Patents

Literature

203results about How to "Improve final performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

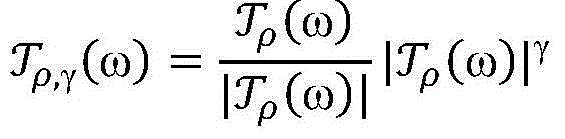

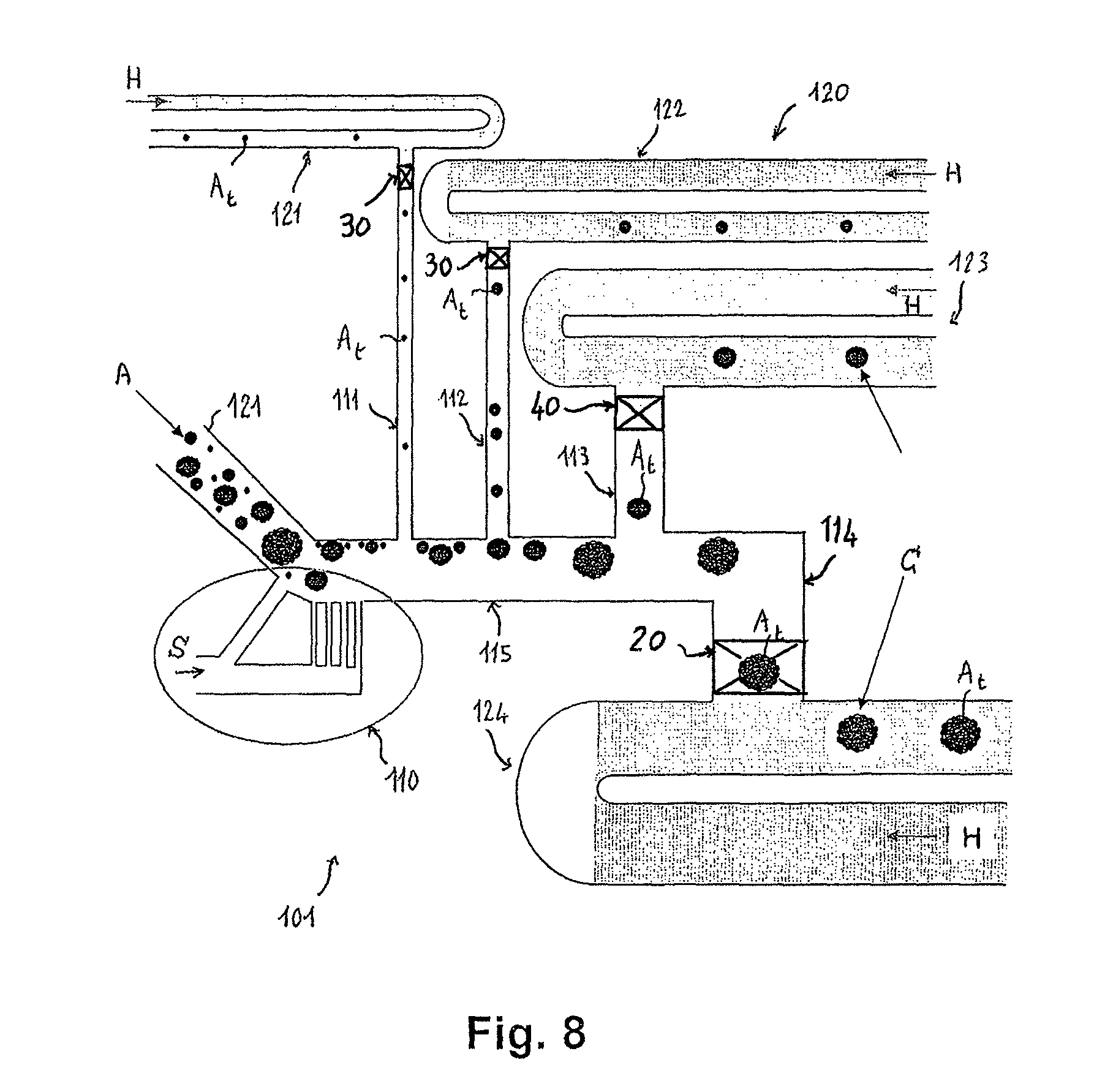

Microfluidic system and method for sorting cell clusters and for the continuous encapsulation thereof following sorting thereof

ActiveUS20090286300A1Minimized pressure lossMaintenance conditionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCell cluster

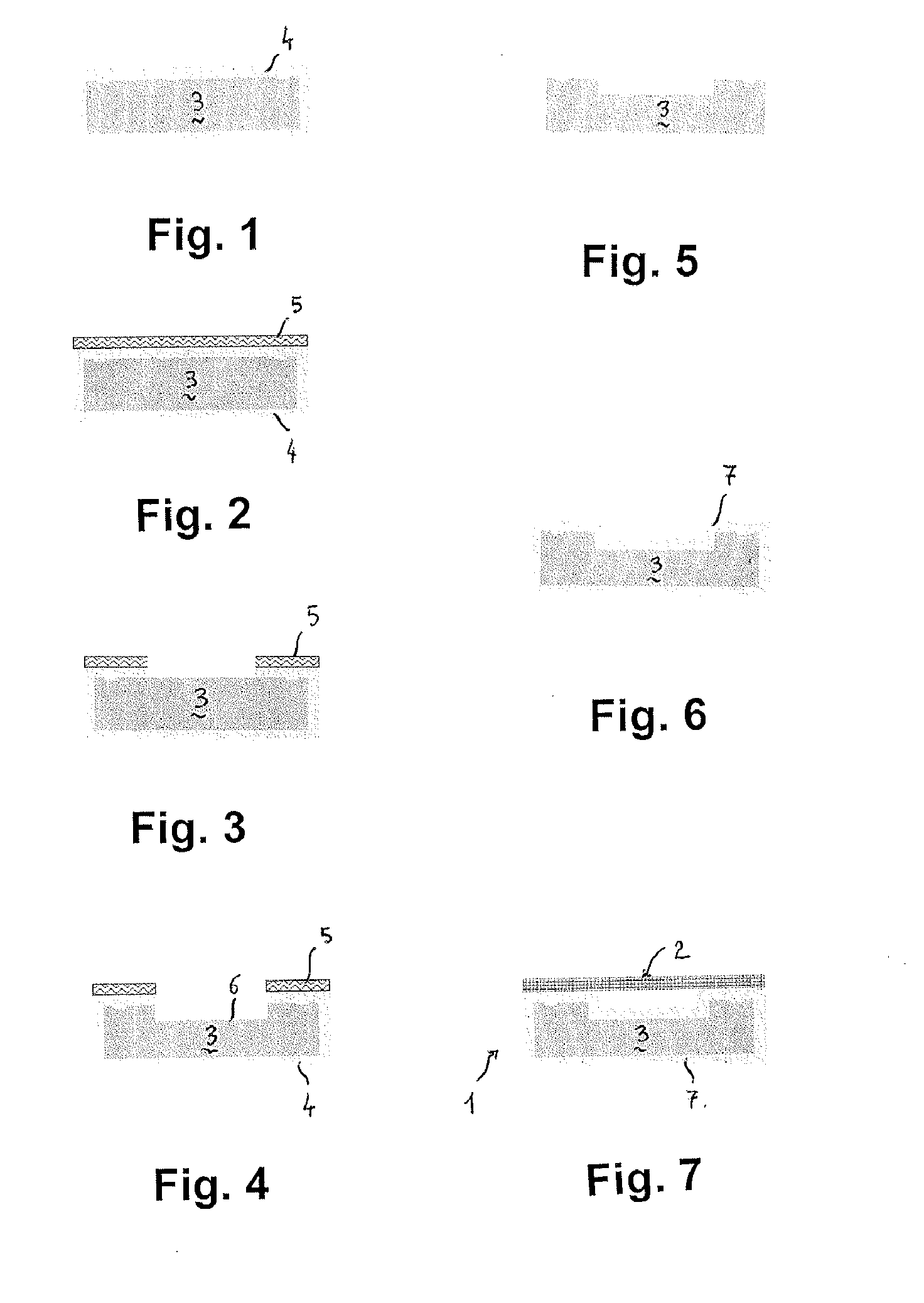

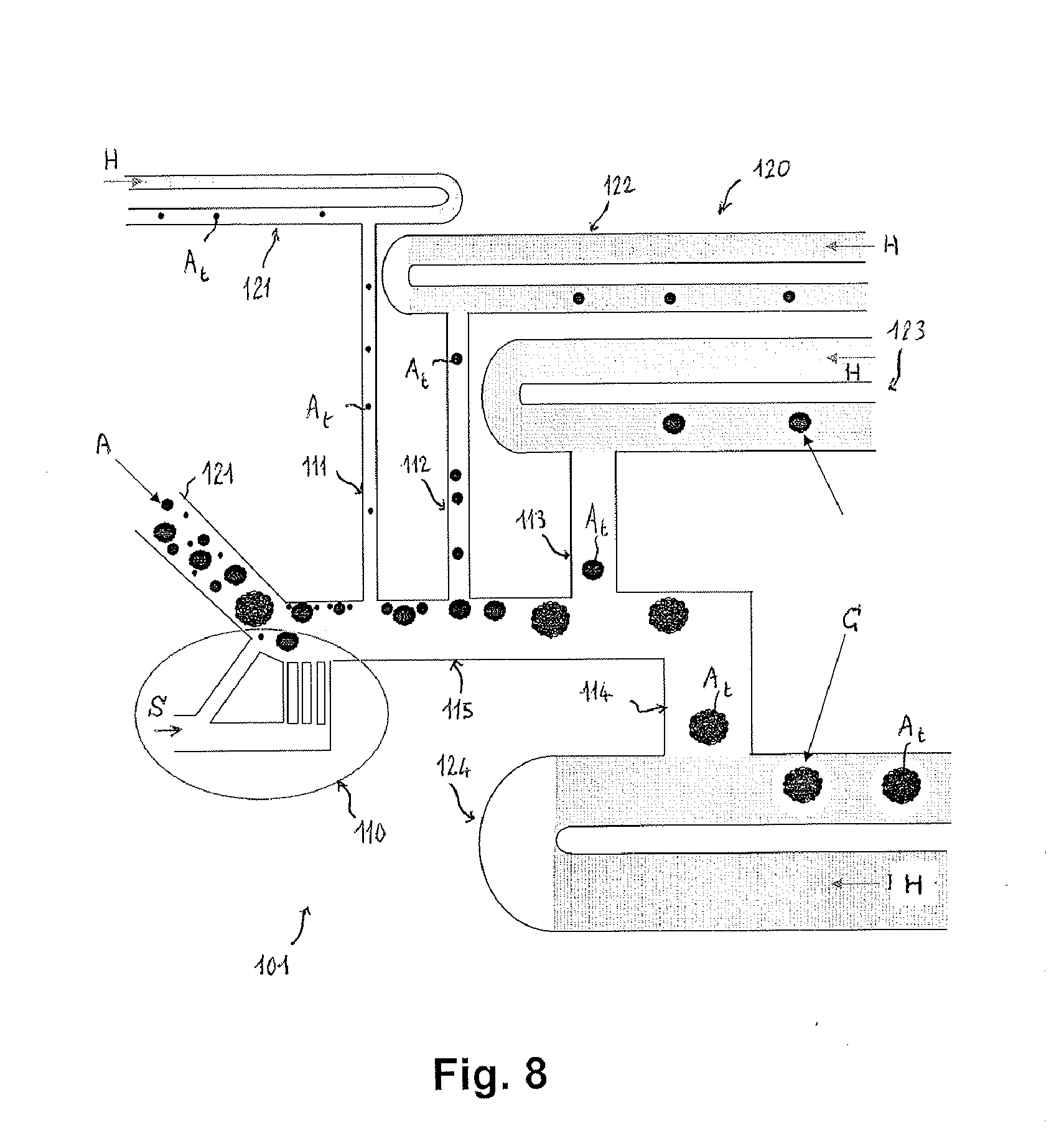

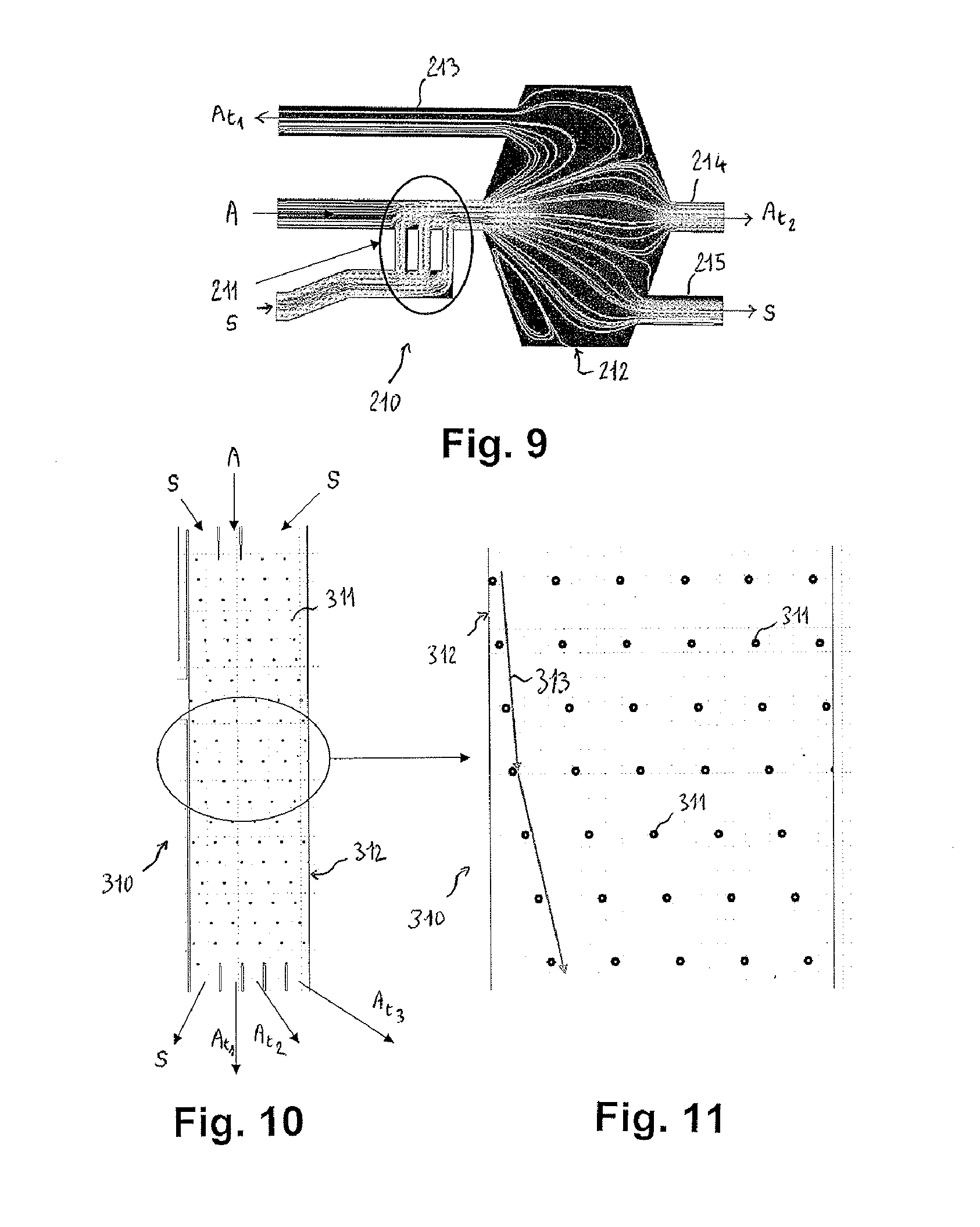

A microfluidic system and method for sorting cell clusters, and for the continuous and automated encapsulation of the clusters, once sorted, in capsules of sizes suitable for those of these sorted clusters is provided. The microfluidic system comprises a substrate in which a microchannel array comprising a cell sorting unit is etched and around which a protective cover is bonded, and the sorting unit comprises deflection means capable of separating, during the flow thereof, relatively noncohesive cell clusters, each of size ranging from 20 μm to 500 μm and of 20 to 10 000 cells approximately, such as islets of Langerhans, at least two sorting microchannels arranged in parallel at the outlet of said unit being respectively designed so as to transport as many categories of sorted clusters continuously to a unit for encapsulation of the latter, also formed in said array.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

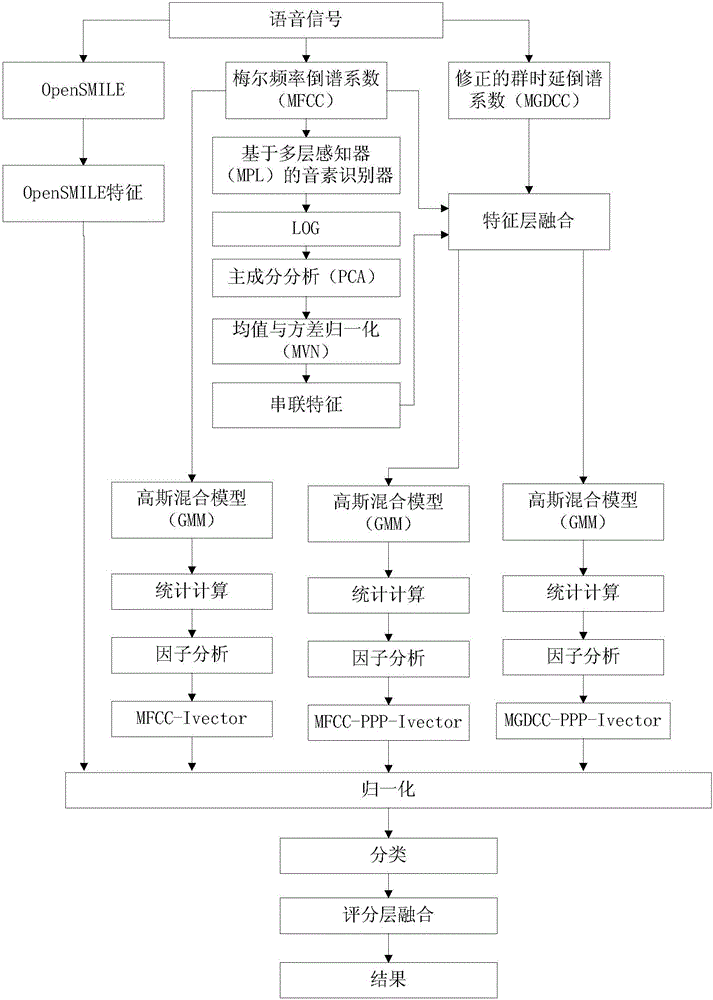

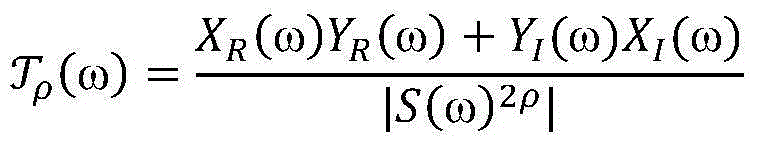

Countercheck method for automatically identifying speaker aiming to voice deception

ActiveCN105139857ACountermeasures work wellEnhanced confrontation abilitySpeech analysisCosine similaritySupport vector machine

The invention provides a countercheck method for automatically identifying a speaker aiming to voice deception, which is a voice anti-spoofing technology based on a method combining various features and a plurality of sub-systems. According to the invention, the serial features of the posterior probability of a phoneme in the phonological level and the MFCC features of voice level or MFDCC features of phase level are combined, thus the performance of the system is significantly enhanced. By combining the provided i-vector sub-system and OpenSMILE (open Speech and Music Interpretation by Large Space Extraction criterion containing voice and rhythmic information, the final presentation of the system is further enhanced. To a back-end model, the development datum are used; and under the situation of knowing deceptive attacks, a two-level support vector machine has better performance compared with one-level cosine similarity or PLDA evaluations, while the one-level evaluation approach has better robustness under the situation without seeing the test datum and knowing the deceptive conditions.

Owner:SUN YAT SEN UNIV +1

Microfluidic system and method for sorting cell clusters and for the continuous encapsulation thereof following sorting thereof

ActiveUS8263023B2Improve final performanceMinimize formationSamplingTransportation and packagingEngineeringLangerhans Islets

A microfluidic system and method for sorting cell clusters, and for the continuous and automated encapsulation of the clusters, once sorted, in capsules of sizes suitable for those of these sorted clusters is provided. The microfluidic system comprises a substrate in which a microchannel array comprising a cell sorting unit is etched and around which a protective cover is bonded, and the sorting unit comprises deflection means capable of separating, during the flow thereof, relatively noncohesive cell clusters, each of size ranging from 20 μm to 500 μm and of 20 to 10 000 cells approximately, such as islets of Langerhans, at least two sorting microchannels arranged in parallel at the outlet of said unit being respectively designed so as to transport as many categories of sorted clusters continuously to a unit for encapsulation of the latter, also formed in said array.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

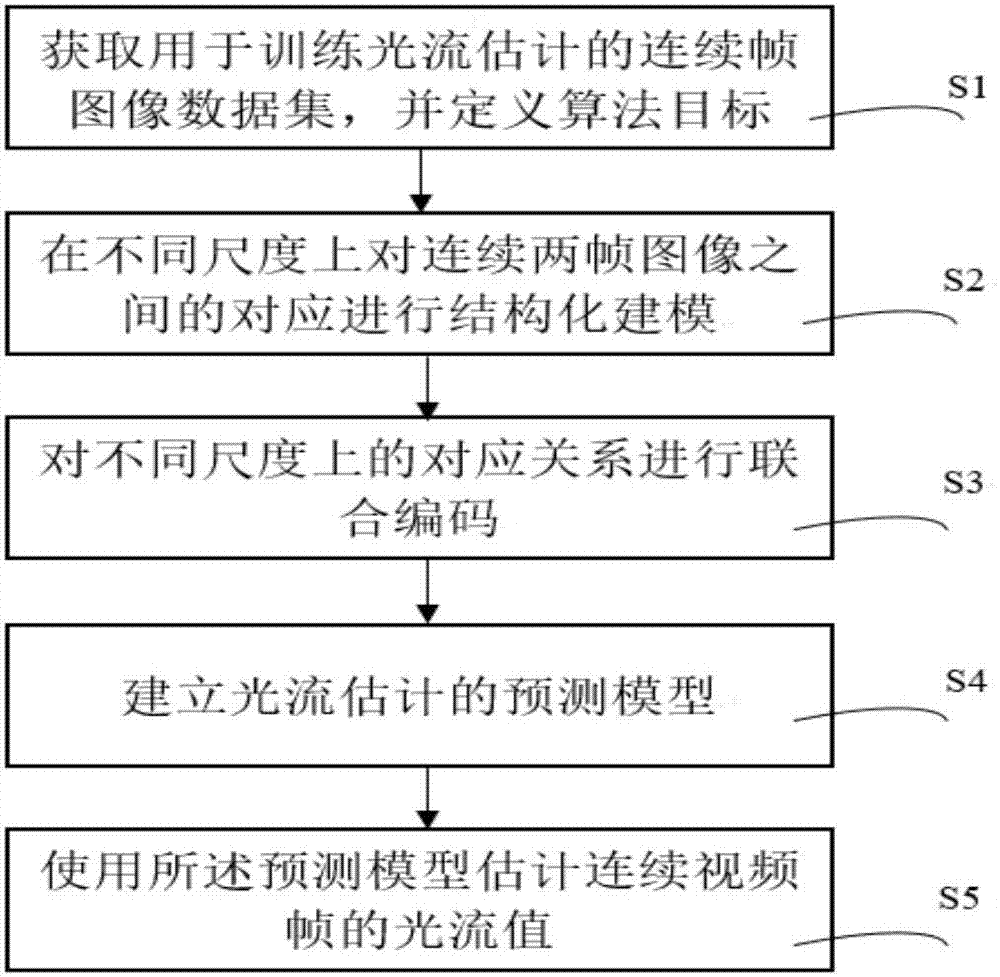

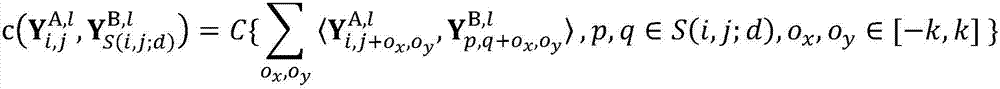

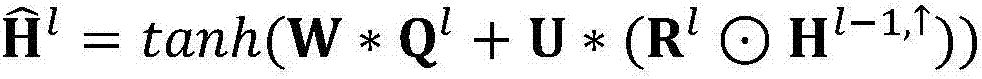

Optical flow estimation method based on multiple dimensioned corresponding structuring learning

The invention discloses an optical flow estimation method based on multiple dimensioned corresponding structuring learning; under given successive video frames, the method can parse the motion conditions of the first frame relative to the second frame; the method specifically comprises the following steps: obtaining a successive frame image data set used for training optical flow estimation, and defining an algorithm object; carrying out structuring modeling for correspondences between two successive frame images in different dimensions; joint encoding the corresponding relations in different dimensions; building an optical flow estimation prediction model; using the prediction model to estimate the successive video frame optical flow values. The optical flow estimation method is applied to the optical flow motion analysis in true videos, and can provide better effect and robustness under various complex conditions.

Owner:ZHEJIANG UNIV

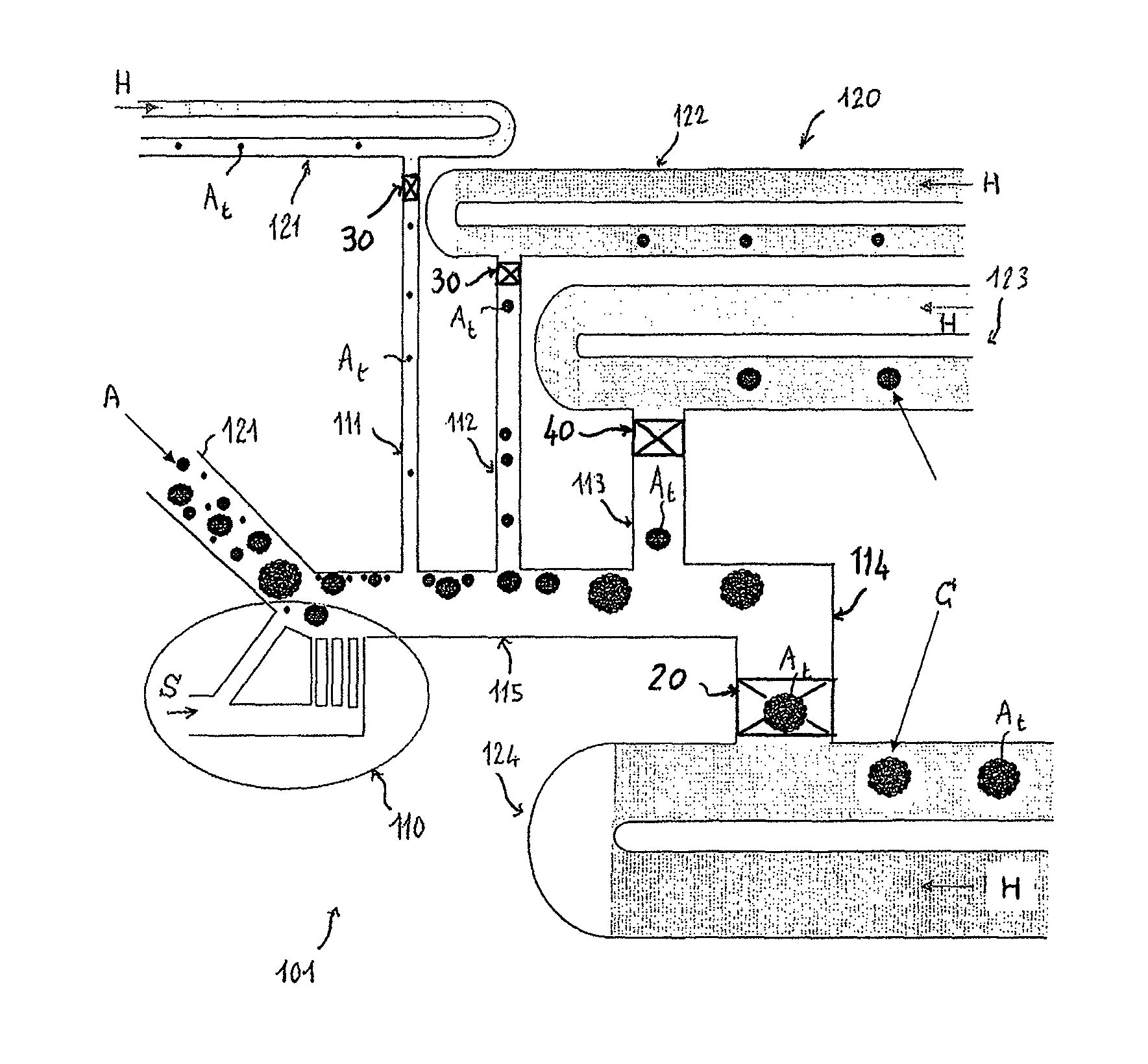

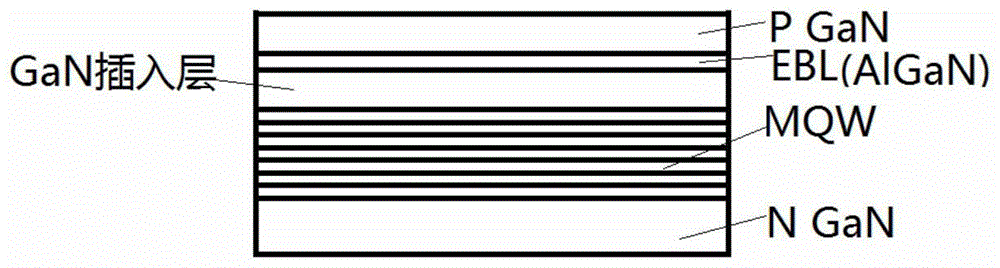

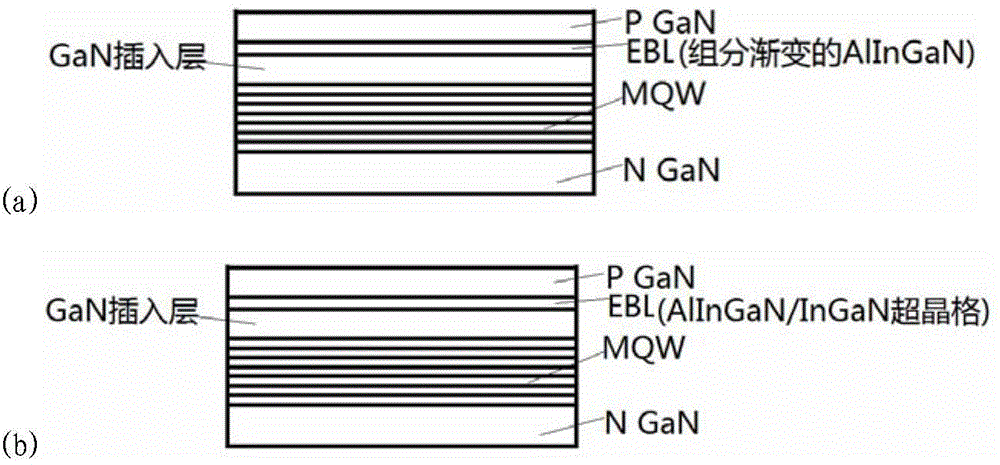

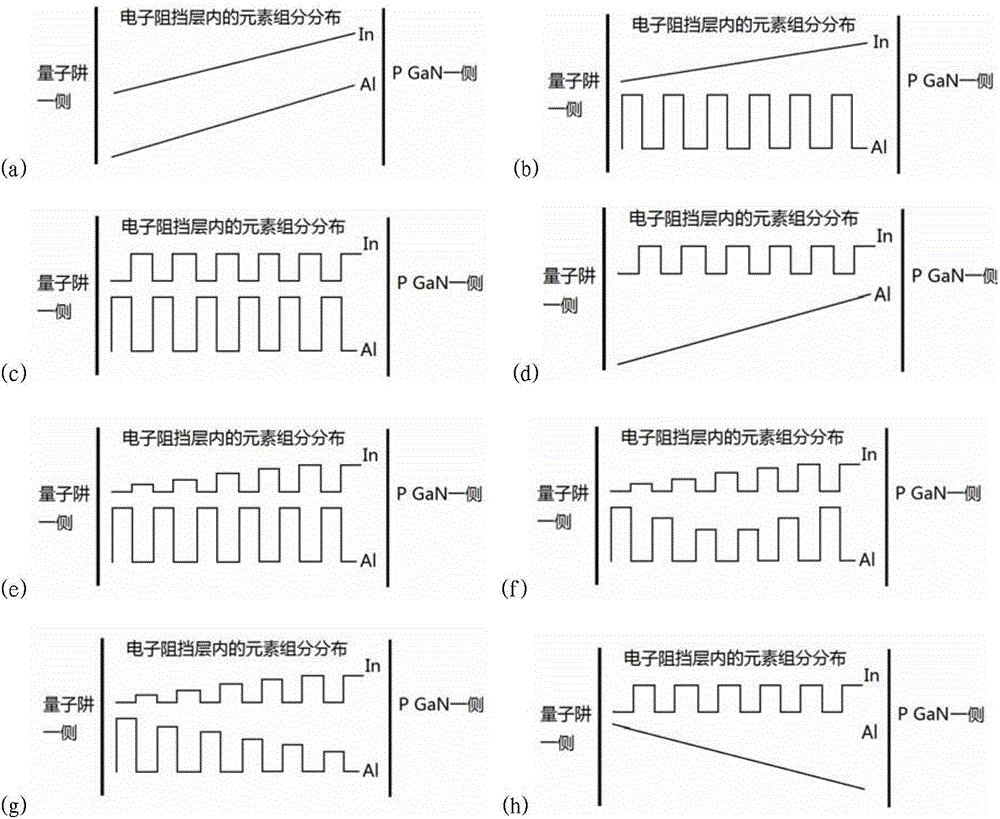

Electron blocking layer structure of photoelectric device

InactiveCN104659171AImprove compound efficiencyImprove electronic efficiencySemiconductor devicesBlocking layerPhotoelectric effect

The invention provides an electron blocking layer structure of a photoelectric device. The electron blocking layer structure is characterized in that structure matching between a quantum well and a P layer is achieved through adjusting a lattice structure and a band gap as much as possible; meanwhile, the formation of a polarized electric field is reduced, the formation of a negative charge area in an electron blocking layer is weakened as much as possible, and further the efficiency is improved; the electron leakage caused by energy band bending of the electron blocking layer and the increment of hole potential energy of the P layer are weakened. The electron blocking layer structure of the photoelectric device adopts AlInGaN or AlInGaN / InGaN super-lattice structure growth, wherein the In component is less than or equal to 10 percent; the Al component is less than or equal to 40 percent; the gradual distribution of the In component and the Al component exists in the electron blocking layer, and gradual change principles of the In component and the Al component are mutually independent; as for the electron blocking layer with an AlInGaN / InGaN super-lattice structure, the gradual change of the In component occurs in a super-lattice AlInGaN or a super-lattice AlInGaN / InGaN or in both the super-lattice AlInGaN and the super-lattice AlInGaN / InGaN.

Owner:西安利科光电科技有限公司

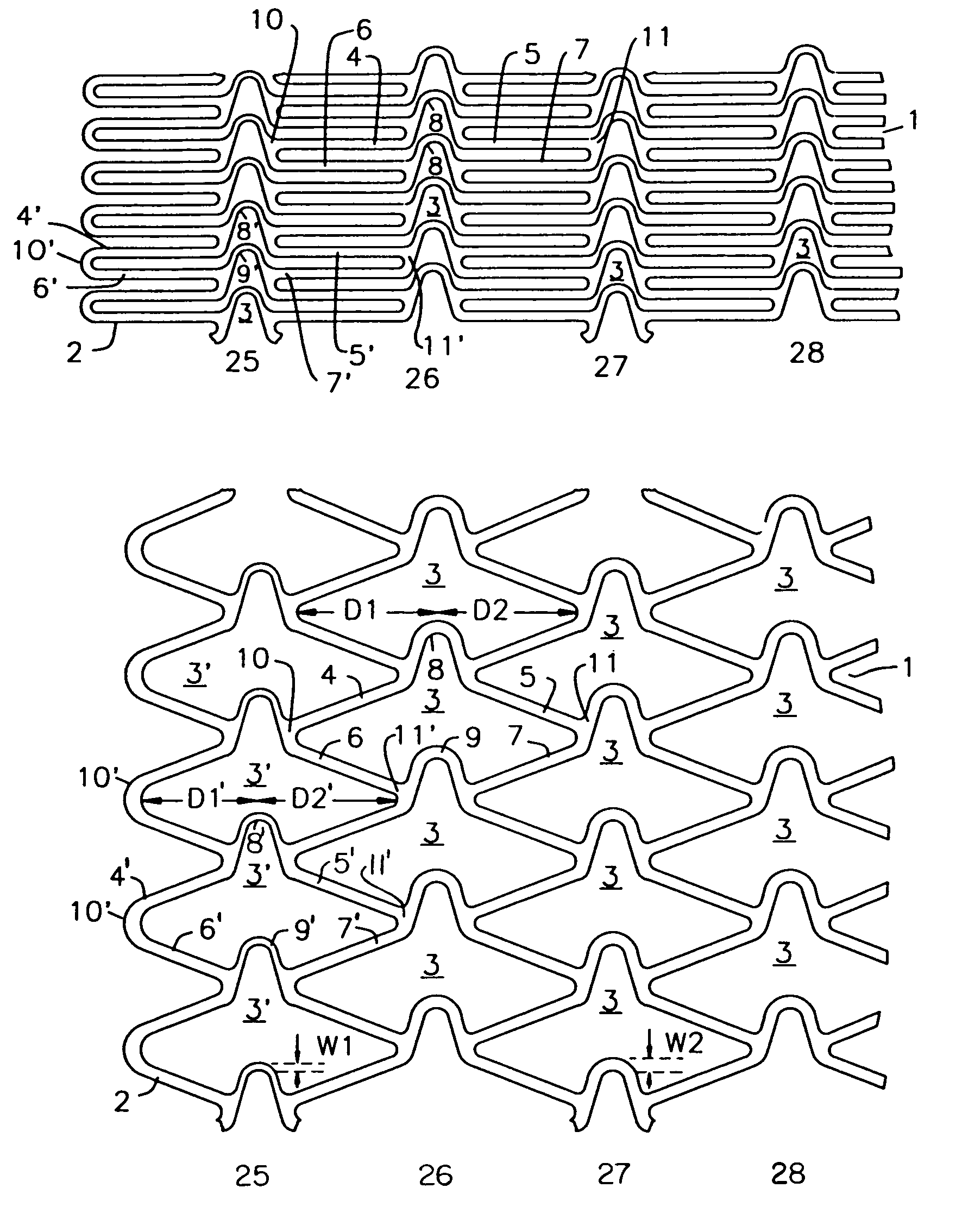

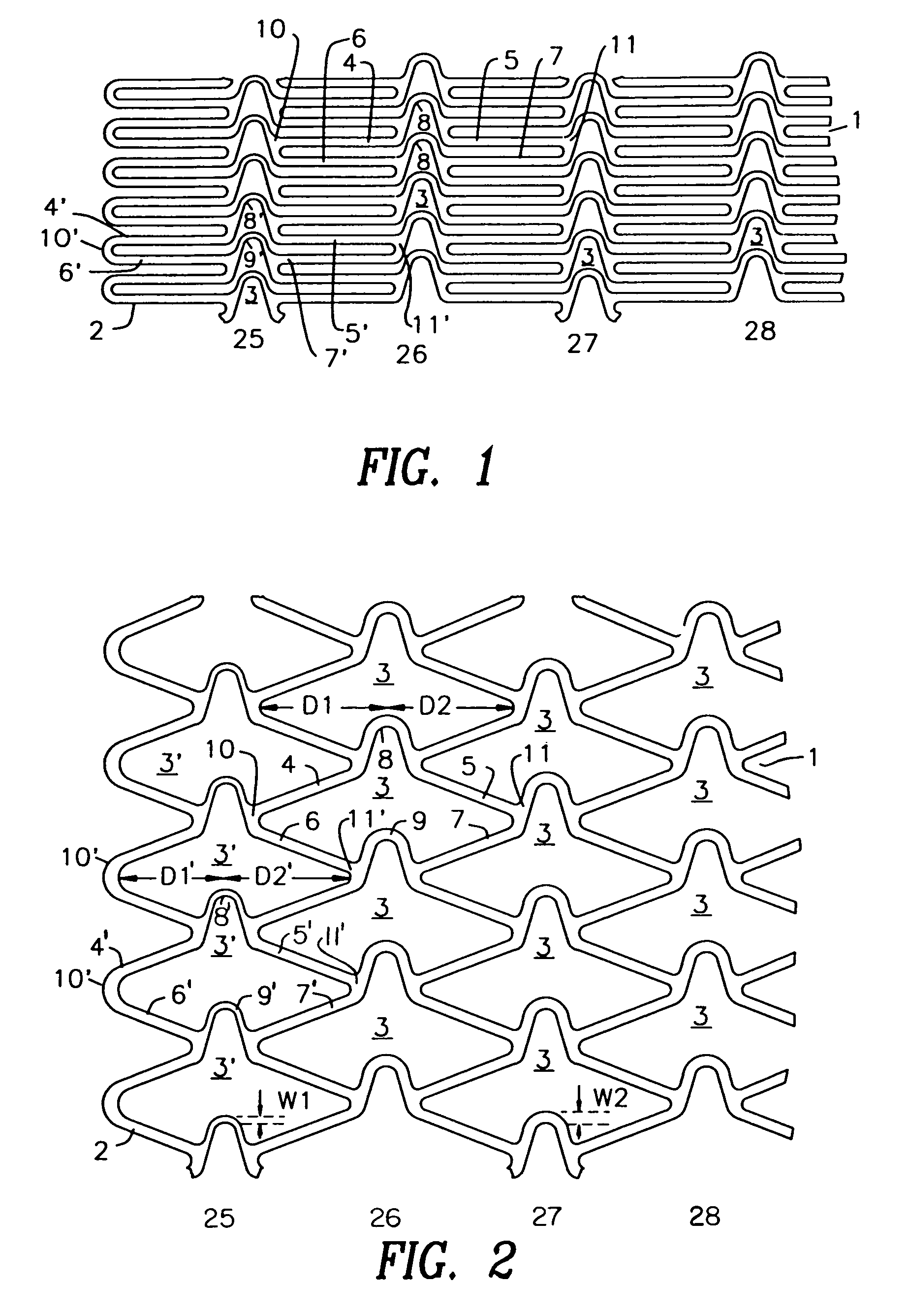

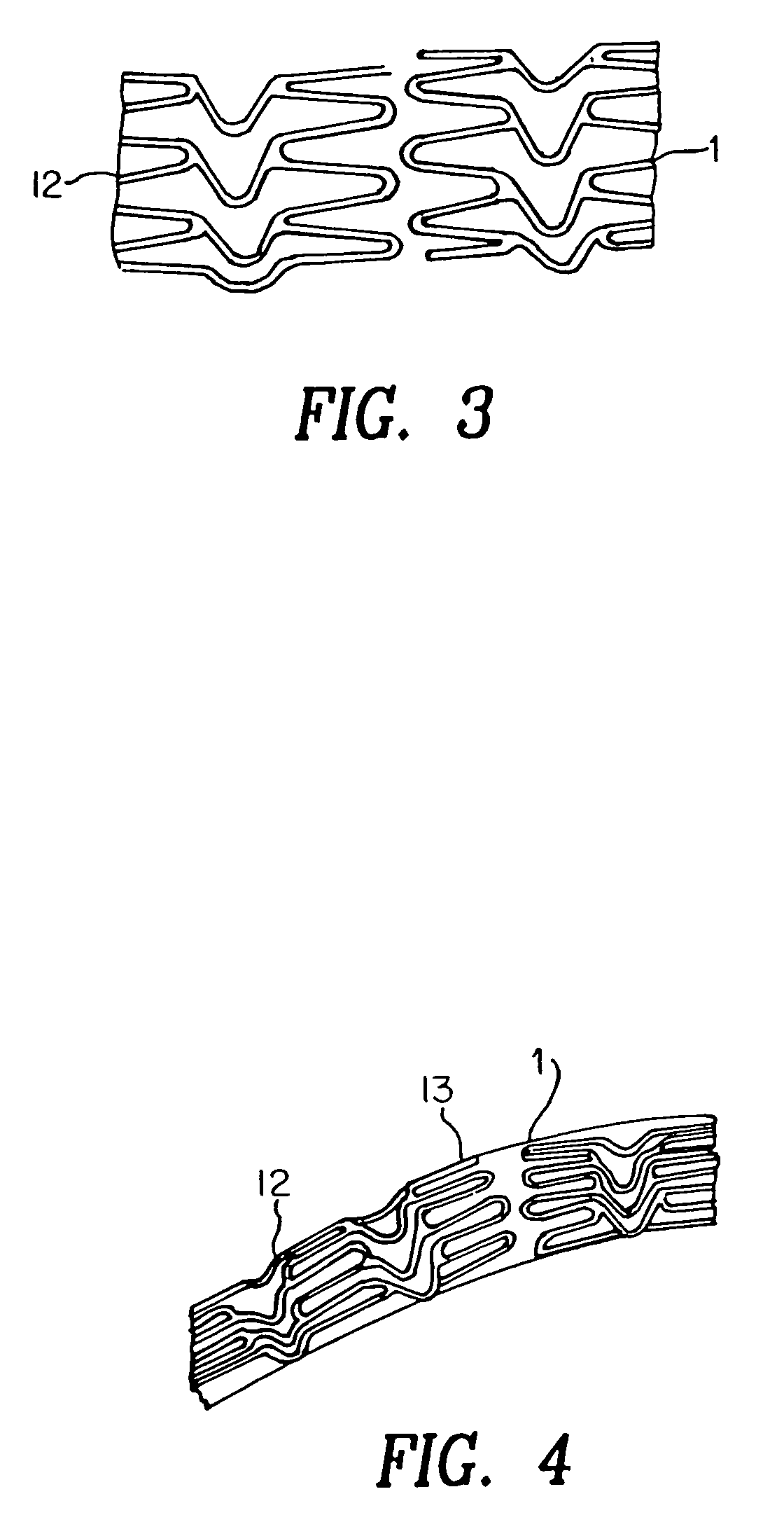

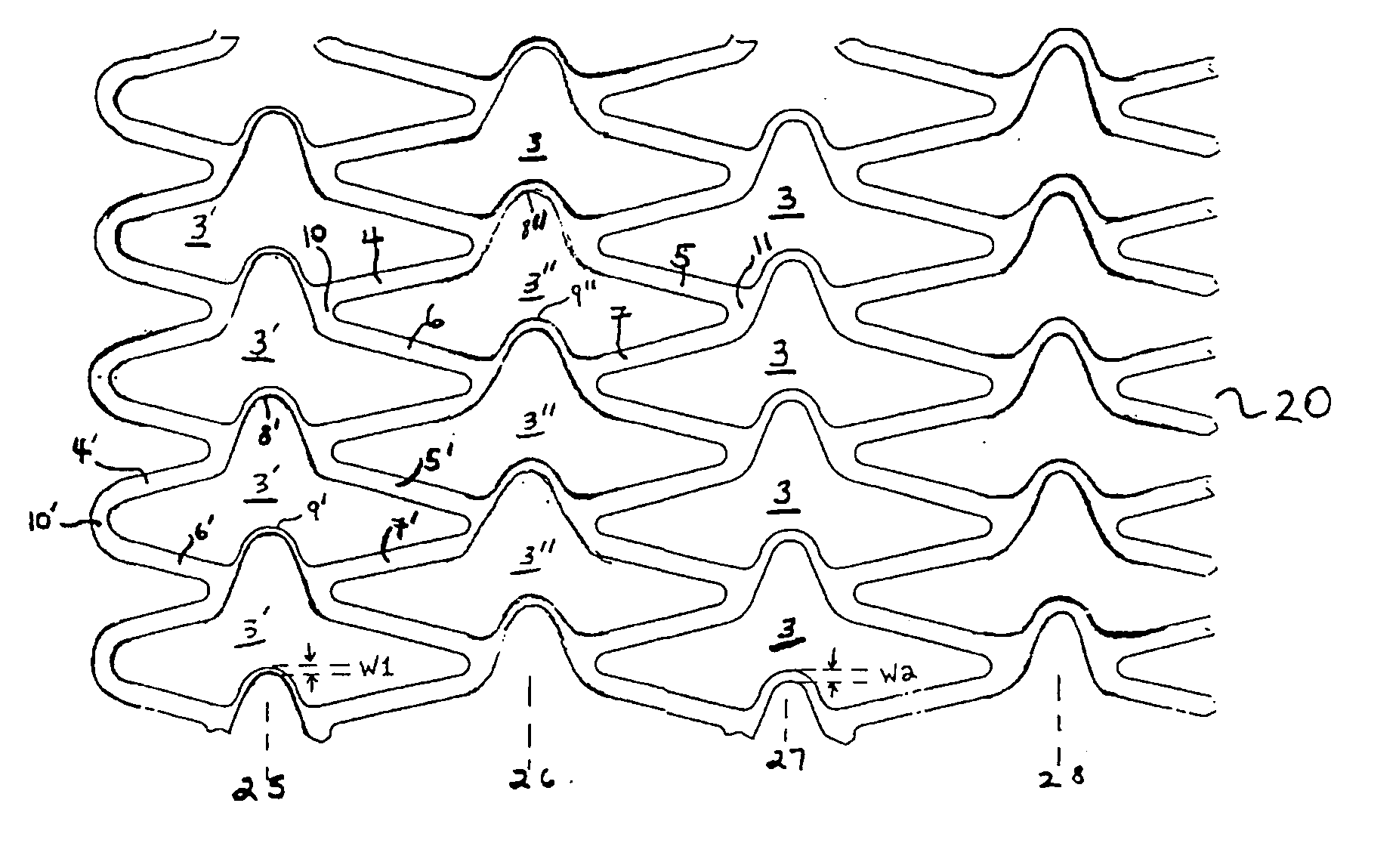

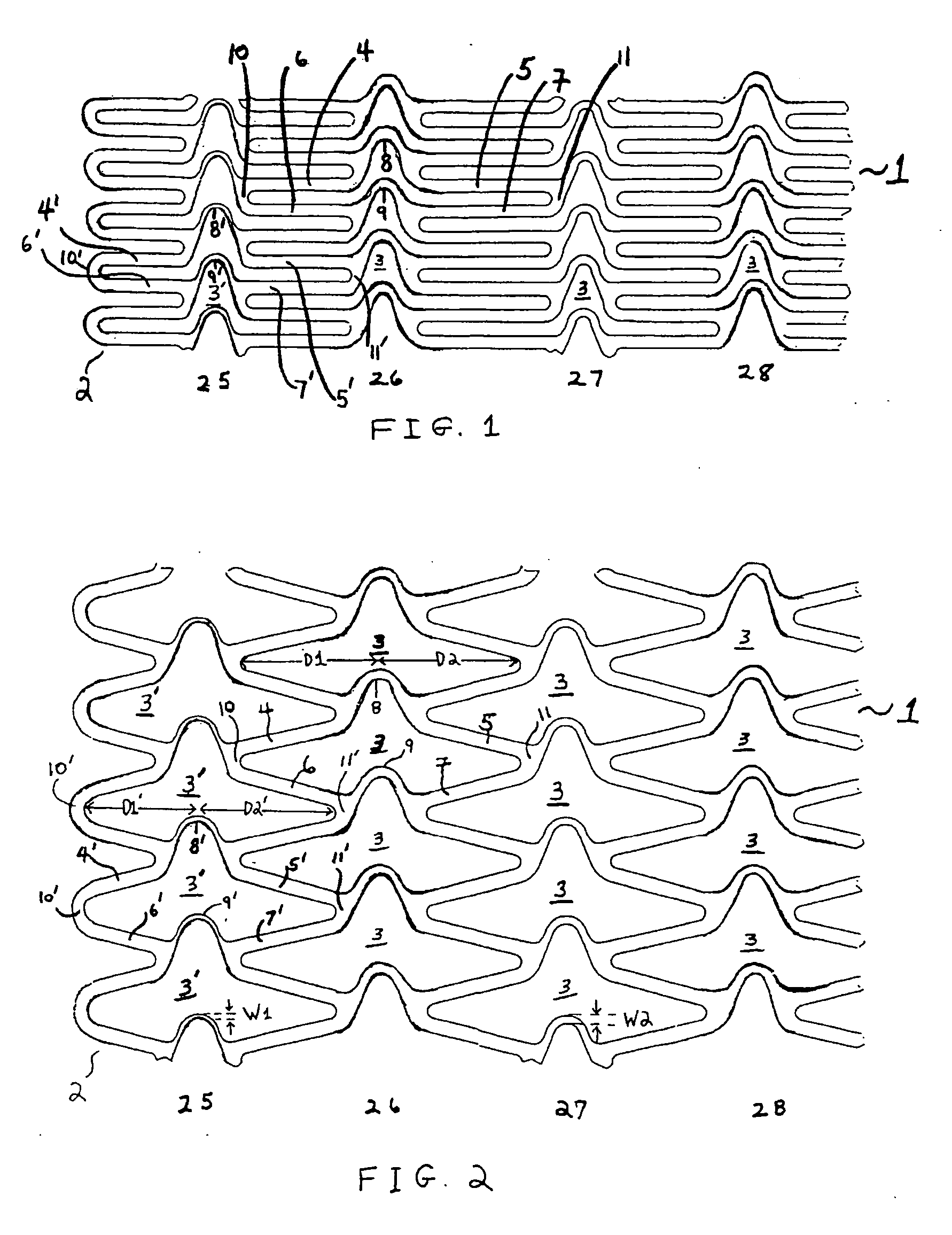

Stent with variable features to optimize support and method of making such stent

InactiveUS7044963B1Improve stent end effectIncrease or decrease thicknessStentsSurgeryVariable featuresIntravascular stent

An intravascular stent especially suited for implanting in curved arterial portions or ostial regions. The stent can include an end region which is fabricated to have a greater radial strength than the remaining axial length of the stent. Such a stent is particularly suited for use in ostial regions, which require greater support near the end of the stent. The stent alternatively can include sections adjacent the end of the stent with greater bending flexibility than the remaining axial length of the stent. Such a stent is particularly suited for use in curved arteries. The stent can also be constructed with an end that has greater radial strength and sections adjacent the end with greater bending flexibility. Such a stent prevents flaring of the stent end during insertion.

Owner:MEDINOL LTD

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

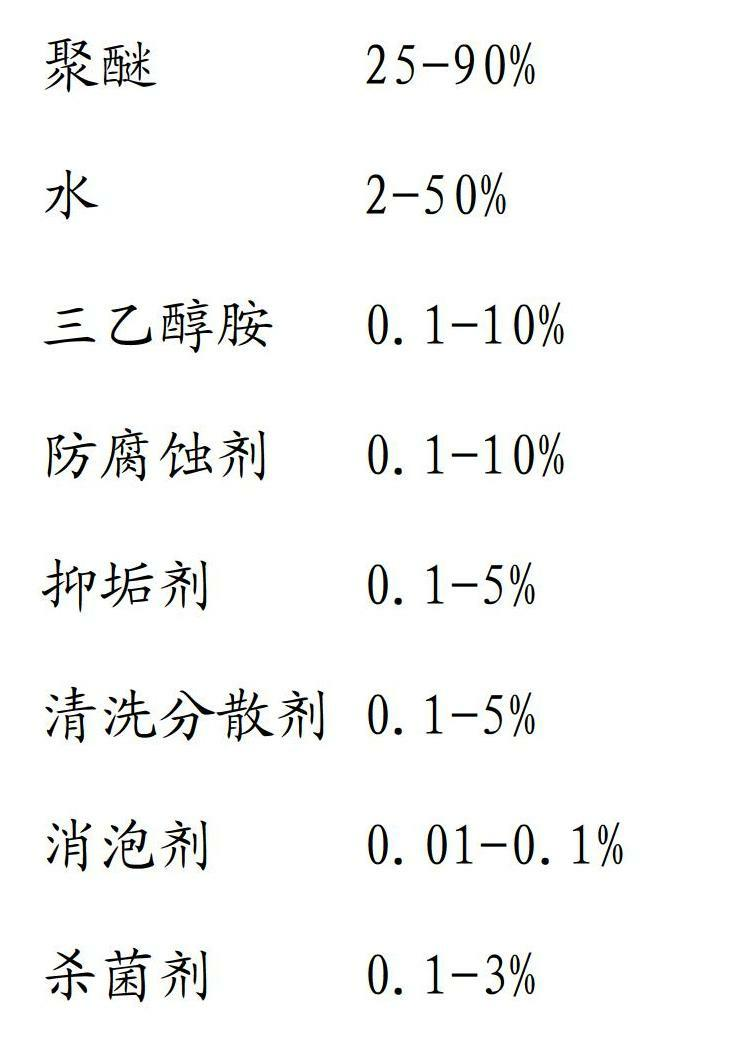

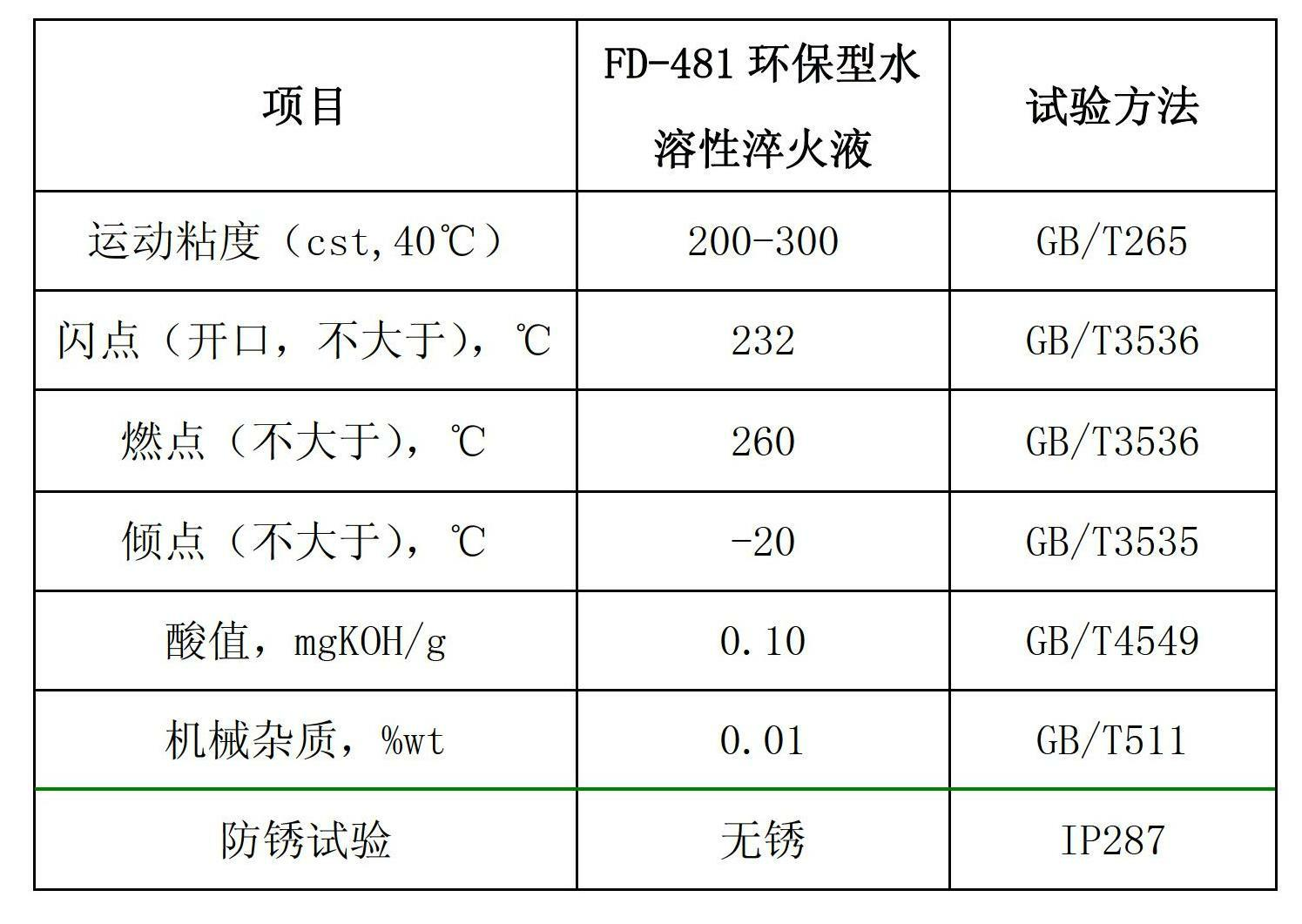

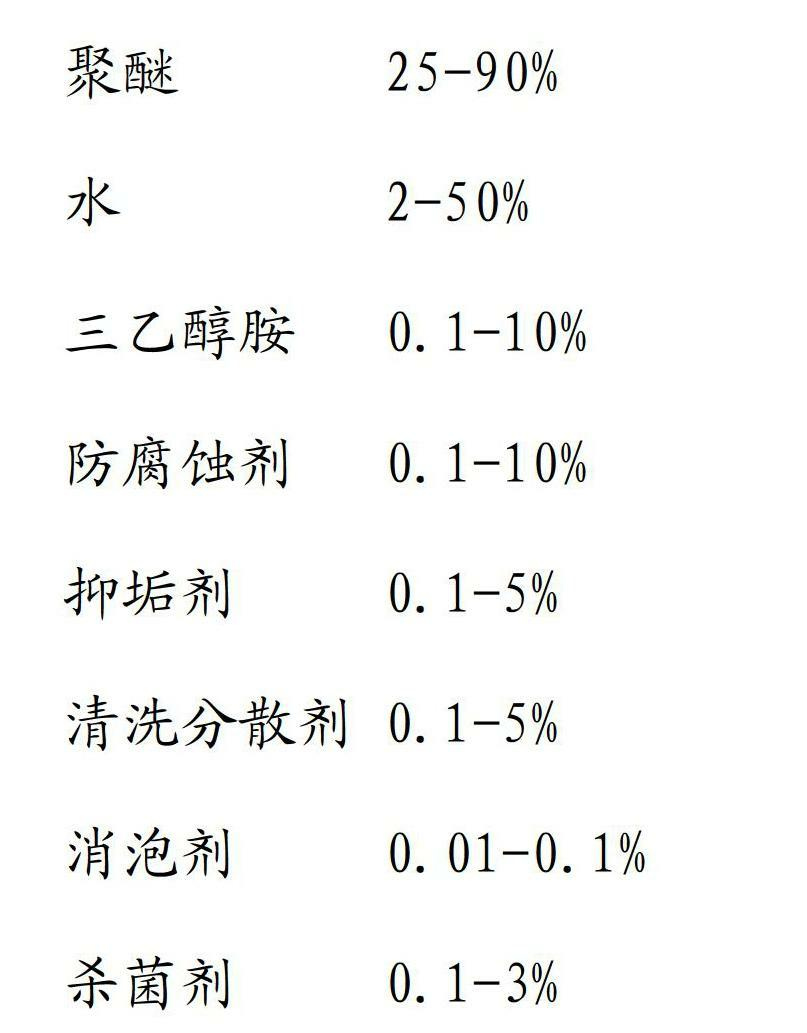

Environmental protection water-solubility quenching liquid

ActiveCN102643963AImprove final performanceImprove machining accuracyQuenching agentsSolubilitySurface cleaning

The invention discloses environmental protection water-solubility quenching liquid, which, by weight, comprises components of 25-90% of polyether, 2-50% of water, 0.1-10% of triethanolamine, 0.1-10% of anticorrosive agent, 0.1-5% of dirty restrain agent, 0.1-5% of washing dispersing agent, 0.01-0.1% of antifoaming agent and 0.1-3% of fungicide. The polyether molecular weight is 30000-50000. The water-solubility quenching liquid is compounded with balanced rust-inhibiting additive and the washing dispersing agent, has great cooling speed in a high-temperature cooling stage, can refine grains, has moderate cooling speed in a low-temperature cooling stage, effectively solves cracking and deformation problems in a workpiece cooling process, and improves surface quality of a workpiece. Excellent rust-proof performance effectively protects the quenched workpiece, and rust-proof requirements between working procedures are completely met. The environmental protection water-solubility quenching liquid has prominent surface cleaning performance, scale cinder is avoided, output quantity is small, production efficiency is improved, and production cost is saved.

Owner:上海福岛新材料科技有限公司

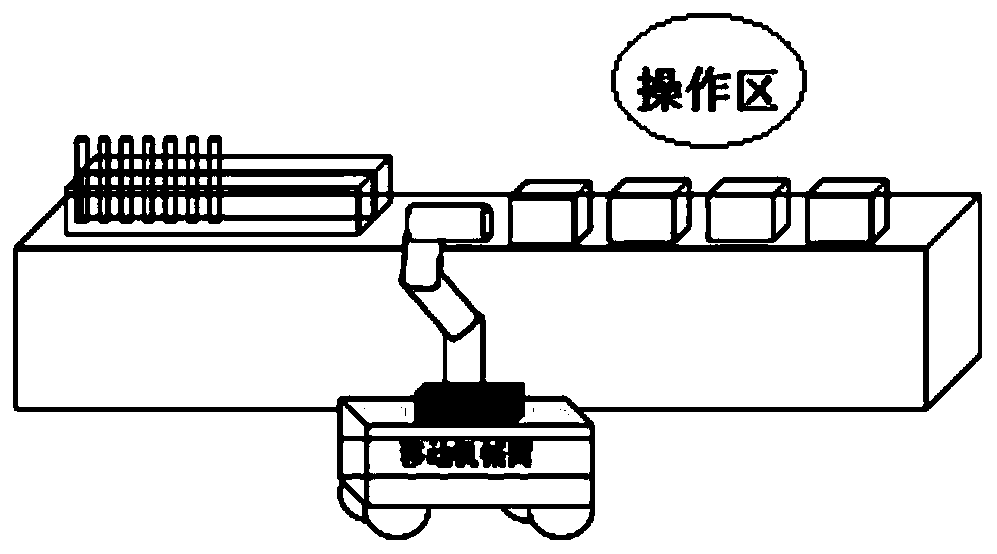

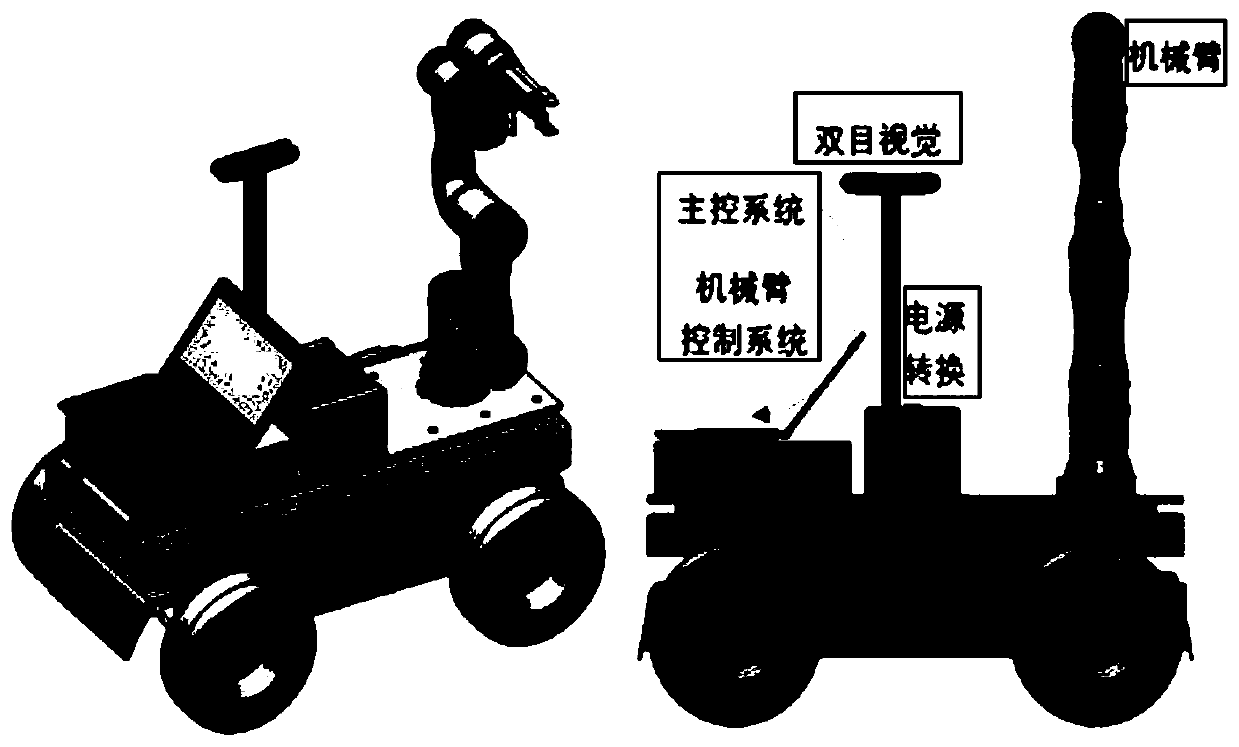

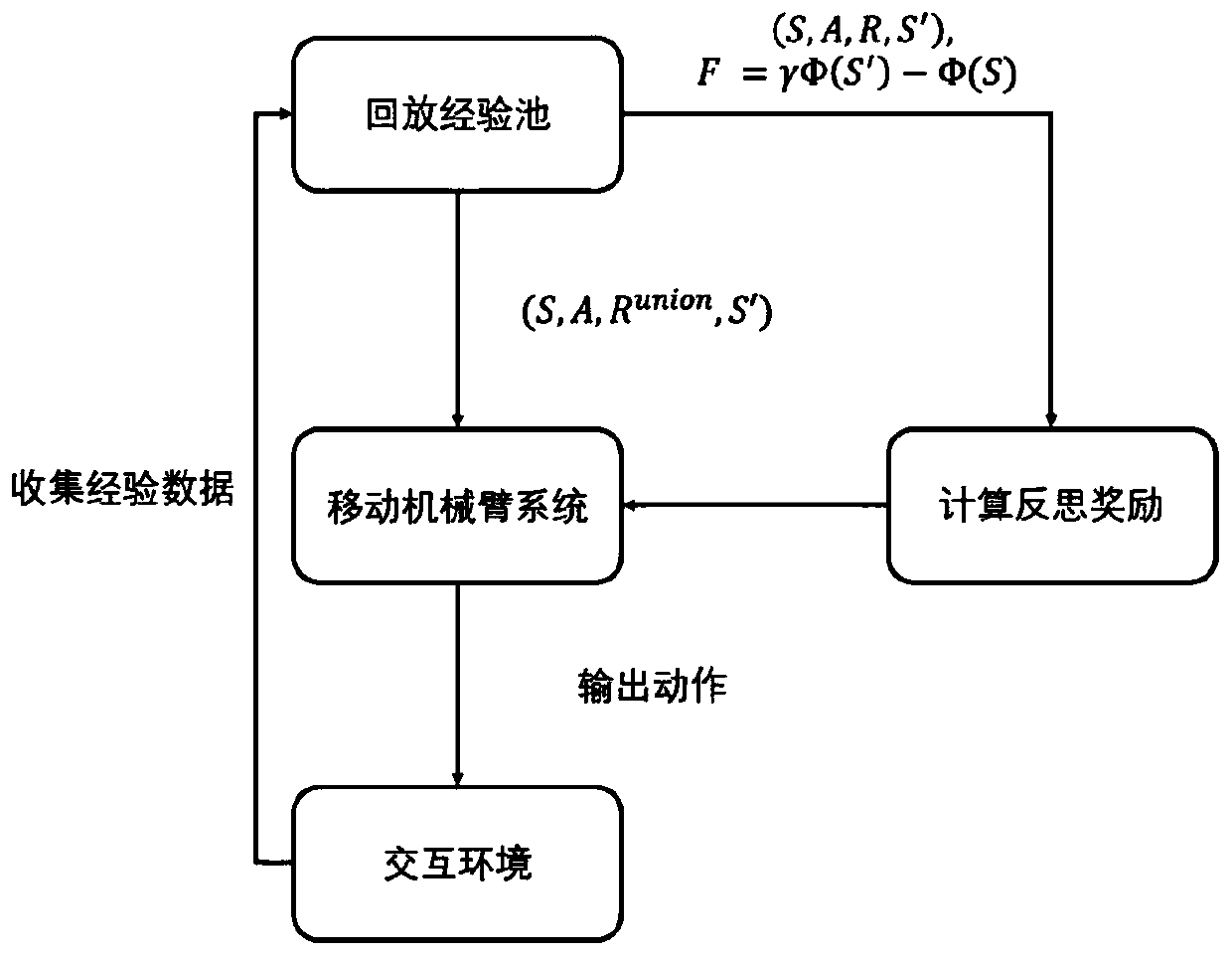

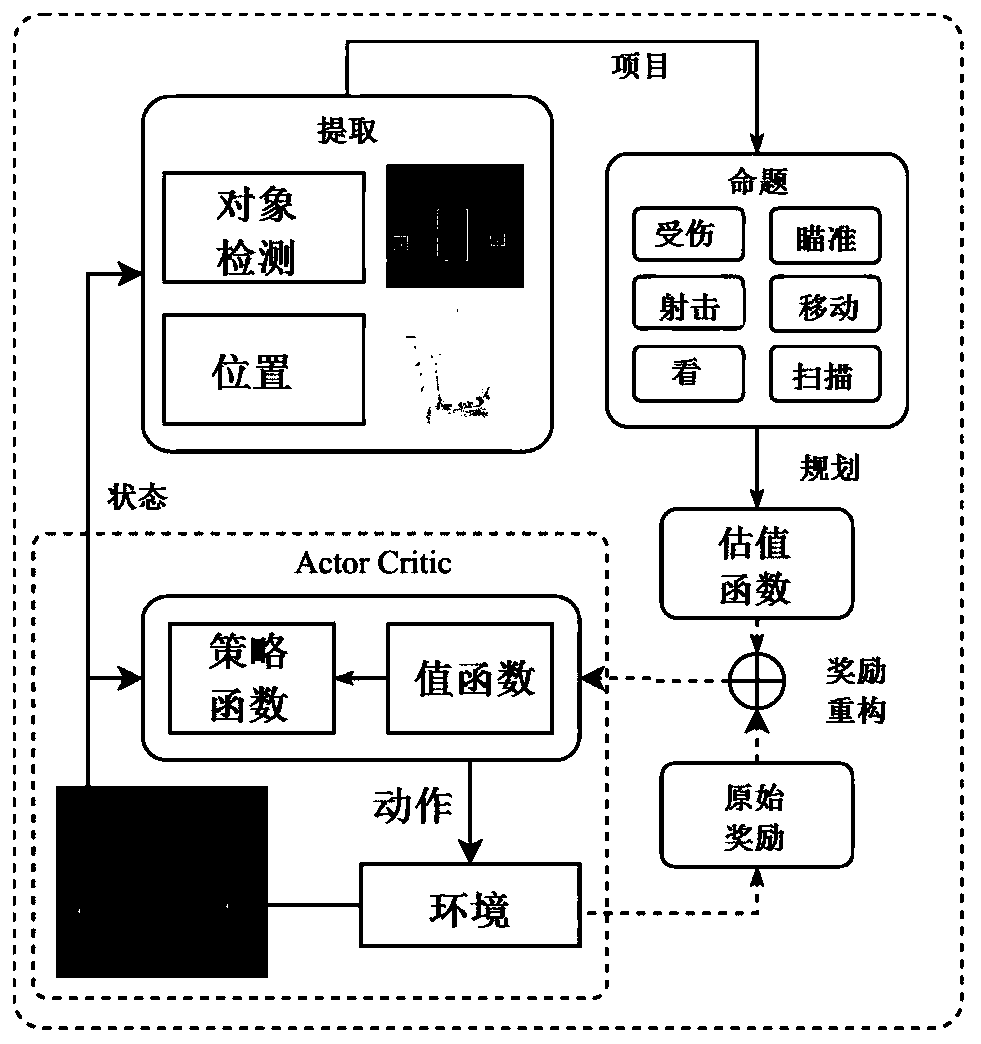

Reinforcement learning awarding method suitable for movable mechanical arm

ActiveCN111515961AImprove learning efficiencyImprove final performanceProgramme-controlled manipulatorSimulationReinforcement learning algorithm

The invention discloses a reinforcement learning awarding method suitable for a movable mechanical arm. The method comprises the following steps that S1, a task scene, an initialization algorithm, various parameters of the movable mechanical arm and a deep network model corresponding to the algorithm are designed; S2, environment information sent by information collection equipment on the movablemechanical arm is reconstructed and rasterized, and a starting position and a target position of the movable mechanical arm are clear and definite; S3, interaction with the environment, training dataare collected and stored in an experience pond; S4, one batch of data is sampled from the experience pond, and through treatment of a reward function, rethinking rewards which are additionally designed are obtained for subsequent training; S5, original rewards and extra rewards are combined, and a deep reinforcement learning algorithm trains the movable mechanical arm to finish a target task in aplanned space; and S6, related training data and final model parameters obtained through training are recorded, and a corresponding optimal strategy is obtained.

Owner:NANJING UNIV +1

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

Dyeing process of nylon fiber

InactiveCN104711874AMild handling environmentReduce damageBiochemical fibre treatmentFibre typesColour fastnessPolymer chemistry

The invention provides a dyeing process of nylon fiber. The dyeing process comprises the following steps: pretreatment, presetting, dyeing soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that in the dyeing procedure, disperse dyes and acidic dyes are used for carrying out dyeing according to the own property of the nylon fiber, so that the dyeing effect is improved; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:袁英英

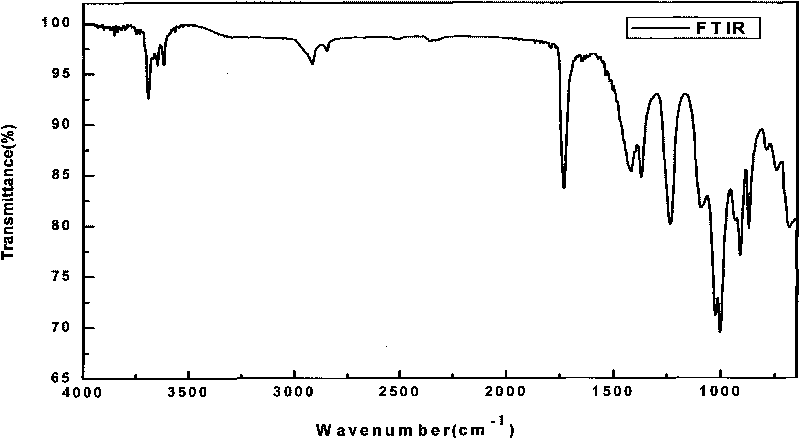

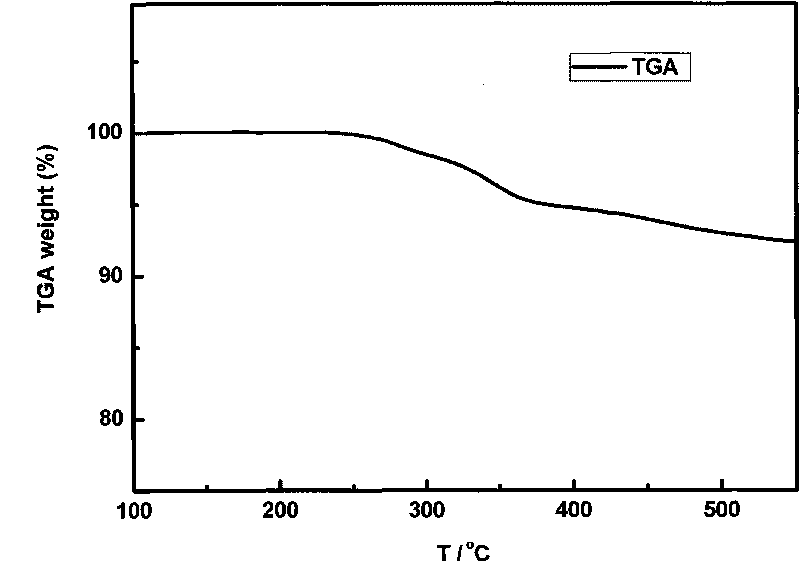

Heat-resisting flame-retardant fiberglass product for industrial heat preservation and preparation method thereof

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

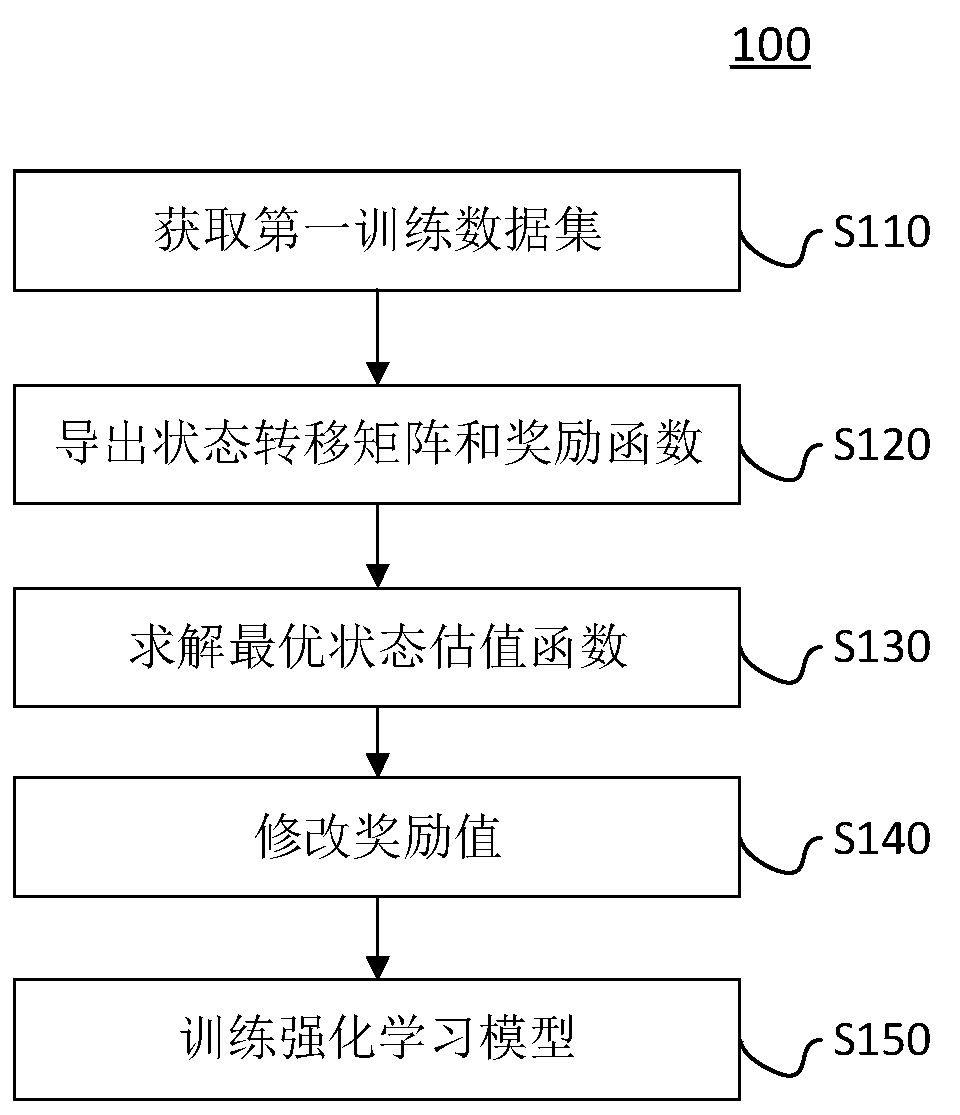

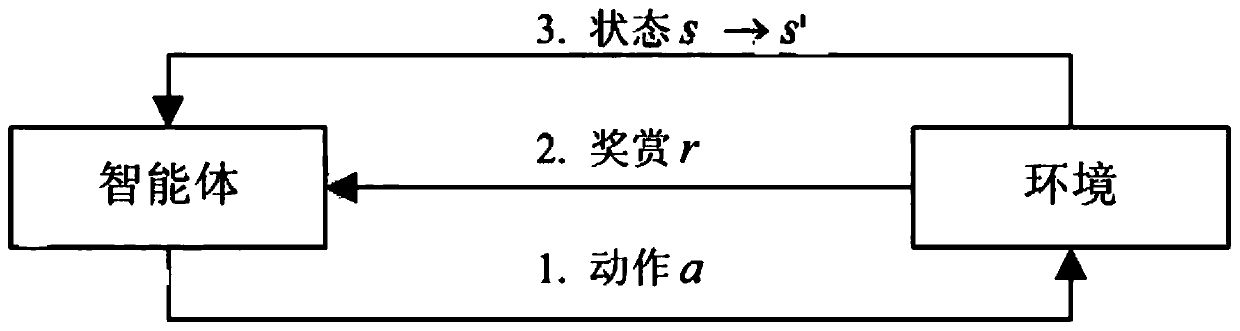

A method and apparatus for reinforcement learning

InactiveCN109858630AEnhance the final effectIncrease training speedMachine learningNeural architecturesTraining data setsReinforcement learning algorithm

The invention discloses a method and apparatus for reinforcement learning. The method comprises the following steps: running a reinforcement learning model to obtain a first training data set; deriving a state transition function and a reward function of the reinforcement learning model by counting the first training data set; based on the state transition function and the reward function, solvingan optimal state estimation function through a relation reinforcement learning algorithm; modifying a reward value in the first training data set by using the optimal state estimation function; and training the reinforcement learning model by using the modified first training data set. According to the method, the final effect obtained by training the reinforcement learning model can be improved,and the training speed of the reinforcement learning model can be increased, so that the application of reinforcement learning in each actual scene is expanded.

Owner:TSINGHUA UNIV

Stent with variable features to optimize support and method of making such stent

InactiveUS20060173531A1Improve final performanceIncrease or decrease thicknessStentsSurgeryVariable featuresInsertion stent

An intravascular stent especially suited for implanting in lumens having variable characteristics such as curvatures, changing diameters as found in ostial regions or variable wall compliance during systolic cycles. The stent can include an end region which is fabricated to have a greater radial strength than the remaining axial length of the stent. Such a stent is particularly suited for use in ostial regions, which require greater support near the end of the stent. The stent alternatively can include sections adjacent the end of the stent with greater bending flexibility than the remaining axial length of the stent. Such a stent is particularly suited for use in curved arteries. The stent can be constructed with an end that has greater radial strength and sections adjacent the end with greater bending flexibility. Such a stent prevents flaring of the stent end during insertion. The stent can also be constructed to have increased longitudinal flexibility when expanded such that it flexes with the vessel wall during systolic cycles.

Owner:MEDINOL LTD

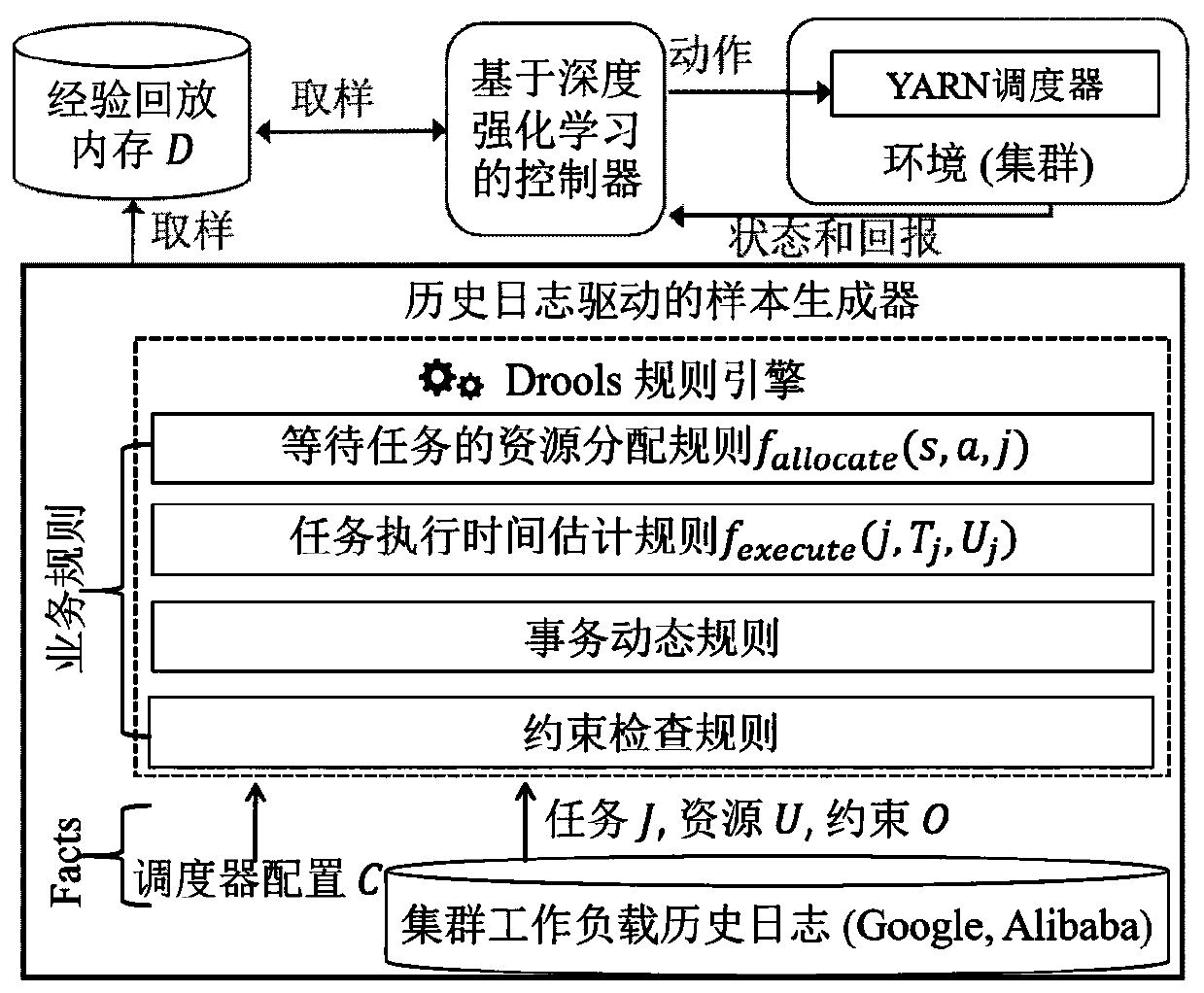

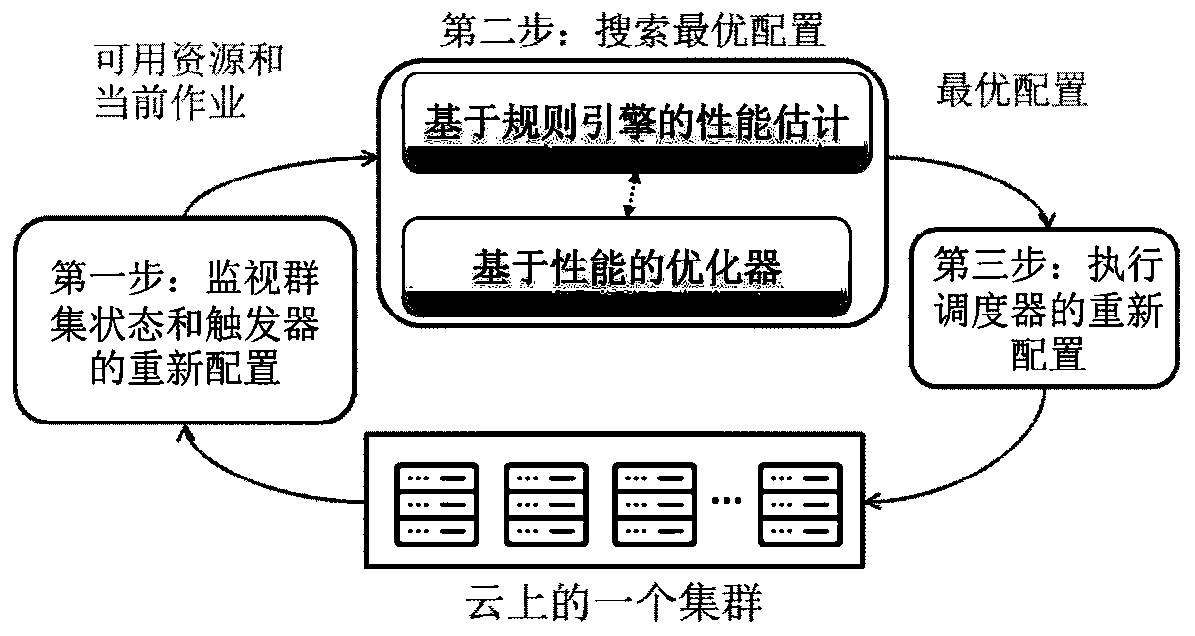

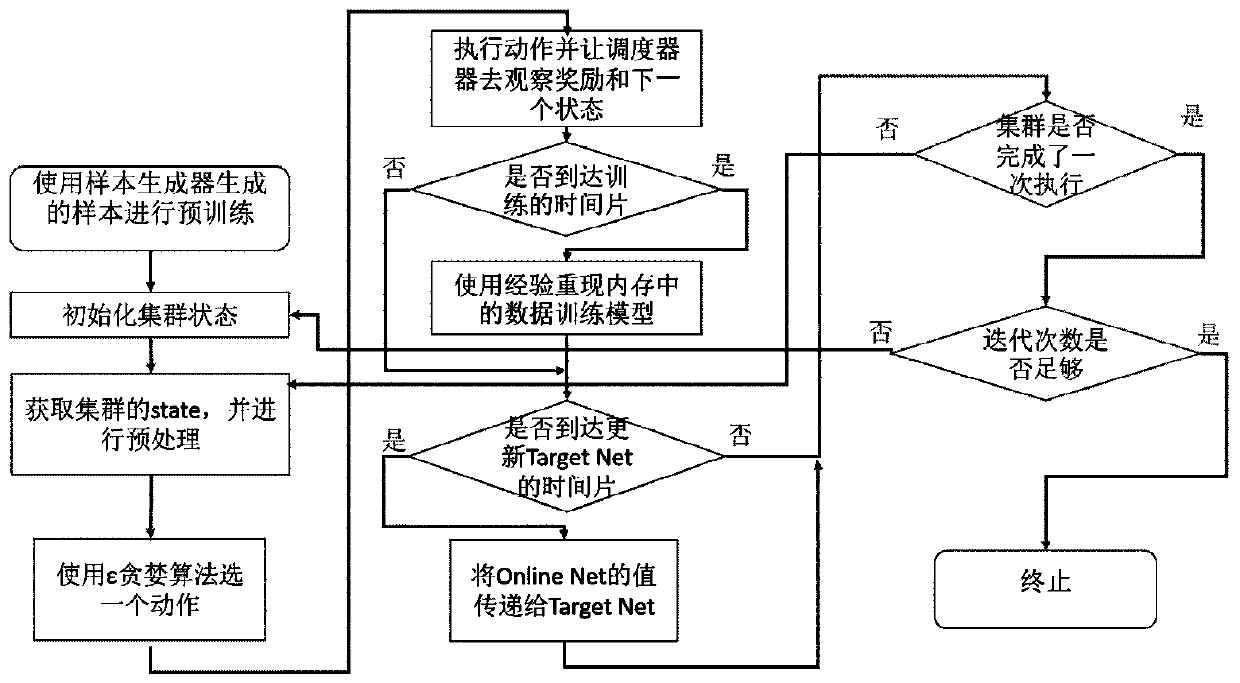

Adaptive configuration method for short-time variable big data job cluster scheduling

ActiveCN110737529AAdapt to heterogeneityImprove training efficiencyProgram initiation/switchingResource allocationConfiguration optimizationOptimal scheduling

The invention discloses an adaptive configuration method for short-time variable big data job cluster scheduling. The method is a self-adaptive cluster scheduler configuration optimization method provided by aiming at the characteristics of cloud platform isomerism, cluster scheduler configuration optimization of dynamic load, isomerism of cloud platform load and short-time variability. Cloud platform loads can be divided into service applications and analysis applications, and different classifications are different in resource consumption and time requirements. According to the method, the configuration of the cluster scheduler is adjusted according to the state information of the job and the information of the cluster environment; the optimal scheduling configuration is always kept; therefore, the operation performance is improved, the operation delay is reduced, the heterogeneous load of the cloud platform can be better adapted, and the optimal configuration item corresponding to the current cluster state can be better found, so that the waiting time of the cluster operation is close to the minimum, the operation efficiency is improved, and the short-time variable big data operation is effectively scheduled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Process of dyeing silk fabric

InactiveCN104727165AMild handling environmentReduce damageBiochemical fibre treatmentHeating/cooling textile fabricsColour fastnessPolymer chemistry

The invention provides a process for dyeing a silk fabric. The process comprises the steps of pre-treatment, pre-shaping, modifying treatment, dyeing, soaping, color fixing, post-arrangement, drying, shaping, calendering and rolling. According to the method, the fabric is modified in advance by chitosan to improve the dyeing rate, and the difficulty of the subsequent dyeing step is reduced; in the dyeing step, the chitosan is used as a mordant, and mangosteen hull serving as a natural dye is used and is free of poison and environmentally friendly; the dyeing firmness is good by additionally arranging the soaping and color fixing steps, environment-friendly formaldehyde-free TCD-R is adopted in the color fixing step, color-fixed fibers are stepwise dried, so that the fiber firmness degree is greatly improved; the post-arrangement process is additionally added, so that the color firmness and softness of the fabric is improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG CHENGLE CHEM FIBER

Composite material of inorganic nonmetallic mineral loaded with titania layer, preparation process and use thereof

InactiveUS20130052243A1Simple processLow costMaterial nanotechnologyBiocideNanoparticleRefractive index

The invention discloses composite materials, comprising an inorganic nonmetallic mineral as a support and a nanotitania layer loaded on the support, wherein the layer is comprised of a plurality of titania nanospheres, and the titania nanosphere is comprised of a plurality of nanotitania single particles. The invention also discloses composite materials further comprising one or more functional layers loaded on the nanotitania layer. The above composite materials may not only take advantage of the high refractive index and the high covering power of the nanotitania layer, but also make use of the good photocatalytic activity of the small single nanoparticles. Furthermore, the composite materials can be more readily coated by other functional layer(s) to prepare functionally strengthened or multi-functional composite materials. The invention also discloses methods for preparing the composite materials. The composite materials may be used as an additive with good compatibility in various industrial fields.

Owner:SHANGHAI WORLD PROSPECT CHEMTECH

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

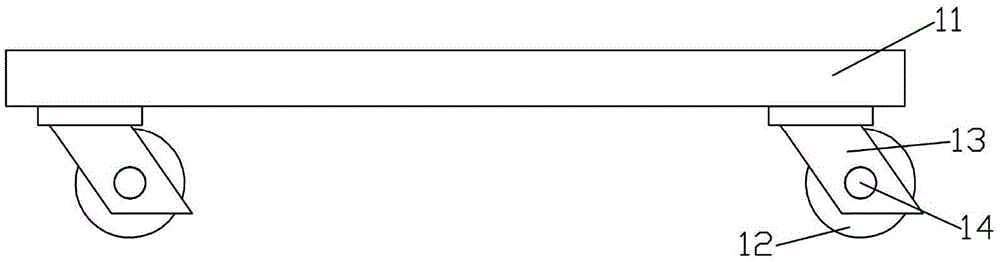

Movable paint spraying machine

InactiveCN105521899AImprove final performanceAvoid manual interventionSpraying apparatusControl systemMechanical engineering

The invention discloses a movable paint spraying machine. The movable paint spraying machine comprises a movable frame, a swinging and rotating unit, a spray gun, a travelling driver, a swinging and rotating driver and a control system. The swinging and rotating unit is connected to the movable frame rotationally. The spray gun is hinged to the swinging and rotating unit. The travelling driver is used for driving the movable frame to move. The swinging and rotating driver is used for controlling the swinging and rotating unit to swing and rotate. The control system is connected with the travelling driver and the swinging and rotating driver electrically to control movement of the movable frame and the swinging and rotating unit. The movable paint spraying machine has the advantages that the movable paint spraying machine has multi-angle multi-direction moving and swinging functions and can spray paint automatically, so that manual work is avoided, and personal injuries are reduced; the spraying speed is high, and paint is smooth and fine in hand feel; the paint is sprayed out in the form of mist, so that the paint can be well sprayed to corners and gaps, and final effect of paint films is good.

Owner:JIAMA MACHINERY COATING SCI & TECH SUZHOU CO LTD

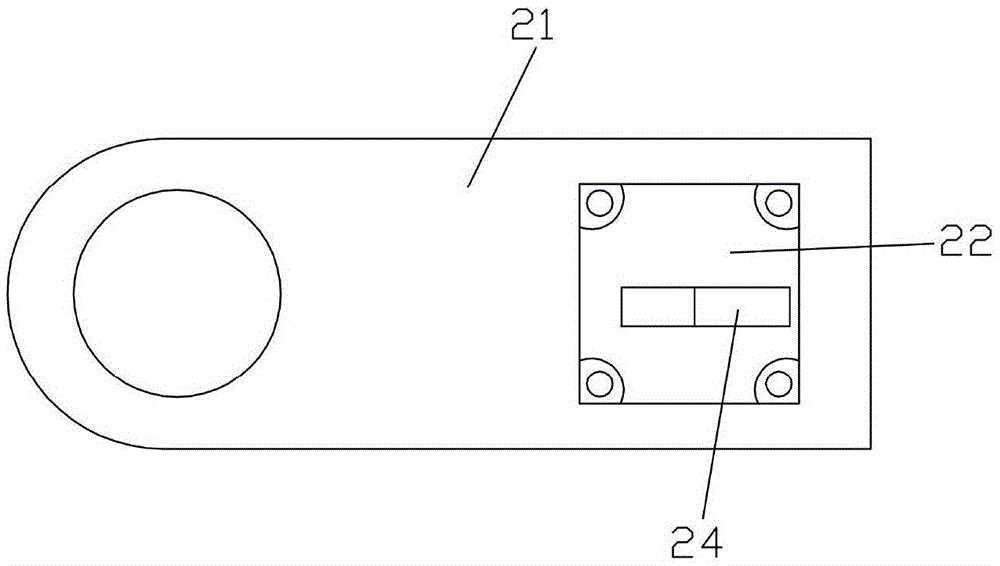

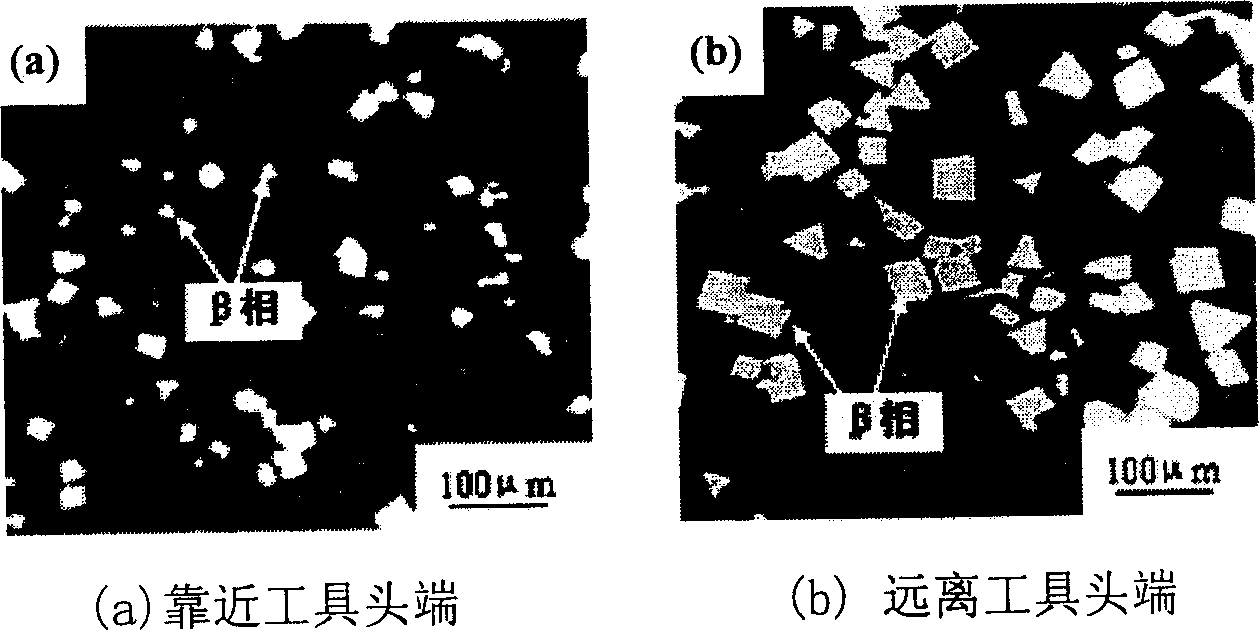

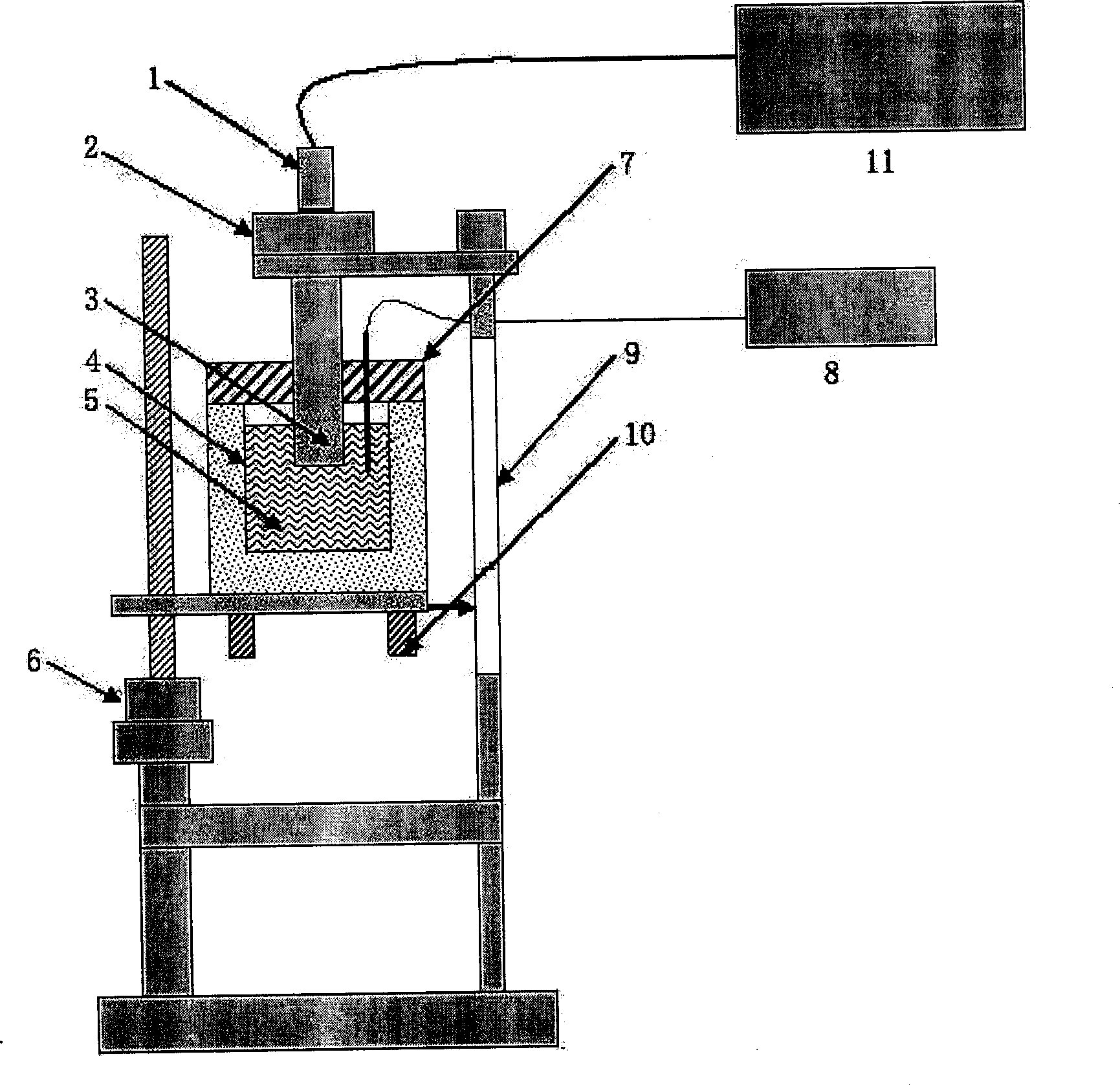

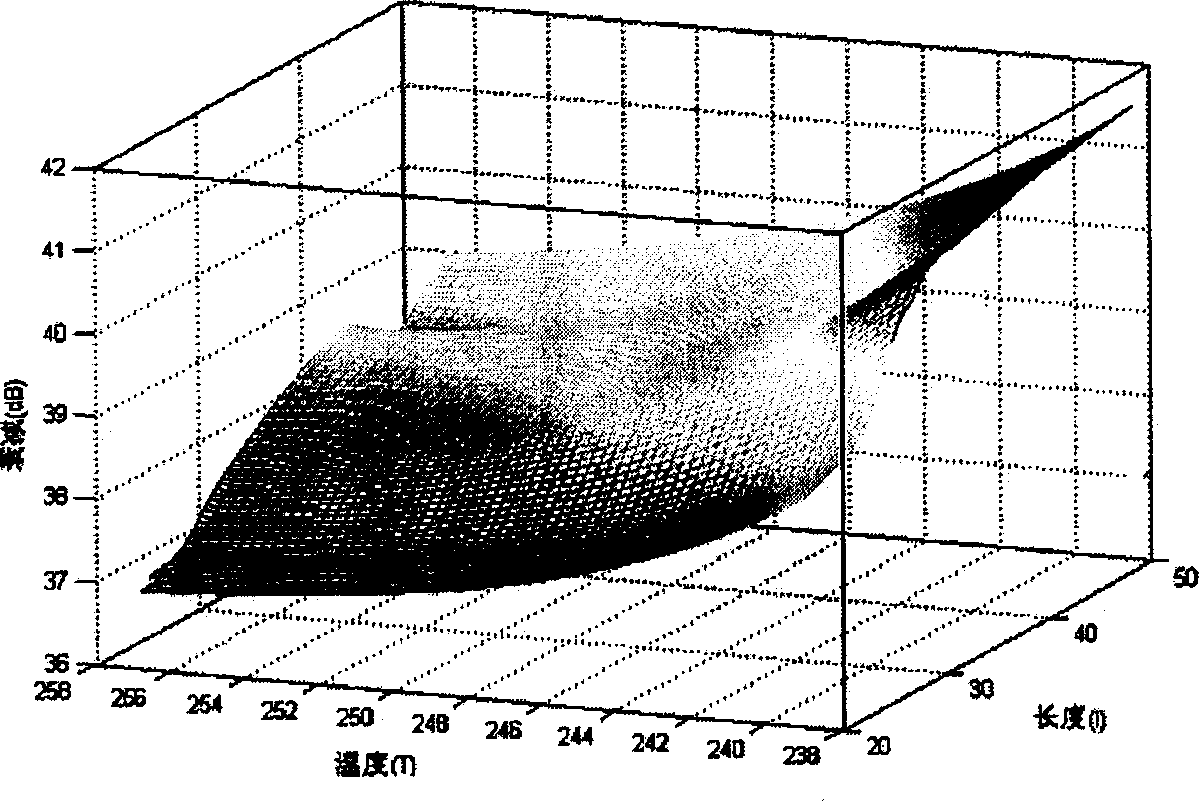

Method for measuring effective propagation distance of ultrosonic in metal melt and its special device

InactiveCN1869680AImprove final performanceImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationTransceiver

The invention relates to a method and special device for measuring effective propagation length of ultrasonic wave in metal melt, and the method uses probe ultrasonic transceiver, indirectly guides ultrasonic wave through guide rod into metal melt, measures attenuation values of ultrasonic wave at different propagation lengths, adopts MATLAB software to make data fitting and calculates the effective propagation length of ultrasonic wave in metal melt. And the method can measure attenuation of ultrasonic wave in low temperature, medium temperature, high temperature and corrosive melt melts, and has low cost and high probe service life. And the device has a main character of comprising ultrasonic wave propagation length regulating system and temperature collecting system.

Owner:SHANGHAI UNIV

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for polyamide fabric

InactiveCN105177987AProcess temperature changeLow processing temperatureBiochemical fibre treatmentUltrasonic/sonic fibre treatmentPolyamideAmmonium chloride mixture

The invention discloses a dyeing and finishing process for polyamide fabric. The provided process comprises pretreatment, pre-setting, modified processing, dyeing, soaping, dye fixation, post-finishing, drying, setting, calendering and rolling. Supersonic waves are employed for pretreatment, fabric is subjected to low temperature plasma processing before the dyeing step, then 2,3-epoxy propyl trimethyl ammonium chloride is employed for modification processing of the fabric, the dyeing degree of the fabric is raised, and difficulty of the subsequent dyeing step is lowered. During the dyeing step, a lot of alkaline substances and inorganic salt are not used, natural dyes are employed, colophony powder is added as a dye-fixing agent, the dye-fixing effect is enhanced, environment pollution is avoided, and green environmental protection requirements are met. Montmorillonite is employed for modification processing and flame retardation processing of the fabric, and thus the flame retardation of the fabric is high. Anti-yellowing reagents are used both in the pre-setting and setting steps, and thus the final fabric is not easy to turn yellow.

Owner:TAICANG TIANLONG CHEM FIBER

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Dyeing process of polyester cotton fiber fabric

ActiveCN103993487AAvoid wrinklesAvoid severe shrinkageHeating/cooling textile fabricsDyeing processDisperse dyePolymer science

The invention provides a dyeing process of a polyester cotton fiber fabric. The dyeing process comprises the following steps of preforming, pretreatment, drying, dyeing, washing, soaping, color fixing, drying, forming and winding. According to the dyeing process, a high-temperature leveling agent is added during dyeing, so that the problem that level dyeing effect and penetration dyeing effect are affected and even generate color dots and color patches occur caused by gathering of dyes because the heat stability resistance of fuel is reduced due to temperature increase is avoided, and the dyeing effect is good; the temperature is increased in a stepped progressive mode in the dyeing procedure, and the temperature increase and decrease velocity and the dyeing time are strictly controlled, so that high dyeing fastness, dyeing uniformity and good dyeing stability of the polyester cotton fiber fabric are achieved; the dyes with single property are not used and dispersed dyes and neutral dyes are compounded in the dyeing procedure, and the dispersed dyes and the neutral dyes supplement each other, so that good dyeing fastness is achieved; the traditional two-bath two-step method dyeing is abandoned, and the one-bath one-step method dyeing is adopted, so that the energy is saved, and the emission amount is reduced.

Owner:广东欣薇尔服装有限公司

Antistatic finishing process of chemical fiber fabric

InactiveCN103993473AImprove comfort performanceImprove overall performanceSynthetic fibresDyeing processDyeingPolymer chemistry

The invention provides an antistatic finishing process of a chemical fiber fabric. The antistatic finishing process comprises the following steps of pretreatment, preforming, dyeing, drying, padding, drying, baking, forming, calendering and winding. According to the antistatic finishing process, the chemical fiber fabric is firstly refined and then subjected to alkali weight reduction treatment during the pretreatment, so that the comfortable property of the chemical fiber fabric is enhanced, the integral property of the chemical fiber fabric is enhanced and the stability of the chemical fiber fabric is enhanced under the condition that the chemical fiber fabric is not damaged, and the stability of subsequent steps, namely the dyeing, the padding, the forming and the calendaring is guaranteed; an antistatic agent is added to the padding procedure, so that the antistatic property of the chemical fiber fabric is effectively improved, and the waterproof property and softening property of the chemical fiber fabric are both greatly enhanced through added waterproof agent and softener, the chitosan is also added to the padding procedure, the chitosan is a high-molecular substance with natural antibacterial and deodorant property, is safe and environmentally friendly, can also be used as the antistatic agent, and the antistatic property and antibacterial and deodorant property of the chemical fiber fabric are all greatly enhanced after the chitosan is added.

Owner:TAICANG MENGFAN CHEM FIBER

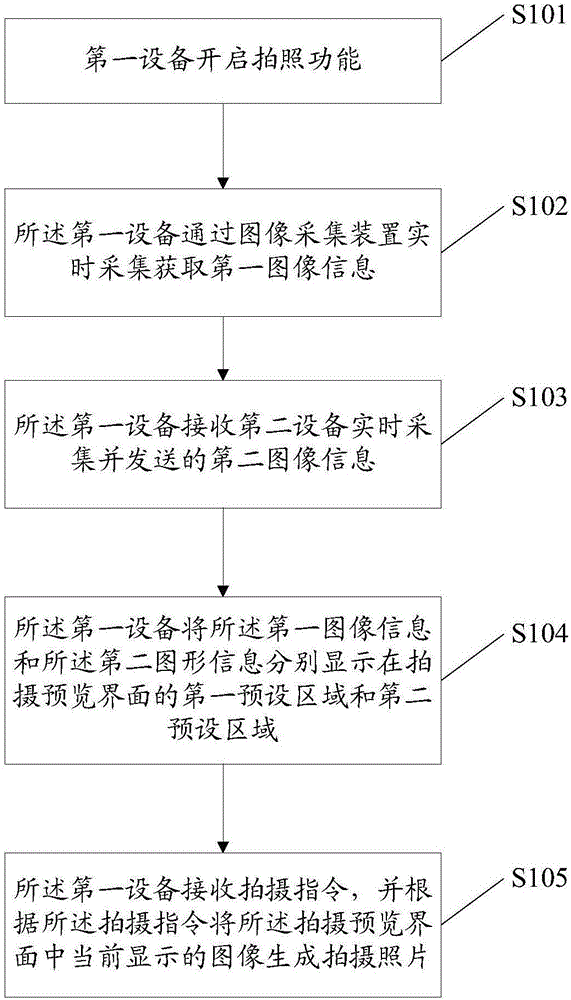

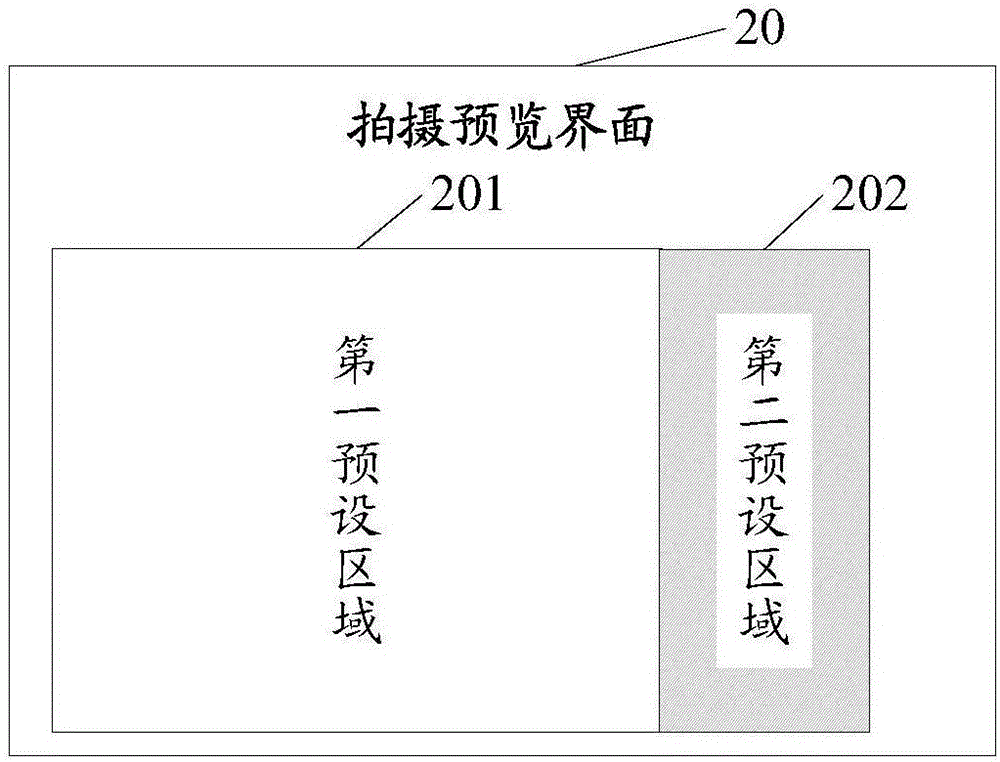

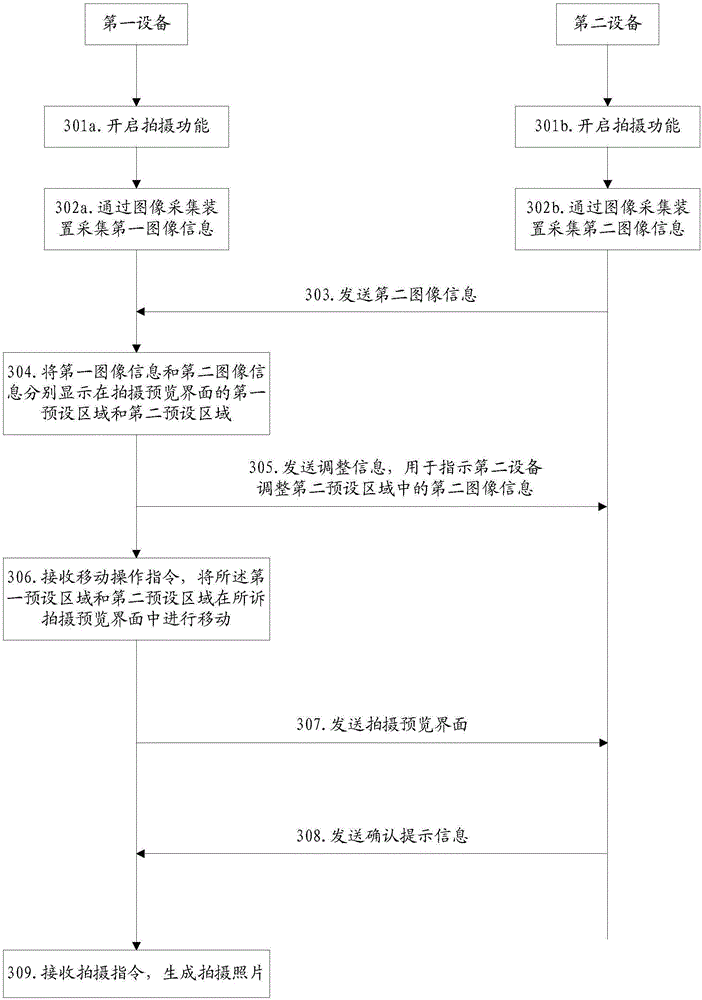

Photograph processing method and image photograph equipment

InactiveCN106331528AImprove final performanceImprove experienceTelevision system detailsColor television detailsComputer scienceImage generation

The embodiment of the invention discloses a photograph processing method and an image photograph equipment. The photograph processing method can comprises a first equipment image acquisition device for timely collecting the first image information, wherein the first equipment receives image information collected and sent timely by the second equipment, the first equipment displays the first image information and the second image information in the first preset area and the second preset area in the photograph preview interface, the first equipment receives photograph orders and makes current mage in the photograph preview interface generate photograph photo according to photograph orders. The method can take the group photo in different sites in the same photo. In the place where a great deal of group photos is needed, the embodiment of the invention cal solve the problem that relative or friend cannot participate in group photograph for individual reason.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Aramid fabric high-efficiency dyeing and finishing process

InactiveCN104988711AImprove hydrophilicityImprove dye uptakePhysical treatmentFibre typesInorganic saltsProcess engineering

The invention discloses an aramid fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. According to the dyeing and finishing process, before the dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; at the same time, ultrasonic treatment is adopted during modification treatment, so that the time is saved and the treatment efficiency is improved; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com