Movable paint spraying machine

A spraying machine, mobile technology, applied in the direction of spraying devices, etc., can solve the problems of heavy protection workload of the construction team, easy to appear flower marks, uneven rollers, etc., to reduce personal injuries, smooth and delicate hand feeling, and good final effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

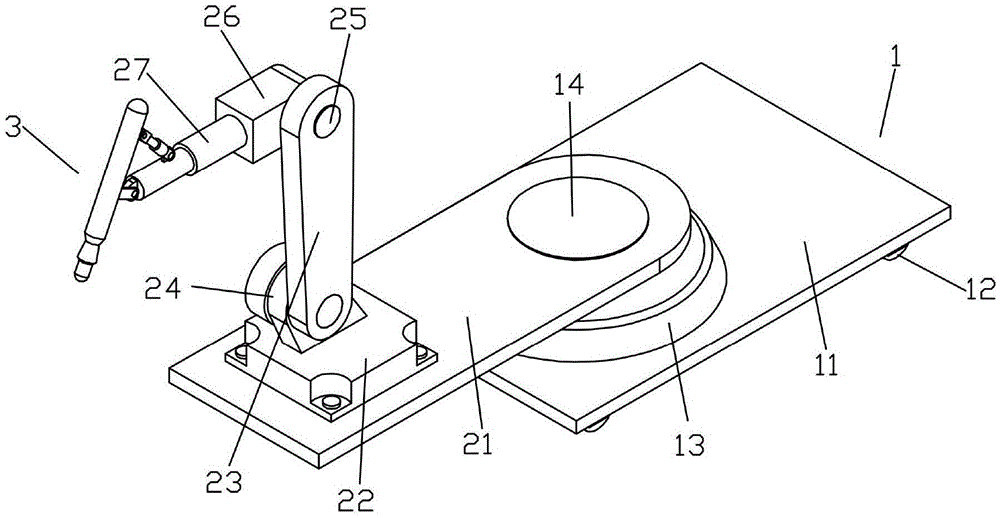

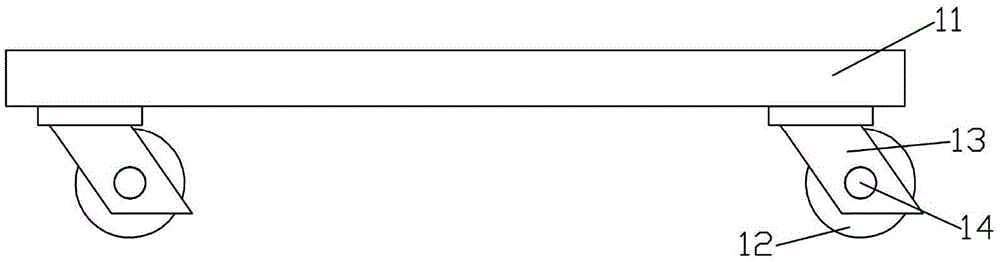

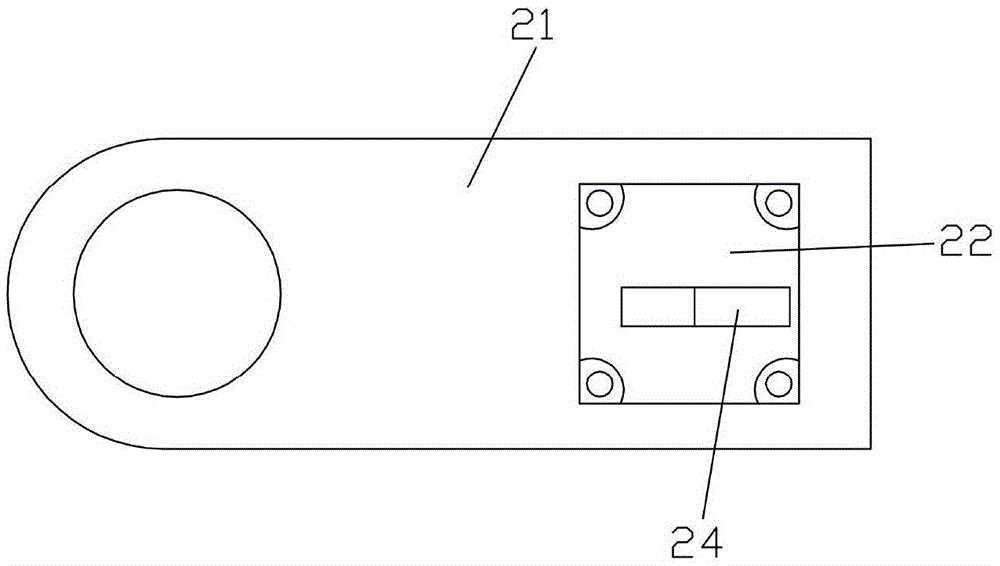

[0021] Such as Figure 1-3 As shown, the mobile paint spraying machine includes a mobile frame 1, a swing rotation unit, a spray gun 3, a walking drive device, a swing rotation drive device and a control system (not shown in the figure), and the swing rotation unit is rotatably connected to the mobile frame 1 Above, the spray gun 3 is hinged on the swing rotation unit, the travel drive device is used to drive the movement of the mobile frame 1, the swing rotation drive device is used to control the swing and rotation of the swing rotation unit, the control system is connected with the travel drive device, the swing rotation drive device Electrically connected to control the action of moving the frame and swinging the rotating unit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com