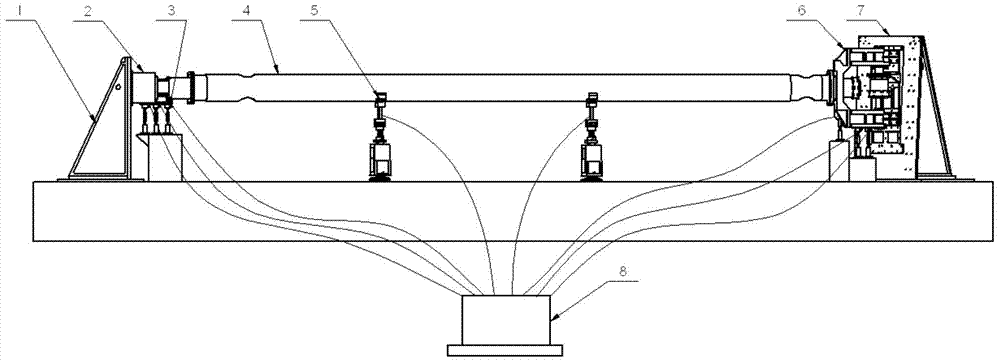

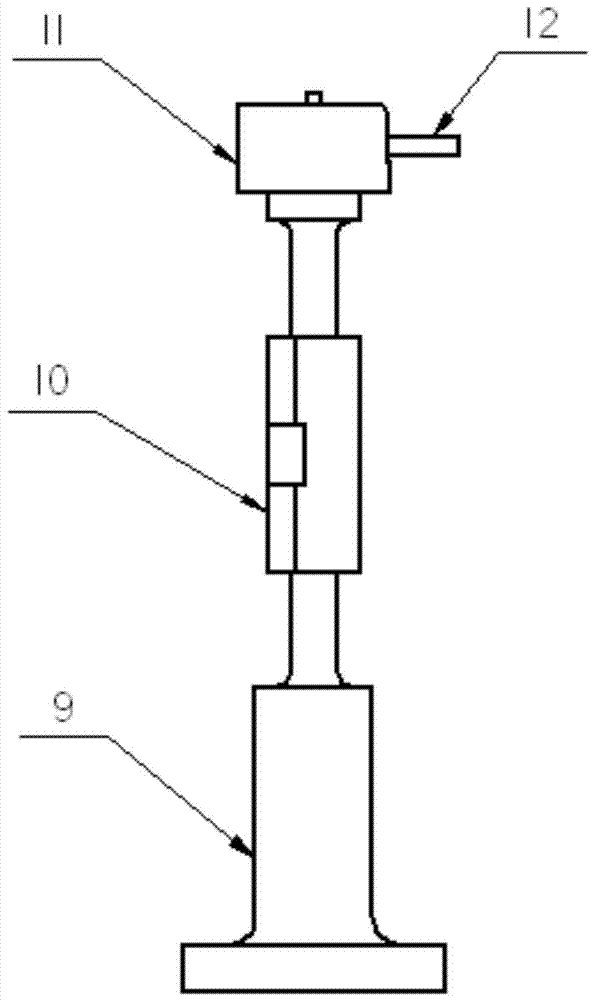

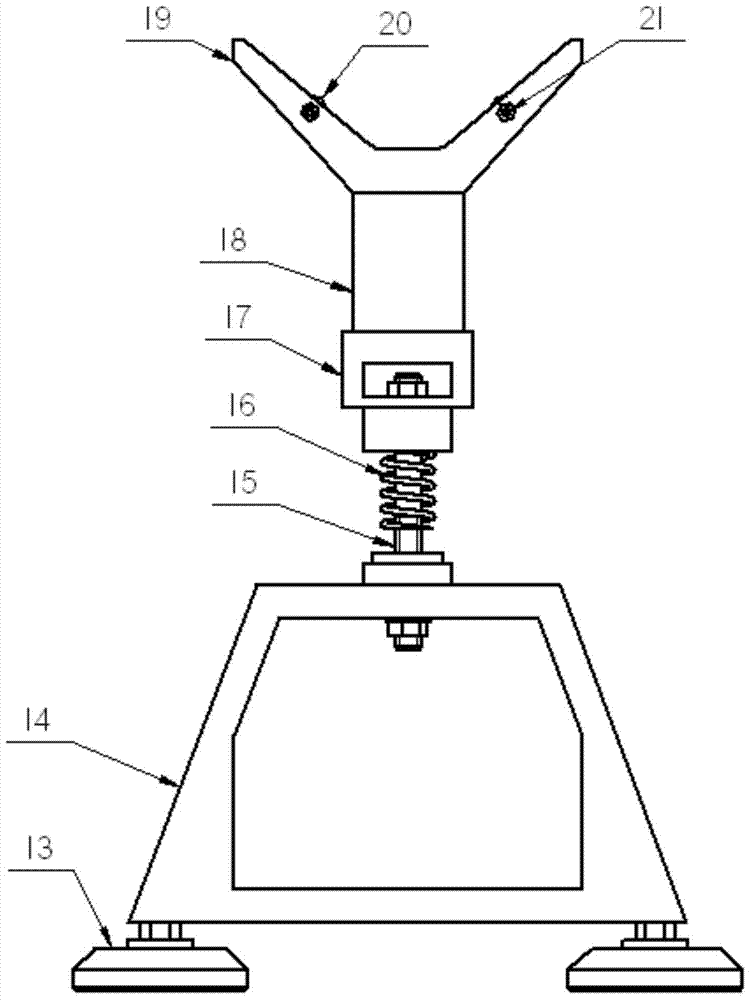

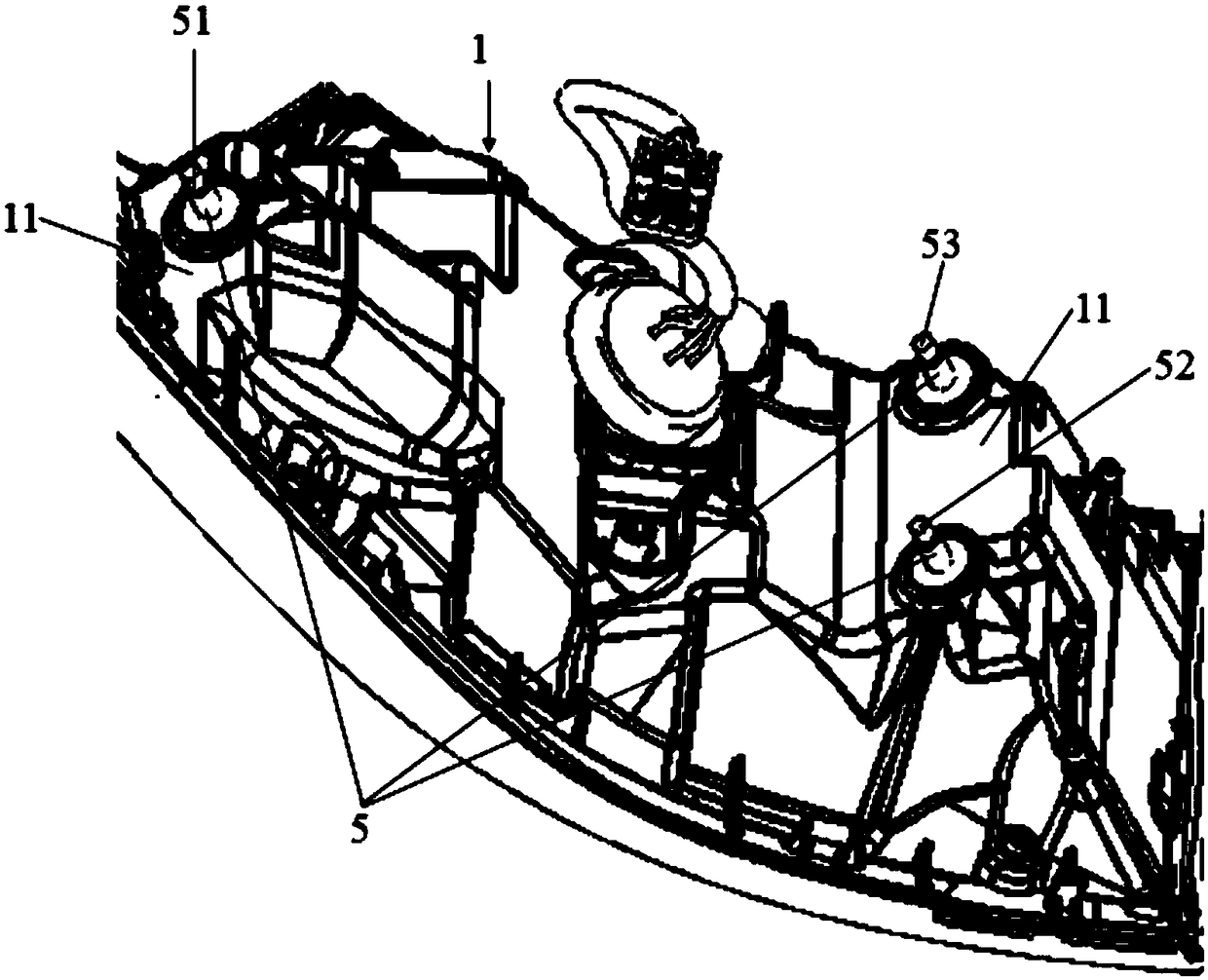

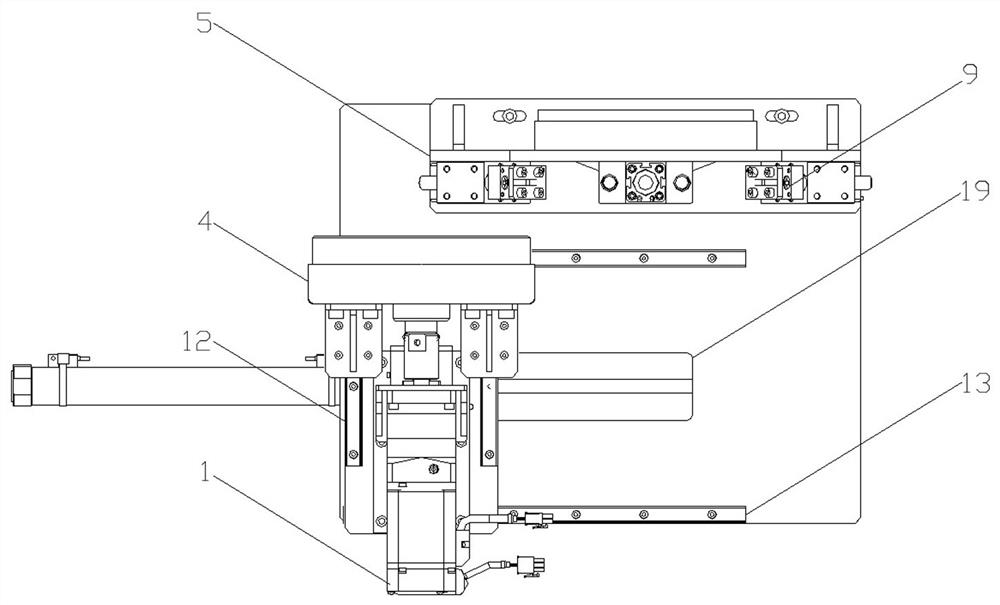

Posture adjustment and unloading efficiency detection integrated device

ActiveCN104842153AOptimal Assembly MethodImprove assembly efficiencyForce transducersMetal working apparatusEngineeringIntegrated devices

The invention relates to a posture adjustment and unloading efficiency detection integrated device, in particular to the posture adjustment and unloading efficiency detection integrated device for space expansion mechanism zero-gravity assembling and ground zero-gravity assembling for space high-precision complex expansion mechanisms, and belongs to the technical field of space expandable mechanism precision assembling. Through a tail end supporting plate and a root supporting plate, a complex assembling reference on a space expansion mechanism is ingeniously transferred, an assembling method is improved, and assembling efficiency is improved. Multi-freedom-degree posture adjustment on joint space postures of the space expansion mechanism is achieved in the mode of combining a plurality of joint supporting components. Unloading force is detected online in the assembling process through a sensor and a data collecting and processing system, and stabile and reliable unloading efficiency in the assembling process is guaranteed. An air foot and rolling bearing mode is adopted, the assembling stress of the space expansion mechanism is effectively reduced, and assembling precision is improved.

Owner:BEIJING SATELLITE MFG FACTORY

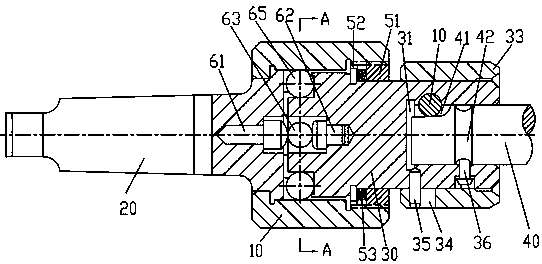

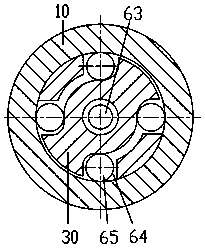

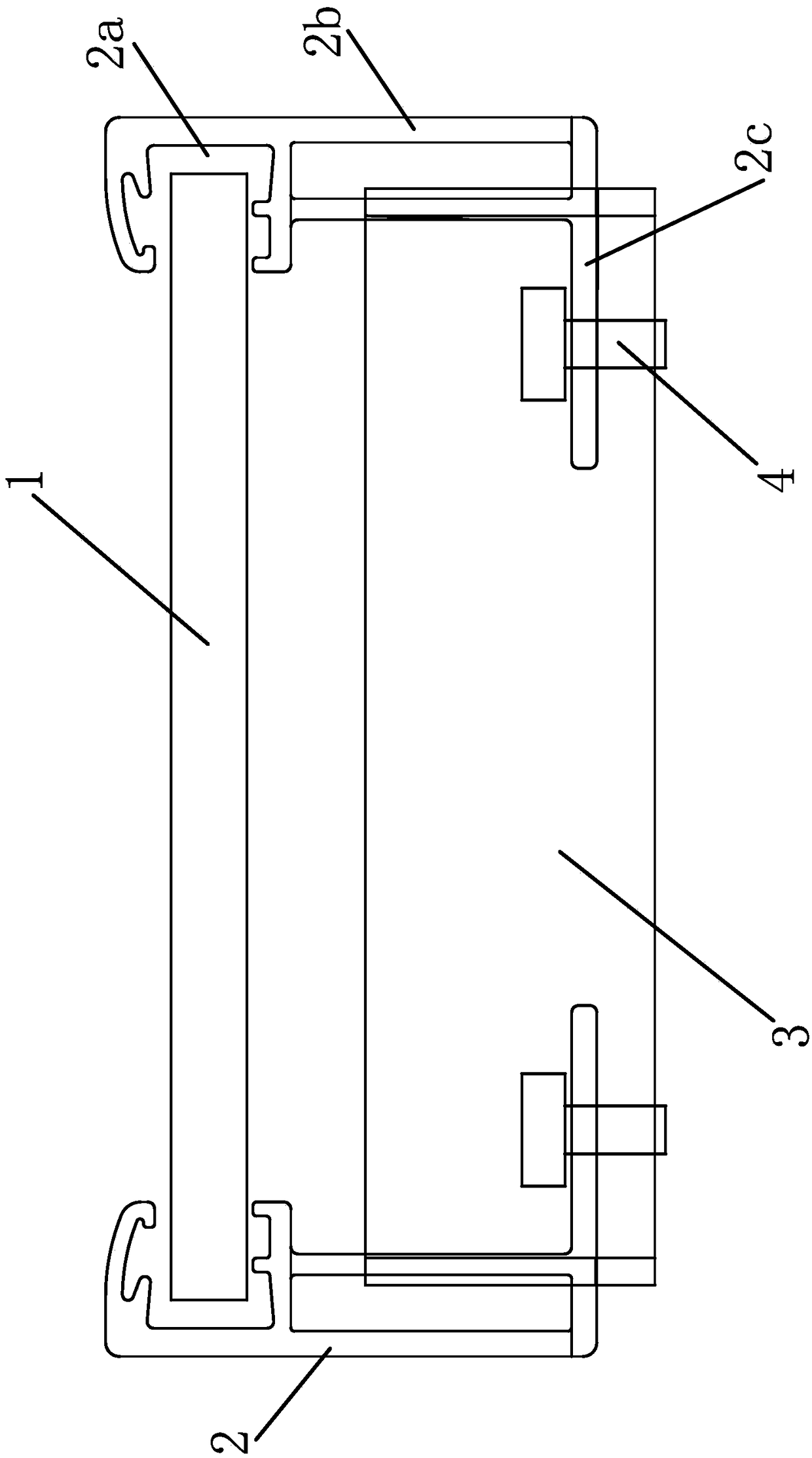

Floating reamer handle applied to finish machining of small-column inner hole and assembling method of floating reamer handle

The invention relates to a floating reamer handle applied to the finish machining of a small-column inner hole and an assembling method of the floating reamer handle. The floating reamer handle comprises an outer sleeve, wherein a step hole is formed in side end of the outer sleeve, a movable joint rod which penetrates out one side end of the outer sleeve and is provided with Morse taper is arranged in the outer sleeve, a movable joint connecting sleeve which penetrates out the other side end of the outer sleeve is further arranged in the outer sleeve, the movable joint connecting sleeve is limited in the outer sleeve through a tightness adjusting mechanism, an adjusting mechanism for finely adjusting the cut depth is arranged at the end part, located in the outer sleeve, of the movable joint connecting sleeve, and a shaft rod for mounting a milling cutter is mounted at the other end of the movable joint connecting sleeve through a connecting mechanism. The floating reamer handle simple and skillful in structure and convenient to manufacture, a 'horn mouth' phenomenon occurring at a hole is effectively avoided, and meanwhile, the assembling method is simple and convenient.

Owner:FUZHOU UNIVERSITY

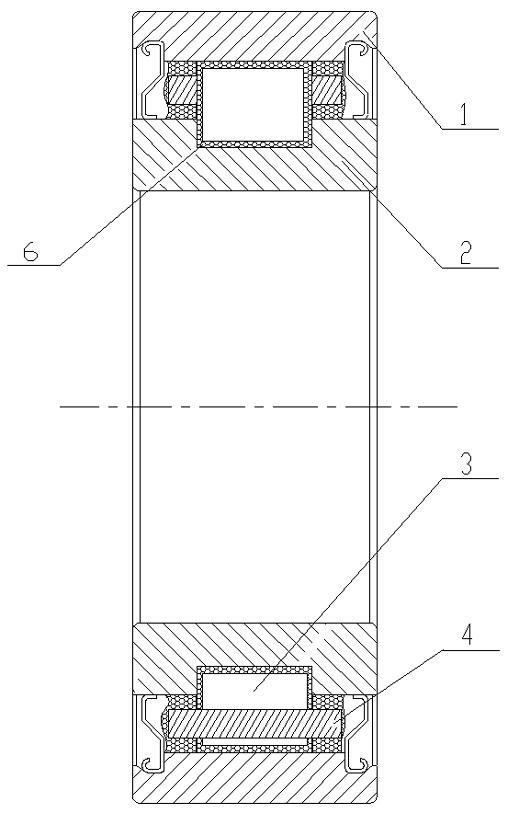

Method for assembling rolling bearing with oil

ActiveCN102135139AOptimal Assembly MethodAvoid direct contactBearing componentsRolling-element bearingEngineering

The invention provides a method for assembling a rolling bearing with oil. The method comprises the following steps of: 1, cleaning and drying a bearing component; 2, dip-coating preorder lubricant on the working surface of a bearing; and 3, assembling the bearing. The lubricant selected by an open bearing is an oil membrane, and the lubricant selected by a closed bearing is an oil membrane or a lipid membrane; in the step 3, postorder lubricant is added after the sleeving or the sleeving of the bearing during bearing assembling; and the preorder lubricant and the postorder lubricant are the same or compatible with each other. A lubricant coating step which is added before the bearing is sleeved in the method for assembling the rolling bearing overcomes the technical bias that technical staff in the field think that the rolling bearing is needed to be kept dried before being assembled and sleeved; and the lubricant is coated in the assembly process in advance, so that the direct contact of the working surface during bearing assembling is avoided, friction on the working surface is very small, friction scratching is reduced greatly and the method for assembling the bearing is improved.

Owner:SHANGHAI F&S BEARING TECH

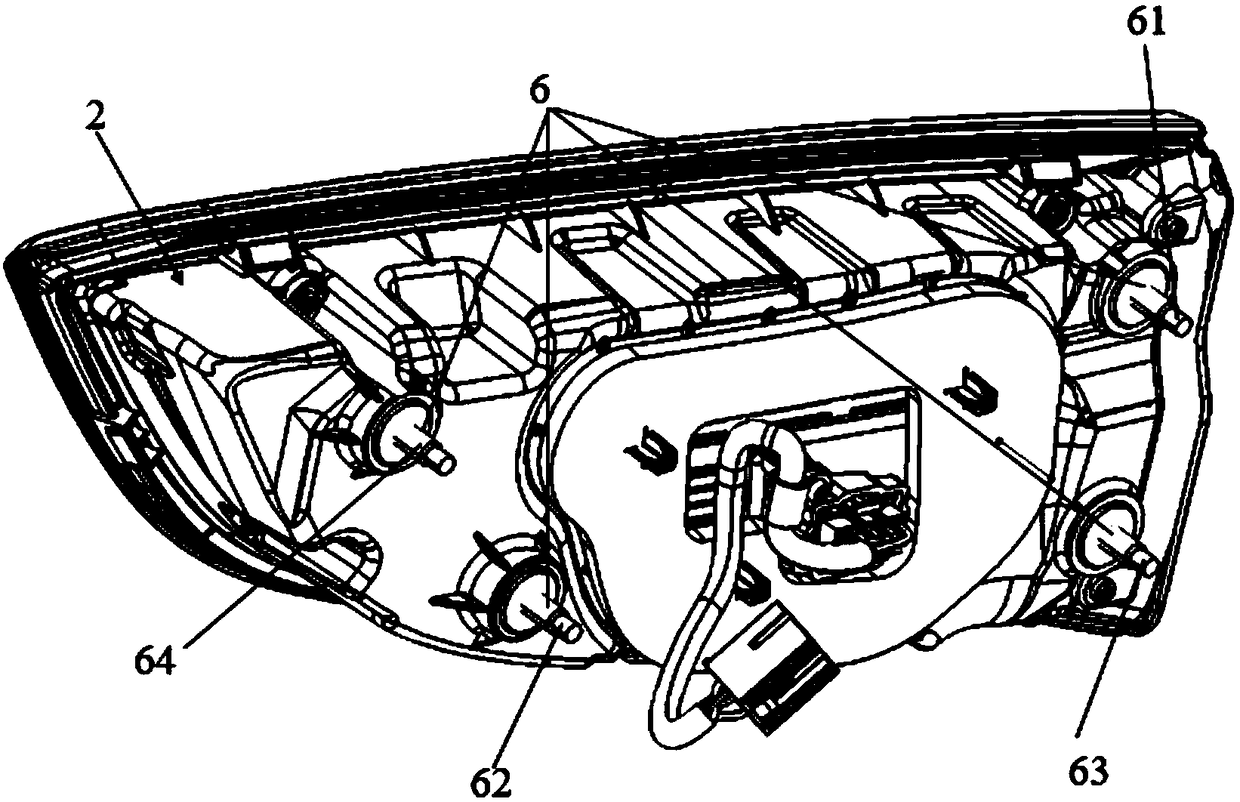

Vehicle tail light fixing structure and vehicle tail light assembly method

ActiveCN109466430AEasy to control clearance and surface differenceReduce usageInternal combustion piston enginesOptical signallingAerospace engineering

The invention discloses a vehicle tail light fixing structure. The vehicle tail light fixing structure comprises a fixed tail light, a movable tail light, a vehicle body side outer plate and a back door outer plate; the fixed tail light is installed on the vehicle body side outer plate, and the movable tail light is installed on the back door outer plate. In this way, the position of the fixed tail light relative to the vehicle body side outer plate and the position of the movable tail light relative to the back door outer plate are conveniently adjusted, and then the clearance plane difference between the fixed tail light and the vehicle body side outer plate and the clearance plane difference between the movable tail light and the back door outer plate are easily controlled; the fixed tail light is directly installed on the vehicle body side outer plate, the movable tail light is directly installed on the back door outer plate, the use of an inner plate is reduced, materials for thevehicle body are reduced, and lightweight design is facilitated; besides, the technological dimension chain is reduced technologically, the assembly error is reduced accordingly, and the clearance plane differences of the tail lights and the vehicle body are reduced. The invention further discloses a vehicle tail light assembly method.

Owner:CHERY COMML VEHICLE ANHUI

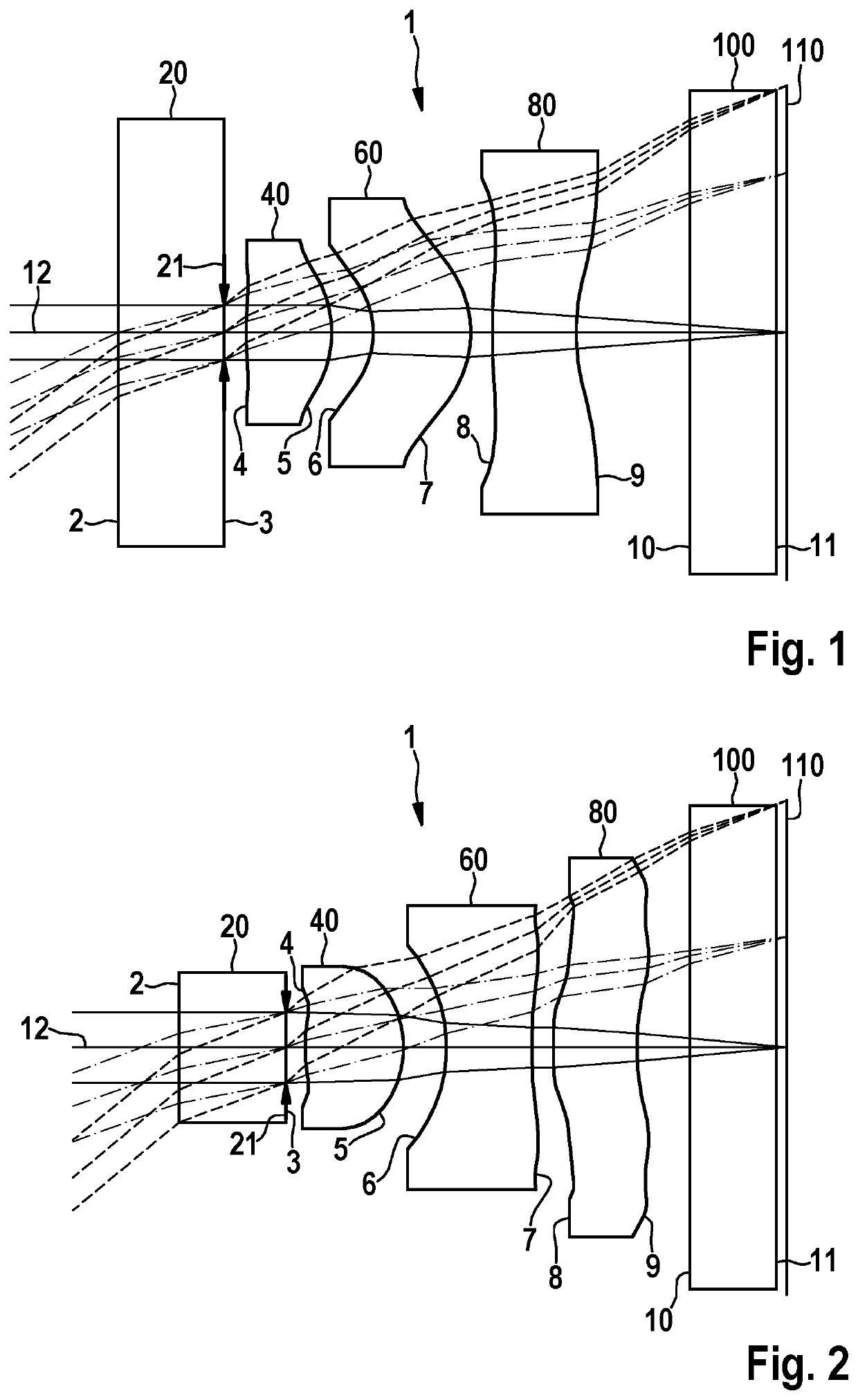

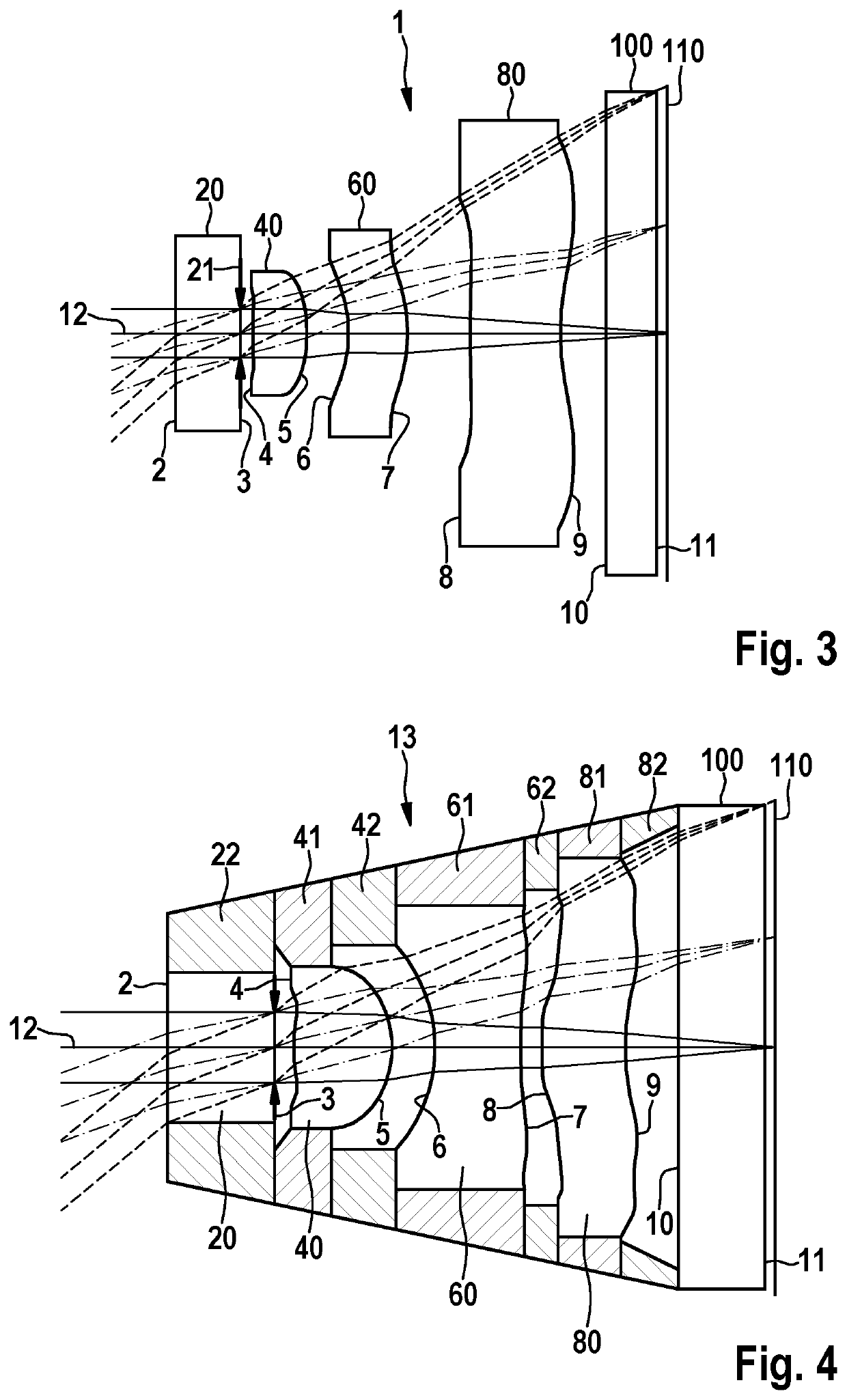

Lens System for a Video Endoscope, Endoscope Objective, Video Endoscope, and Assembly Method

PendingUS20210157120A1Stable and robust arrangementEasy to assembleSurgeryEndoscopesOphthalmologyCrystalline materials

A lens system (1) for a video endoscope comprises, in order from an object side, a cover glass (20), a first lens (40), a second lens (60) and one or more further lenses, wherein all lenses are single lenses. An aperture stop (21) is arranged at the object side of the first or the second lens (40, 60), all lenses on an image side of the aperture stop (21) are aspherical, all lenses are made of glass or of a crystalline material, and at least one lens has a refractive index n approximately equal to or exceeding 1.66. The invention also relates to an endoscope objective, to a video endoscope, and to a method for assembling an endoscope objective.

Owner:KARL STORZ GMBH & CO KG

Method for rapidly assembling breast heel in shoes production

The invention discloses a method for quickly assembling rolled heels in the production of shoes. The large palm surface of the heel is sanded and raised; the bonding surface is sanded and raised; After the heel line is within 2~3mm from the edge of the inner bottom, the side and the inner bottom are sanded and raised; the adhesive surface is brushed with glue; one 19mm nail is nailed on each side of the rear end of the inner bottom and on both sides of the heel For round nails, after driving 5mm into the inner bottom, use the pair of pliers to pinch off the nail cap obliquely; align the large palm of the heel with the bonding position, place it flat on the tip of the nail rod, and tap the small palm of the heel with a hammer to make The nails are glued to the correct position; the heel nails are nailed in the shoe cavity, and the holes are pierced with a straight cone from the shoe cavity to determine the nail position and the angle of the nails; the heel nails are nailed. This method improves the assembly method of the rolled heel, simplifies the assembly process, the rolled heel is assembled in place, and the rolled heel is installed smoothly. Make people difficult to grasp the problem of balance when wearing.

Owner:刘代学

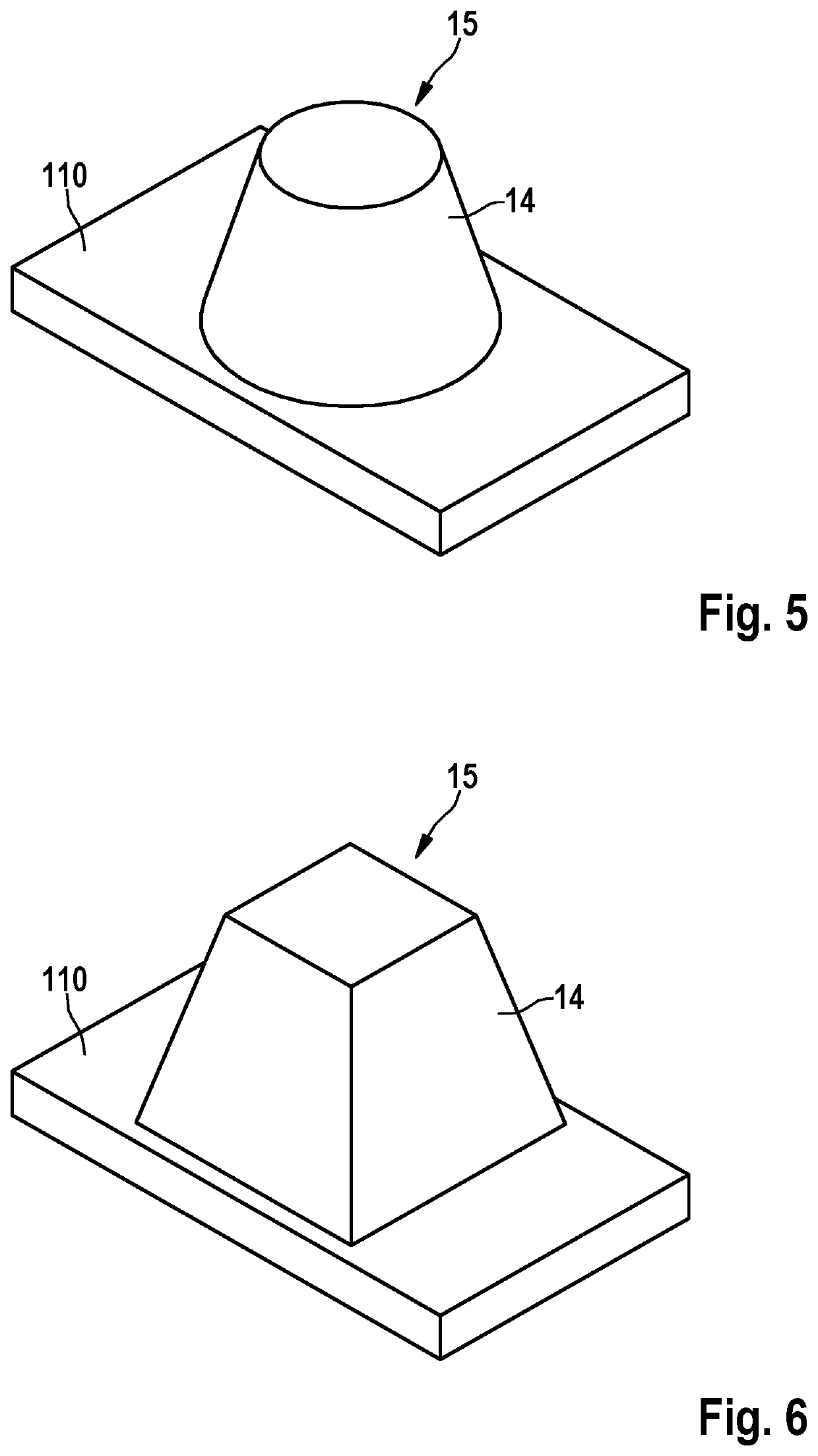

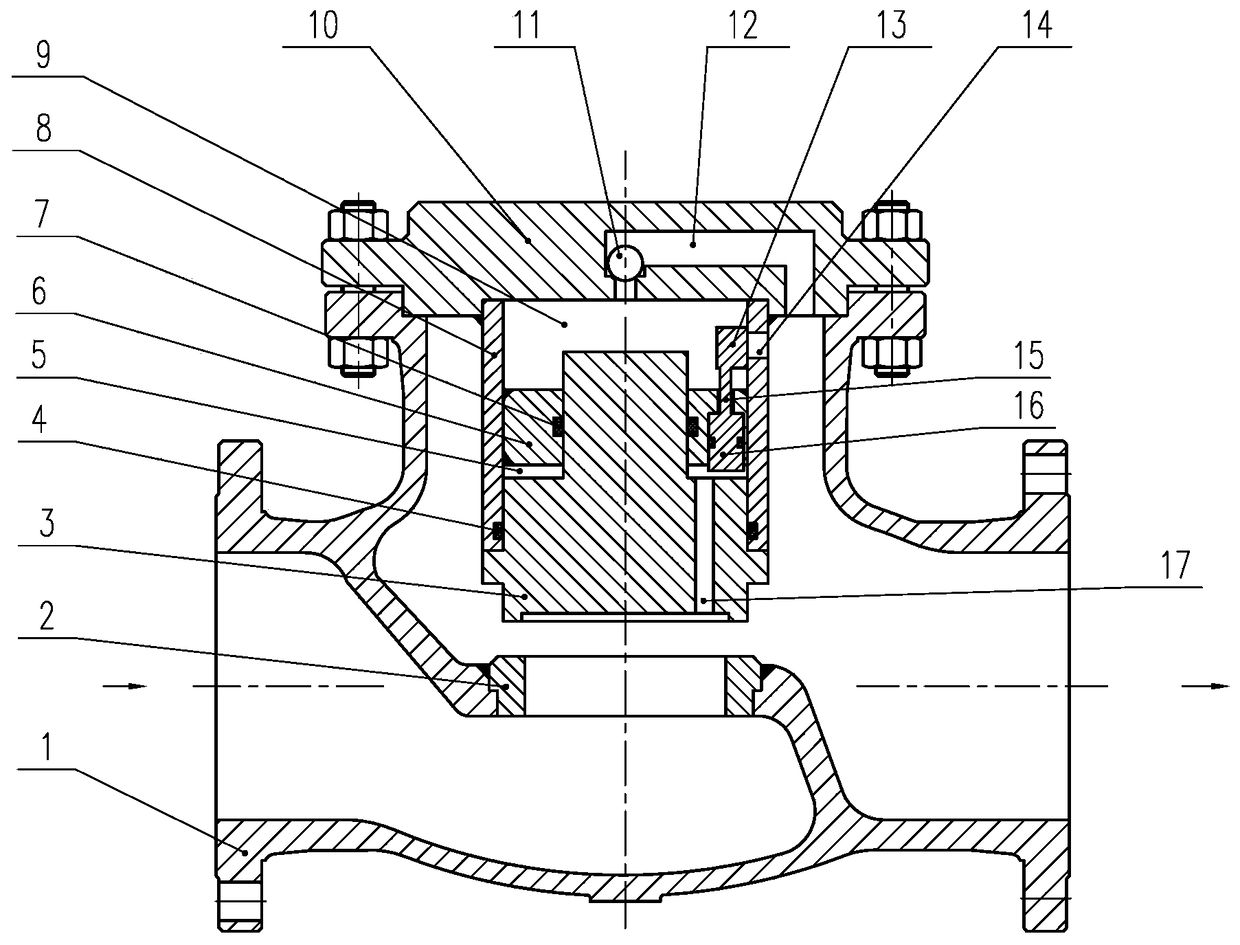

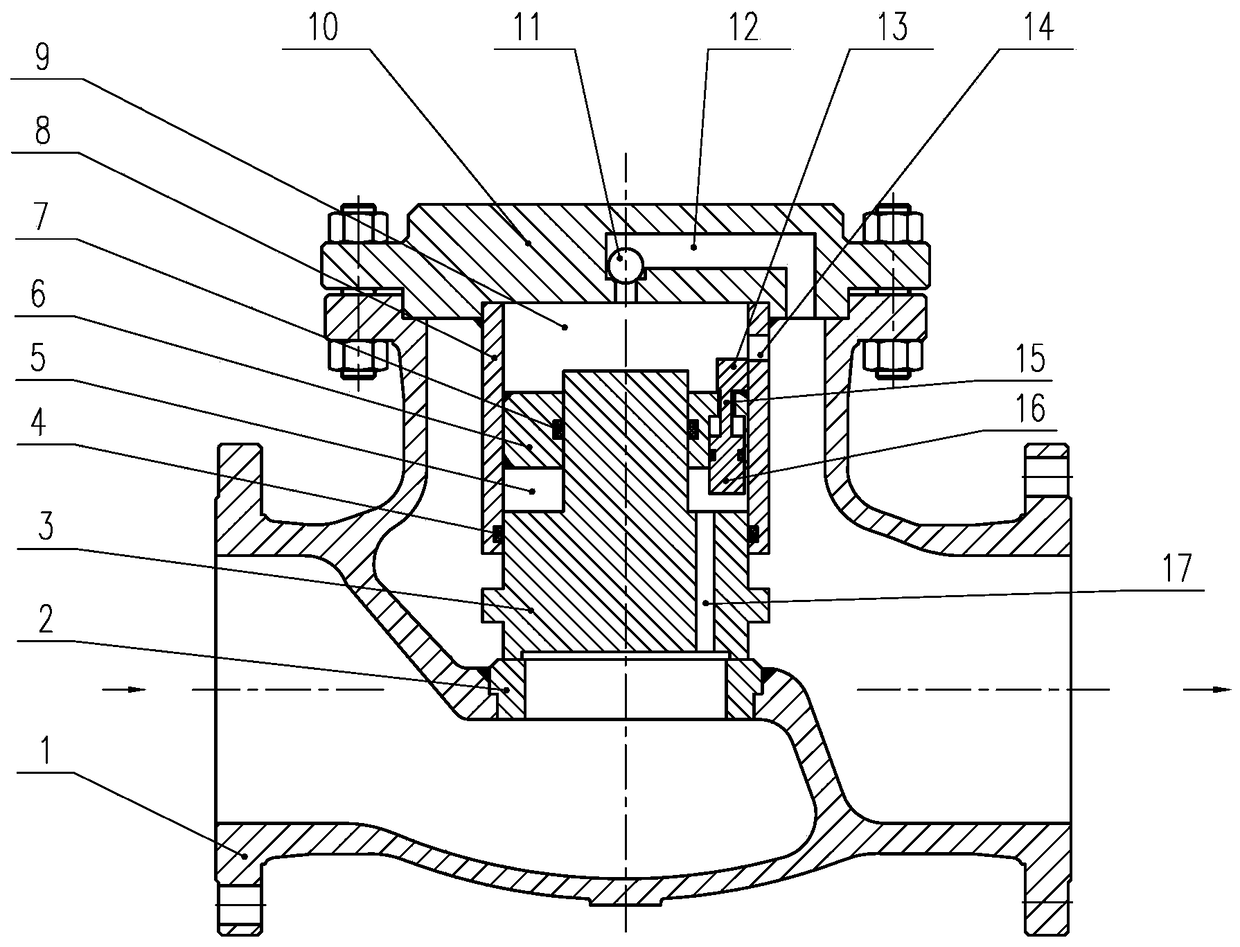

Anti-shock lift check valve

ActiveCN106870779BEasy to assembleOptimal Assembly MethodCheck valvesValve members for absorbing fluid energyEngineeringCounterbore

The invention relates to an anti-impact lift check valve. The anti-impact lift check valve is characterized in that an isolation block is arranged inside a guide sleeve, and a guide inner cavity is divided into a piston cavity and a pressure regulating cavity through the isolation block; the piston cavity is located above the isolation block, and the pressure regulating cavity is located below the isolation block; an air inlet hole is formed in the upper portion of the guide sleeve; one end of the air inlet hole communicates with the piston cavity, and the other end of the air inlet hole communicates with an outlet flow channel; a valve clack is composed of a valve clack head and a valve clack handle; the lower end face of the valve clack head is provided with a valve clack sealing surface capable of being sealed with a valve seat sealing surface; the upper end of the valve clack head stretches into the pressure regulating cavity, and the valve clack handle is installed at the upper end of the valve clack head; the upper end of the valve clack handle penetrates through a center hole of the isolation block to stretch into the piston cavity; a regulating hole perpendicular to the valve clack sealing surface is formed between the upper end face and the lower end face of the valve clack head, and the regulating hole communicates with an inlet flow channel and the pressure regulating cavity; an inverted counterbore hole is formed in the portion of the isolation block, and a floating plug is arranged at the inverted counterbore hole; and an air outlet hole is formed in a valve deck. The anti-impact lift check valve has the advantages that the valve clack sealing surface and the valve seat sealing surface cannot be damaged easily, the service life is long and noise is small.

Owner:JIANGSU JINFUCUN PETROLEUM EQUIP CO LTD

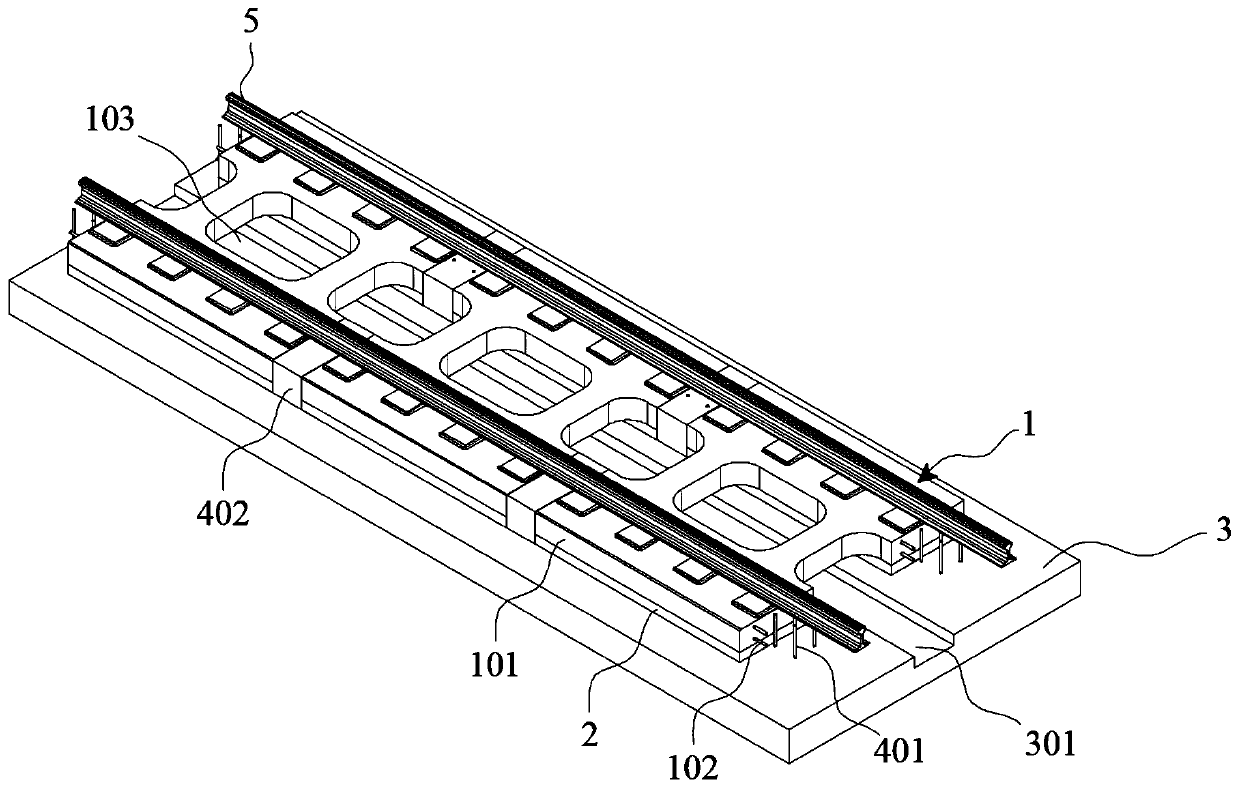

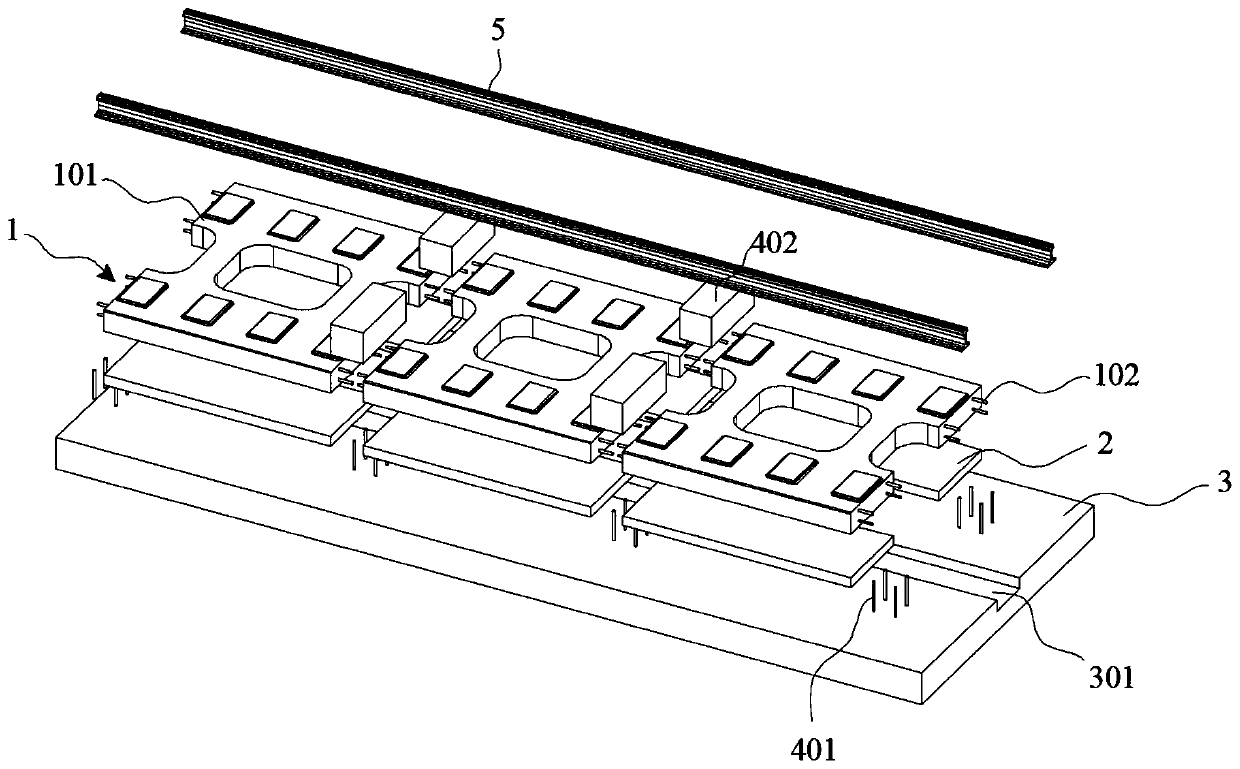

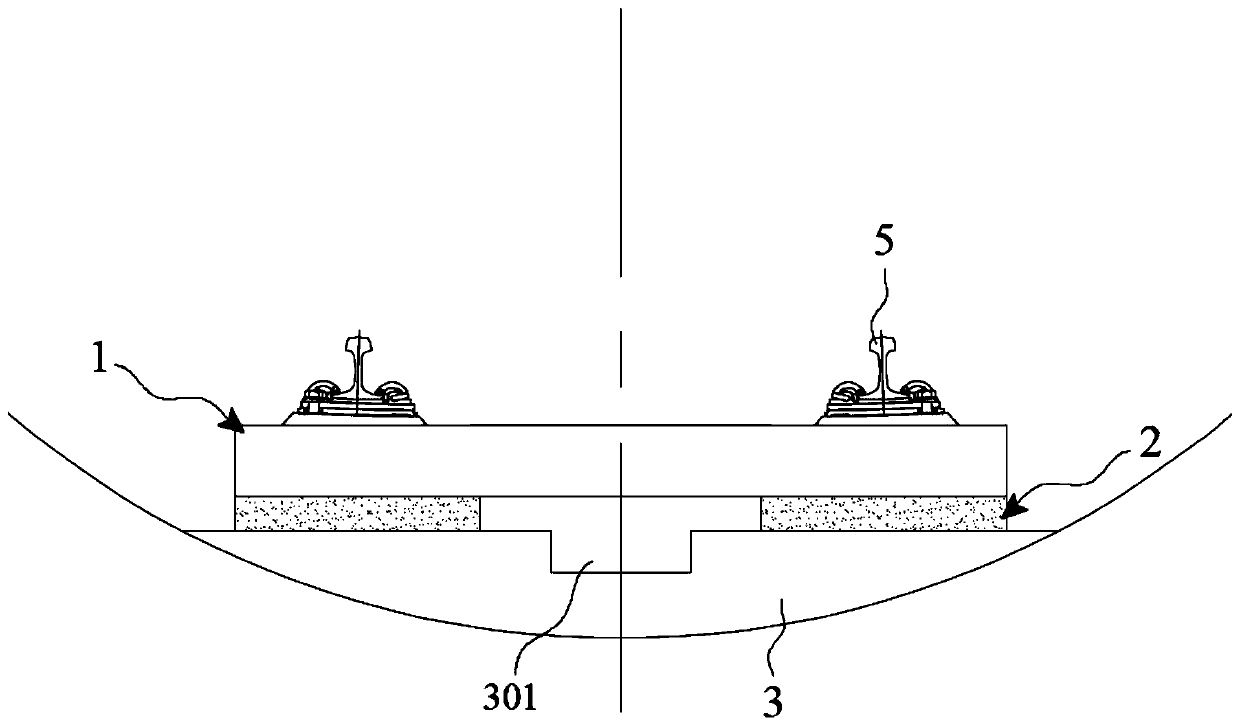

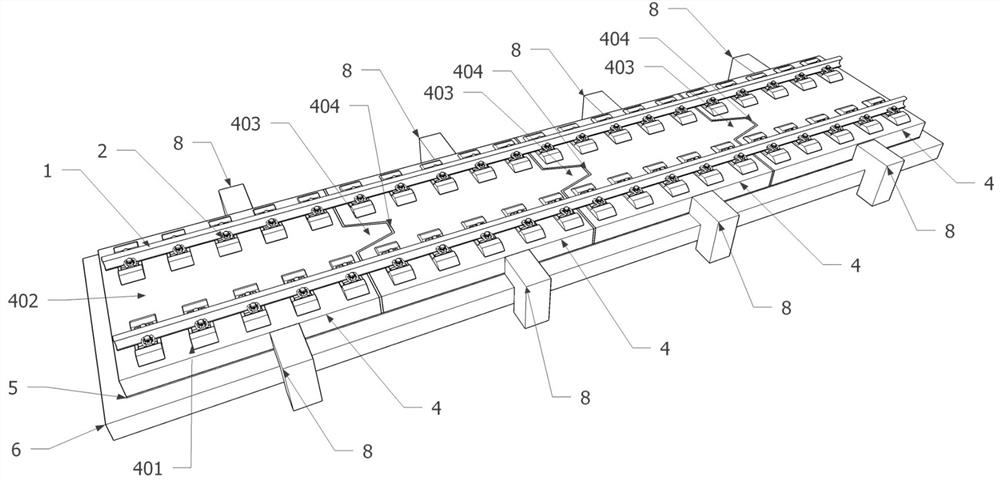

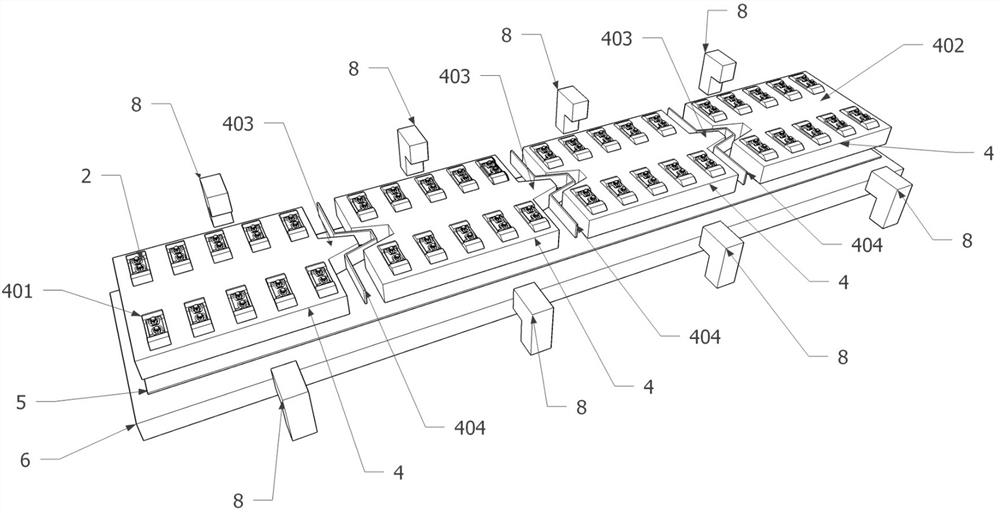

Assembled ballastless track structure and longitudinal connecting structure thereof

The invention discloses a longitudinal connecting structure of an assembled sleeper slab-type or a track slab-type ballastless track structure and a ballastless track structure including the longitudinal connecting structure. Two embedded longitudinal steel bars are longitudinally connected through an extrusion sleeve, the butting ends of the two longitudinal steel bars are separately inserted into the two ends of the extrusion sleeve, and the extrusion sleeve deforms and is locked under the extrusion of a portable extruder. According to the longitudinal connecting structure of the assembled sleeper slab-type or the track slab-type ballastless track structure and the ballastless track structure including the longitudinal connecting structure, the accuracy during site laying construction can be improved, disassembly and installation are convenient, the construction difficulty is reduced, the speed of site construction is increased, the structure is simple, and positioning of a sleeper slab or a track slab is convenient.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

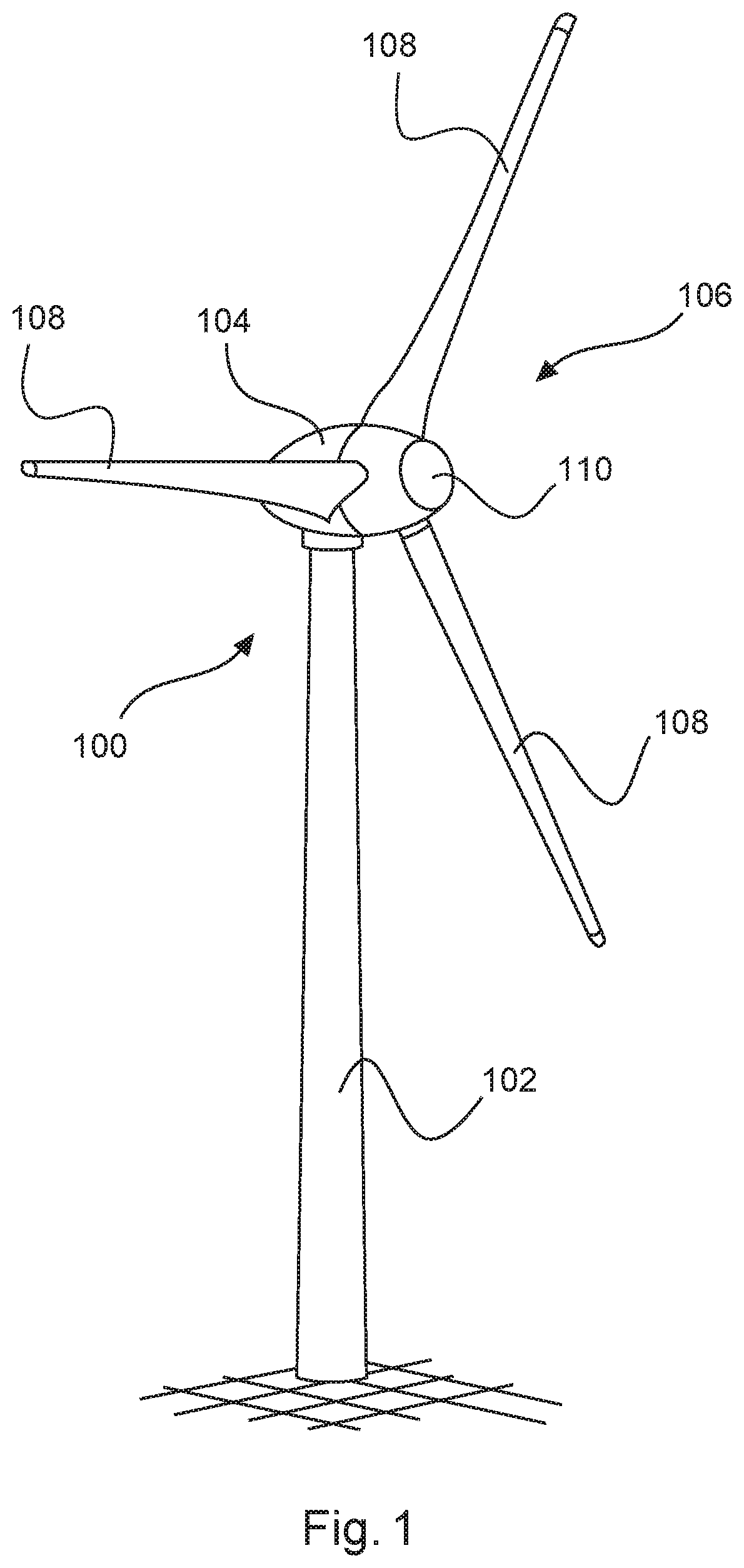

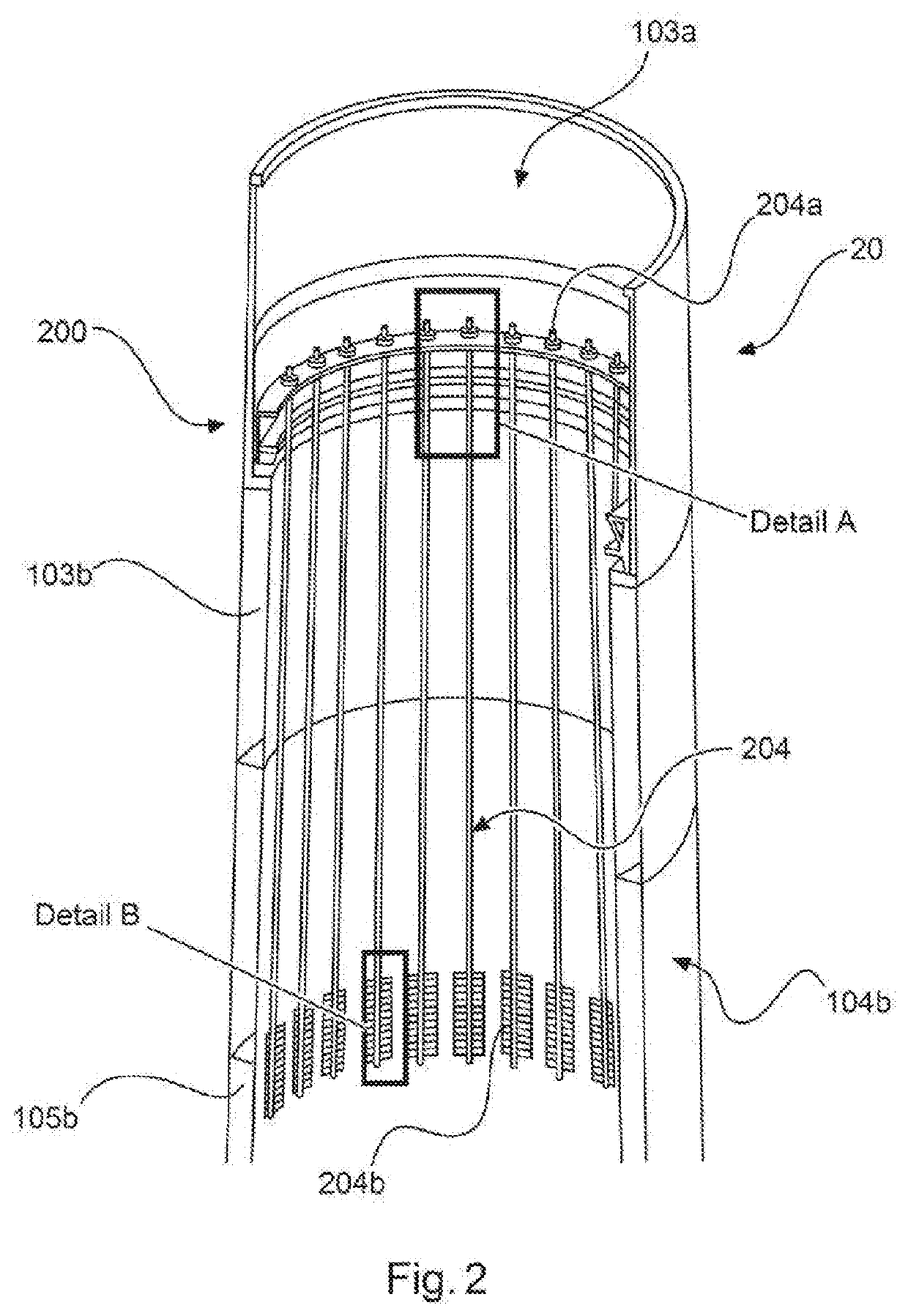

Annular bracket for externally loading a tower segment, external loading system of a hybrid tower, tower section of a hybrid tower, hybrid tower, wind turbine, and assembly method of an external loading system for a hybrid tower

ActiveUS20200263446A1Increase the sectionEasy windingWind motor supports/mountsTowersPower stationTower

An annular bracket for the external tensioning of a tower segment, in particular a tower segment of a wind power plant, to an external tensioning system of a hybrid tower, preferably a hybrid tower of a wind power plant, to a tower section of a hybrid tower, preferably a hybrid tower of a wind power plant, to a hybrid tower, preferably a hybrid tower of a wind power plant, to a wind power plant, and to an assembly method of an external tensioning system for a hybrid tower, preferably for a hybrid tower of a wind power plant. An annular bracket for the external tensioning of a tower segment, in particular a tower segment of a wind power plant, with a connector element for the connection of a tensioning element, a bearing element for the transmission of a tensioning force to a tower segment, and an annular force transmission element for the transmission of the tensioning force between the connector element and the bearing element, the bearing element being at a greater spacing in the radial direction from a longitudinal axis of the annular bracket than the connector element, is described.

Owner:WOBBEN PROPERTIES GMBH

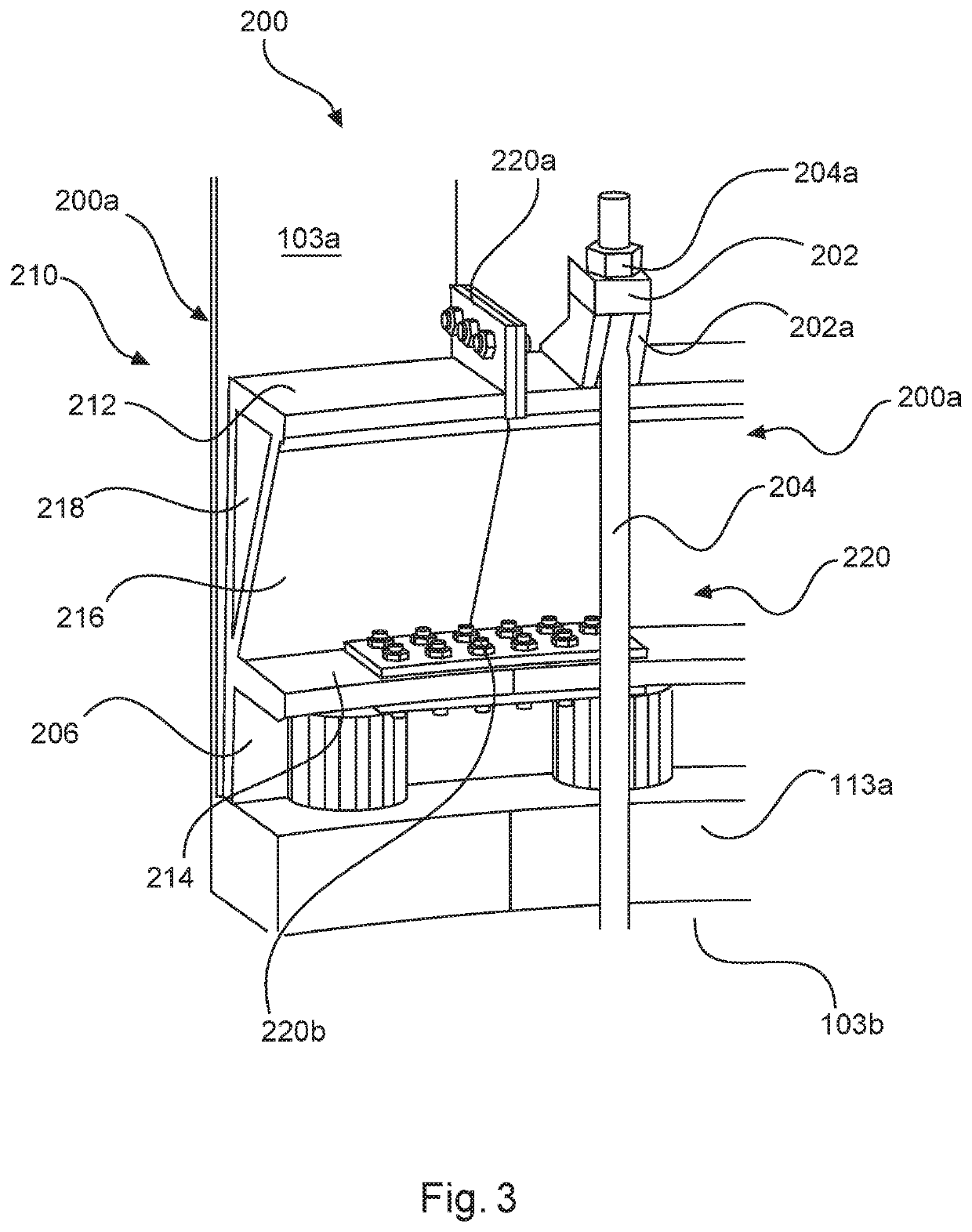

Preliminary assembly system and assembly method for vehicle body component parts

InactiveUS6849820B2Low cost measureConstant relative freedomWelding/cutting auxillary devicesArc welding apparatusEngineeringKnife blades

A preliminary assembly system for joining a body side panel and a floor panel of an automotive vehicle in a loose-fit hemming joint state by bending a claw piece extending from a main body of one of the panels to hold the other of the panels, prior to welding. The preliminary assembly system comprises a die to be in contact with a back-side surface of the main body of one of the panels in a region forming a loose-fit hemming joint section. Additionally, a main bending blade is provided to be movable to approach the die to bend the claw piece until the loose-fit hemming joint state is established. The main bending blade is moved to approach the die by a movement amount which is mechanically determined relative to a surface of the other of the panels during formation of the loose-fit hemming joint section.

Owner:NISSAN MOTOR CO LTD

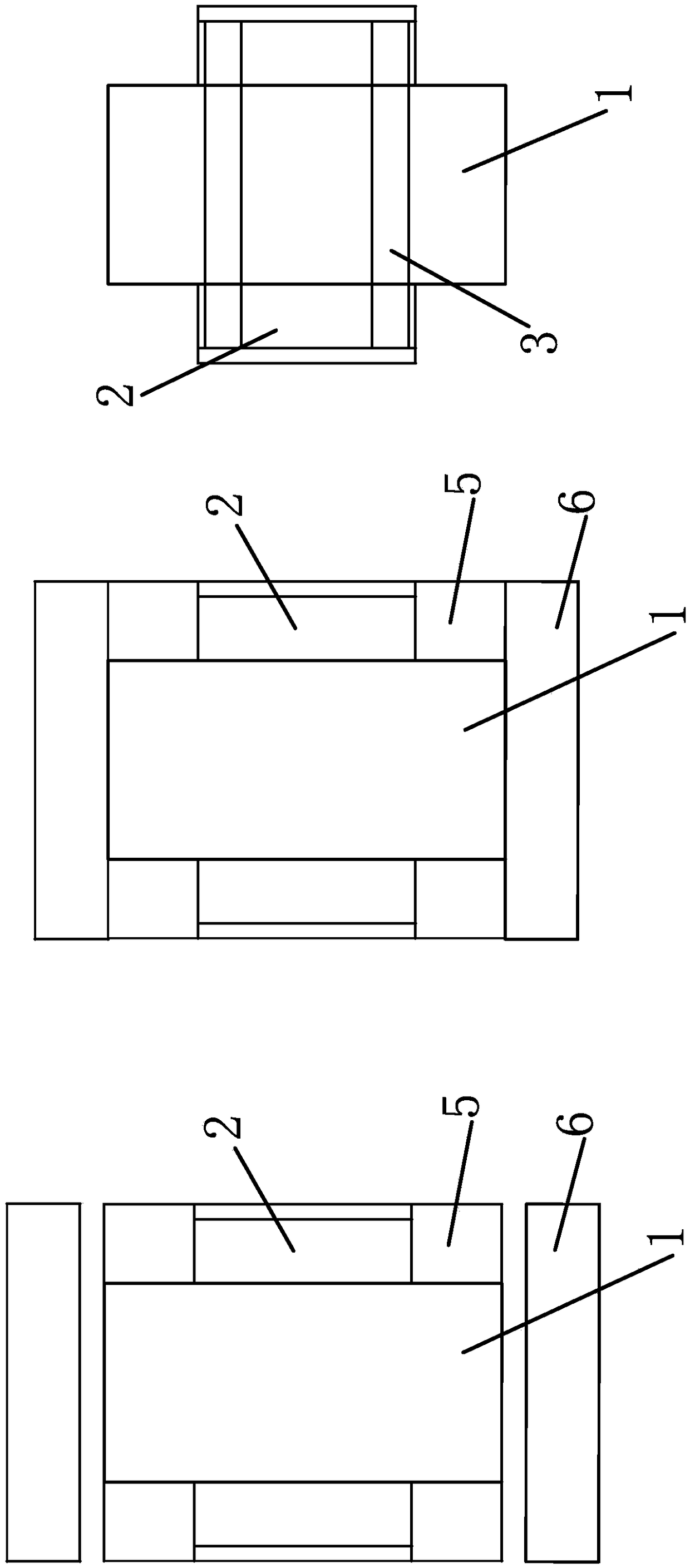

Improved photovoltaic module and assembly method thereof

InactiveCN108880420AReduce weightReduce installation costsPhotovoltaic supportsPhotovoltaic energy generationMechanical engineeringPhotovoltaics

The invention provides an improved photovoltaic module and an assembly method thereof. The improved photovoltaic module comprises a dual-glass assembly and a frame, wherein the frame comprises two long edges and two short edges, wherein the two long edges and the two short edges are encircled to form a rectangular frame, the lengths of the long edges are smaller than the length of the dual-glass assembly, the lengths of the short edges are smaller than the length of the dual-glass assembly, clamping grooves are formed in the tops of the long edges, clamping plates are arranged at the bottoms of the long edges, a support plate is vertically arranged between each clamping groove and each clamping plate, clamping holes are formed in two ends of the short edges, the lengths of two sides of thedual-glass assembly are embedded into the clamping grooves of the long edges along corresponding clamps, the long edges are arranged at a middle position of the dual-glass assembly, the short edges are clamped onto the clamping plates of the long edges by the clamping holes, the two short edges are arranged between the two long edges, a plurality of installation holes are formed in the clamping plates at the long edges, and elastic bolts penetrate through the installation holes. The method comprises the steps of 1) positioning; 2) assembling the long edges; 3) assembling the short edges; and4) completing frame installation.

Owner:晶科能源(海宁)有限公司 +1

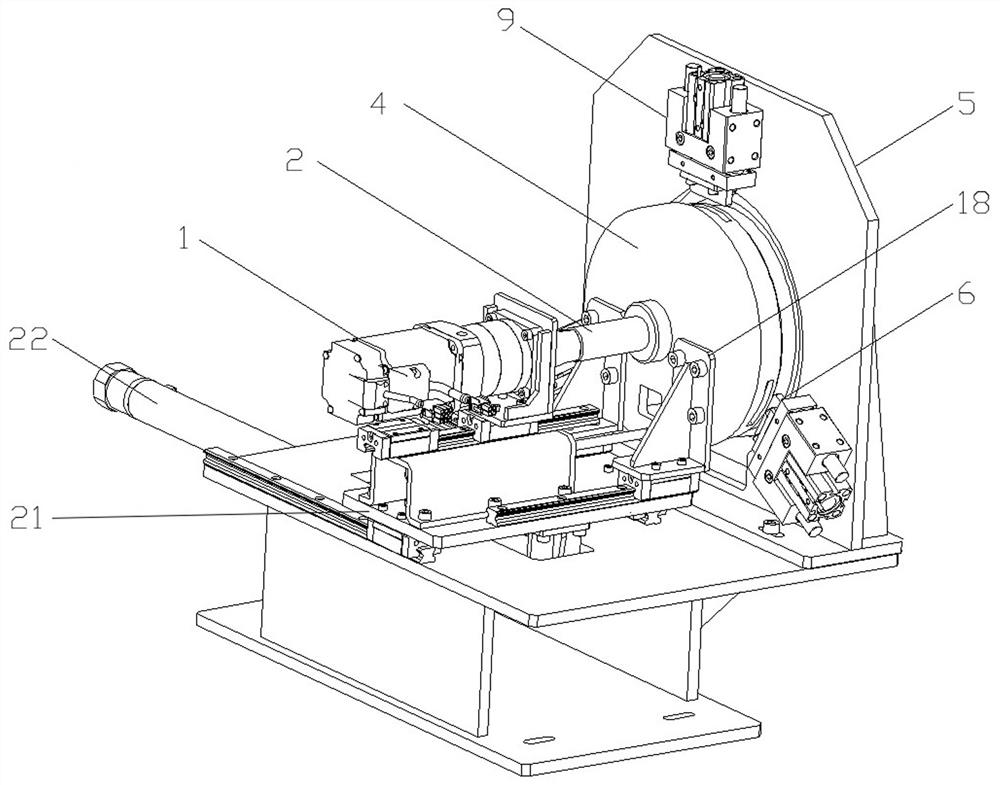

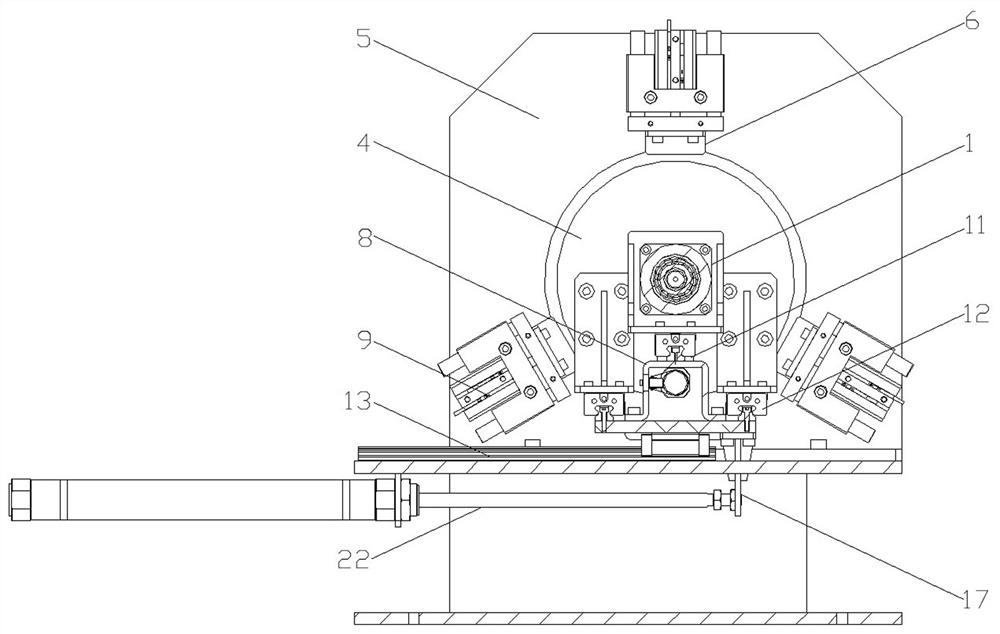

Large-diameter end cover propelling mechanism, assembling method and press-fitting tightening equipment

ActiveCN113118747ALabor savingReduce labor intensityMetal working apparatusElectric machineryEngineering

The invention discloses a large-diameter end cover propelling mechanism, an assembling method and press-fitting tightening equipment. The large-diameter end cover propelling mechanism comprises a press-fitting assembly and a positioning assembly, the press-fitting assembly provides propelling force to propel an end cover to enter a press-fitting end of a barrel, the press-fitting assembly comprises a press-fitting motor, a connecting screw and a screw block, one end of the connecting screw is connected with a power output shaft of the press-fitting motor, and the other end of the connecting screw is connected with the screw block; and the positioning assembly is used for fixedly connecting an end cover positioning seat and the barrel and comprises an end plate and the end cover positioning seat, the end plate is located at one end of the barrel, a through hole for the end cover and the end cover positioning seat to penetrate through is formed in the center of the end plate, and a positioning insertion block for integrally connecting the end cover positioning seat and the barrel is installed on the end plate on the outer edge of the through hole. The large-diameter end cover propelling mechanism has the advantages that the end cover can be automatically grabbed, a tool can be automatically placed, the tool can be automatically propelled and jacked, meanwhile, threaded parts can be automatically centered, automatic assembly is achieved under the condition that the coaxiality is guaranteed, manpower is reduced, the labor intensity is lowered, and therefore the working efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

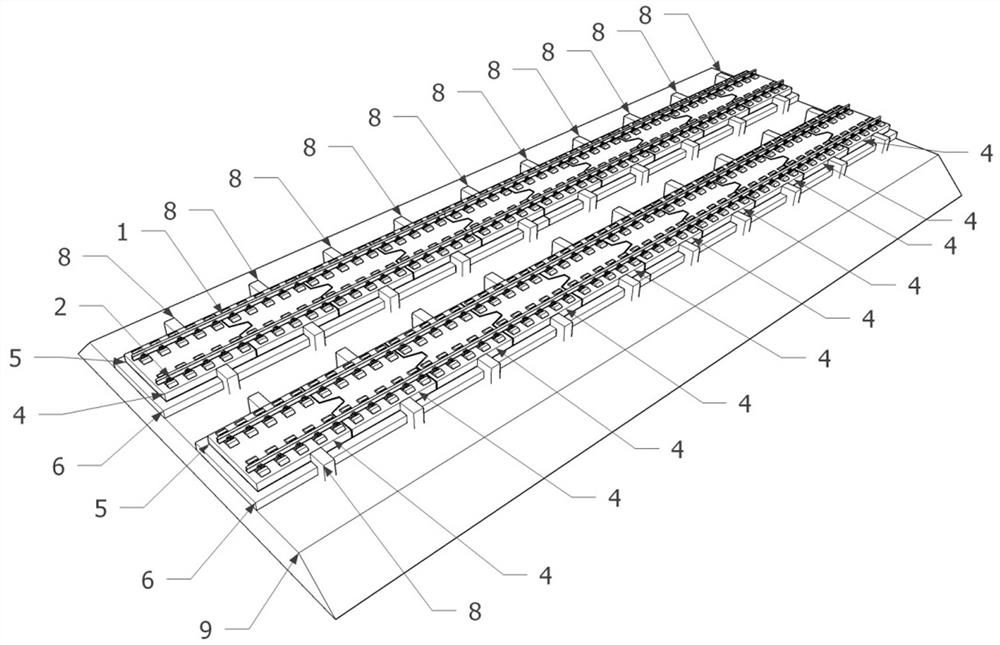

External limiting module split mounting type track structure

ActiveCN113550176AEasy rideImprove molding efficiencyBallastwayRailway fasteningTrackwayStructural engineering

The invention discloses an external limiting module split mounting type track structure which comprises a base plate, the base plate forms top face millimeter-level precision through cast-in-place or is prefabricated and formed in a factory, an adjusting layer is cast in place on a foundation or is replaced by novel materials such as asphalt, and the base plate is pressed downwards by a track plate during cast-in-place so as to form the top face millimeter-level precision; a middle layer is laid on the base plate, track units are sequentially laid on the middle layer, and each track unit comprises a prefabricated track plate module; a concave-convex embedded structure is further arranged between every two adjacent sets of track plate modules. The further comprises two sets of limiting strips, the two sets of limiting strips are arranged on the two sides of the track plate module respectively, and the limiting strips are connected to the supporting foundation and abut against the track plate module for limiting. In the structure, multiple modules are combined, the applicability is high, the prefabricated modules are miniaturized and light, production, transportation and installation are convenient, the structure is simple, the assembly method is simple and convenient, the assembly efficiency is high, and replacement is easy.

Owner:NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com