Continuous-lubrication extrusion mold

A technology for extrusion dies and lubricants, applied in the direction of metal extrusion dies, etc., can solve problems such as poor lubrication effect, increased cost and difficulty of mold manufacturing, and wear and tear of the coating on the surface of the mold, so as to avoid coarse crystal ring defects and improve Effect of surface quality, continuous and stable lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

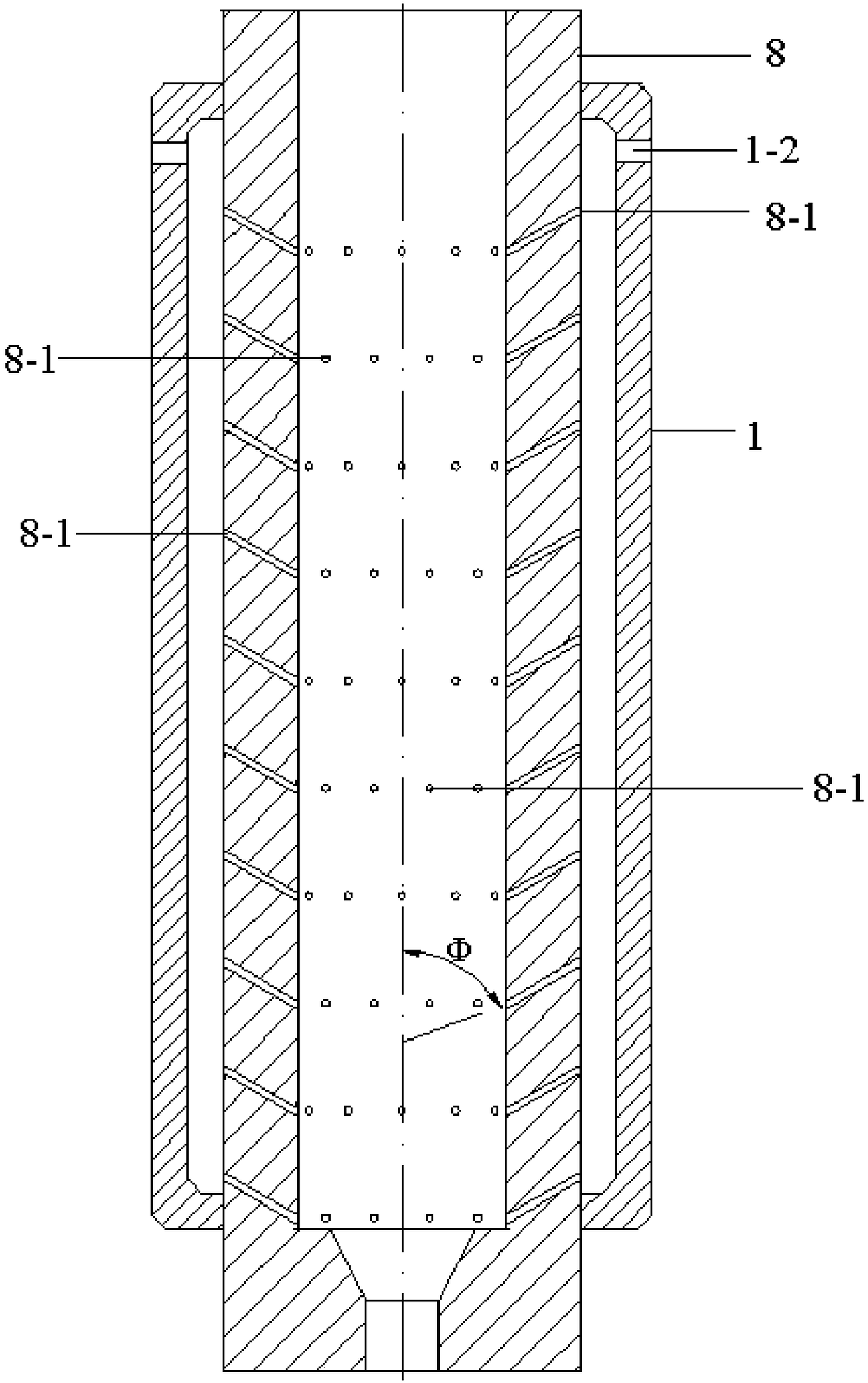

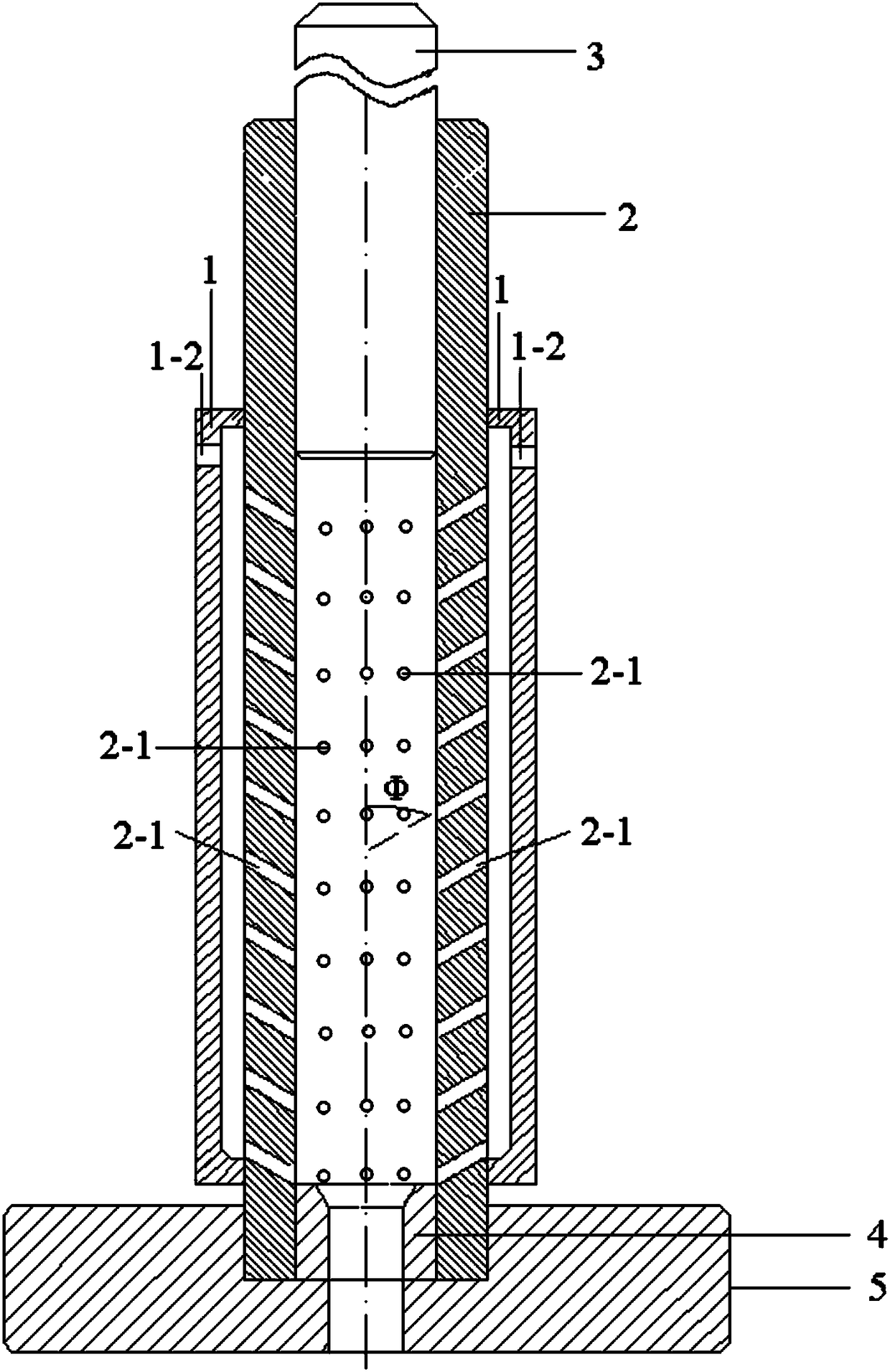

[0025] Specific embodiment one: this embodiment is a continuous lubricated extrusion die, such as figure 1 , specifically composed of a lubricant storage tank 1 and an extrusion die 8;

[0026] The lubricant storage tank 1 is a hollow structure, and at least one first lubricant injection hole 1-2 is arranged on the upper part of the side wall of the lubricant storage tank 1. The first lubricant injection hole 1-2 is a through hole, and the first lubrication The lubricant injection hole 1-2 communicates with the inside of the lubricant storage tank 1;

[0027] At least one lubricant hole 8-1 is arranged on the side wall of the extrusion die 8, the lubricant hole 8-1 is a through hole, and the lubricant hole 8-1 communicates with the inside of the extrusion die 8; the lubricant hole 8 The angle Φ between -1 and the vertical axis is 30°~90°;

[0028] The lubricant storage tank 1 is set on the outside of the extrusion die 8, and the contact between the upper end surface and the ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: the diameter of the lubricant hole 8 - 1 is 0.1 mm to 5 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

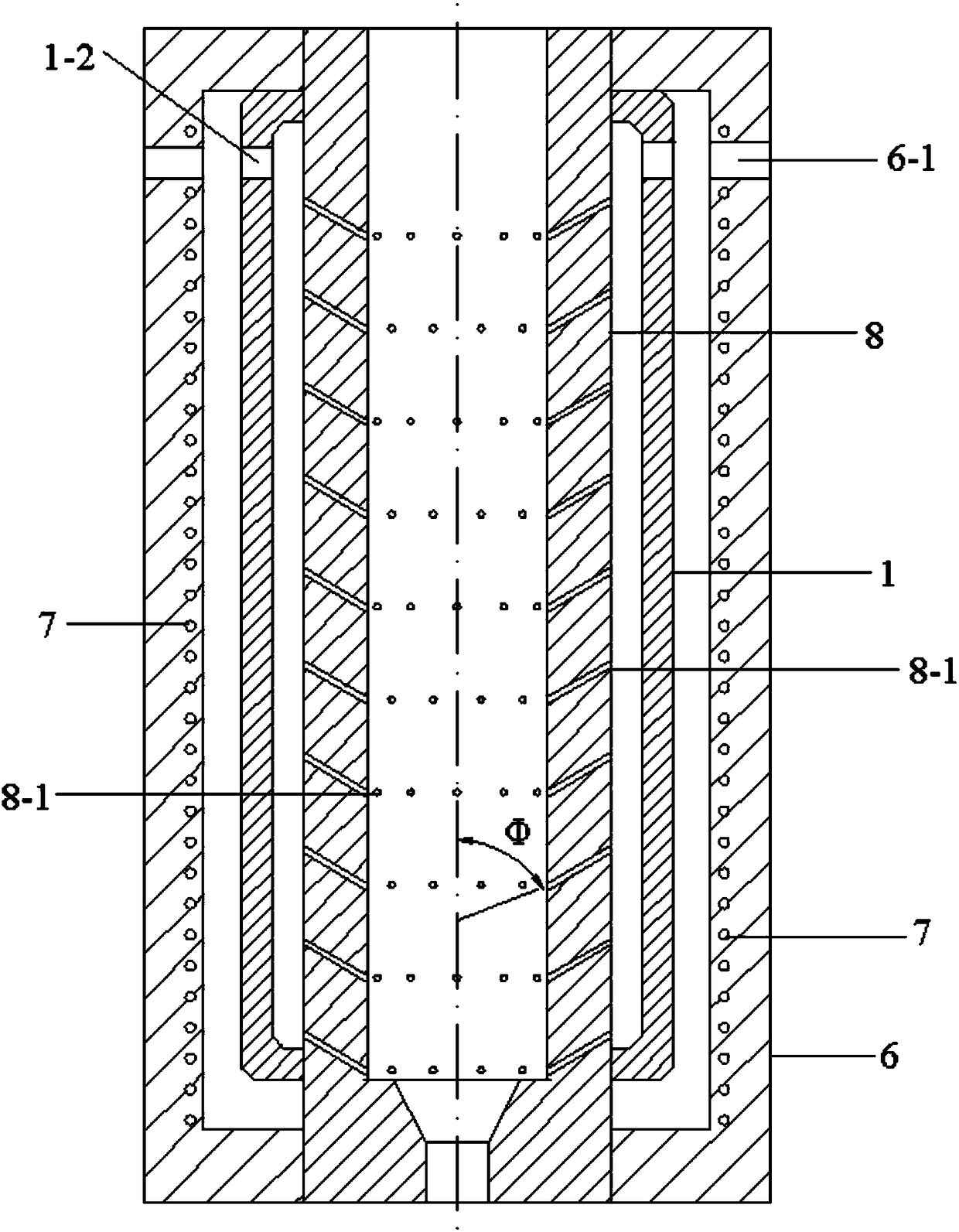

[0036] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: if figure 2 , the outer wall of the lubricant storage tank 1 is covered with a thermal insulation cover 6, and the upper part of the side wall of the thermal insulation cover 6 is provided with at least one second lubricant injection hole 6-1, and the second lubricant injection hole 6-1 is a through hole; At least one heating resistance wire 7 is arranged in the heat preservation cover 6 . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com