External limiting module split mounting type track structure

An assembly-type, track technology, applied in the field of rail transit, can solve problems such as difficult maintenance and repair of track structures, poor quality stability, and difficult replacement, so as to improve molding efficiency and quality, facilitate transportation and installation, and quickly and conveniently disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

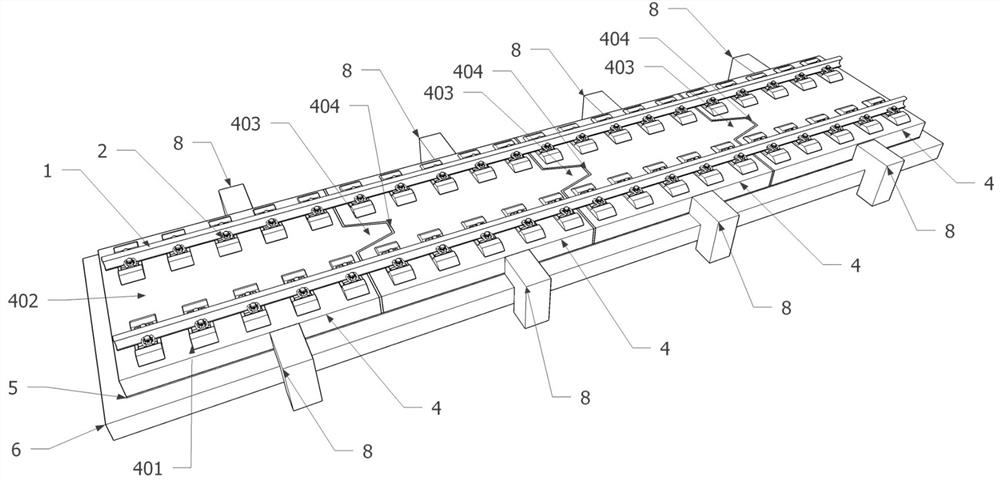

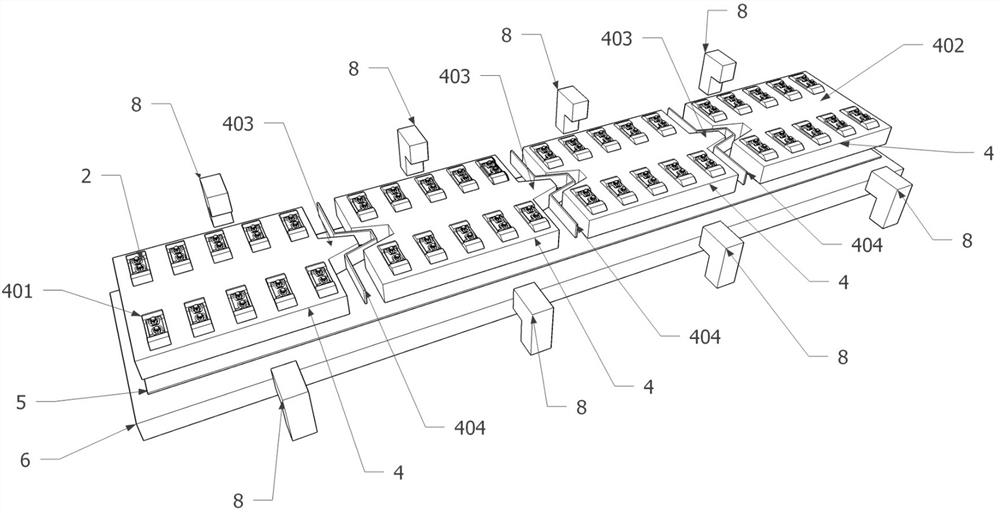

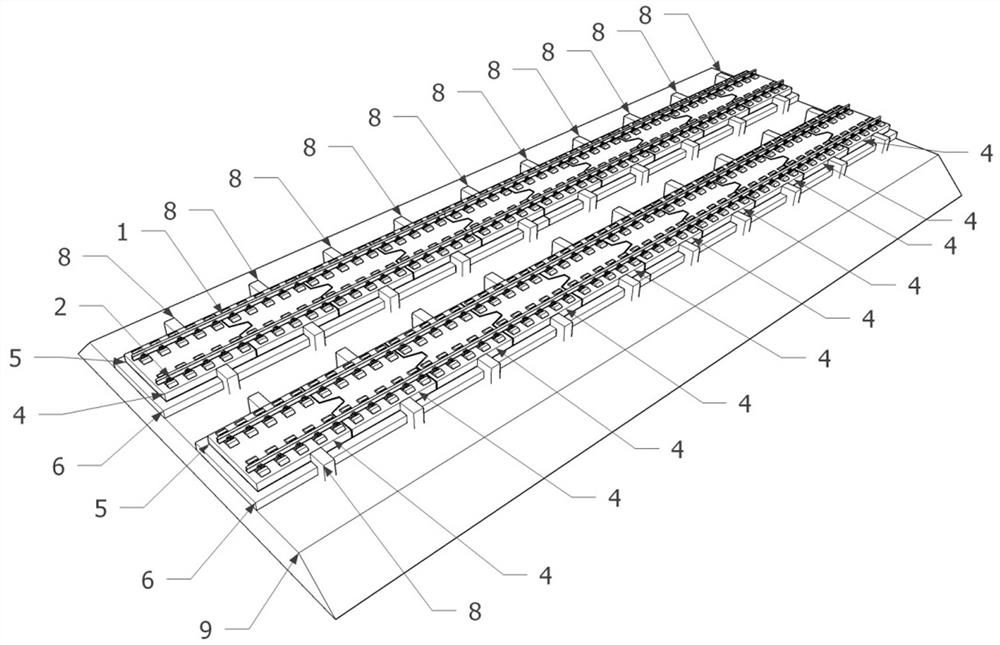

[0035] refer to figure 1 and figure 2 , a preferred embodiment of the present invention provides an assembled track structure of an external limit module, including: a base plate 6 that plays a supporting role and is used for leveling the assembled track structure of an external limit module, and the base plate 6 is cast on site On the support foundation and extending along the running direction of the train, the base plate 6 is laid with an intermediate layer 5 which plays an isolation role and extends along the length direction of the base plate 6. The track slab module 4 is prefabricated and used to guide and support the train. There is also a concave-convex interlocking structure between two adjacent groups of track plate modules 4, which is used to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com