Improved photovoltaic module and assembly method thereof

A photovoltaic module and double-glass module technology, applied in the field of solar energy, can solve the problems of increased downstream costs such as installation, high double-glass manufacturing costs, and increased quality, so as to reduce installation costs, reduce frame weight and cost, and reduce the size of the long side Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0028] Analyzing the force and action of the frame, the force of the installation position from the edge is relatively small, and the structure can be optimized. The conventional installation method will generate large internal stress inside the module when it is subjected to external changes such as geographical settlement and bracket bending. It will cause the cells inside the module to be cracked or damaged, which is not conducive to improving the long-term outdoor life of the module.

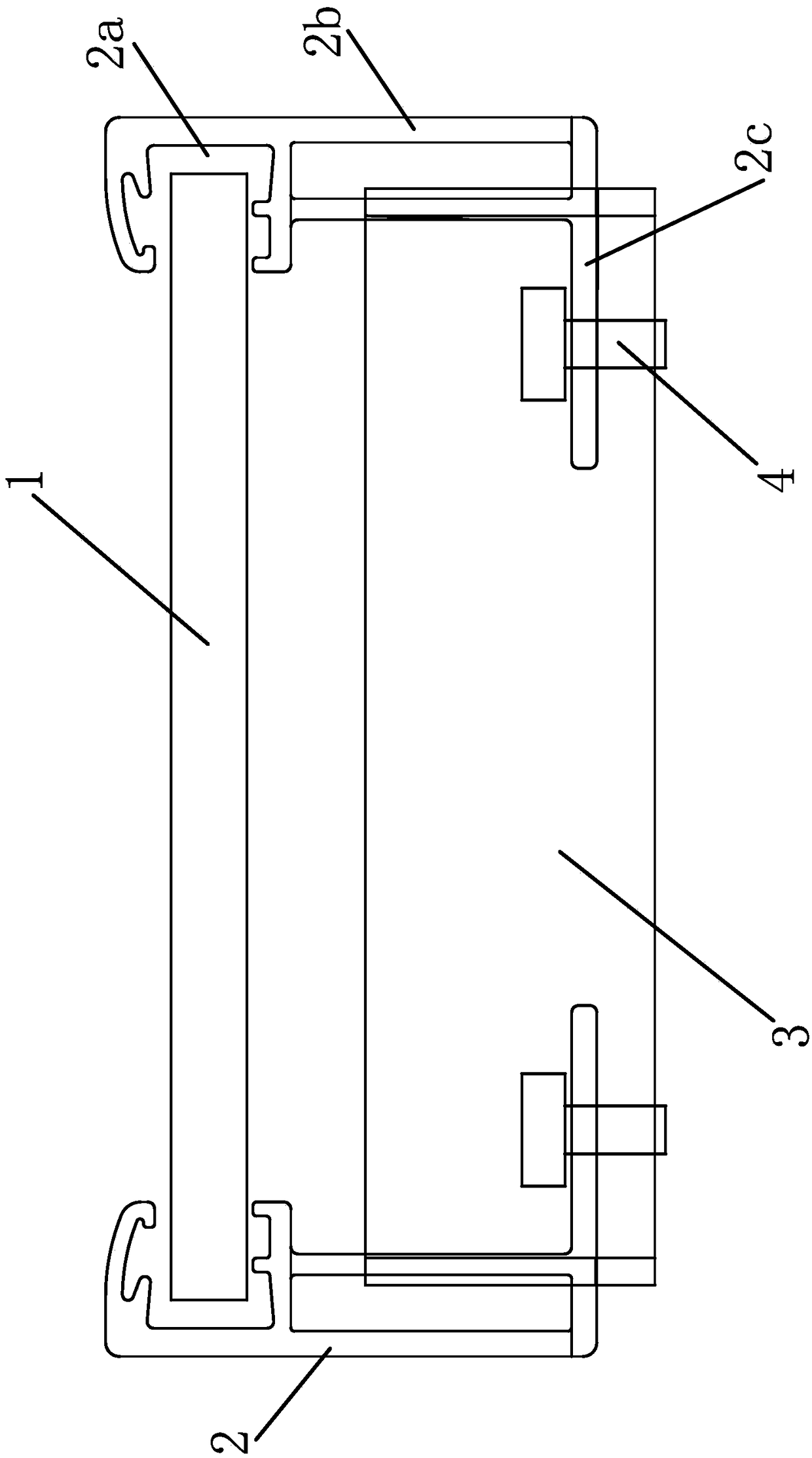

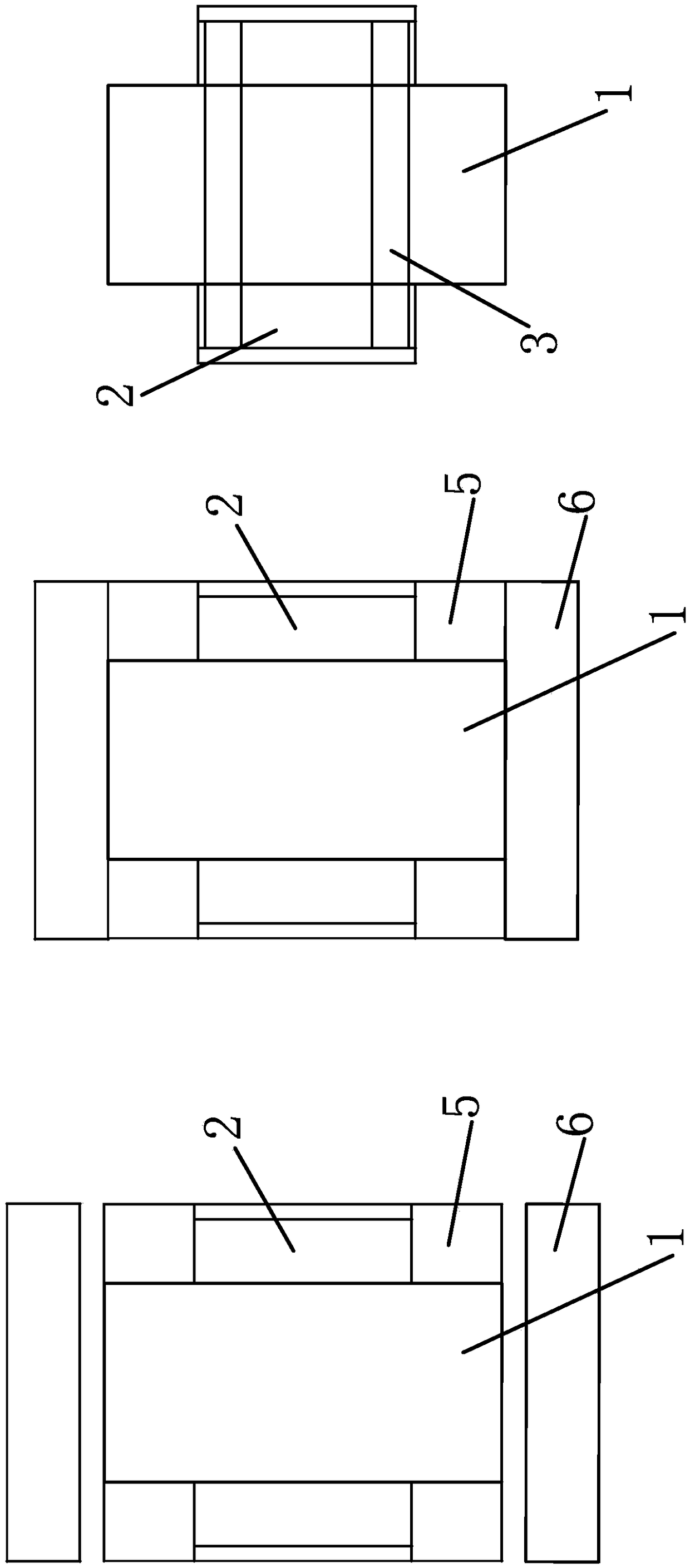

[0029] like figure 1 As shown, the improved photovoltaic module includes a double glass module 1 and a frame, the frame includes two long sides 2 and two short sides 3, and the two long sides 2 and two short sides 3 are surrounded to form a rectangular frame, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com