Floating reamer handle applied to finish machining of small-column inner hole and assembling method of floating reamer handle

A technology of small cylinder and inner hole, applied in the direction of reamer, reaming device, metal processing equipment, etc., can solve the problem of bell mouth, etc., and achieve the effect of simple and ingenious structure and simple assembly method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

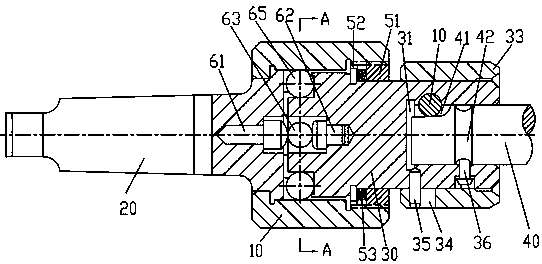

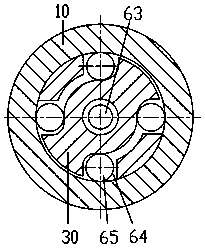

[0020] refer to figure 1 and figure 2

[0021] A floating reamer shank applied to the finishing of small cylindrical inner holes, comprising an outer sleeve 10 with a stepped hole at one end, the outer sleeve is provided with a hole that passes through one end of the outer sleeve and has a Mo The joint rod 20 of the taper, the connecting end of the joint rod is provided with a stepped part matched with the outer sleeve. The outer sleeve is also provided with a joint socket 30 that passes through the other side of the outer sleeve. An adjustment mechanism for micro-adjusting the cutting depth is provided on the end of the joint, and the other end of the joint sleeve is equipped with a shaft 40 for installing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com