Method for assembling rolling bearing with oil

An assembly method and rolling bearing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of great harm, affecting bearing surface quality, vibration and noise operating life, working surface scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for assembling the rolling bearing with oil of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] The method for assembling the rolling bearing with oil of the present invention comprises the following steps:

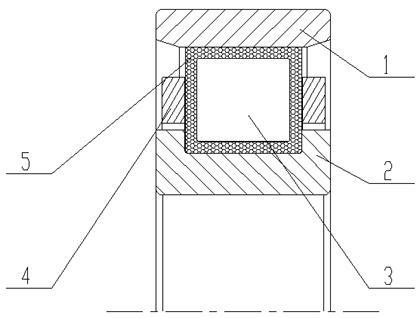

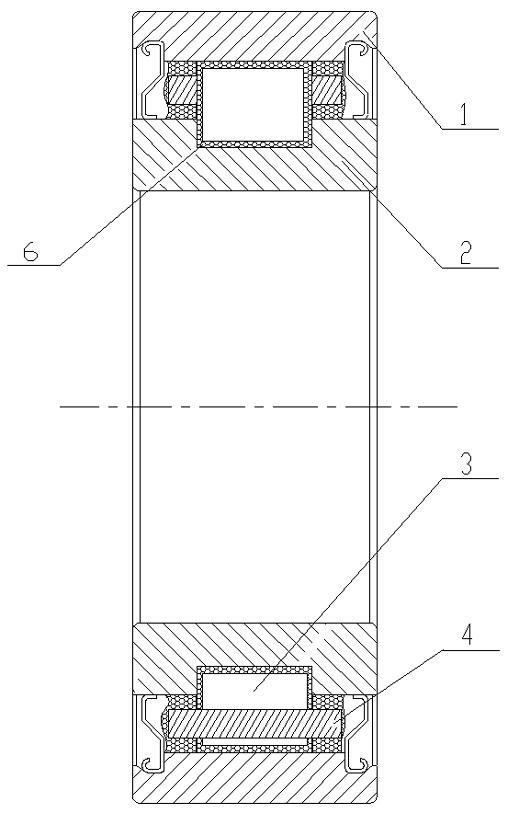

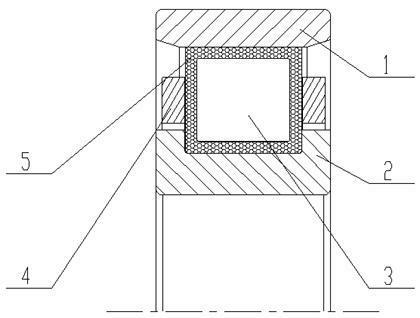

[0018] Such as figure 1 Shown, open single row cylindrical roller bearings.

[0019] Step 1: Take the rolling element 3 that has been mechanically processed and is waiting to be assembled, and clean and dry it.

[0020] Step 2, according to the anti-rust storage conditions of the rolling bearing, select a suitable lubricating oil, and then immerse or coat the rolling body 3 with oil, so that the surface of the rolling body is covered with an oil film 5, the thickness of which is 0.1-100 microns.

[0021] Step 3: According to the normal cylindrical roller bearing assembly process, the rolling element 3 covered with the oil film 5 on the above working surface is selected and riveted w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com