Method for improving quasi-beta forging deformation uniformity of titanium alloy high-rib forge piece

A titanium alloy and uniformity technology, which is applied in the field of titanium alloy processing, can solve the problems of small deformation at the top of the rib, unqualified forging performance, and deformation dead zone, etc., to achieve increased deformation, large metal flow deformation, and uniform deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for improving the uniformity of quasi-beta forging deformation of TC18 titanium alloy high-strength forgings, comprising the following steps:

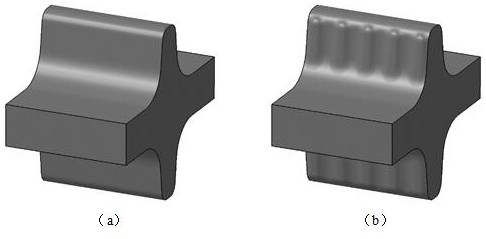

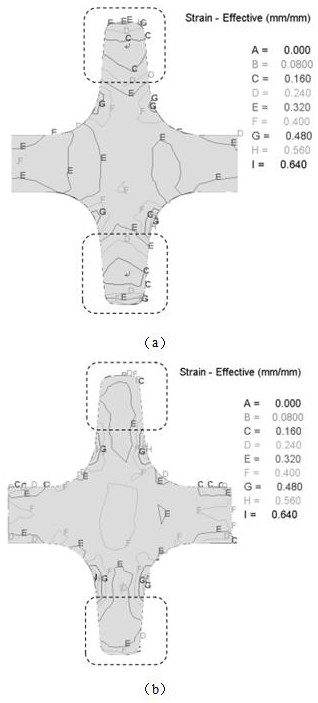

[0022] S1, before quasi-β forging, carry out finite element simulation to the improved pre-forging model through software, optimize the structural size parameters of the improved pre-forging model and perform quasi-β forging simulation calculation, so that the improved pre-forging model The deformation of the final forging model obtained after quasi-β forging is within the effective deformation range of 20% to 40%; wherein, the improved pre-forging model is vertically arranged on the rib side wall of the conventional pre-forging Boss. The schematic diagram of the conventional pre-forging model is as follows figure 1 As shown in (a), the schematic diagram of the improved pre-forging model is as follows figure 1 (b) shown.

[0023] In this example, see figure 1 (b) Bosses are provided on both sides of the ribs of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com