Magnetic-fluid-coated textured surface lubricating substrate and processing method thereof

A treatment method and texturing technology, applied in the field of ferrofluid in the textured and magnetized hard coating surface lubricating substrate and its treatment, can solve the problems of high brittleness of the hard coating and scratches on other workpieces, and achieve improved durability Abrasiveness, prolonging the lubrication cycle, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail with reference to the drawings and embodiments, but the protection scope of the present invention is not limited to the embodiments.

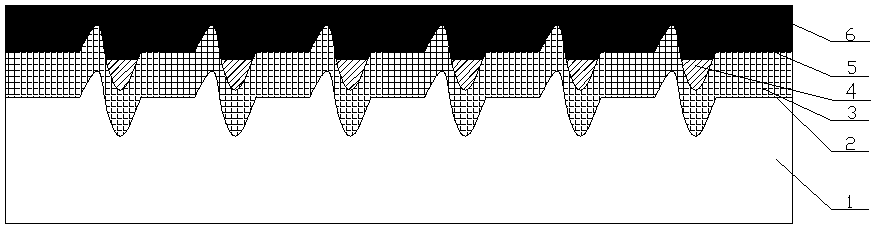

[0028] As shown in the accompanying drawings, in this embodiment, a magnetic fluid treatment method for lubricating the textured and magnetized hard coating surface according to the present invention includes YT15 hard alloy 1, hard coating TiC3, CoCr-based Magnetic film 4, Fe 3 o 4 Ferrofluid 6. The deposition method is chemical vapor deposition. Concrete preparation steps are as follows:

[0029] (1) Pretreatment: Polish the YT15 cemented carbide 1 to the mirror surface, remove the surface contamination layer, put it in alcohol and acetone in turn, and ultrasonically clean it for 30 minutes each to remove the sweat stains and oil stains on the surface, and dry it sufficiently.

[0030] (2) Use Nd:YAG pulsed laser to texture the surface of YT15 cemented carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com