Ultra lapping machining centering fixture for bearing inner ring roller

A technology of bearing inner ring and centering fixture, which is applied in the direction of grinding workpiece support, etc., to achieve good elasticity, good uniformity of deformation, and improve the effect of axial positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

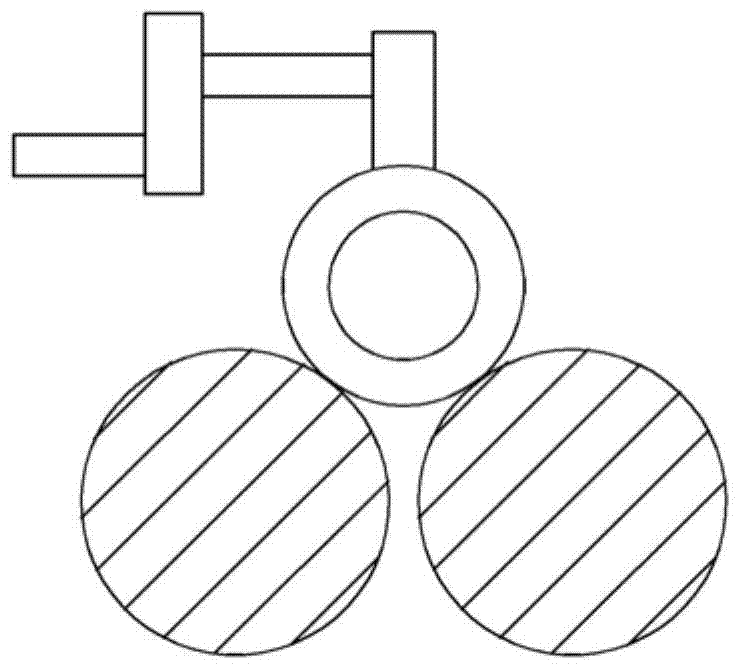

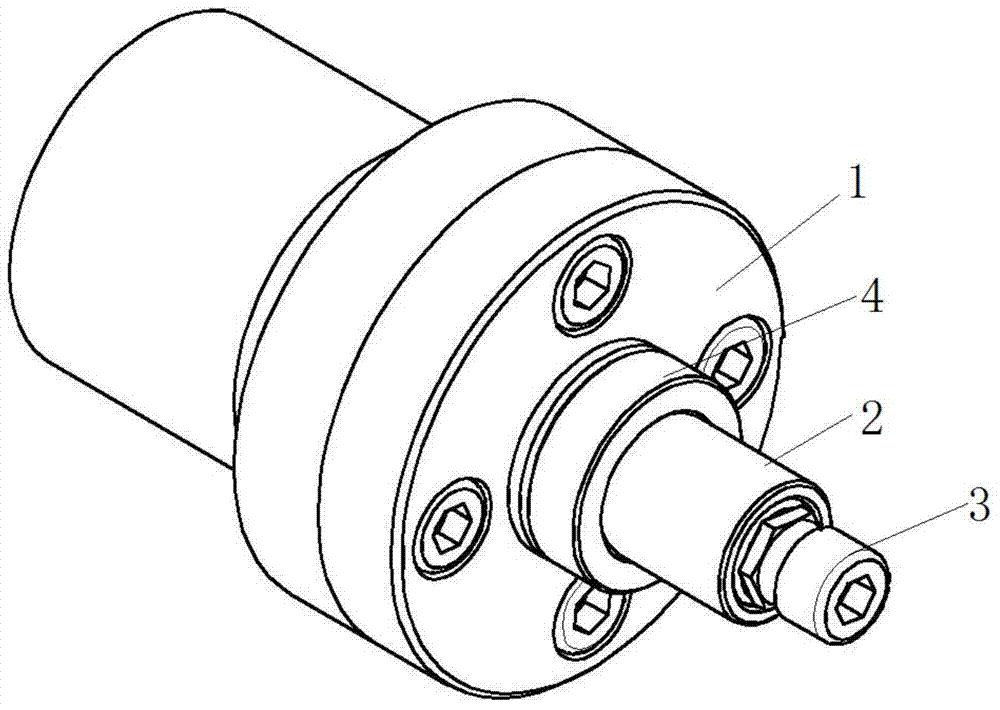

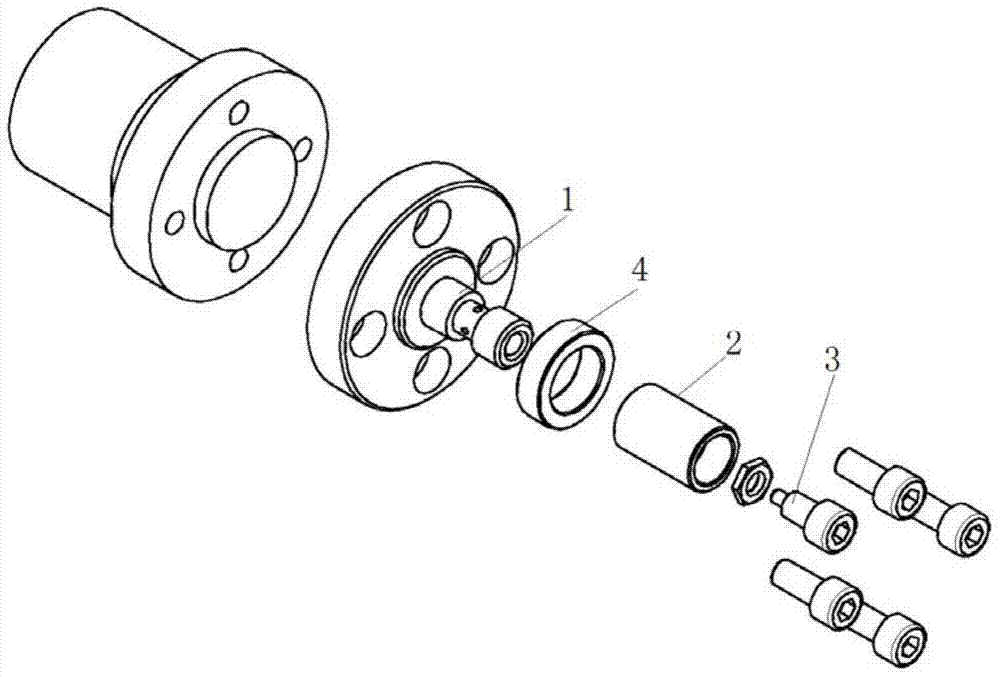

[0015] Such as Figure 2 to Figure 4 As shown, the centering fixture for the ultra-finishing machining of the raceway of the bearing inner ring includes a clamp body 1, a thin-walled sleeve 2, a live column 3, a positioning block 4, and a liquid plastic 5.

[0016] There is an outer annular groove on the clamp body 1, and there is a live column cavity inside the clamp body 1. The live column cavity communicates with the outer annular groove. The front end of the clamp body 1 is threaded to connect the live column 3, and the front end of the live column 3 extends into the live column cavity. , the thin-walled sleeve 2 has an inner annular groove, the thin-walled sleeve 2 is sleeved outside the clamp body 1, the thin-walled sleeve 2 and the clamp body 1 are connected by interference fit, the inner ring of the thin-walled sleeve 2 Liquid plastic is poured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com